Method for reducing deposition on back heated surface of biomass boiler

A tail heating surface, biomass boiler technology, applied in the field of biomass-fired boilers, can solve the problems of reduced combustion efficiency and corrosion of boilers, and achieve the effects of reducing ash deposition, reducing gas phase precipitation, and slowing down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

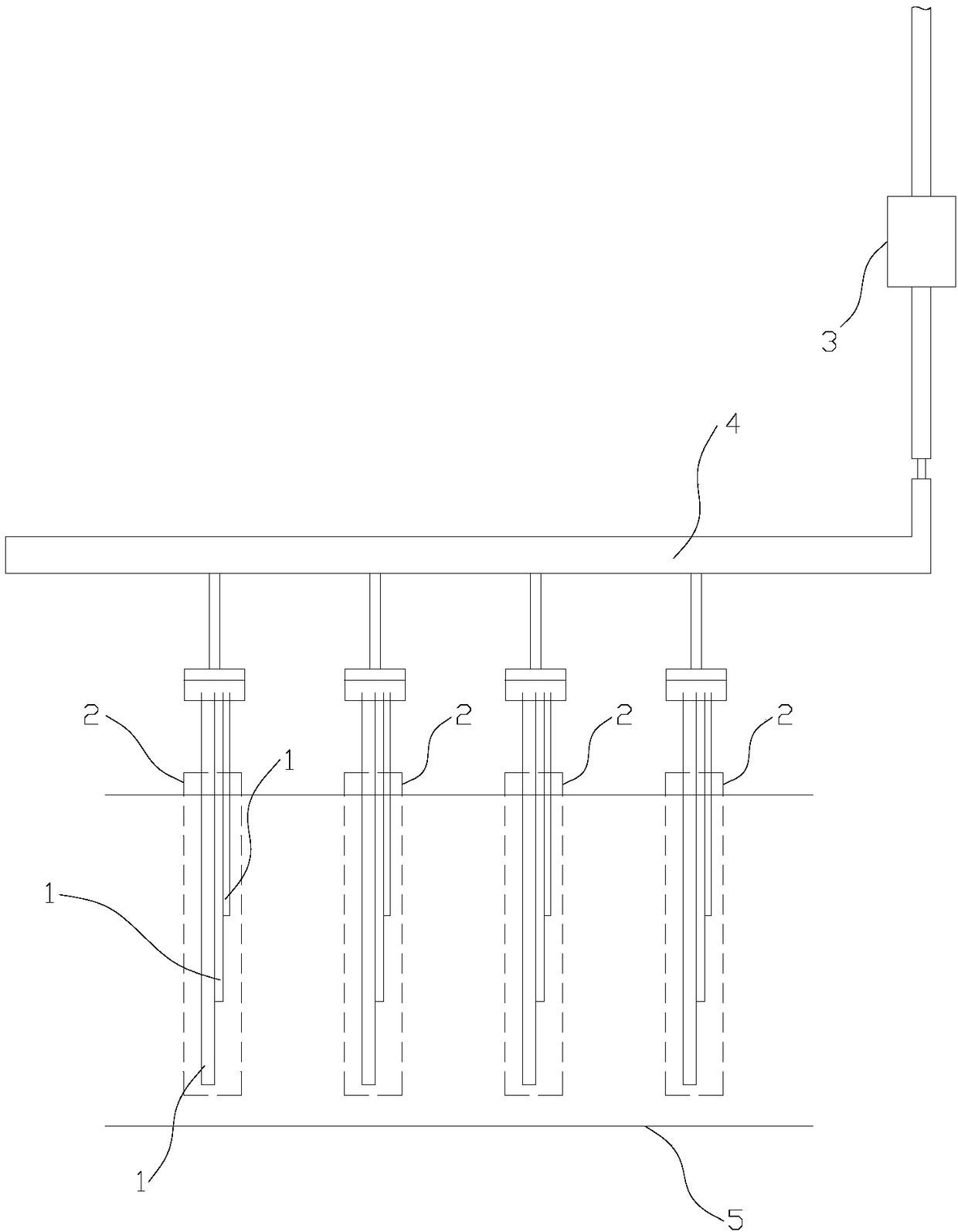

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] A method for reducing deposition on the heating surface at the tail of a biomass boiler. According to the content of alkali metal in the fuel ash, the flue gas temperature at the furnace outlet is controlled between 700 and 850°C. The temperature of the flue gas at the furnace outlet is 5 along the horizontal flue at the furnace outlet. The average temperature detected by several thermocouples 1 distributed in the flue 5 along the length direction. According to the alkali metal content of the biomass fuel, the present invention controls and adjusts the flue gas temperature at the outlet of the furnace between 700 and 850°C, reduces the gas phase precipitation of the alkali metal during the fuel combustion process, and thus saves coal on the heating surface at the tail of the boiler. The dust deposition on the parts of the boiler is signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com