High-precision vertical depth positioning device of numerically-controlled reciprocating wire cutting machine tool

A cutting machine tool, vertical depth technology, applied in the field of tools, can solve the problems that the traditional structure is difficult to achieve, and achieve the effect of no noise in movement, sensitive transmission response, stable and reliable accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

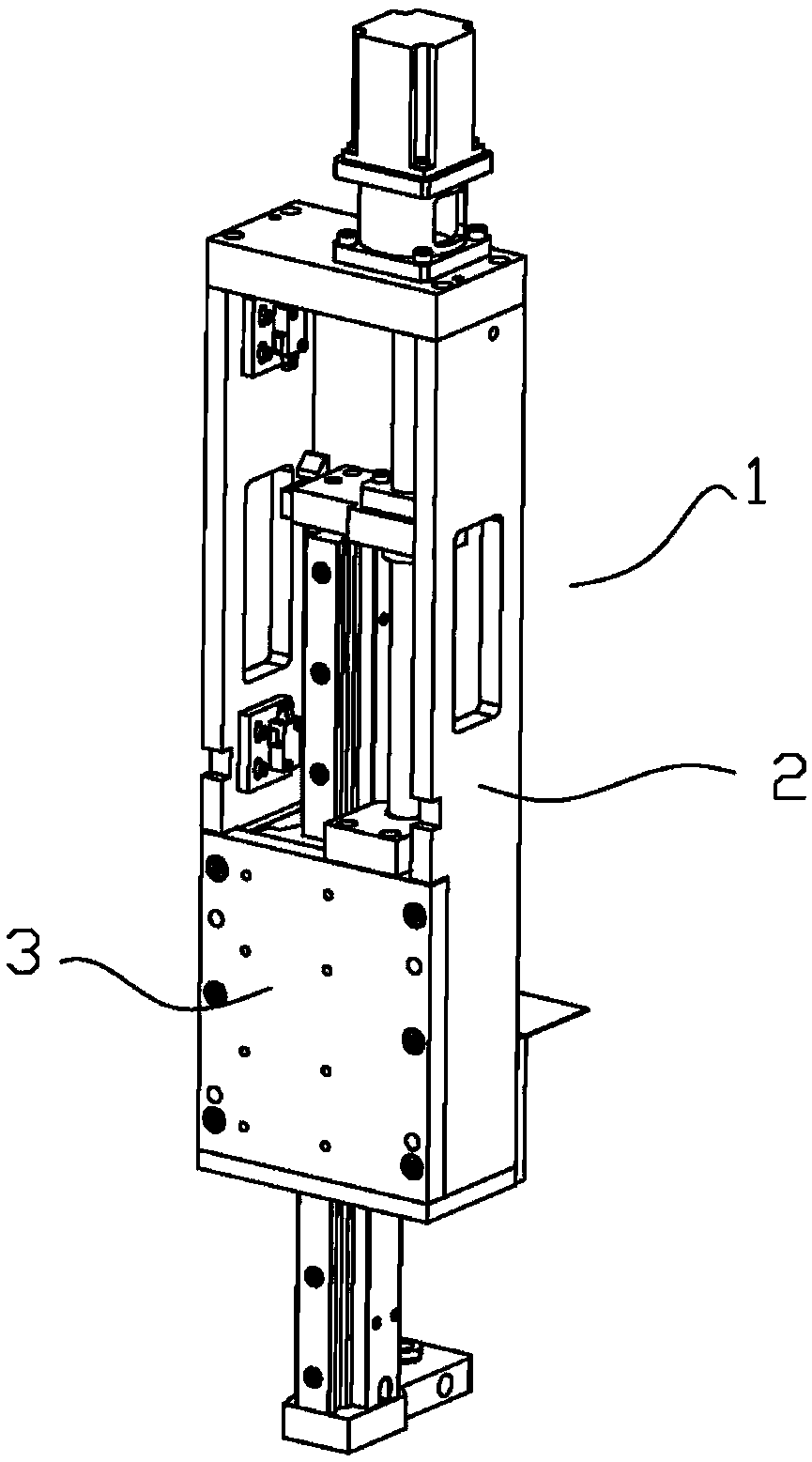

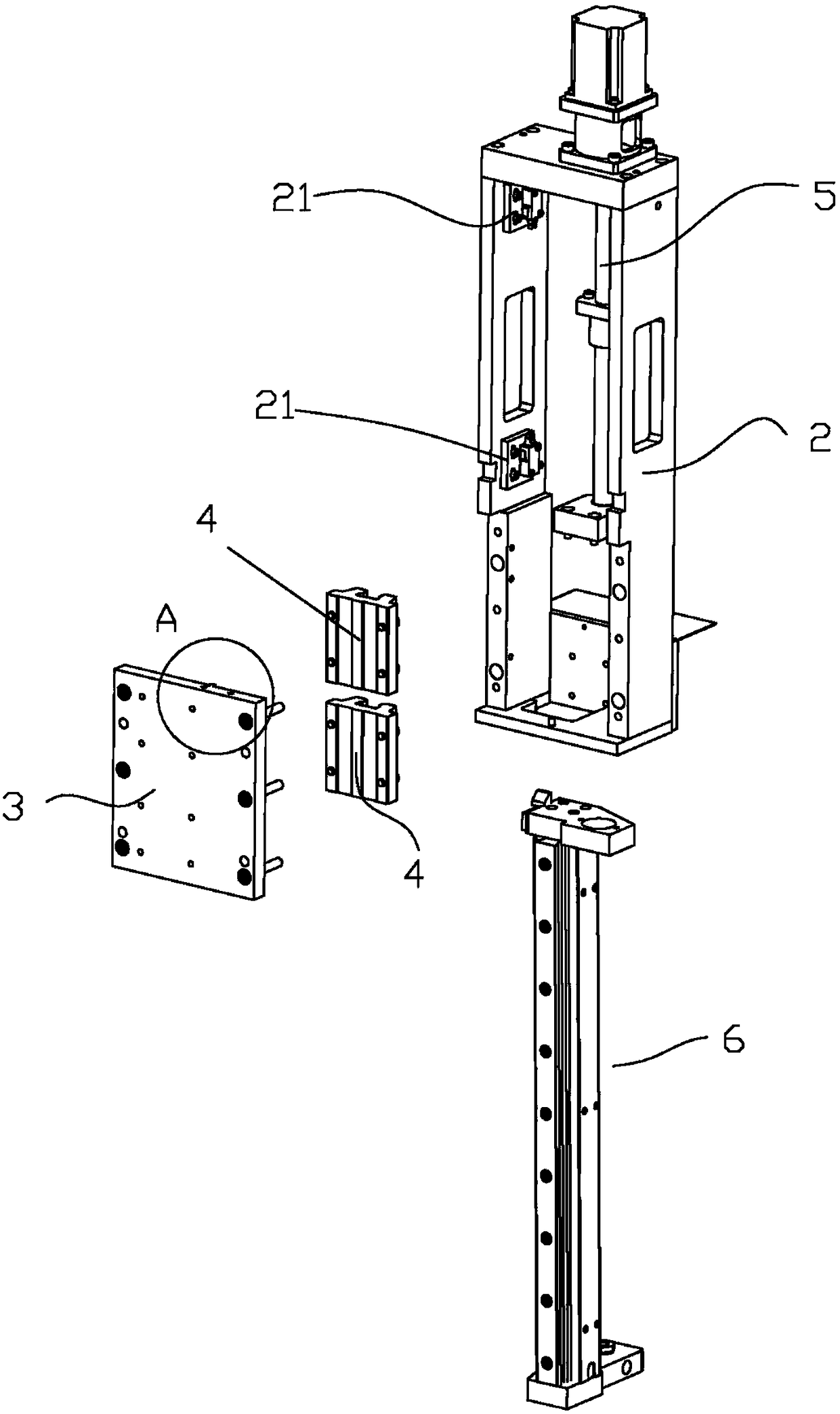

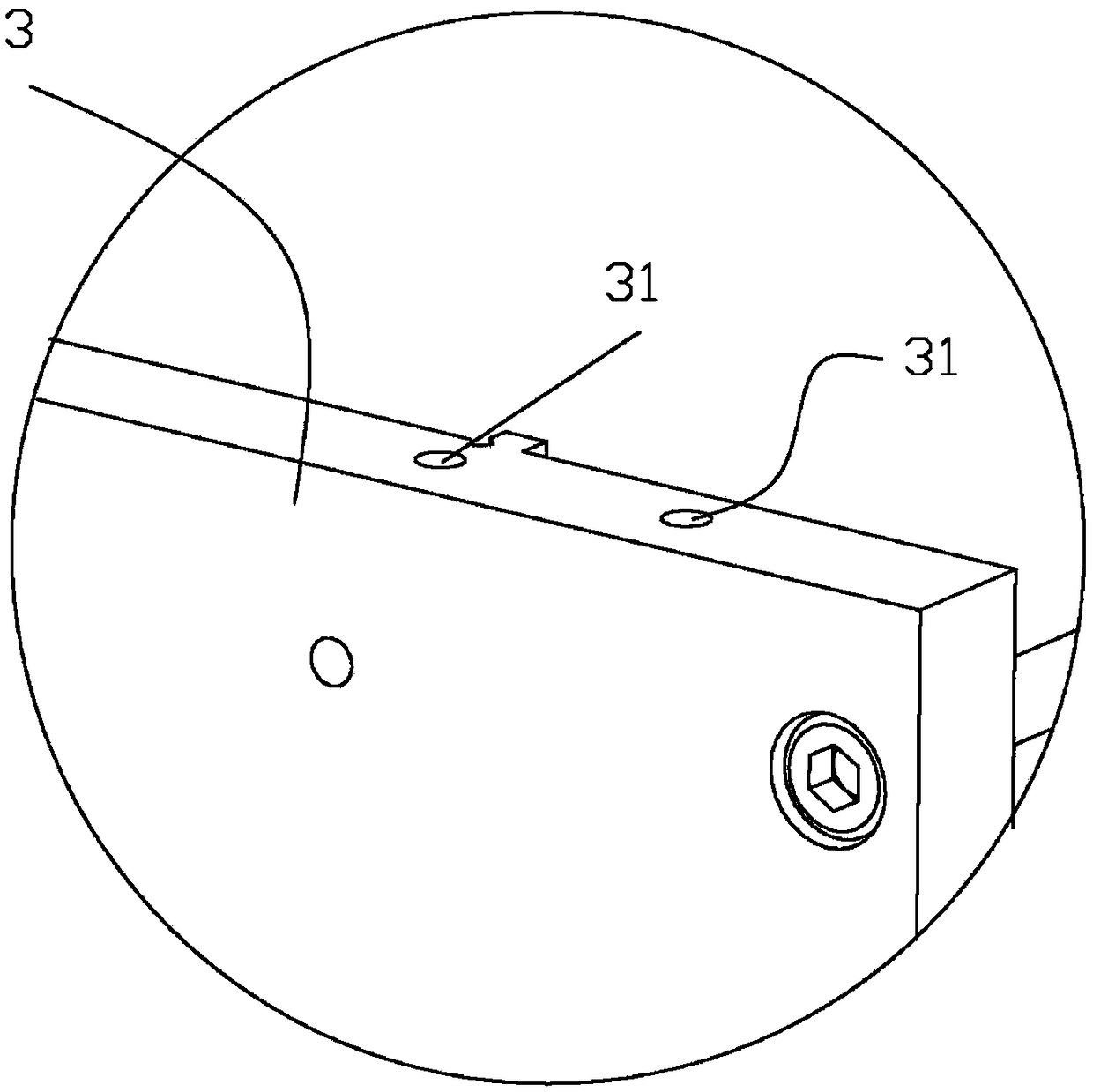

[0023] Such as Figure 1 to Figure 3 As shown, the high-precision vertical depth positioning device 1 of the CNC reciprocating wire cutting machine tool includes a main body support 2, a pair of micro switches 21 are arranged on the inner wall of the main body support 2, and a guide rail bottom plate 3 is provided at the bottom of the main body support 2 , the top of the guide rail base plate 3 is provided with a pair of base plate connection holes 31, and the screw base 53 is provided with a pair of screw base holes 531.

[0024] A pair of detachable guide rail bases 4 are arranged on the upper surface of the guide rail base plate 3 , and a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com