Push and pull type extractor hood oil stain partition

A range hood, push-pull technology, applied in the field of kitchen purification equipment, can solve problems such as drifting, oil mist splashing, oil mist can not be sucked away, etc., to achieve the effect of convenient disassembly, economical and practical, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

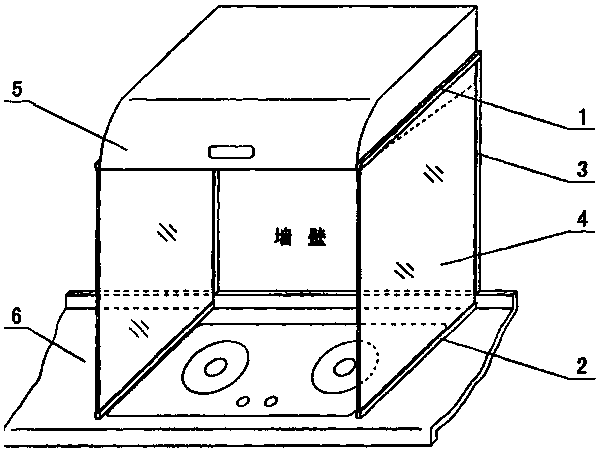

[0008] Embodiment 1: As can be seen from Fig. 1, the present invention is made up of upper rail 1, lower rail 2, rail rod 3 and partition board 4; partition board 4 adopts toughened glass plate in the present embodiment, has fire prevention, waterproof, high temperature resistance, corrosion resistance , transparent, easy to clean, etc.; the two upper rails 1 are respectively fixed on both sides of the range hood 5 cabinet by bonding, and the two lower rails 2 are respectively fixed on both sides of the cooker or the operating table 6 by bonding. The upper track 1 and the lower track 2 are on the same plane; two track rods 3 are fixed on the wall by bonding, and are located between the upper track 1 and the lower track 2 on both sides; the partition board 4 is a tempered glass plate inserted in the upper track 1, In the groove of the lower track 2 and the track bar 3.

[0009] After the present invention is installed, the partition board 4 is located on both sides of the range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com