Method for adapting a touch point of a friction clutch

A technology of friction clutches and clutches, applied to clutches, mechanical equipment, etc., which can solve the problems of inability to monitor the pressure of the clutch system, driving loss, inability to use the clutch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

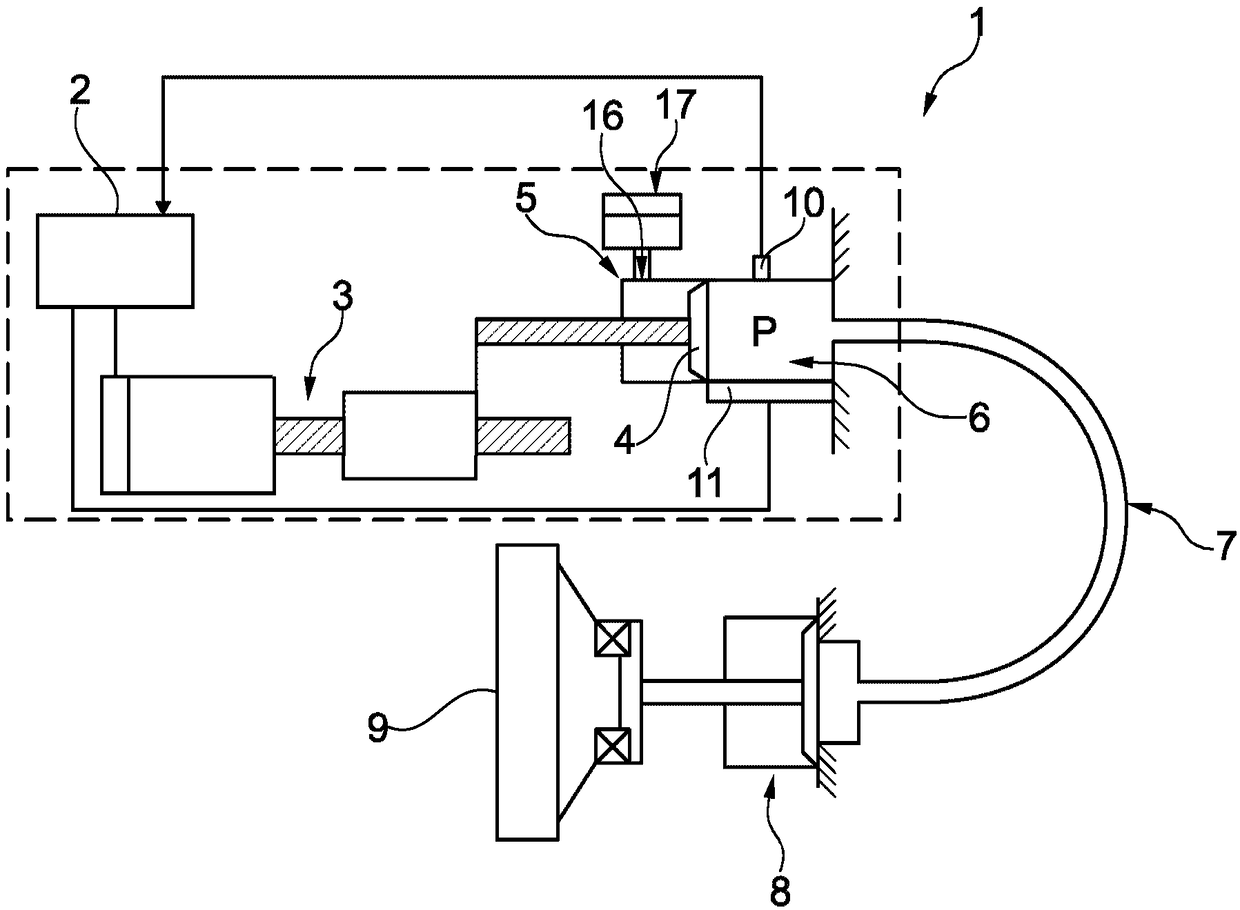

[0027] exist figure 1 The structure of a hydrostatic clutch operating system 1 with a hydrostatic clutch actuator 3 as used in a vehicle is schematically shown in . A hydrostatic clutch operating system 1 includes a controller 2 for controlling a hydrostatic clutch actuator 3 . When the position of the clutch actuator 3 changes, the piston 4 of the master cylinder 5 moves to the right along the actuator stroke, wherein the volume in the master cylinder 5 is changed and a pressure p is generated in the master cylinder 5 . The pressure p is transmitted via the hydraulic fluid 6 serving as pressure medium via the hydraulic line 7 to the secondary cylinder 8 , which directly operates the friction clutch 9 . The friction clutch 9 is called a directly operated clutch, since the operation takes place without an interposed lever spring. In this case, the pressure p of the hydraulic fluid 6 induces a stroke change in the secondary cylinder 8 which acts on the actuation of the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com