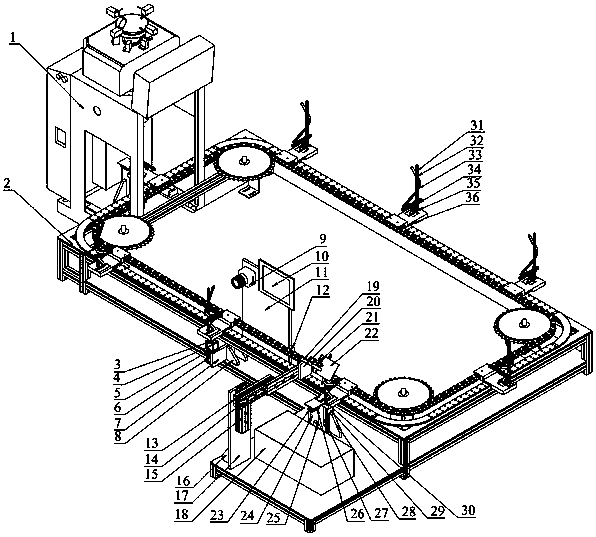

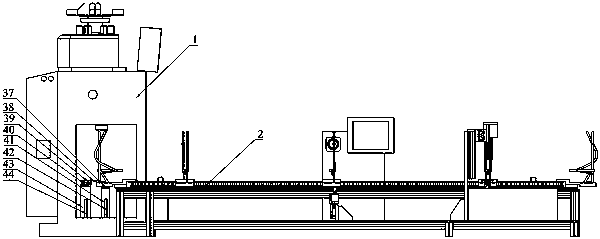

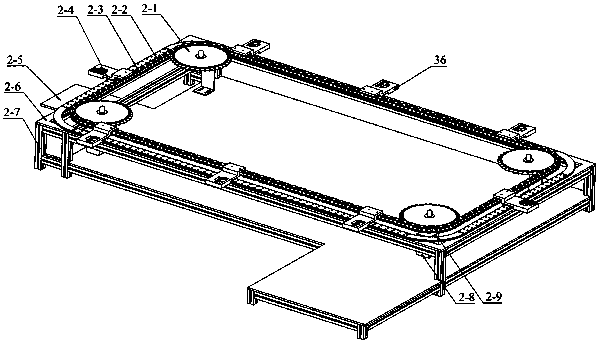

Full-automatic shear stocking machine mold transfer and detection removal device

A rejecting device and fully automatic technology, which is applied in fabric surface trimming, textile material inspection, textile and paper making, etc., can solve problems such as incomplete seams, heavy hosiery workload, and high work intensity, so as to reduce workers' labor Quantity, realize the elimination process, improve the labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The initial state of the sock-connecting side pressure cylinder 39 is the retracted state of the sliding table piston rod, and the working state of the sock-connecting side pressure cylinder 39 is that the slide table of the sock-connecting side pressure cylinder 39 carries the sock-connecting side pressure plate 38 to stretch out. The sock-connecting side pressure plate 38 laterally presses the sock mold base 35 to prevent the sock mold movable support 33 from being pushed up by the sock-connecting jacking cylinder 37 while pushing the whole sock mold out of the sock mold transfer base 36; The initial state of the cylinder 37 is the retracted state of the piston rod of the baffle plate, and the working state is that the piston rod of the baffle plate is stretched out, and the movable support 33 of the sock mold is pushed up, so that the upper end of the sock mold is opened and closed, so that the sock outlet of the sock knitting machine 1 can be opened and closed. Carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com