motor

A technology of components and permanent magnets, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing motor rotation load loss, reducing motor stability, and reducing motor working efficiency, so as to improve stability and weaken harmonics. wave, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

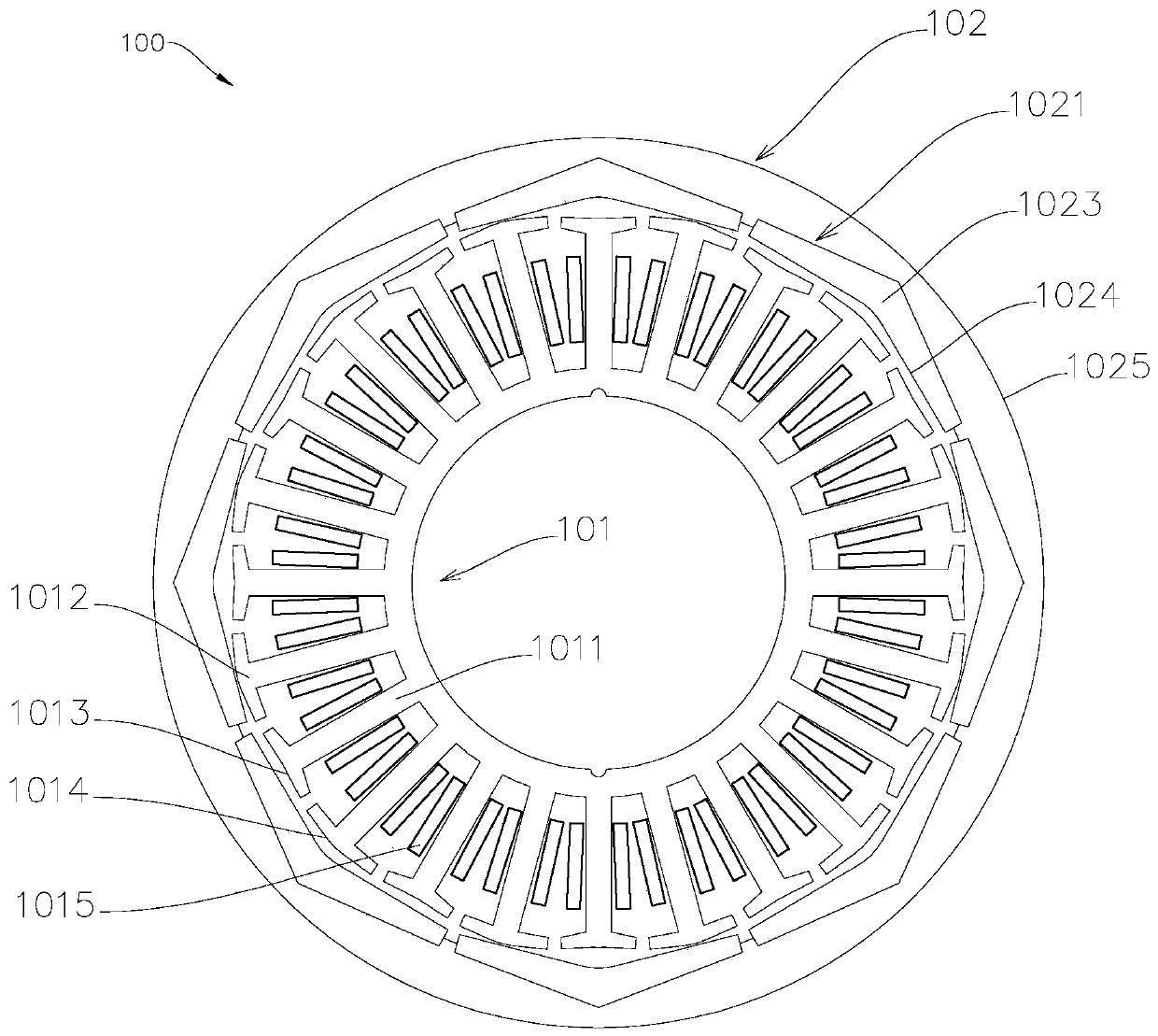

[0026] Such as figure 1 As shown, the motor 100 includes a stator assembly 101 and a rotor assembly 102 . The stator assembly 101 is provided with a magnetic conduction element 1011 , the magnetic conduction element 1011 is provided with teeth, and one end of the teeth facing the rotor assembly 102 is provided with a crown 1012 . The crown 1012 includes a concave crown 1013 and a convex crown 1014 . The concave tooth crown 1013 and the convex tooth crown 1014 are set at intervals, and the working surfaces of each three tooth crowns constitute the unit fluctuation variable in the fluctuation cycle of the convex surface, concave surface and convex surface in turn, so that the radial distance of the working surface of the stator assembly is along the circumferential direction. Has a fluctuating cycle. The rotor assembly 102 includes a permanent magnet array 1021 and a rotor bracket 1025 . Along the radial direction of the motor 100 , the permanent magnets 1023 of the permanent...

no. 2 example

[0032] This embodiment is basically the same as the first embodiment, the difference lies in the number of stator assemblies and rotor assemblies.

[0033] Such as Figure 5 As shown, the motor 500 is a dual-rotor motor, including a first permanent magnet array 501 , a second permanent magnet array 502 and a magnetic permeable element 503 of the stator assembly. Both the working surfaces of the first permanent magnet array 501 and the second permanent magnet array 502 have fluctuation periods. The number of teeth of the outer tooth crown 5031 and the inner tooth crown 5032 of the magnetic permeable element 503 of the stator assembly are equivalent, and both constitute a working surface with a fluctuation period. The working surface of the stator assembly and the working surface of the permanent magnet array work together to produce a thinner air gap with a fluctuating period, which is conducive to the construction of a large and uniform transition force, improves the stabilit...

no. 3 example

[0037] This embodiment is basically the same as the first embodiment, the difference is that teeth of different shapes are formed on the magnetic permeable element.

[0038] Such as Figure 7 , Figure 8As shown, the magnetic permeable element 700 includes a tooth 701 , a crown 702 and a yoke 703 . The tooth width of the tooth 701 near the crown 702 is greater than the tooth width of the tooth 701 near the yoke 703 . The tooth height of the tooth 701 close to the permanent magnet 704 is smaller than the tooth height of the tooth 701 close to the yoke 703 . At the same time, ensure that the cross-sectional area of the part of the tooth 701 between the tooth crown 702 and the yoke 703 is equivalent. It is beneficial to expand the slot width of the magnetic permeable element 700, to increase the conductive cross-sectional area of the winding, to increase the slot fullness rate, to increase the effective side length, to reduce resistance, to reduce copper consumption, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com