High-cover capping machine

A high-cap capping machine and rack technology, which is used in the directions of capping containers tightly with caps, capping machine safety/control, flanged caps, etc. Meet the requirements and other issues to achieve the effect of cleaning the production process, reducing the probability of dust entering the interior of the tank, and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described with reference to the accompanying drawings.

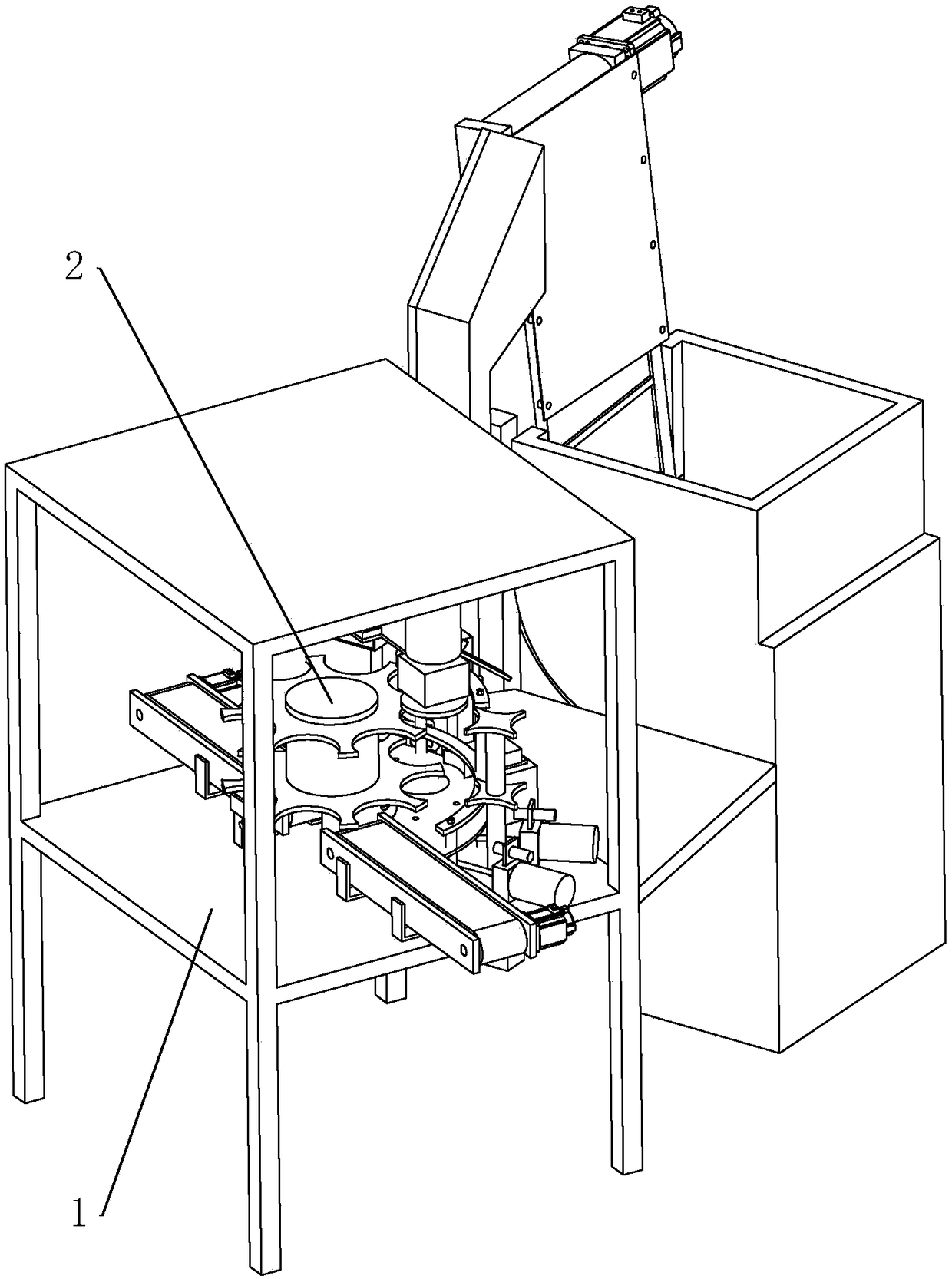

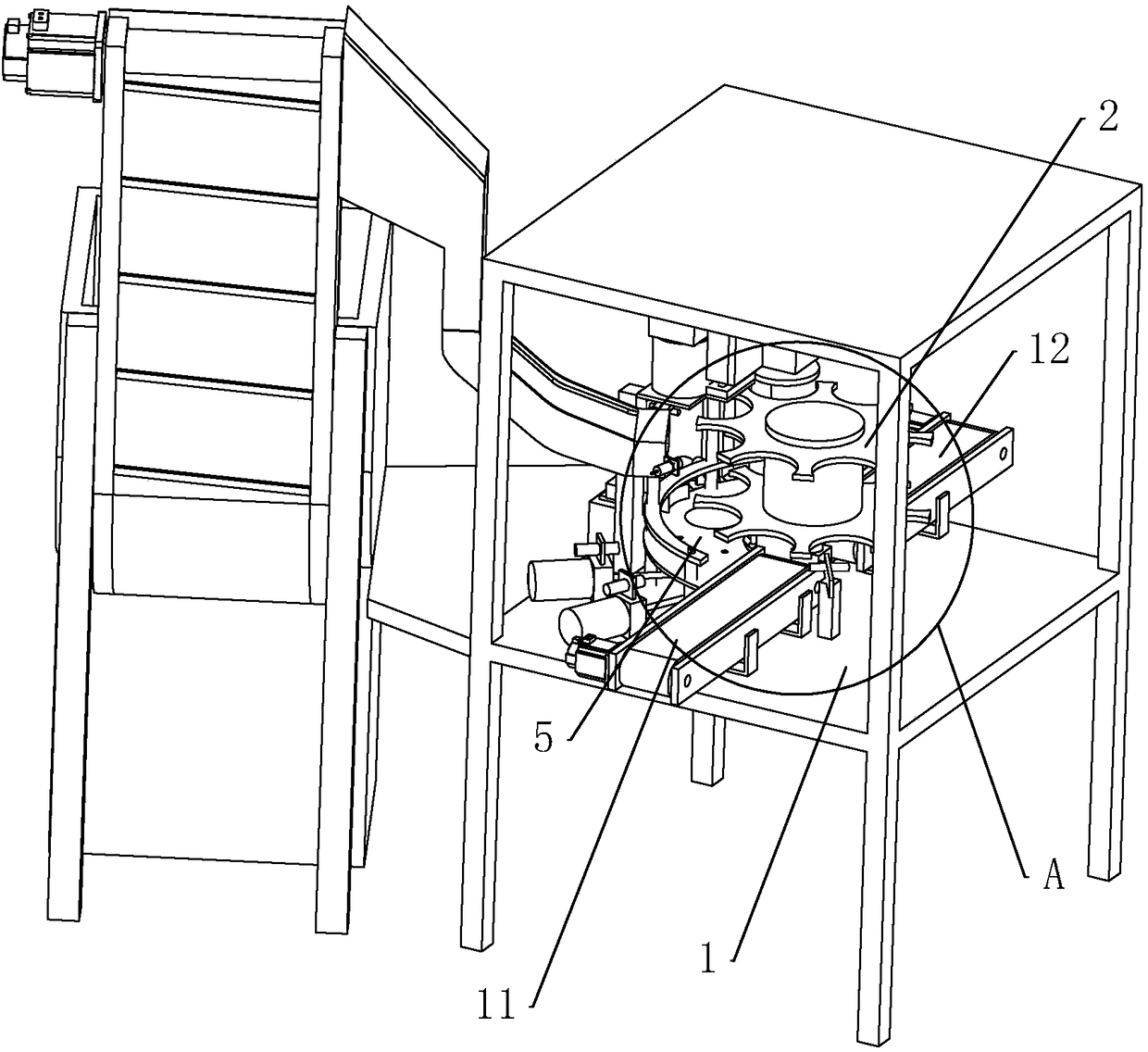

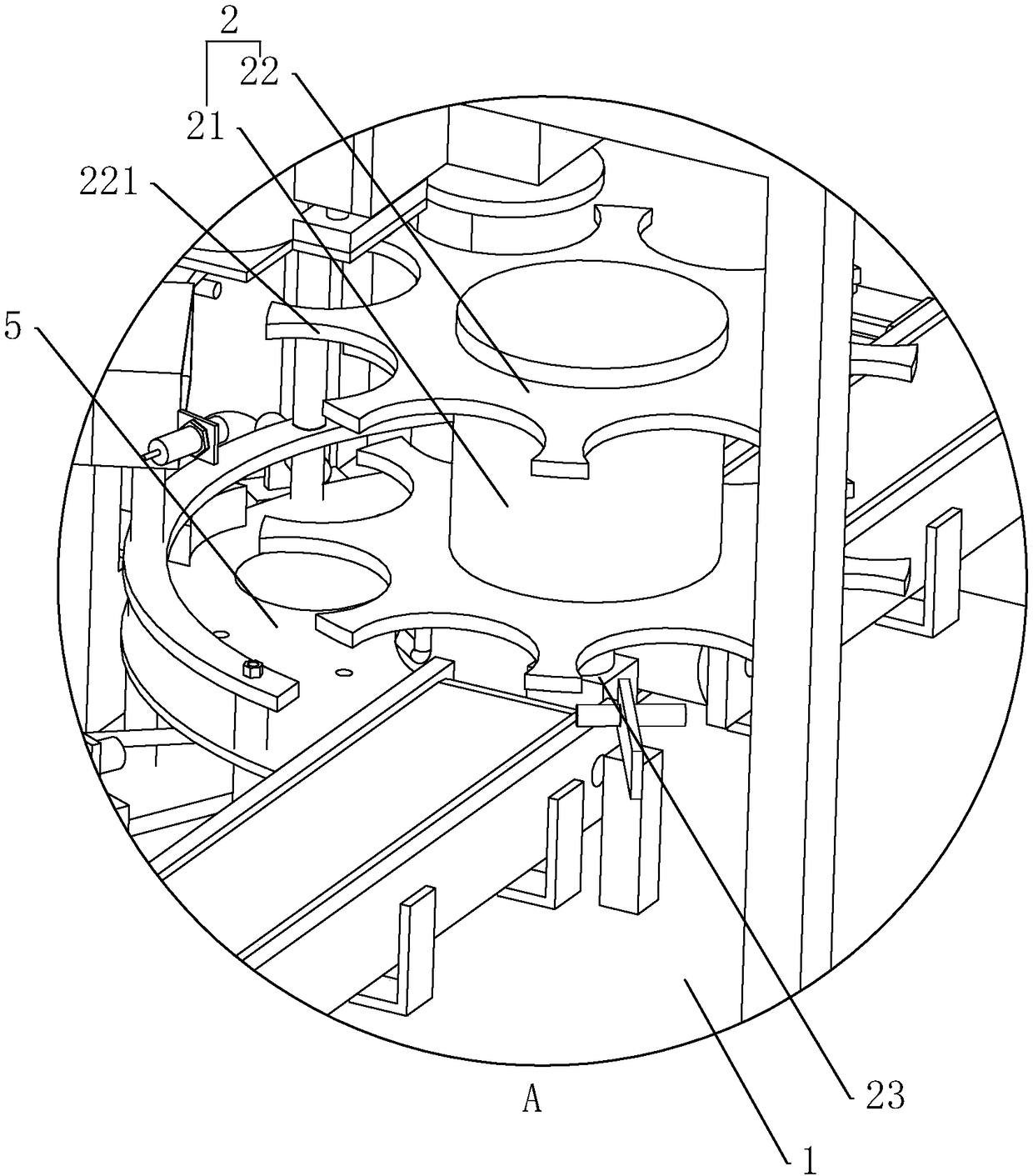

[0044] Such as figure 1 As shown, a high-cap capping machine includes a frame 1 on which a conveying carousel 2 is rotatably connected. Such as figure 2 and image 3 As shown, the conveying carousel 2 is driven to rotate by a rotating motor 23 , and the rotating motor 23 is fixedly connected to the frame 1 . The conveying carousel 2 includes a cylindrical fixed part 21 fixedly connected to the output shaft of the rotating motor 23, and a conveying disc body 22 fixedly connected to both ends of the fixing part 21. Shaped delivery grooves 221, the delivery grooves 221 are evenly distributed along the axis of the delivery tray body 22. A feed conveyor 11 and a discharge conveyor 12 are installed on the frame 1 , and the feed conveyor 11 and the discharge conveyor 12 are located on both sides of the conveying turntable 2 . The frame 1 is fixedly connected with a fan-shaped r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com