Connecting device for transmission shaft and input shaft

A connection device and transmission connection technology, applied in the field of automobile transmission, can solve the problems of large noise, reduce transmission efficiency, time-consuming and laborious, and achieve the effects of reducing air noise, preventing axial movement, and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

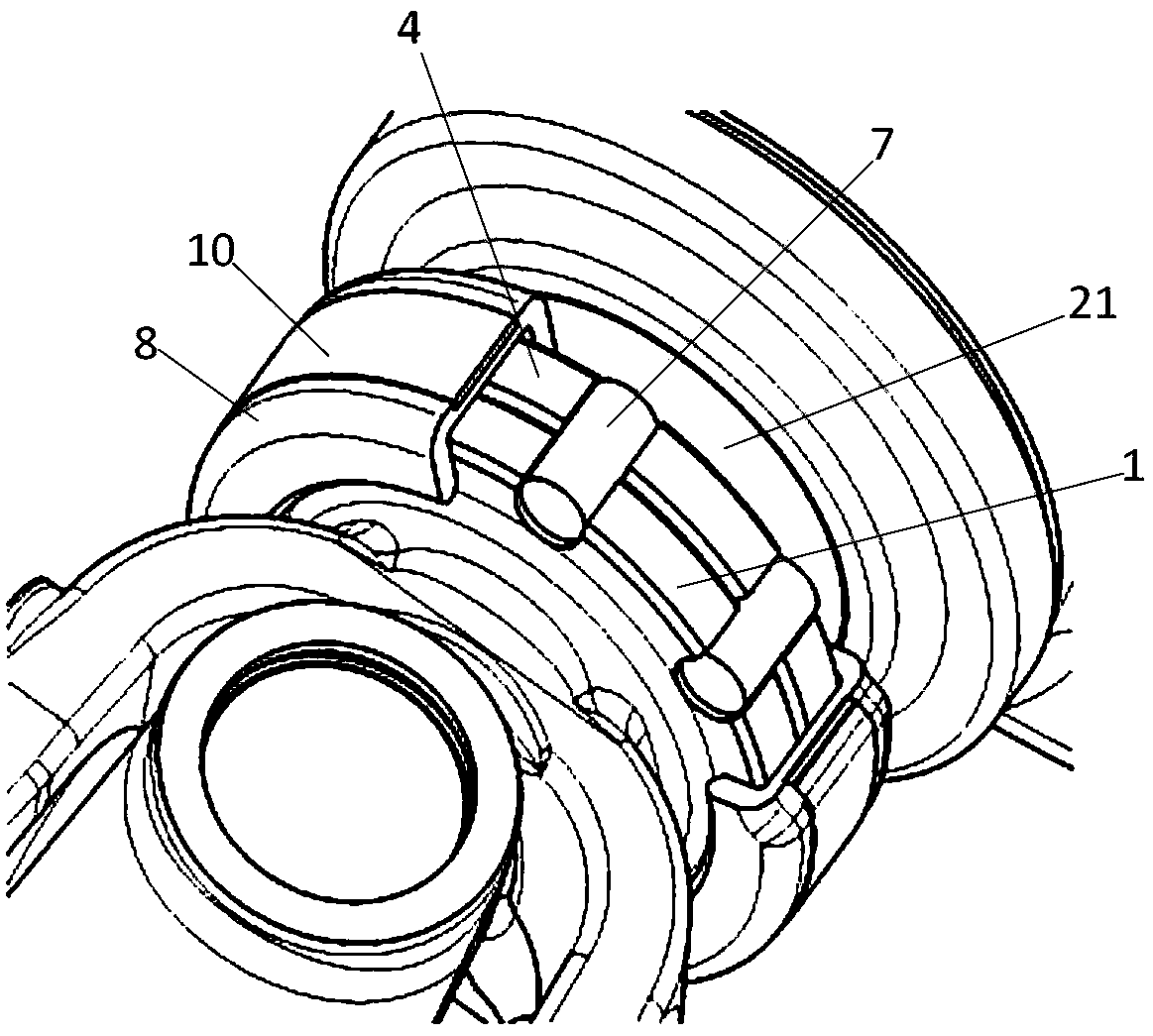

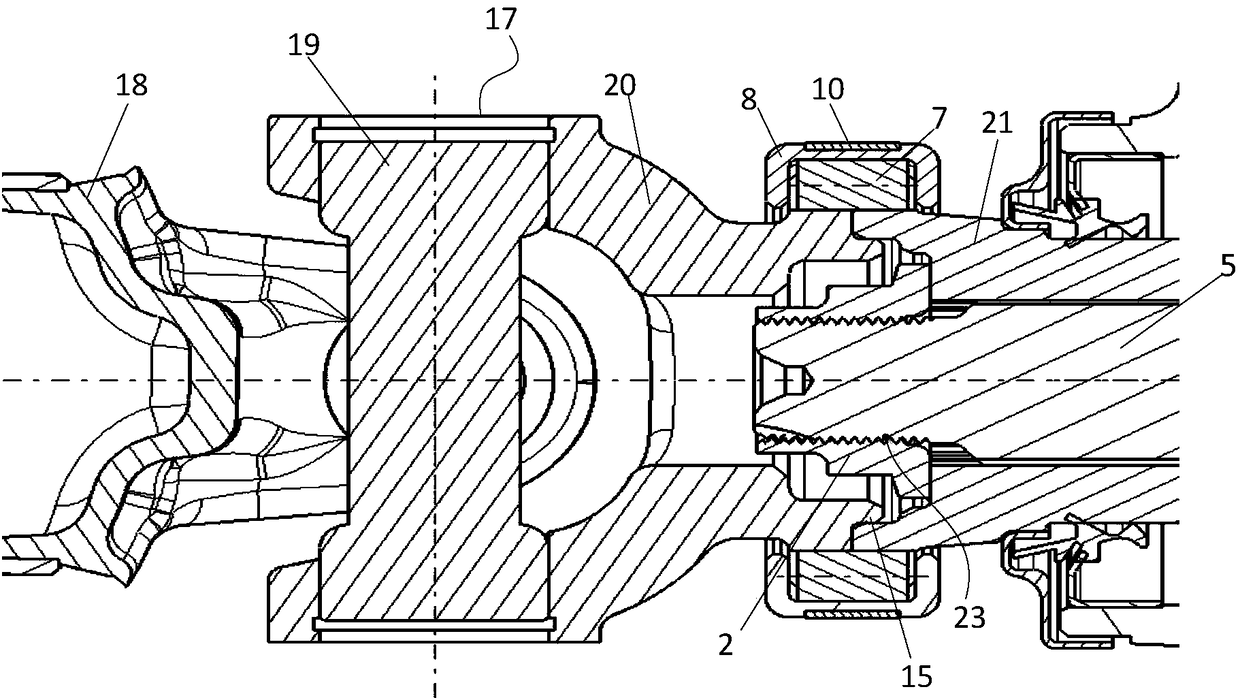

[0034] Please refer to figure 1 with figure 2 , figure 1 Is a three-dimensional cross-sectional view of the present invention; figure 2 It is a schematic diagram of the structure of the present invention; the present invention proposes a connecting device for a transmission shaft and an input shaft, which includes: a first flange 1, a second flange 4, a pin body 7 and a limit ring 8;

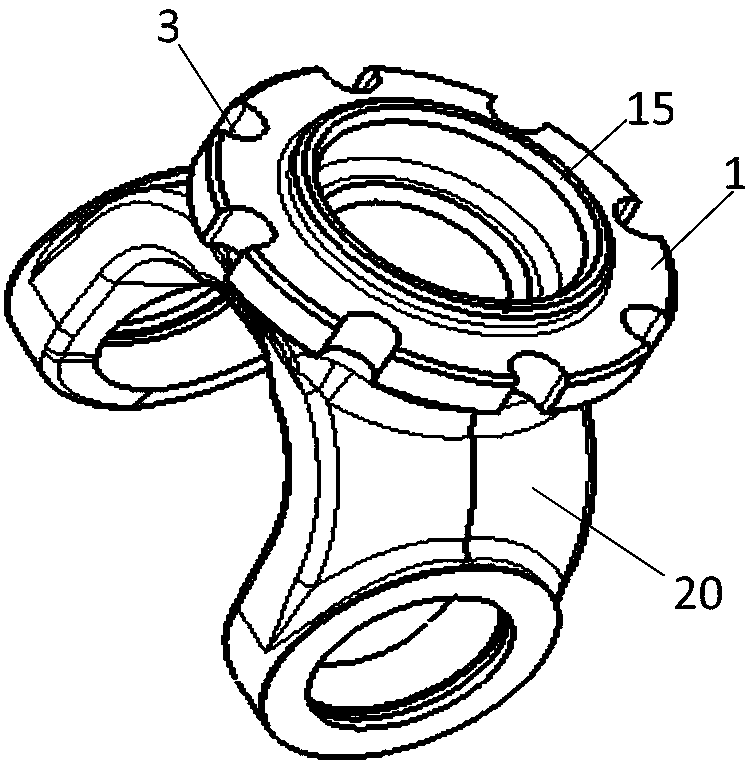

[0035] The first flange 1 is connected to the drive shaft for transmission; please refer to image 3 , image 3 It is the axonometric drawing of the first flange and the second universal joint fork; the outer circumference of the first flange 1 is provided with a number of first through grooves 3; the second flange 4 is connected to the input shaft 5 for transmission, please refer to Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com