A method for strengthening reinforced concrete floor slabs with profiled steel plates

A technology of reinforced concrete and profiled steel plate, which is applied in construction, building maintenance, building construction, etc. It can solve the problem of limited increase in the bearing capacity of reinforced concrete floors, difficulty in controlling the quality of sticking steel, and difficulty in controlling prestressed tension, etc. problems, to achieve the effect of improving rigidity, short construction period and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

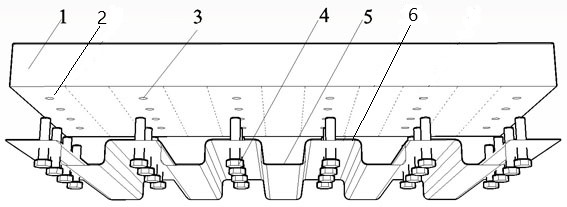

[0022] Embodiment 1: as figure 1 As shown, the one-way floor of a certain building is reinforced. The thickness of the reinforced concrete floor to be reinforced is 100mm, the protective layer is 20mm, the concrete strength grade is C20, and the stress reinforcement arrangement is φ6@200. The reinforcement design requires that the flexural bearing capacity be increased by more than 20%, the flexural stiffness be increased by more than 10%, and the seismic performance is better than that of the structure before reinforcement.

[0023] Using the present invention to reinforce the reinforced concrete floor (1), the construction steps are as follows:

[0024] Step 1: According to the relevant requirements of the profiled steel plate in the steel and concrete composite building (roof) cover structure document with the Atlas No. 05SG522, select the profiled steel plate 5 supported on both sides of the Q235 steel type, and the wall thickness of the profiled steel plate 5 1mm, the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com