Integrated bullet and emission gun thereof

An all-in-one, firing gun technology, applied in the field of firing guns, can solve problems such as the impact of recoil on shooting accuracy, affecting shooting frequency, and poor control, and achieve the effects of reducing control strength, improving shooting accuracy, and reducing recoil force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

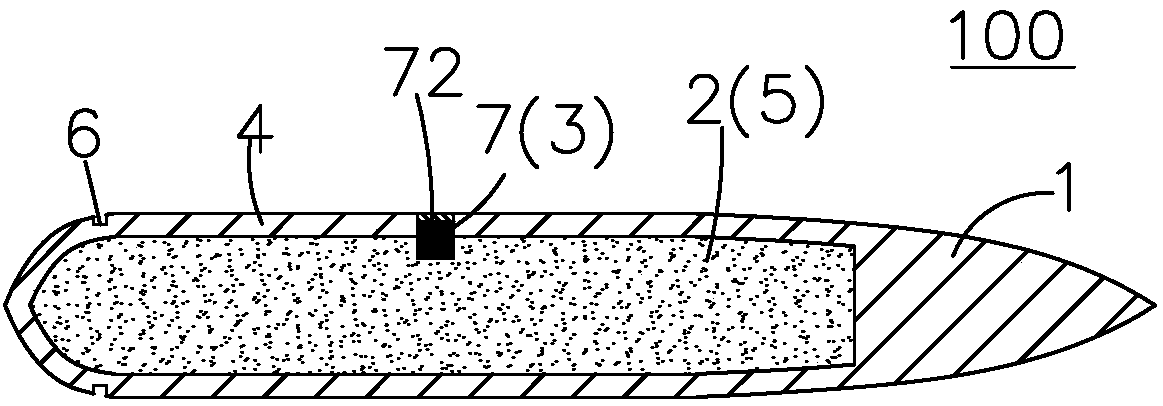

[0027] see figure 1 As shown, the integrated bullet 100 in the first embodiment includes a warhead 1, a medicine chamber 2 and a primer 3, the medicine chamber 2 is a sealed cavity surrounded by the warhead 1 and the chamber shell 4, and the medicine chamber 2 is filled with propellant Or explosives 5, chamber shell 4 and warhead 1 are integrally formed, and chamber shell 4 is also provided with breaking port 6 and primer groove 7, and primer groove 7 is equipped with primer and seals with primer cover 72.

[0028] which, combined with image 3 As shown, the breaching opening 6 in Embodiment 1 is a breaching ring, which is a continuous or discontinuous annular groove around the tail of the chamber shell; the primer groove 7 is located in the cavity the waist of the shell.

Embodiment 2

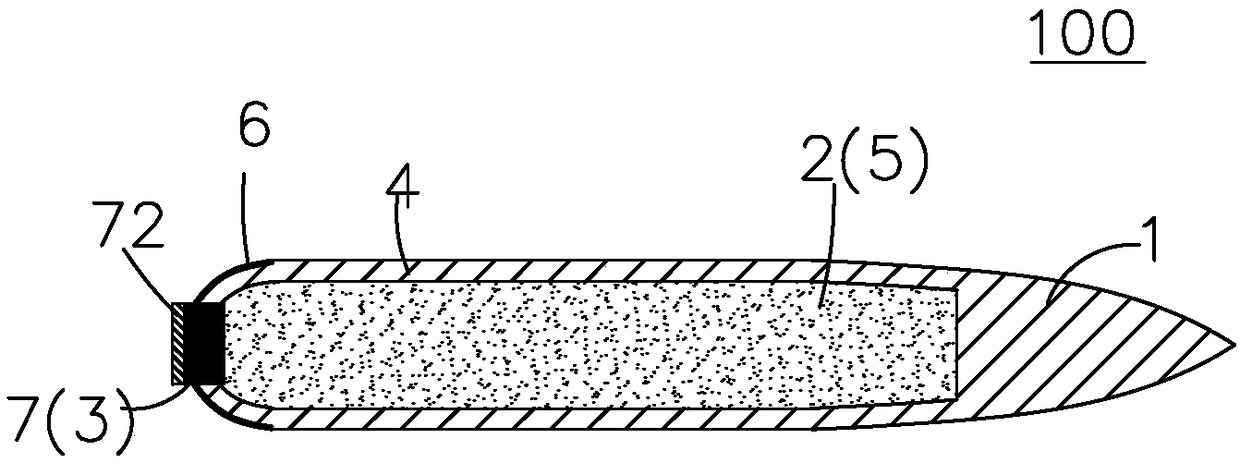

[0030] see figure 2 As shown, it is different from Embodiment 1 in that: the damage opening 6 is a dovetail groove, and the dovetail groove is a "ten" groove or a "m" groove arranged at the center of the tail end of the cavity shell 4 .

[0031] The primer groove 7 is located at the center of the tail end of the chamber shell 4, and is also at the center of the dovetail groove.

Embodiment 3

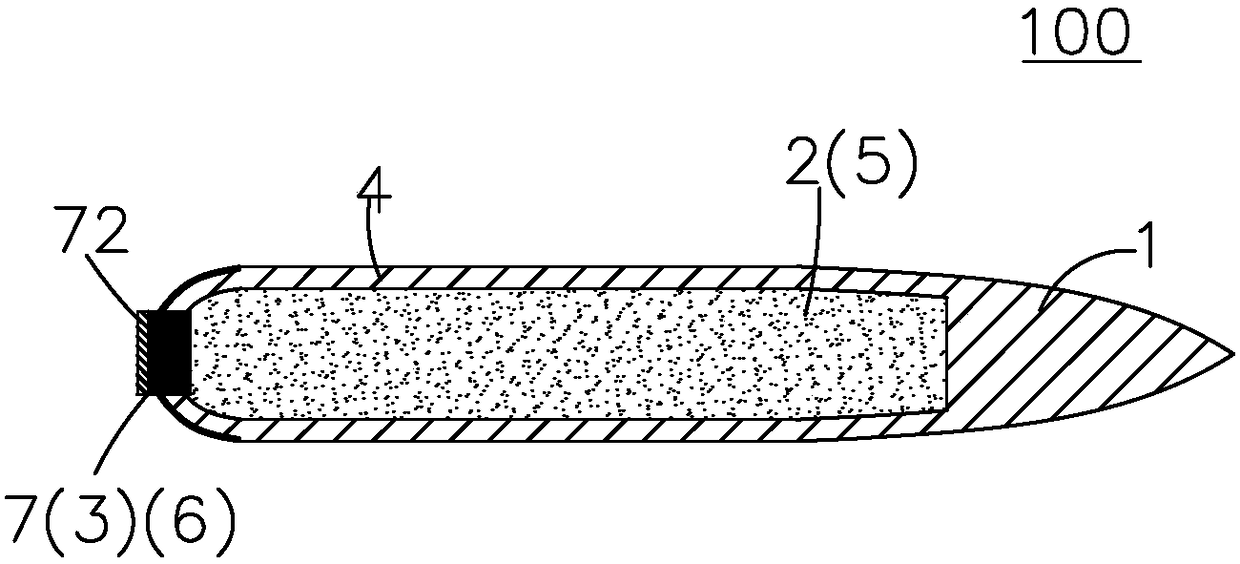

[0033] see image 3 As shown, the difference from Embodiment 1 is that the damage opening 6 and the primer groove 7 are combined into one, that is, the damage opening 6 is borne by the primer groove 7, because the chamber shell 4 After the primer groove is opened, its strength is weaker than other positions, so it can fully undertake the function of the destruction port 6, making the structure more simplified.

[0034] Although the specific structures of the three embodiments are only provided above, it should be noted that in other embodiments of the present invention, when the breaching opening 6 is a breaching ring, the primer groove 7 can also be arranged in the chamber shell 4 at the center of the tail end; or when the destruction opening 6 is a dovetail groove, the primer groove 7 can also be arranged at the waist of the chamber shell 4 . All can realize the present invention.

[0035] see Figure 7 to Figure 9 Shown, describe in detail the launch principle of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com