Watertight door for ship

A technology for watertight doors and ships. It is applied in the field of cabin doors. It can solve the problems of unusable watertight doors with large door openings and limited application range, and achieve the effect of reducing consumption, reducing production costs, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

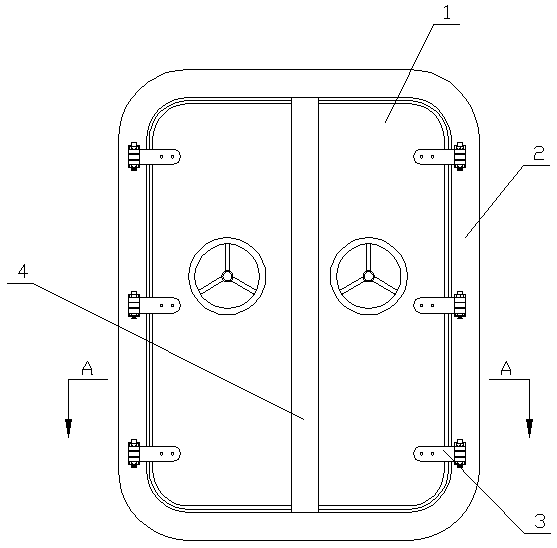

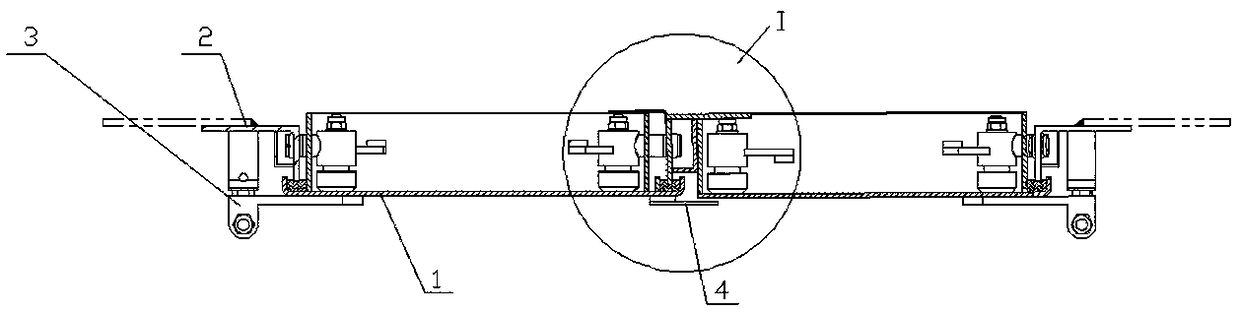

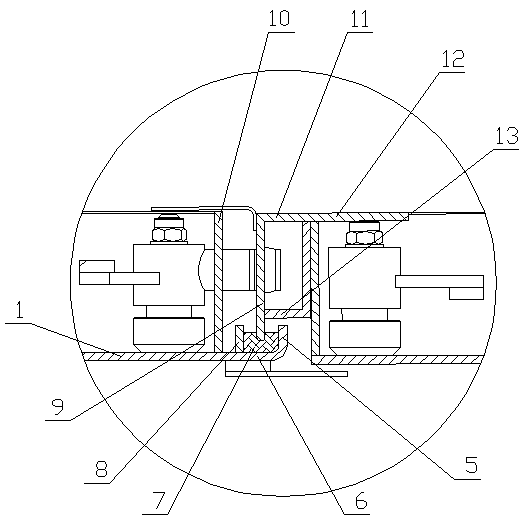

[0013] like figure 1 , figure 2 and image 3 As shown, the ship watertight door of the present invention includes a door frame 2 and a door leaf. There are two door leaves, and the non-adjacent vertical sides of the two door leaves and the corresponding mullions of the door frame 2 are hinged together in a sealed shape by three hinges 3 . Wherein, the door leaf includes a panel 1 , and the inner surface of the panel 1 is connected with an annular enclosure 10 adjacent to the edge, and the surface of the annular enclosure 10 is perpendicular to the panel 1 . Among the adjacent sides of the two panels 1: the adjacent side of one panel 1 is processed with a first overhanging edge 6, the outer edge of the first overhanging edge 6 is processed with an inner fold 5, and the inner fold 5 is provided with a longitudinal The pressure-resistant watertight strip 7 of its vertical total length. The inner edge of the annular coaming 10 of the other panel 1 is welded with a connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com