Paper smashing and recycling device

A recycling device and paper technology, applied in the field of waste paper treatment, can solve the problems of poor packaging sealing, time-consuming and labor-intensive environment, falling off, etc., and achieve the effects of convenient transfer and packaging, preventing environmental pollution, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

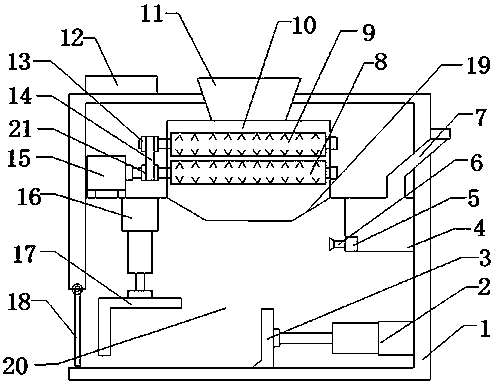

[0016] Such as figure 1 As shown, a paper crushing and recycling device is characterized in that it includes a casing 1, a crushing chamber 10, a water storage tank 4 and a compression chamber 20. An inlet groove 11 is arranged in the middle of the casing 1, and the bottom of the inlet groove 11 is connected to the crushing chamber. The entrance of the chamber 10 and the outlet of the crushing chamber 10 are provided with a baffle 19, and the bottom of the baffle 19 is connected to the compression chamber 20; A21, the driving rod A21 is connected to the driving rod B13 that also passes through the crushing chamber 10 through the endless belt 14, the driving rod A21 is located in the crushing chamber 10 and is covered with a crushing wheel A8, and the driving rod B13 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com