Screw oil pump of carbon dioxide compressor

A technology of gas compressor and carbon dioxide, which is applied in the field of compressor oil pump, can solve the problems of low efficiency and easy suction of excessive liquid by the oil pump, and achieve the effect of low noise, small vibration and good suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

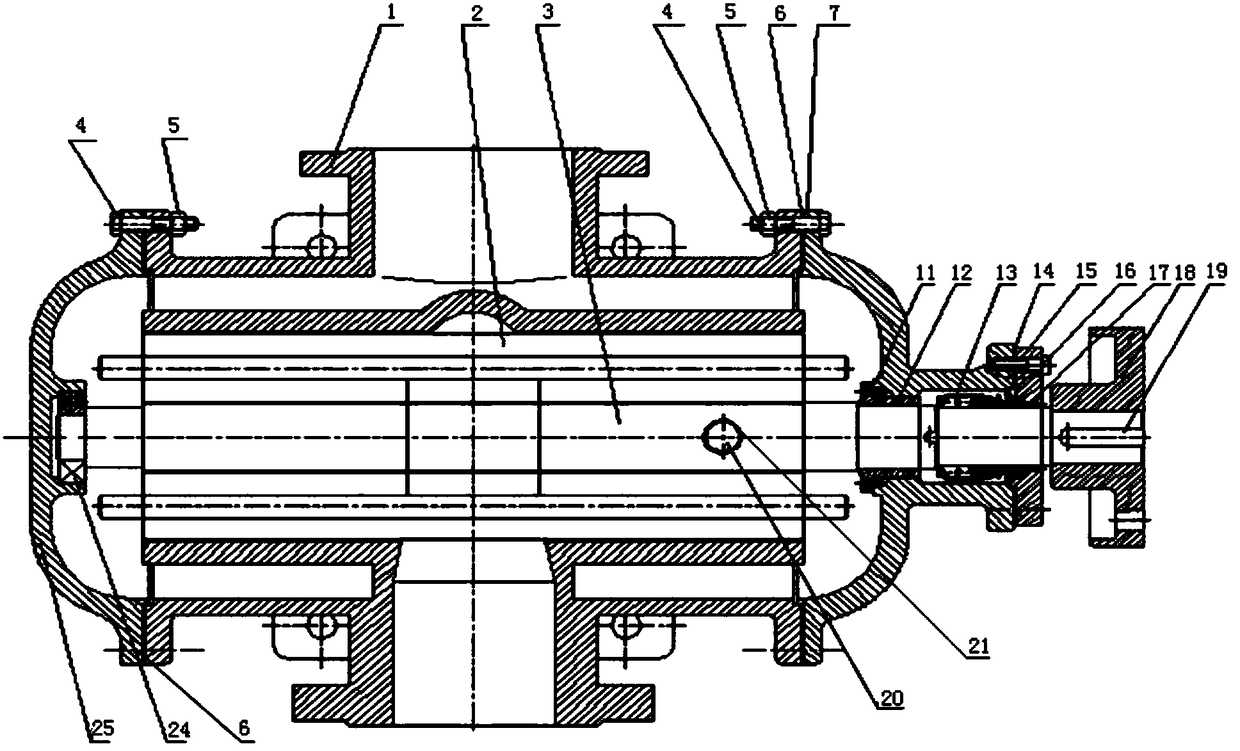

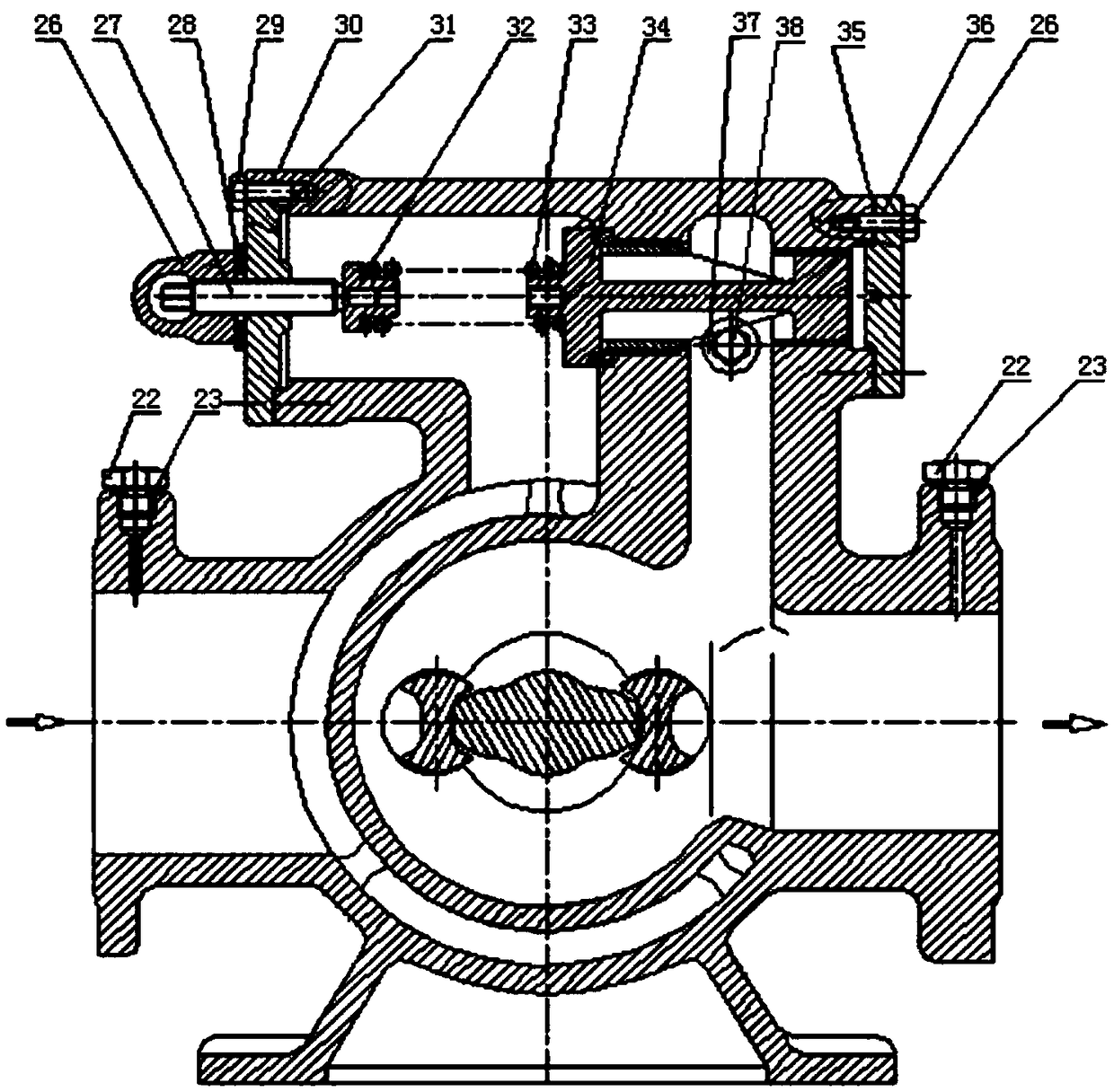

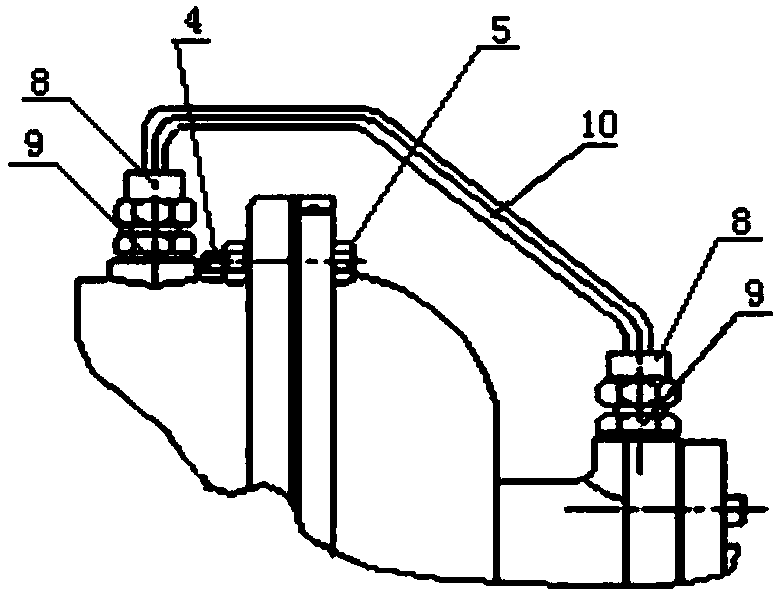

[0029] The screw oil pump of the carbon dioxide gas compressor of the present invention has a structure such as Figure 1 to Figure 6 As shown, the pump casing 1 is included, and the two ends of the pump casing 1 are respectively provided with an end cover 7 and a back cover 25 of the pump body. , a driving screw 3 and two driven screws 2 are arranged in the middle of the pump casing 1, the driven screw 2 is arranged on both sides of the driving screw 3, the driving screw 3 and the driven screw 2 are two-way screw, thread Symmetrical distribution, three screw rods are arranged horizontally and symmetrically meshed with each other. The top of the pump casing 1 is provided with a safety valve. The safety valve includes a pressure regulating screw 27, a spring seat 32, and a valve core 34 connected in sequence. The tightening nut 26 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com