Method for preparing high-efficient gel-free long-chain branching polylactic acid

A long-chain branched, polylactic acid technology, applied in the field of preparation of long-chain branched polylactic acid, can solve problems such as difficult to control cross-linked structure and unfavorable processing by free radical reaction, achieve easy implementation, improved melt strength, equipment The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

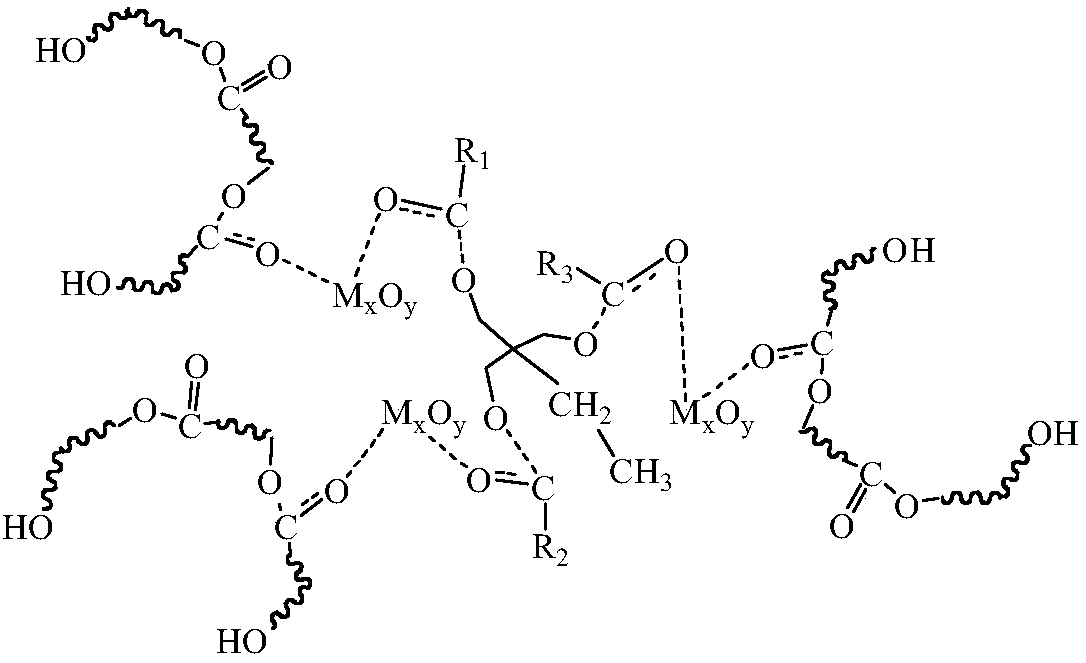

[0024] The invention provides a method for preparing high-efficiency gel-free long-chain branched polylactic acid. In the preparation method, the present invention utilizes the coordination effect between the nanometer metal oxide particles and the macromolecular polylactic acid and the ester group of the multifunctional small molecular ester monomer to activate the ester group, thereby promoting the synthesis of the multifunctional small molecular ester monomer. The transesterification reaction between body and macromolecular polylactic acid is used to prepare long-chain branched polylactic acid with high melt strength and significant strain hardening characteristics. The principle is as follows:

[0025]

[0026] Among them, R 1 , R 2 , R 3 The same or different, it is a hydrocarbon group with 1 to 10 C atoms; M x o y It is a nanometer metal oxide particle, and M is Zn, Sn, Fe, Al, Ti, etc.

[0027] The test equipment that the present invention adopts in the embodime...

Embodiment 1

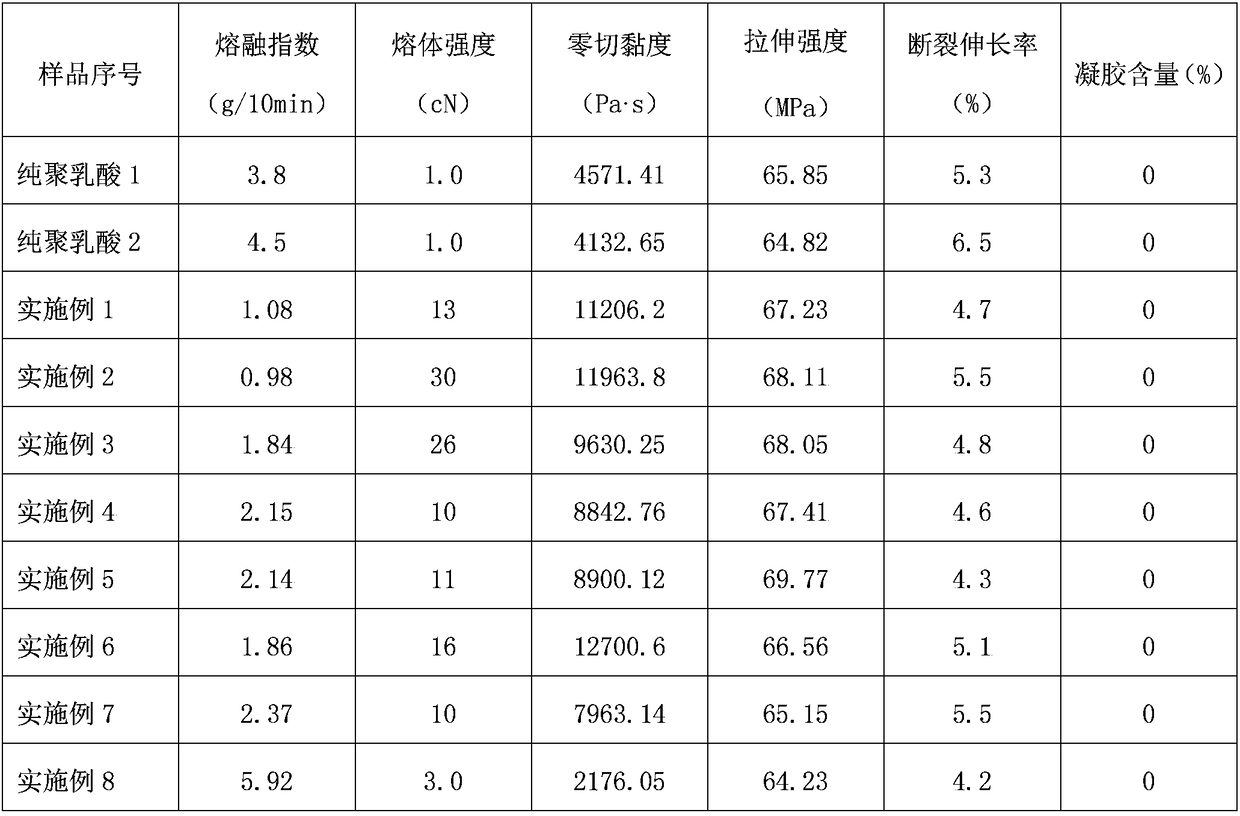

[0033] Take polylactic acid (left-handed polylactic acid pellets, melt index is 3.8g / 10min, molecular weight is 150000, 190°C) and nano-zinc oxide, after drying in a vacuum oven at 60°C for 12h, weigh 100g of dry polylactic acid and 0.2g nanometer zinc oxide (particle size is 50nm) is premixed. Dissolve 2g of trimethylolpropane triacrylate in acetone, and after the dissolution is complete, spray the acetone solution evenly on the premixed polylactic acid pellets, and place the acetone in a vacuum drying oven at 40°C for 6 hours to volatilize the acetone at a vacuum degree of 10 - 6 MPa, then the mixture was added to the material chamber of the internal mixer, the temperature was set to: 185°C in the first zone, 185°C in the second zone, 190°C in the third zone, the rotor speed: 80 rpm, and the material was discharged after 7 minutes of reaction. Some samples were taken for performance testing and melt strength determination. The results are shown in Table 1.

Embodiment 2

[0035] Take polylactic acid (left-handed polylactic acid pellets, melt index of 3.8g / 10min, molecular weight of 150000, 190°C) and nano-zinc oxide, dry in a vacuum oven at 60°C for 12h, weigh 100g of dry polylactic acid and 0.4 g Nano Zinc Oxide 50nm pre-mixed. Dissolve 2g of trimethylolpropane triacrylate in acetone, and after the dissolution is complete, spray the acetone solution evenly on the premixed polylactic acid pellets, and place the acetone in a vacuum drying oven at 40°C for 6 hours to volatilize the acetone at a vacuum degree of 10 - 6 MPa, then the mixture was added to the material chamber of the internal mixer, the temperature was set to: 185°C in the first zone, 185°C in the second zone, 190°C in the third zone, the rotor speed: 80 rpm, and the material was discharged after 7 minutes of reaction. Some samples were taken for performance testing and melt strength determination. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com