Enclosed horizontal battery structure

A horizontal battery, closed technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing / processing, etc., can solve the problem of positive active material or negative active material reducing the service life of the horizontal battery, to increase air pressure, The effect of improving the utilization rate and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

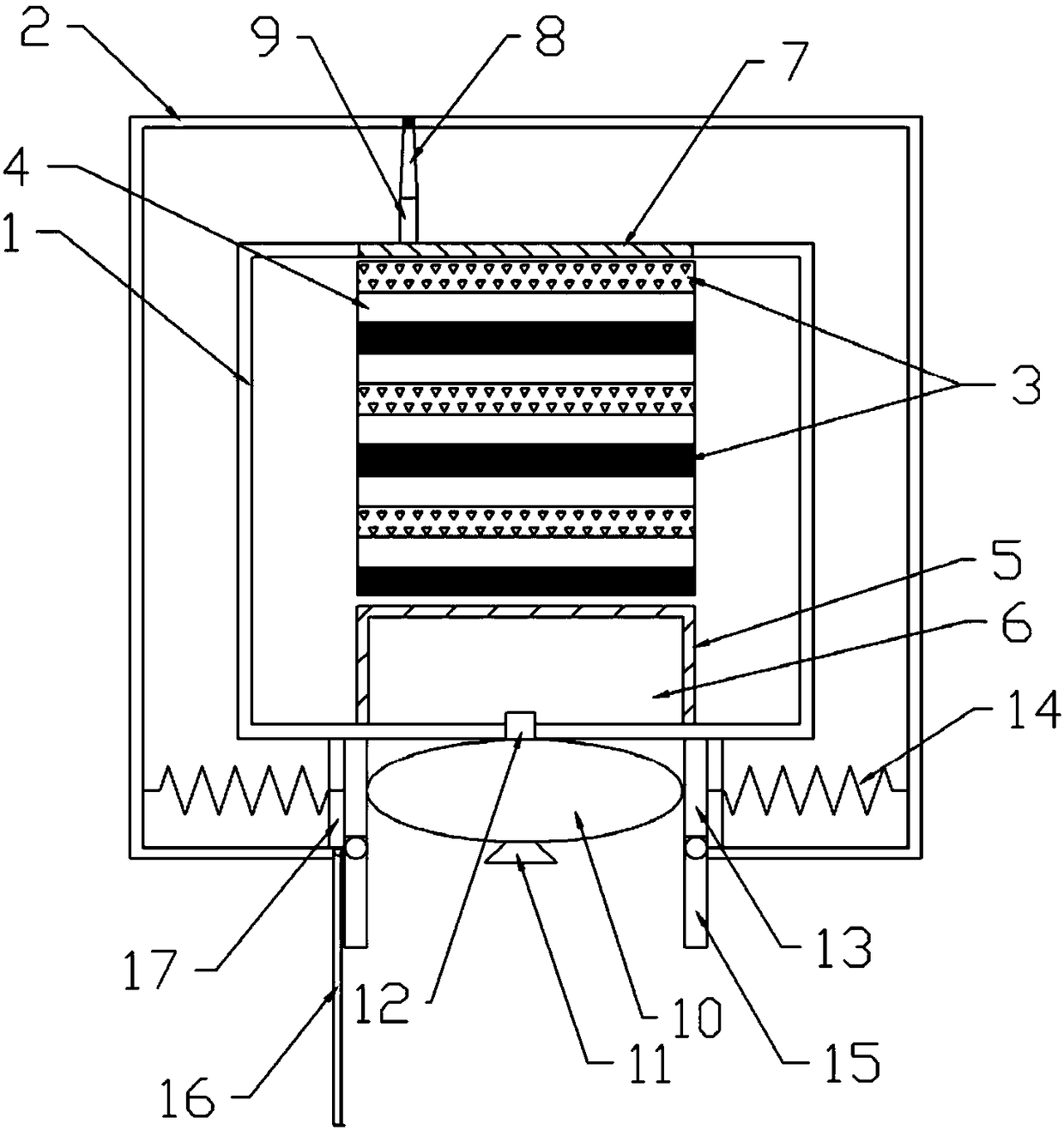

[0016] The reference signs in the drawings of the description include: pressure frame 1, sealing frame 2, pole plate 3, separator 4, spring plate 5, cavity 6, spring leaf 7, marker pen 8, telescopic rod 9, air bag 10, inlet Air port 11, air outlet 12, pressure plate 13, spring 14, hand-held plate 15, cover plate 16, sealing plate 17.

[0017] The embodiment is basically as attached figure 1 As shown: a closed horizontal battery structure of the present invention, including a pressure frame 1 and a sealing frame 2, a number of pole plates 3 are stacked in the pressure frame 1, a separator 4 is stacked between every two pole plates 3, and the pressure frame The bottom wall of 1 is equipped with several spring plates 5, the spring plate 5 and the bottom wall of the pressure frame 1 form a cavity 6, a sealing ring is provided between the spring plate 5 and the pressure frame 1, the pole plate 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com