A lanthanum calcium manganese oxide film preparation equipment with adjustable liv effect

A lanthanum-calcium-manganese-oxygen thin film and effect technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of shortening process adjustment cycle samples, increasing process uncertainty, waste of raw materials, etc., to achieve The effect of shortening the process adjustment cycle, improving the utilization rate of raw materials, and reducing the development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

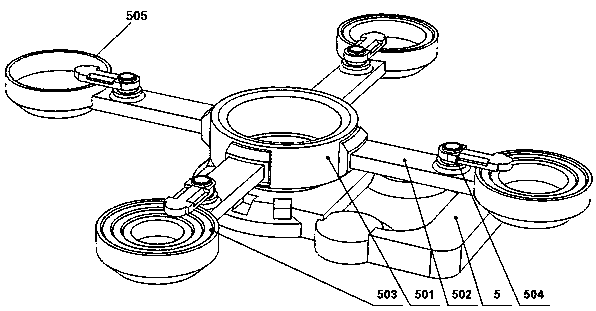

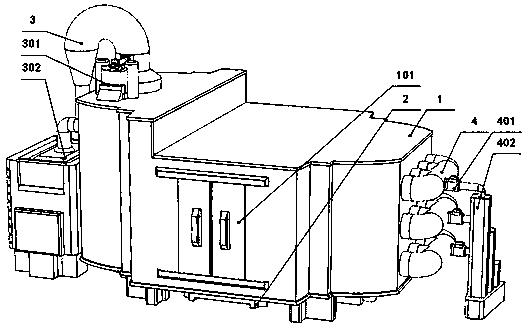

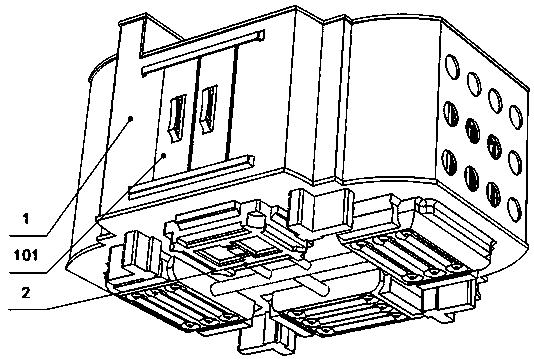

[0046] Embodiment 1: as Figure 1~19 As shown, the lanthanum calcium manganese oxide film preparation equipment with adjustable LIV effect includes a cabinet 1, a laser generator 2, a vacuum system, an atmosphere system, a target system, a thin film system, a spray plating system, a magnetron system, and a film thickness Test system, LIV performance adjustment system; the sealed cabinet door 101 is set at the front end of the cabinet 1, the laser generator 2 is set at the outer bottom of the cabinet 1, the vacuum system is set at the outer side of the cabinet 1, and the atmosphere system is set outside the cabinet 1 On the other side, the target system is set at the inner center of the cabinet 1, the thin film system is set above the target system, the magnetron system and the spraying system are set on one side of the target system, and the magnetron system is located between the target system and the spraying system. Between the plating systems, the LIV performance adjustmen...

Embodiment 2

[0048] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1, except that there are two target setting rods 502, and the heat conducting rod 901 is a telescopic nesting structure.

[0049] When in use, put the target material and the substrate into the target material groove 505 and the U-shaped slot 608 of the target sleeve rod respectively through the sealed cabinet door 101, place the size sleeve 503 in the target material groove according to the size of the target material, and Rotate the rotating buckle 504 to engage and lock the size sleeve 503; close the sealed cabinet door 101 to vacuumize the cabinet body 1 through the vacuum system, wherein the operation speed and effect can be adjusted by adjusting the air valve machine 301; after the vacuum operation is completed, Open the airflow control valve 401, so that the gas in the atmosphere box 402 is evenly dispersed along the shunt pipe 4 and flow into the cabinet 1. The airflow control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com