Patents

Literature

36results about How to "Reduce air noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

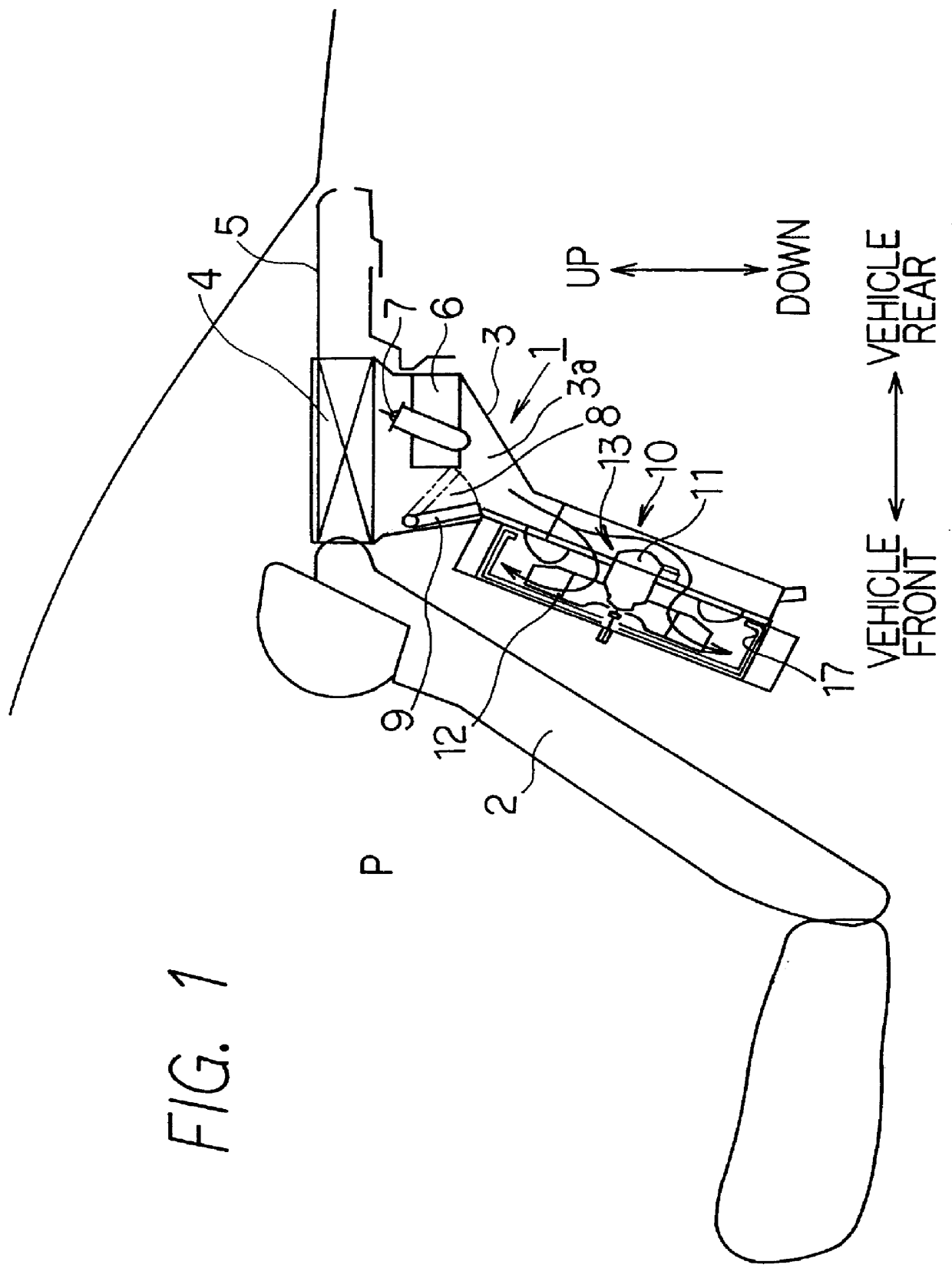

Air conditioning apparatus for a rear seat of vehicle

InactiveUS6093096ASmall pressure lossAdditional componentAir-treating devicesVehicle heating/cooling devicesEvaporatorEngineering

Owner:DENSO CORP

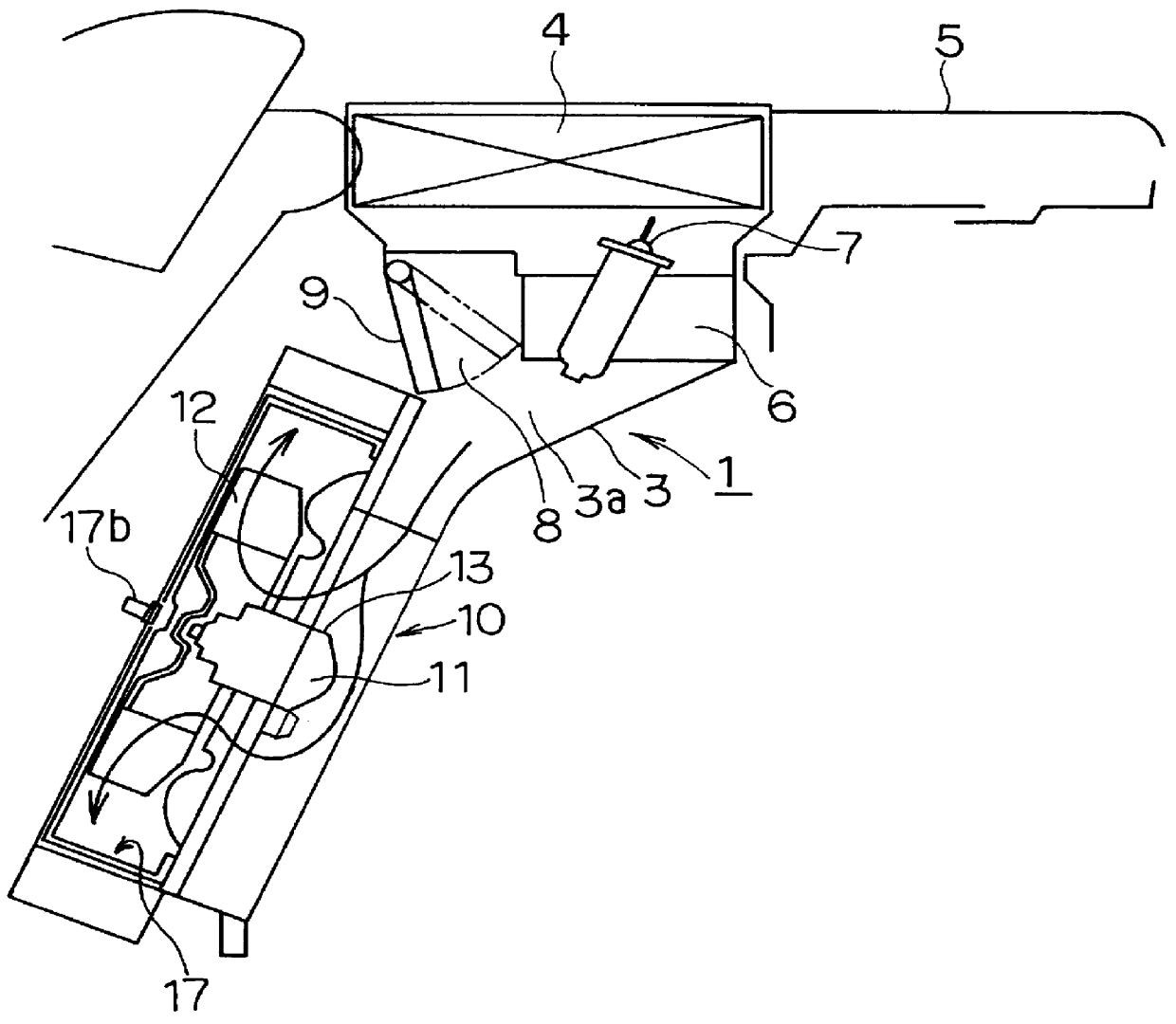

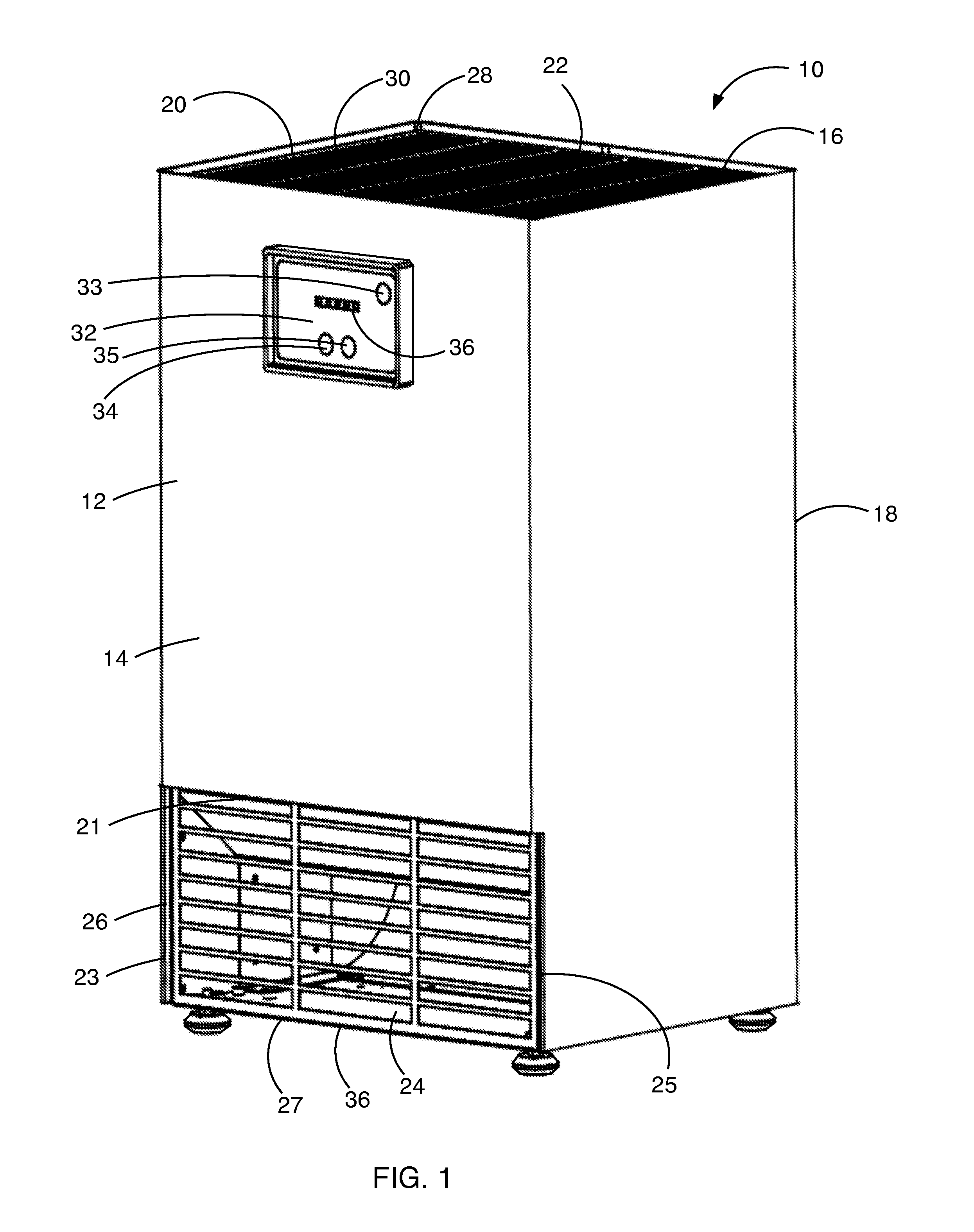

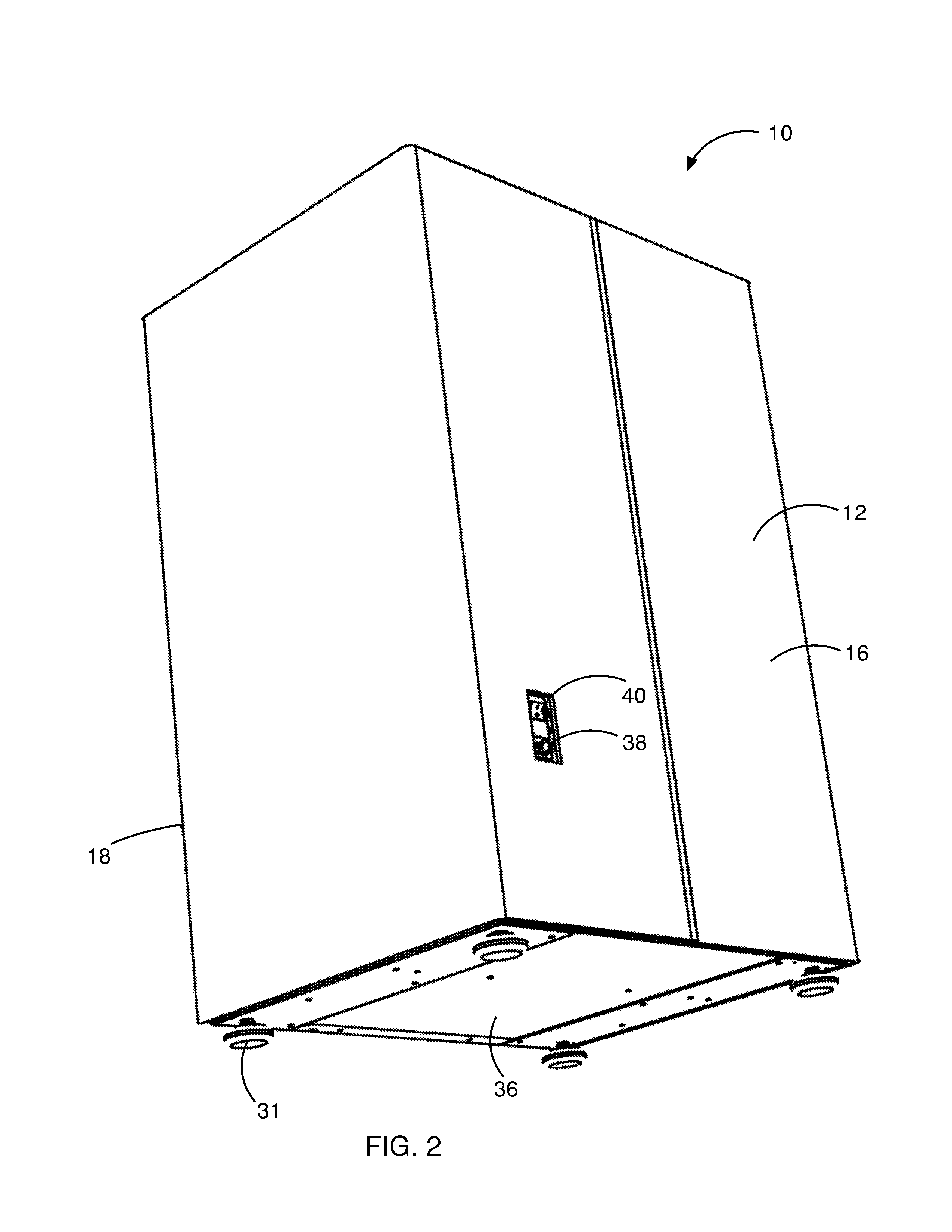

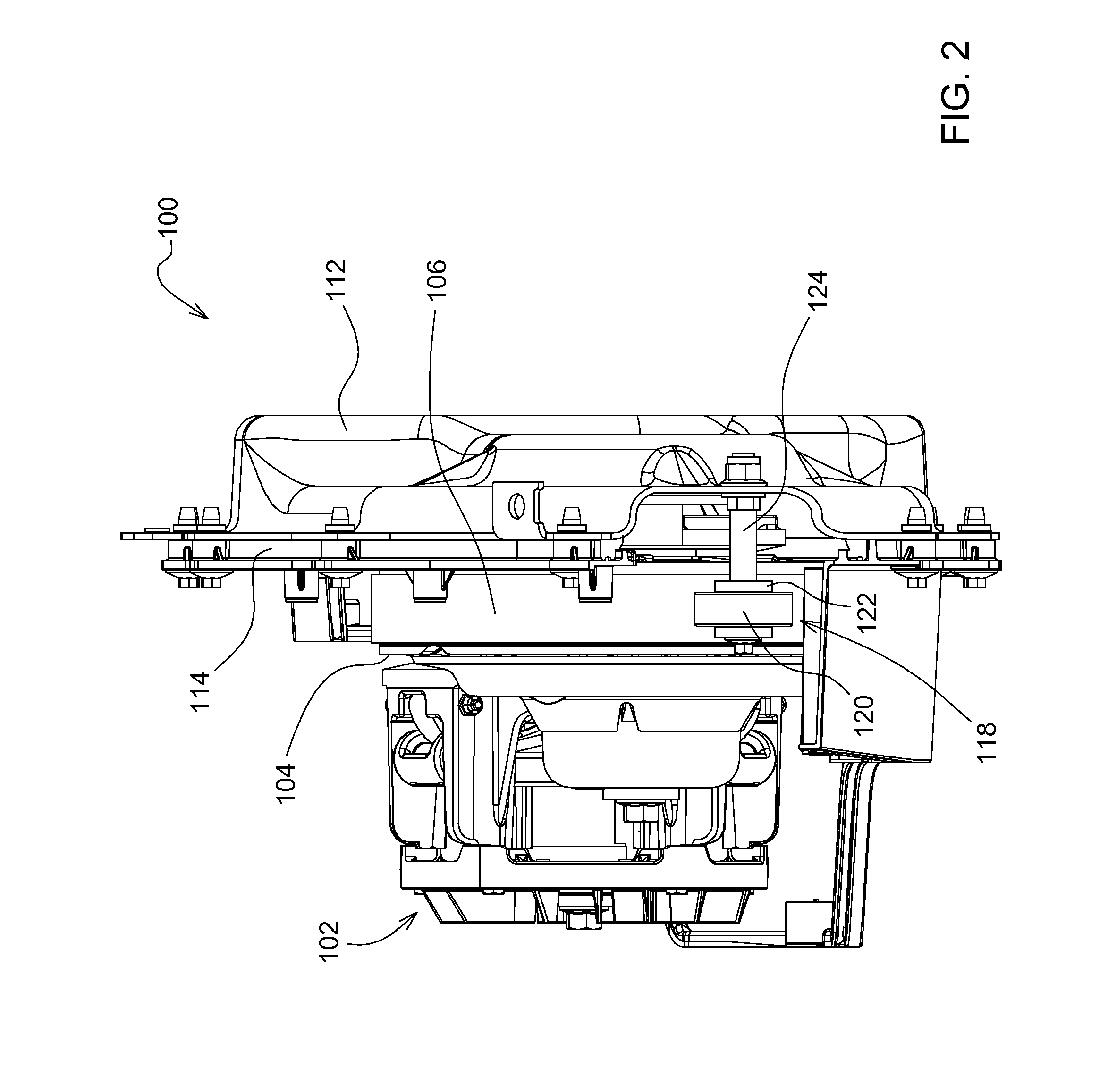

Apparatus for filtering air

InactiveUS20140238243A1Reduces flow restrictionShorten speedCombination devicesMechanical apparatusAir filterEngineering

An air filtering apparatus includes a housing defining a top opening and having a front portion defining a bottom opening. A filter is positioned within the top opening and sealed to the housing so that air flowing into the housing passes through the filter. An expansion chamber is in fluid communication with the bottom opening. A motorized fan is located within the housing and is configured for drawing air through the filter, into the housing and out through the expansion chamber. The air output of the motorized fan is directed toward a bottom of the housing proximate a rear of the housing with the expansion chamber extending from the air output of the motorized fan to the front portion of the housing.

Owner:JARDINE KIP +1

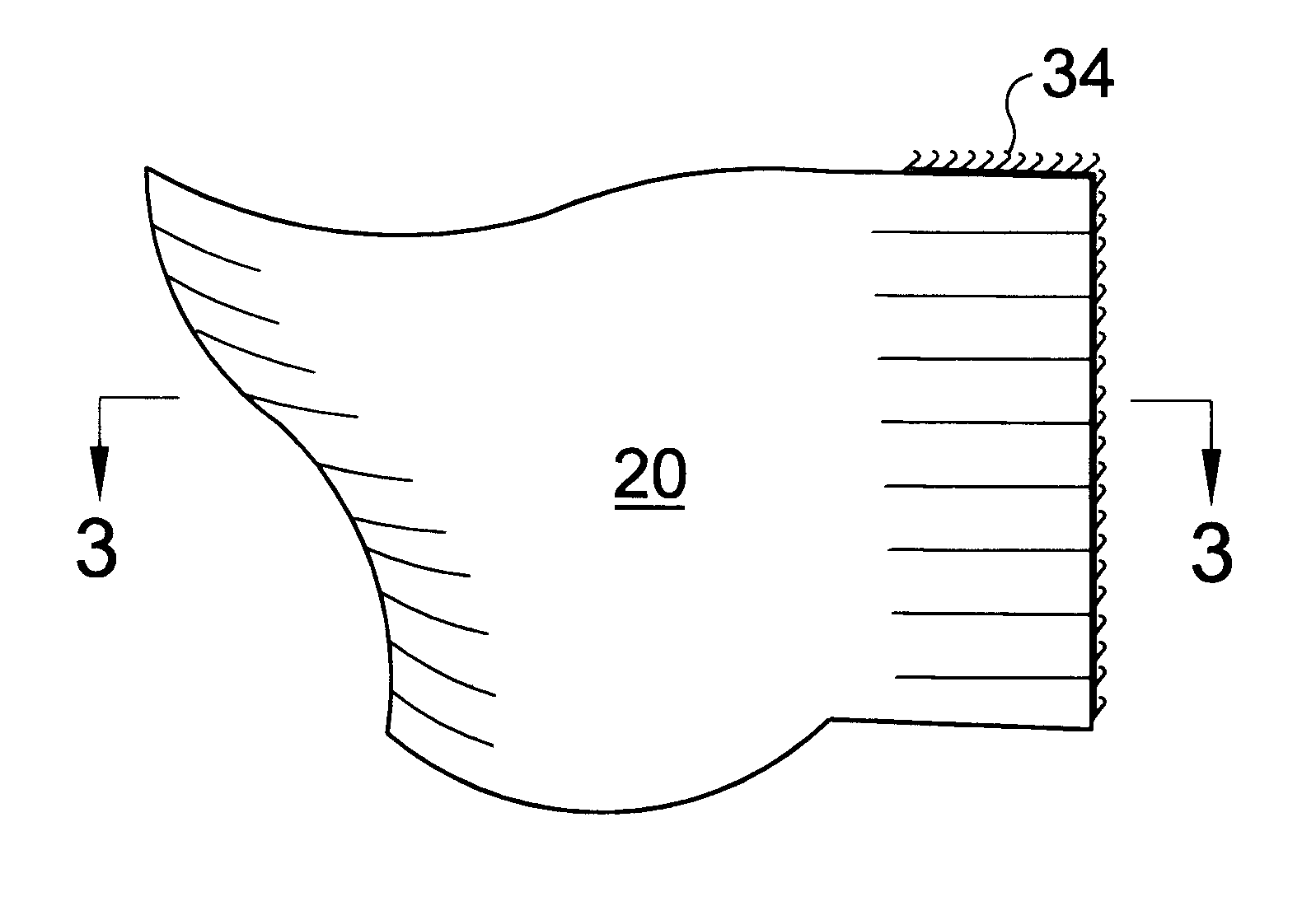

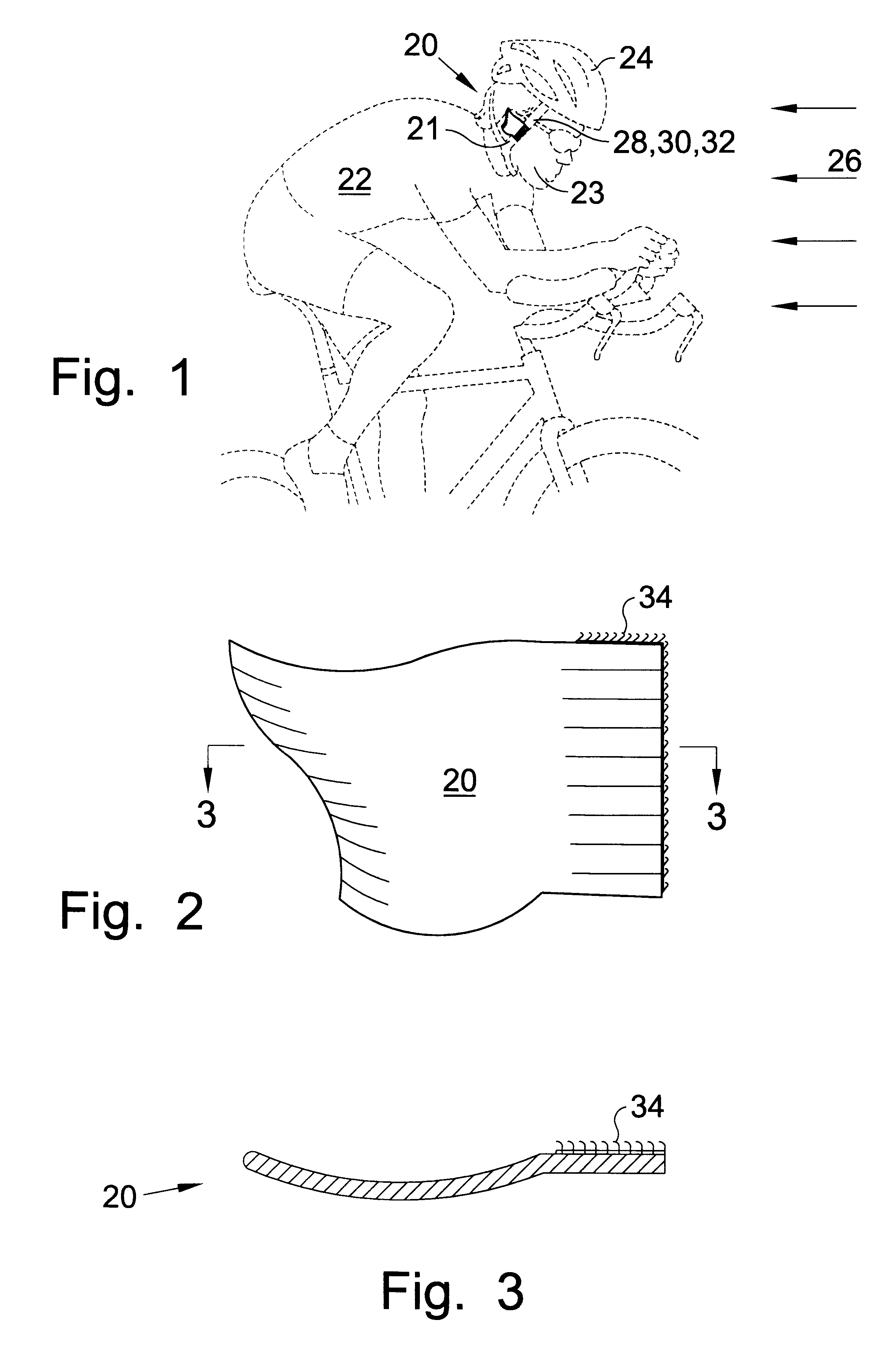

Ear wind shield

InactiveUS6325173B1Improve safety cycleThe process is simple and effectiveMouthpiece/microphone attachmentsHelmetsEngineeringSound masking

A method of alleviating the sound masking effects of wind noise on a cyclist wearing a safety helmet comprising the following steps: designing an ear cover shield having a generally smooth exterior side; positioning the cover shield adjacent to but generally spaced from an ear of the cyclist so that wind is generally deflected from the ear so that the noise of air rushing over the ear is substantially reduced, and the cyclist is better able to hear proximate sound especially that sound generated from directions which he cannot readily see; and, positioning and holding the cover shield adjacent to the ear most preferably by adjustably attaching it to a strap on the helmet. When wearing a cover shield, even in a strong wind, a cyclist is able to hear a vehicle approaching from the rear so that he can accordingly move close to the side of a roadway and ensure that his cycle moves in a straight, unswerving path.

Owner:MILLER WILLIAM B

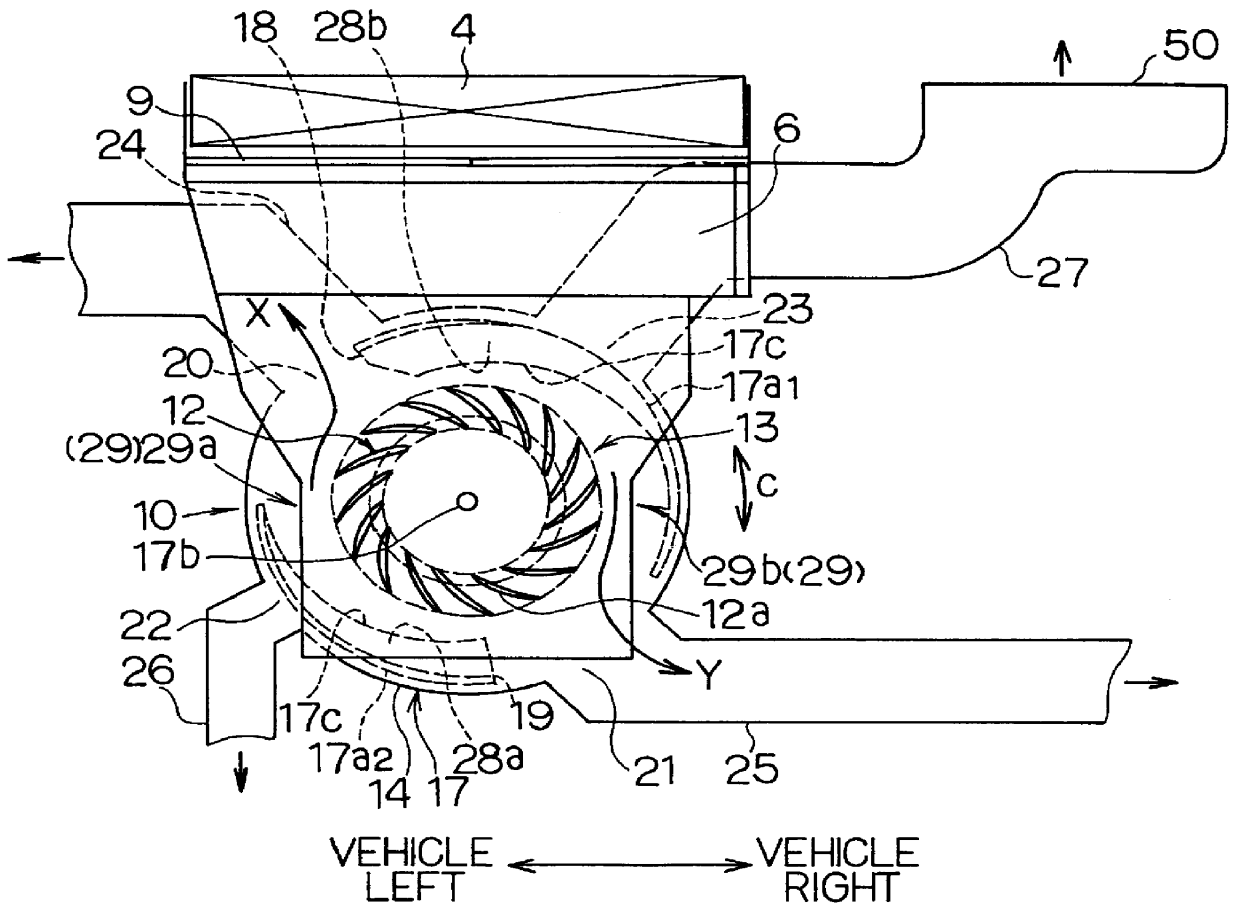

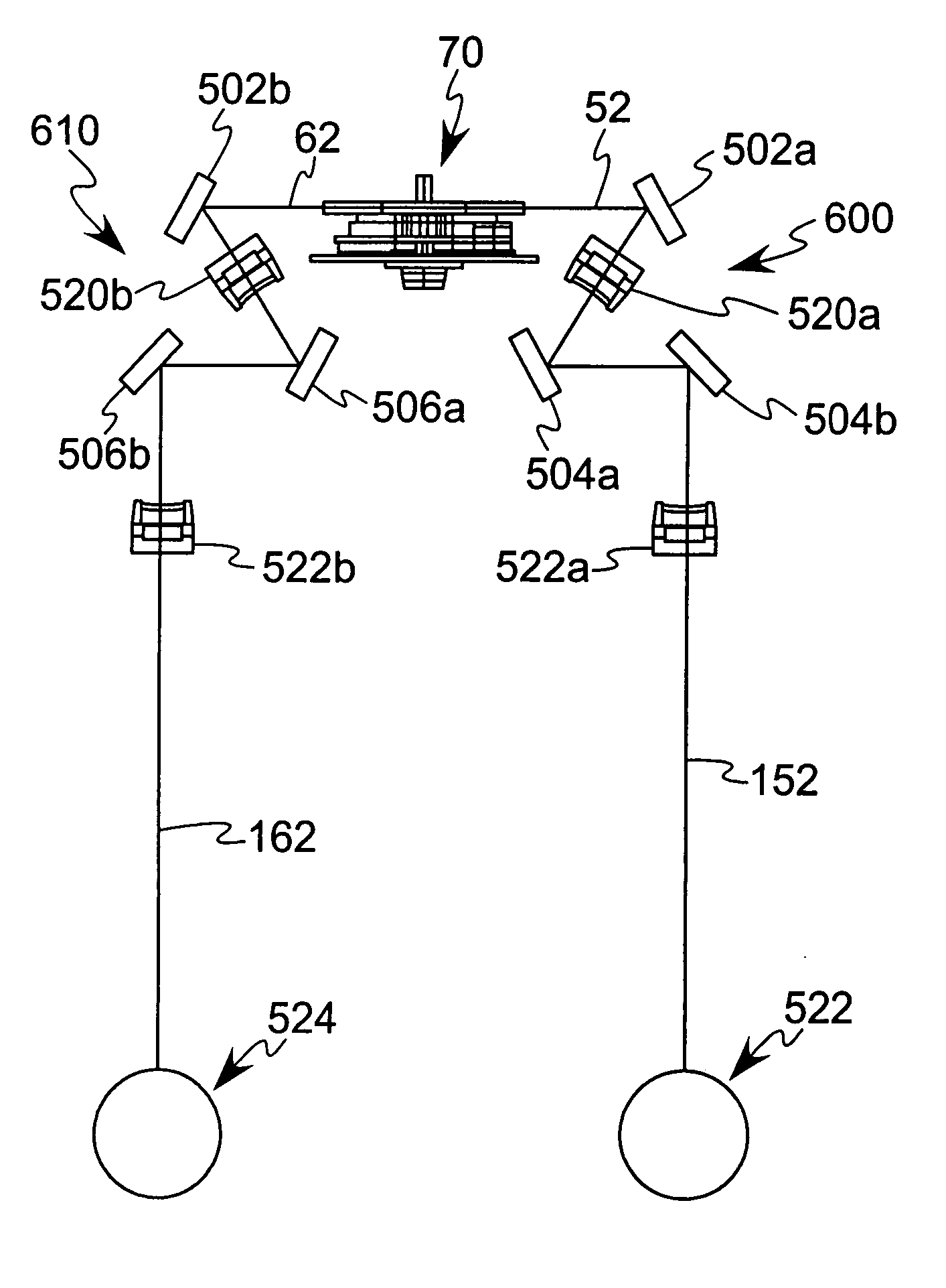

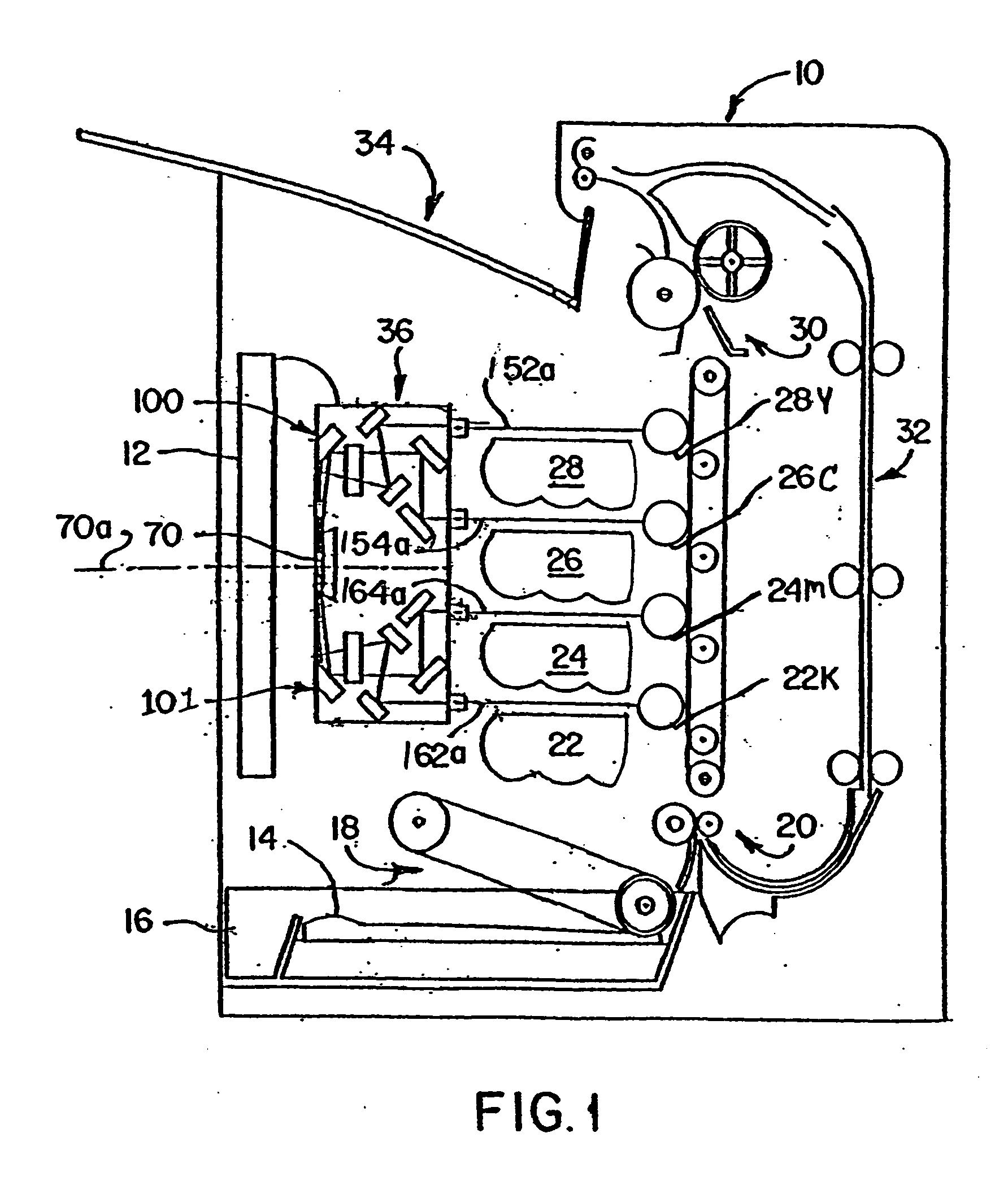

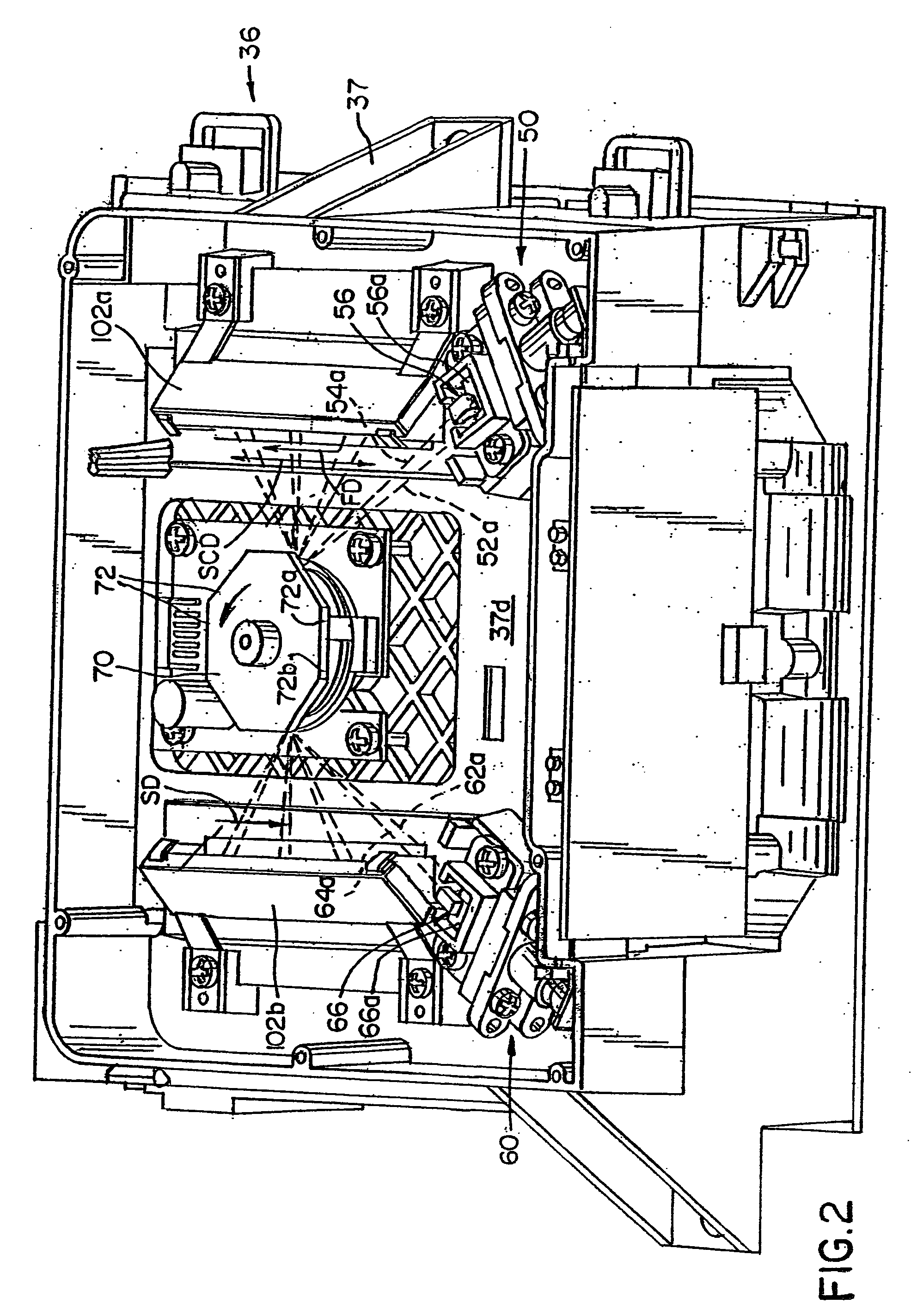

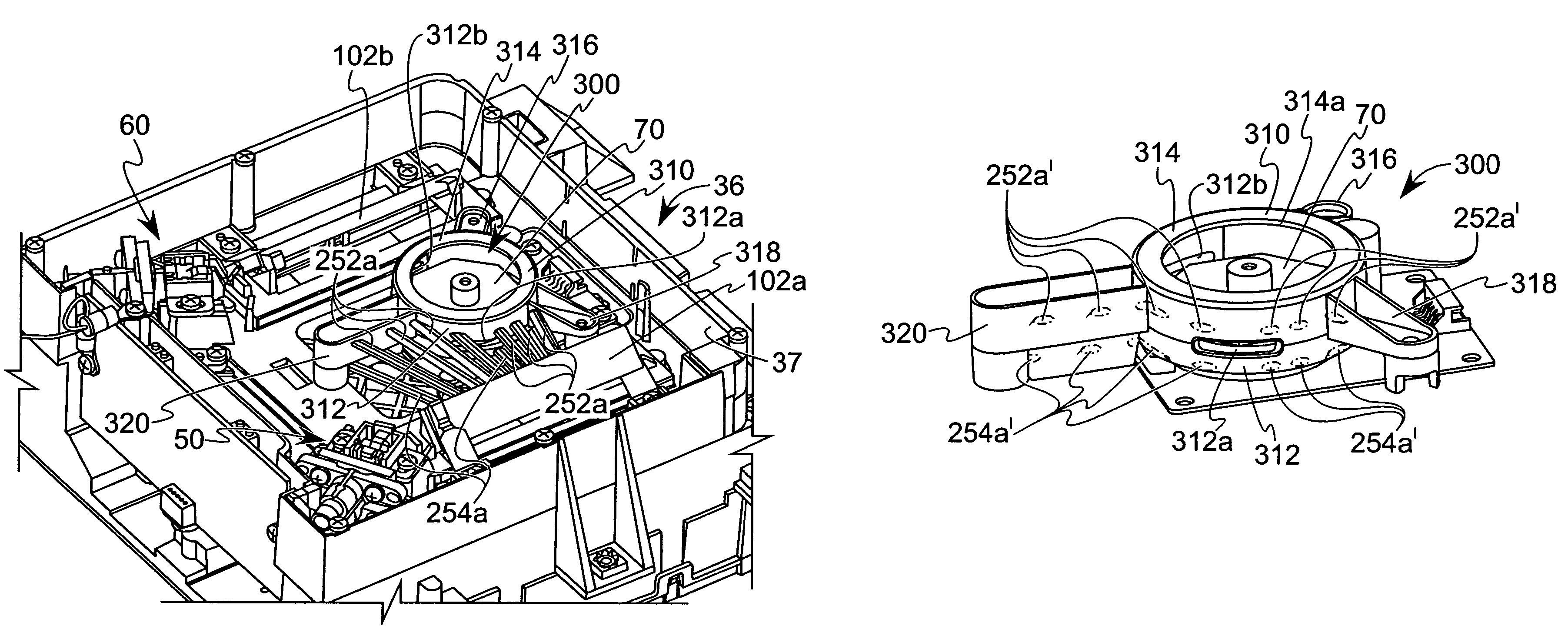

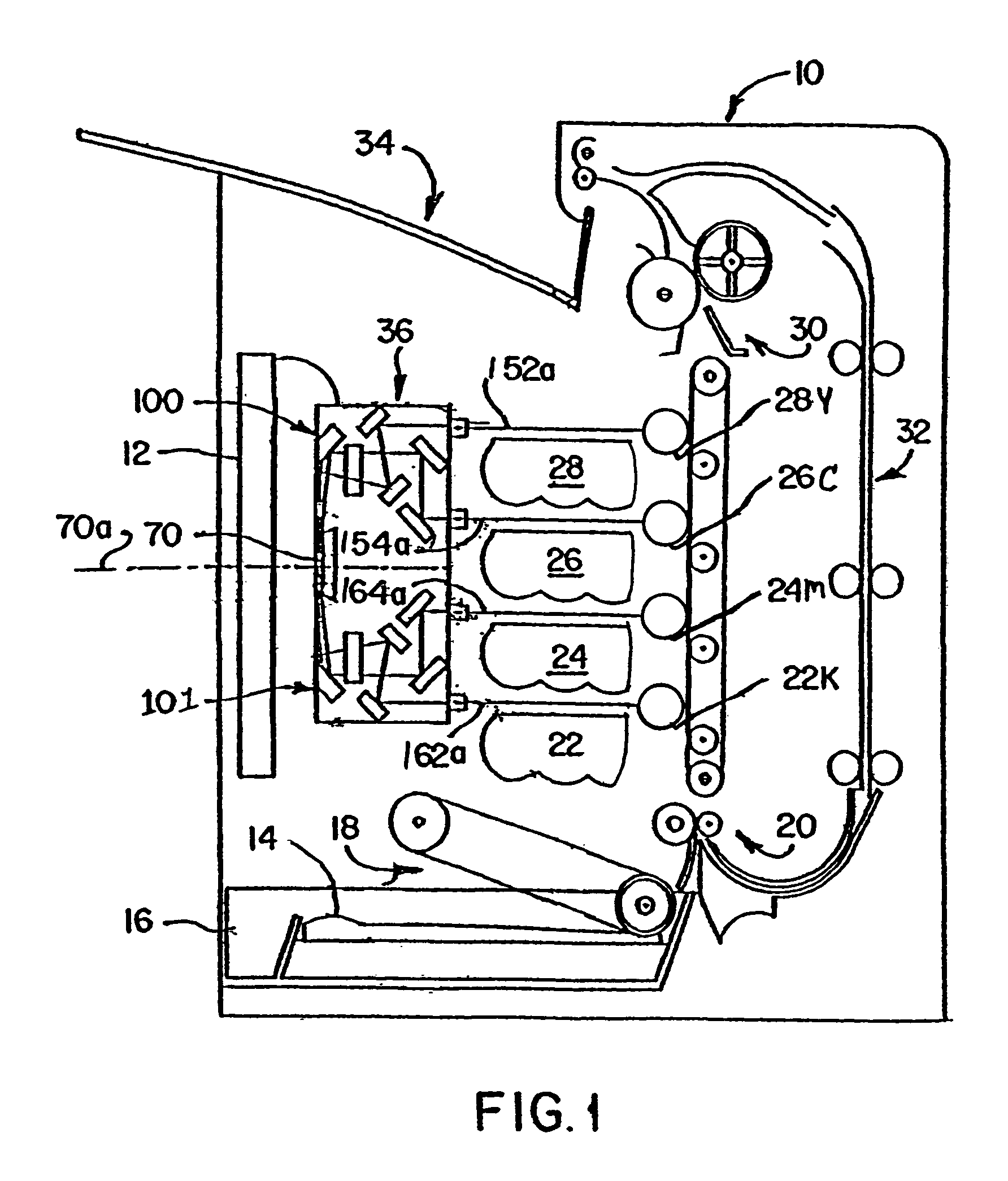

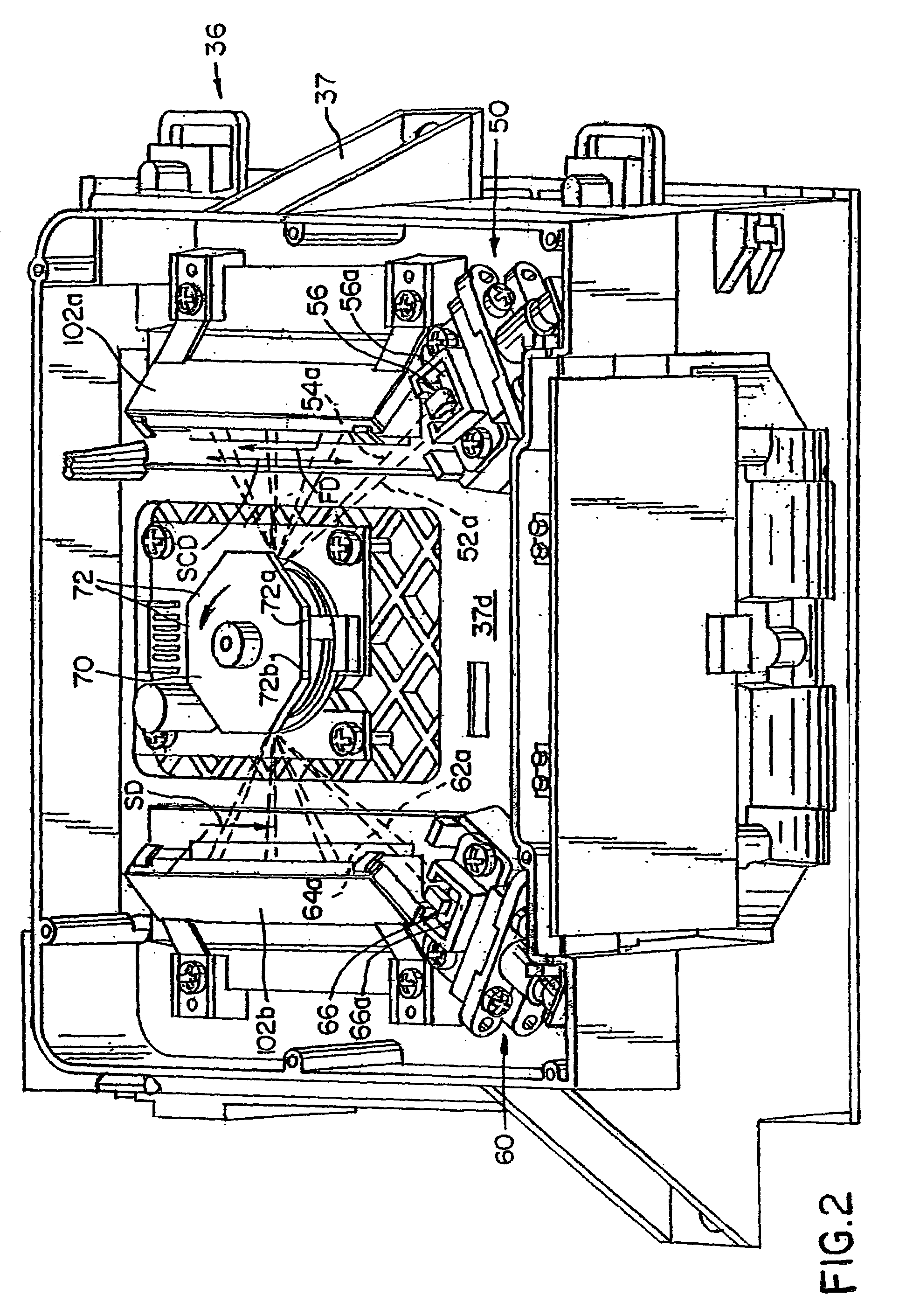

Laser scanning unit including a shield

ActiveUS20060198403A1Reducing and blocking ghosting lightAvoid ghostingOptical resonator shape and constructionPrintingLight beamLaser scanning

A laser scanning unit is provided comprising: a housing; a scanning device; a first pre-scan assembly generating a first light beam and directing the first light beam toward the scanning device; a second pre-scan assembly generating a second light beam and directing the second light beam toward the scanning device; a first post-scan assembly receiving the first light beam reflected from the scanning device and causing a first portion of the first light beam to scan along a first scan path; and a second post-scan assembly receiving the second light beam reflected from the scanning device and causing a first portion of the second light beam to scan along a second scan path. The first post-scan assembly further reflects a second portion of the first light beam in a direction away from the first scan path. A shield is associated with the housing for blocking the second portion of the first light beam reflected by the first post-scan assembly during at least a portion of the scan of the first portion of the first light beam along the first scan path so as to prevent the second portion of the first light beam from entering the second post-scan assembly.

Owner:LEXMARK INT INC

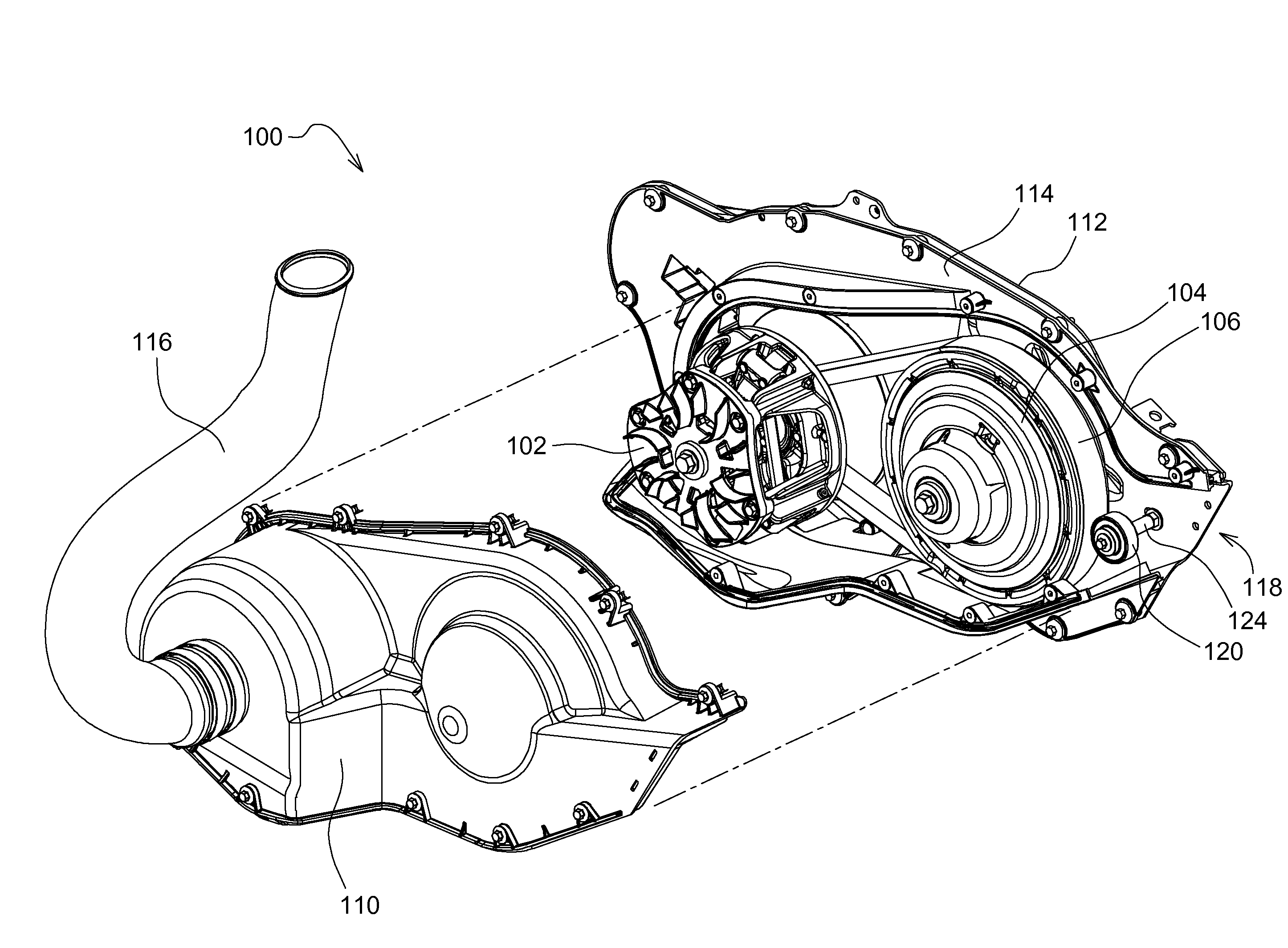

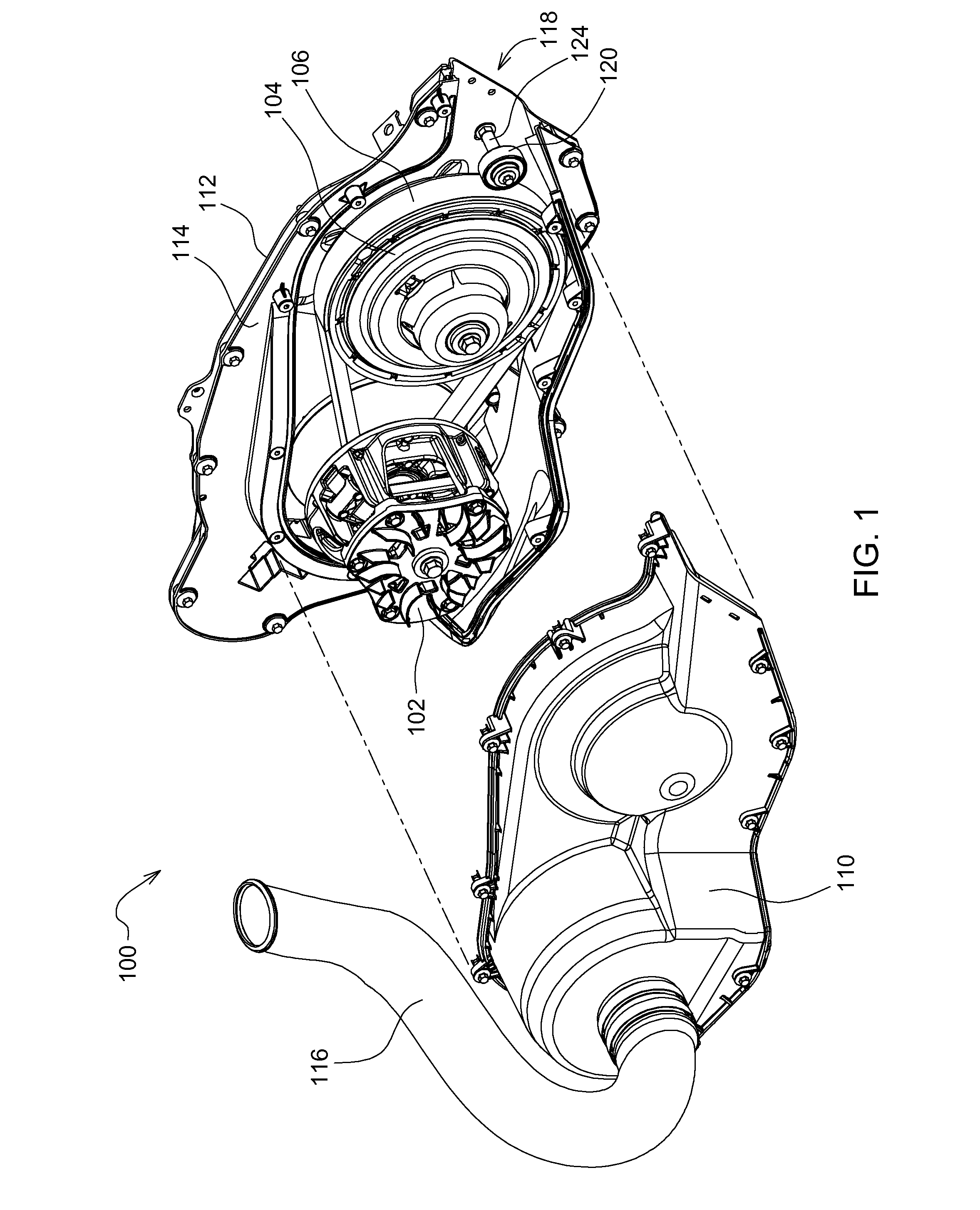

Continuously variable transmission cooling fan

ActiveUS20170045134A1Reduce air noiseImprove coolingPump componentsGear lubrication/coolingClutchVariator

A continuously variable transmission cooling fan includes a moveable sheave cover attached to a drive clutch assembly of a continuously variable transmission, with a plurality of fan blades molded into the moveable sheave cover and arranged around the perimeter of the moveable sheave cover. Each fan blade may have a different length, curvature and angle of position than the adjacent fan blades. The continuously variable transmission cooling fan also may include a plurality of openings in the moveable sheave cover located radially inwardly from the fan blades.

Owner:DEERE & CO

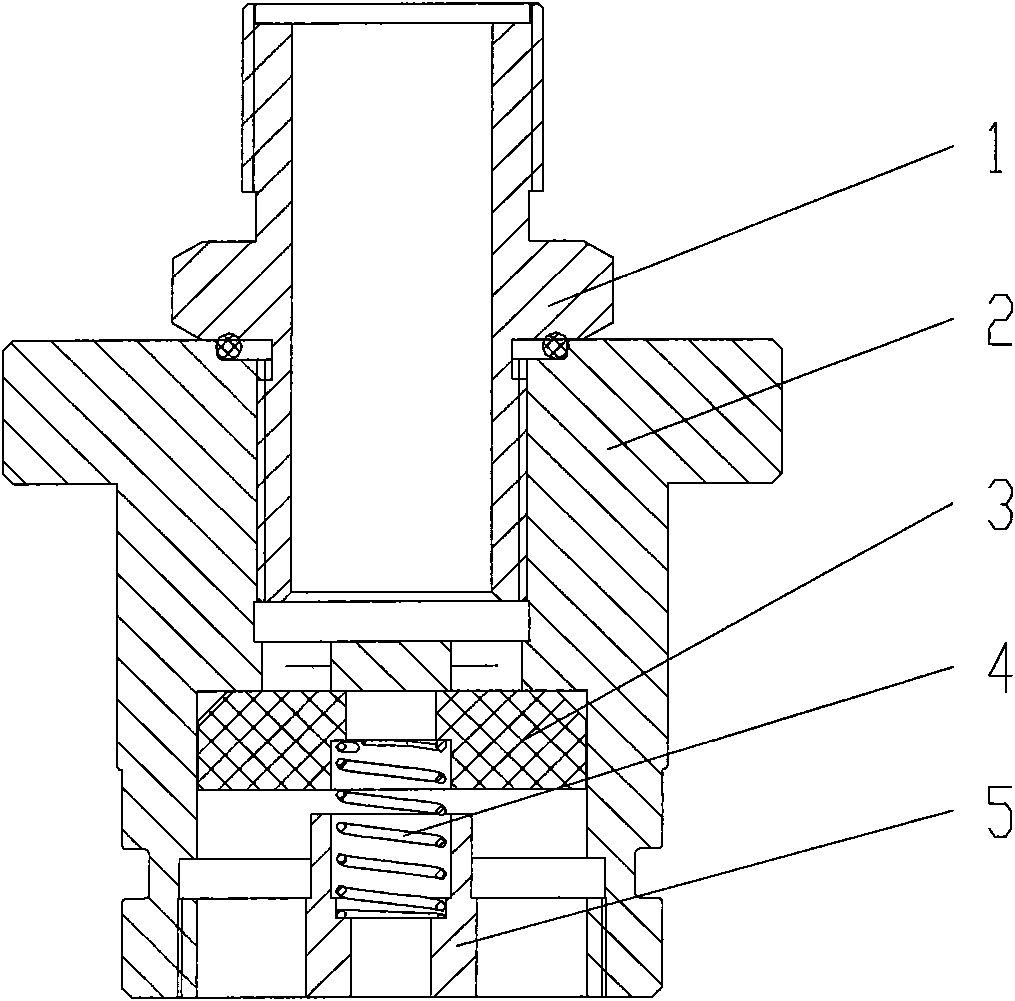

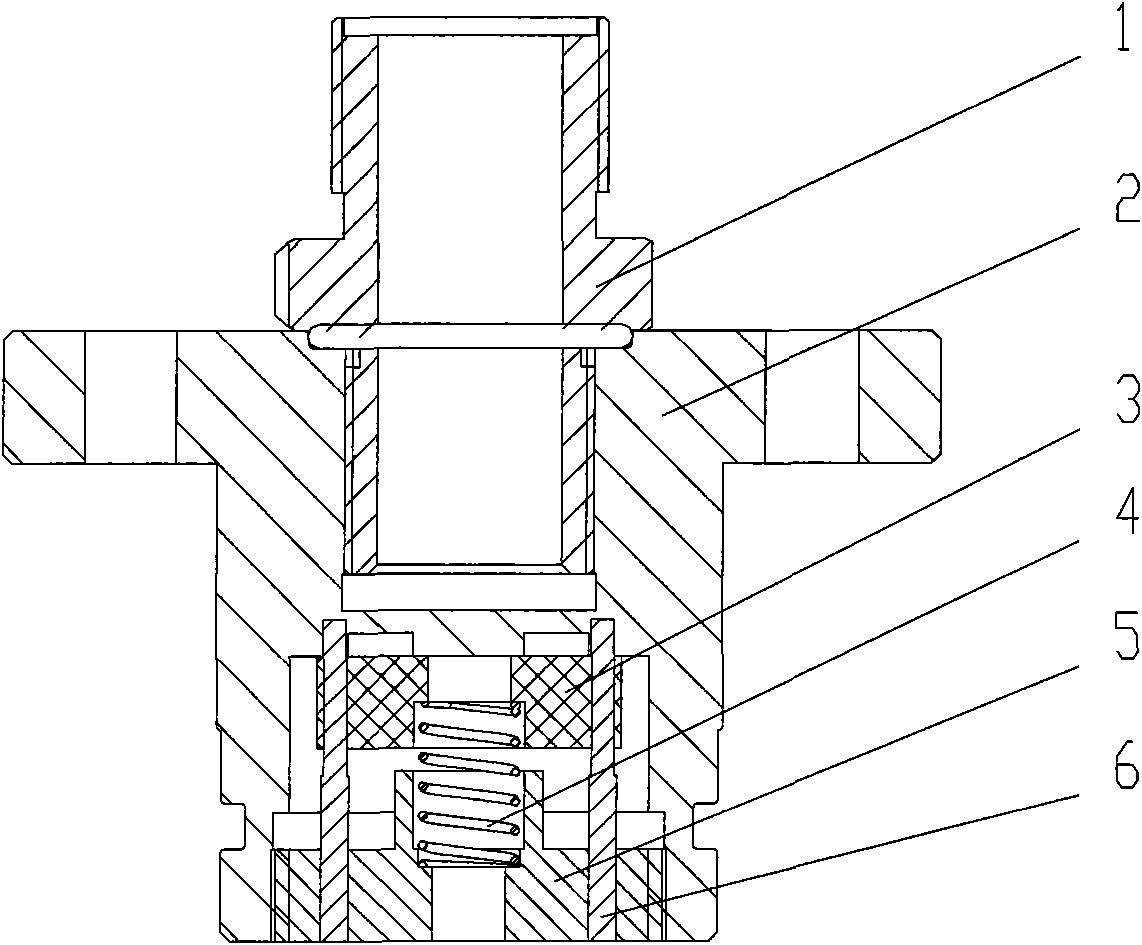

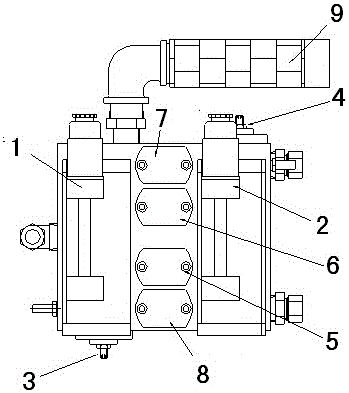

Air inlet and exhaust valve of compressor

ActiveCN101592145AReduce weightAvoid breakingPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveReciprocating motion

The invention discloses an air inlet and exhaust valve of a compressor, which comprises a valve body, an air valve plate, a spring, a spring seat and an air inlet and exhaust connector, wherein the valve body is arranged on the valve seat; the spring applies a pretightening force during installation to press the air valve plate onto the valve seat tightly; seal is formed between the air valve plate and the valve seat to separate the channels positioned above and below the air valve plate; the air valve plate is made of an impact-resistance nonmetal material and is provided with a guide structure preventing the sidewise inclination of the air valve plate during reciprocal motion of the air valve plate; the valve body is provided with a structure matched with the guide structure; and the center of the air valve plate is provided with a central hole for reducing the weight of the air valve plate and increasing circulation area at the same time. The air valve has the advantages of compact arrangement, simple structure, small resistance to air flow, low vibration noise, high reliability and the like and is particularly suitable for use in medium and small flow reciprocating piston type compressors.

Owner:SHANGHAI MICROPOWERS

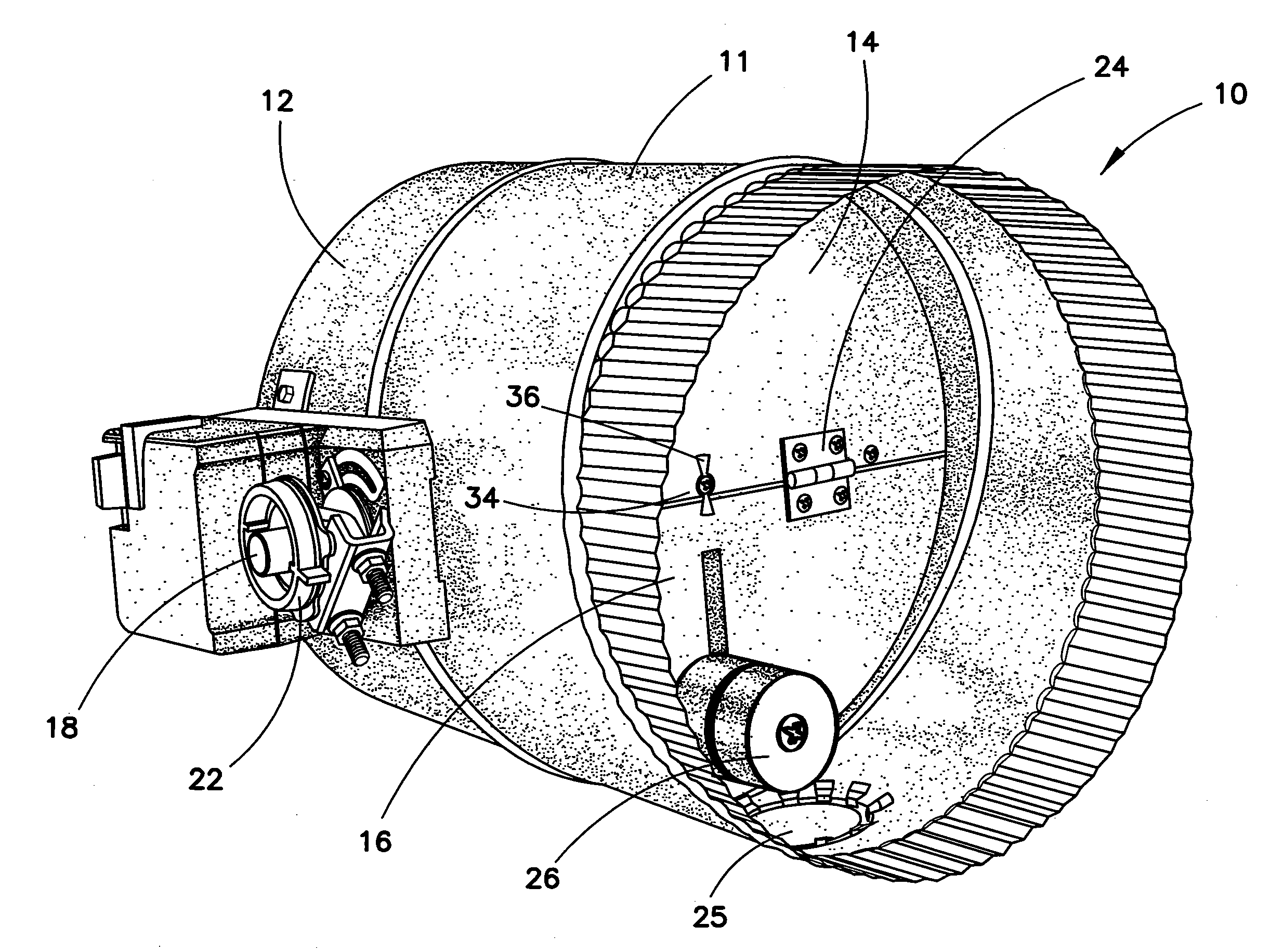

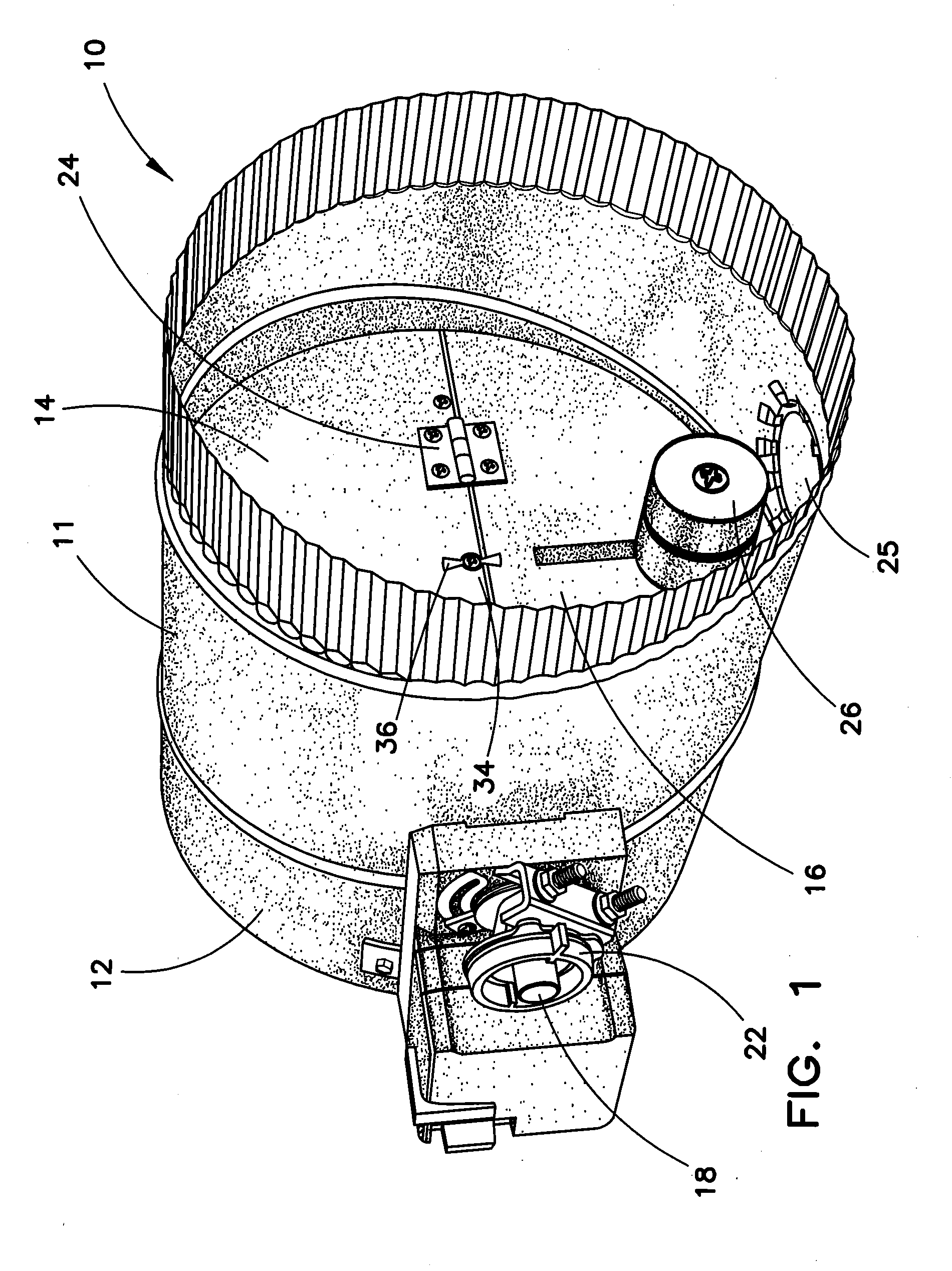

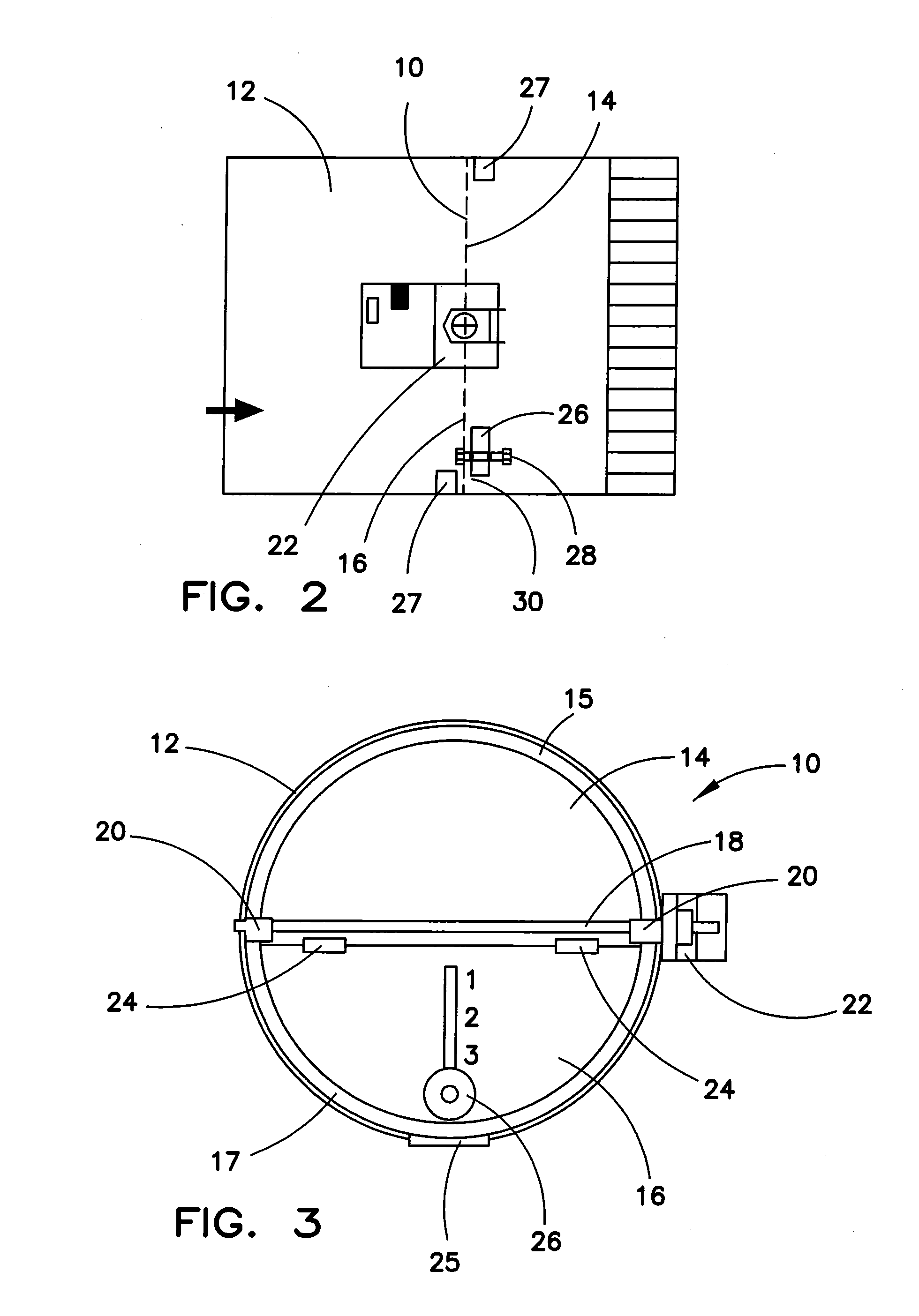

Barometric relief air zone damper

InactiveUS20130149955A1Small sizeReduce air noiseDucting arrangementsMechanical apparatusThermostatEngineering

A zone damper having a first portion responsive to the static pressure in a HVAC system to open and bleed an amount of conditioned air past the damper when the static pressure of the system increases above a selected level, a second portion controlled by a actuator to move between an open and a closed position in response to a zone thermostat, and a coupling mechanism coupling the first and second portions to limit the relative movements of the two portions with respect to each other, and a biasing mechanism exerting a torque against the system static pressure differential. The first portion can be a single one-piece undivided blade pivotally mounted with a shell surrounding the zone damper.

Owner:CONTROLLED HLDG

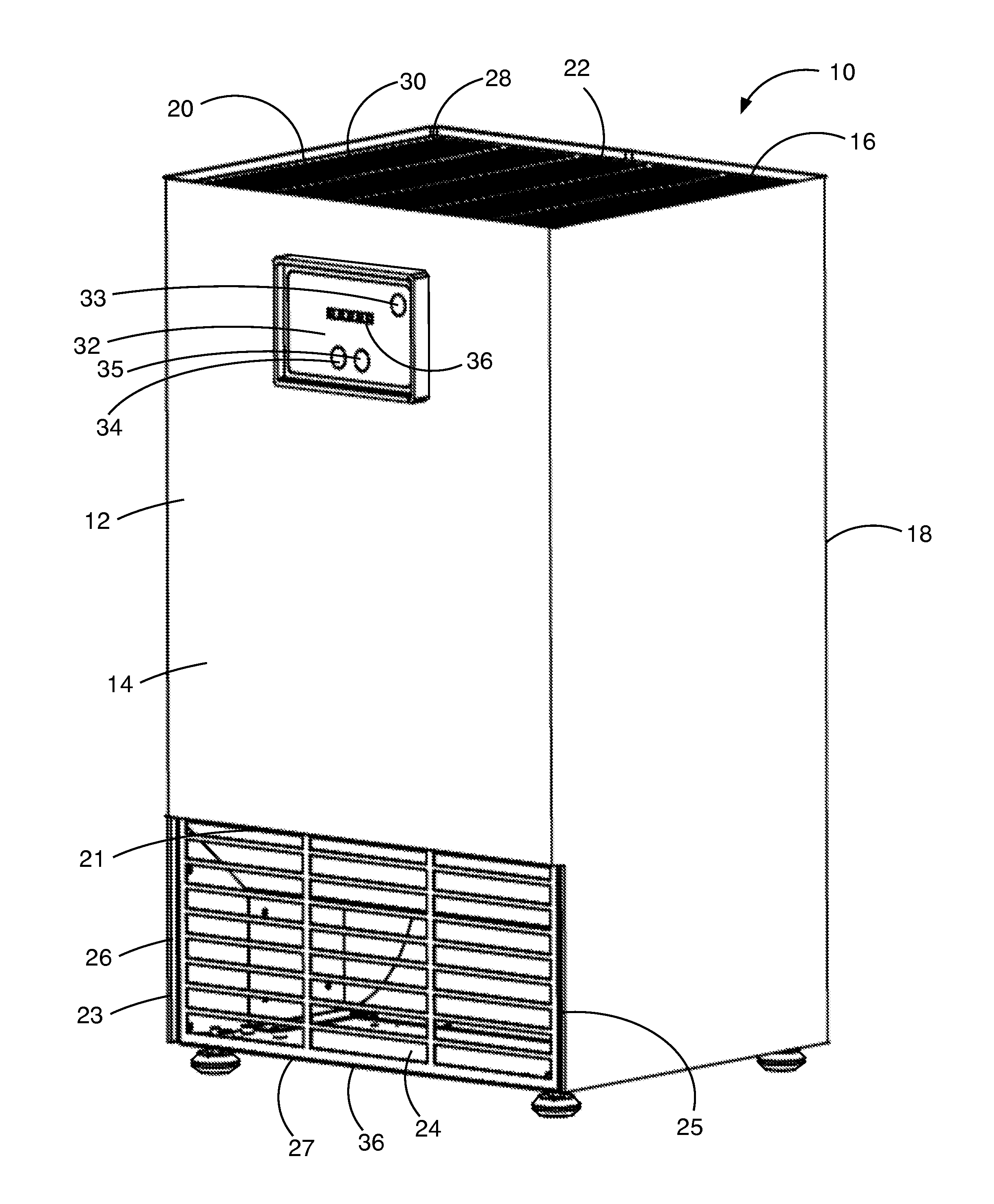

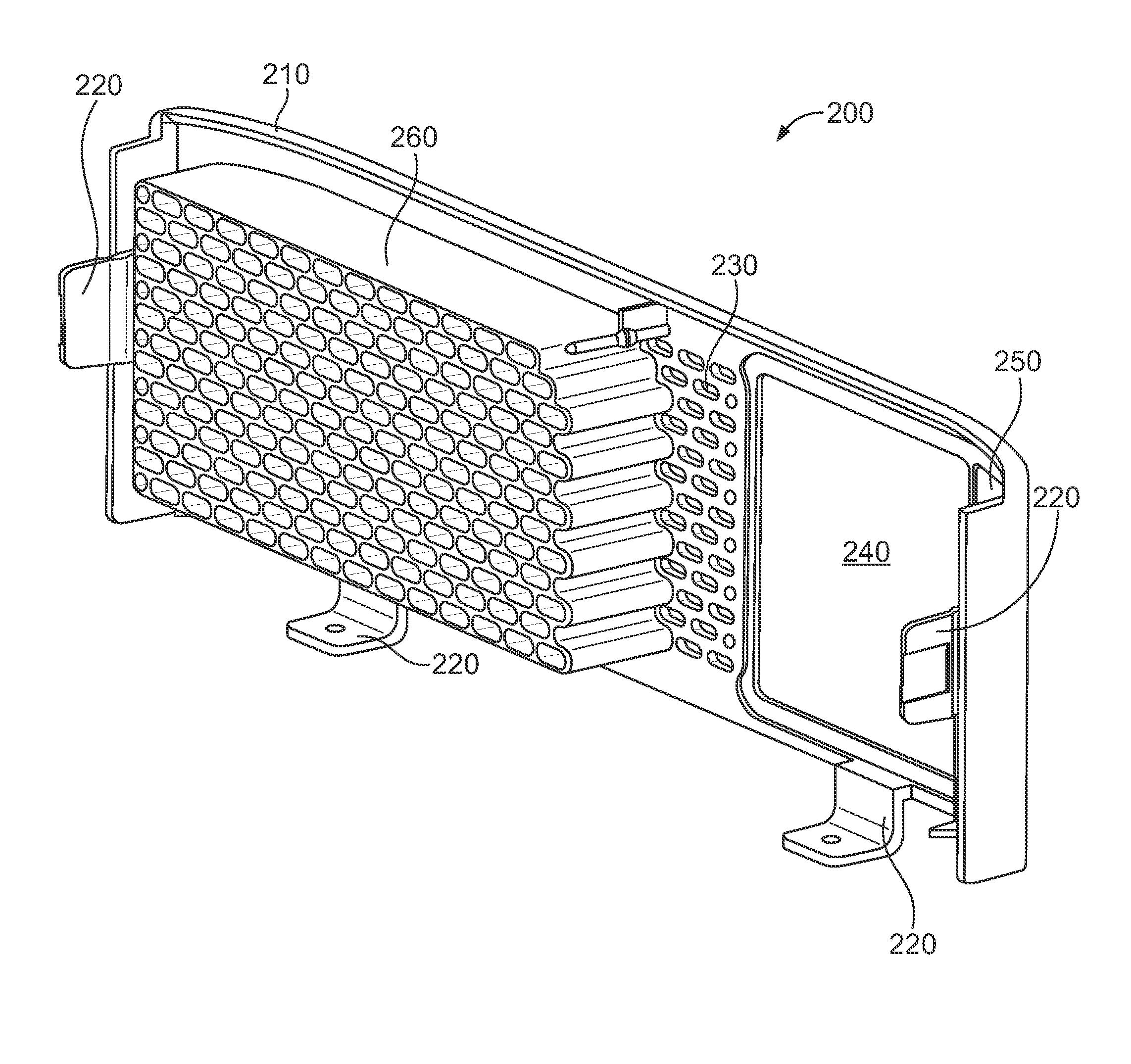

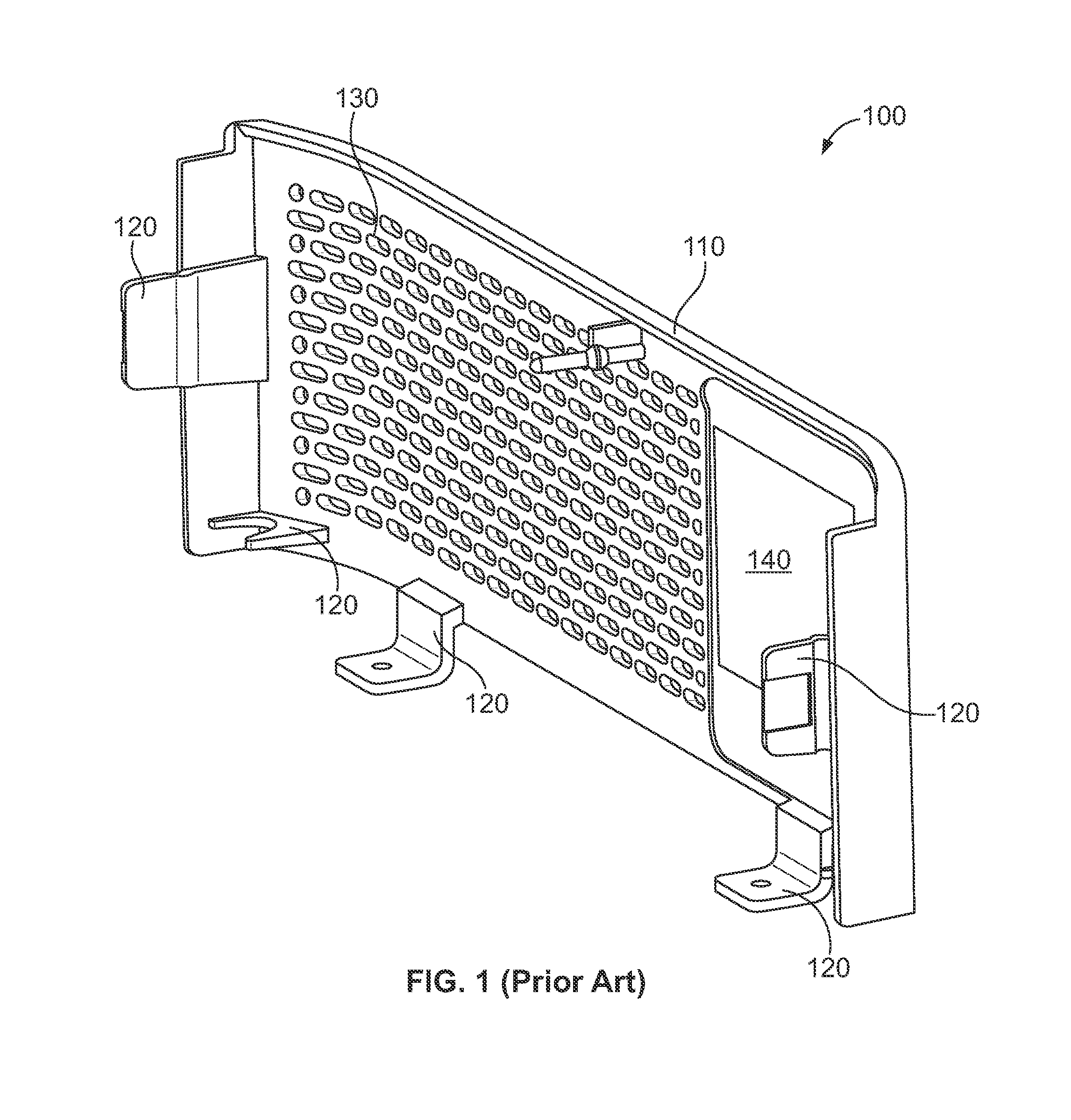

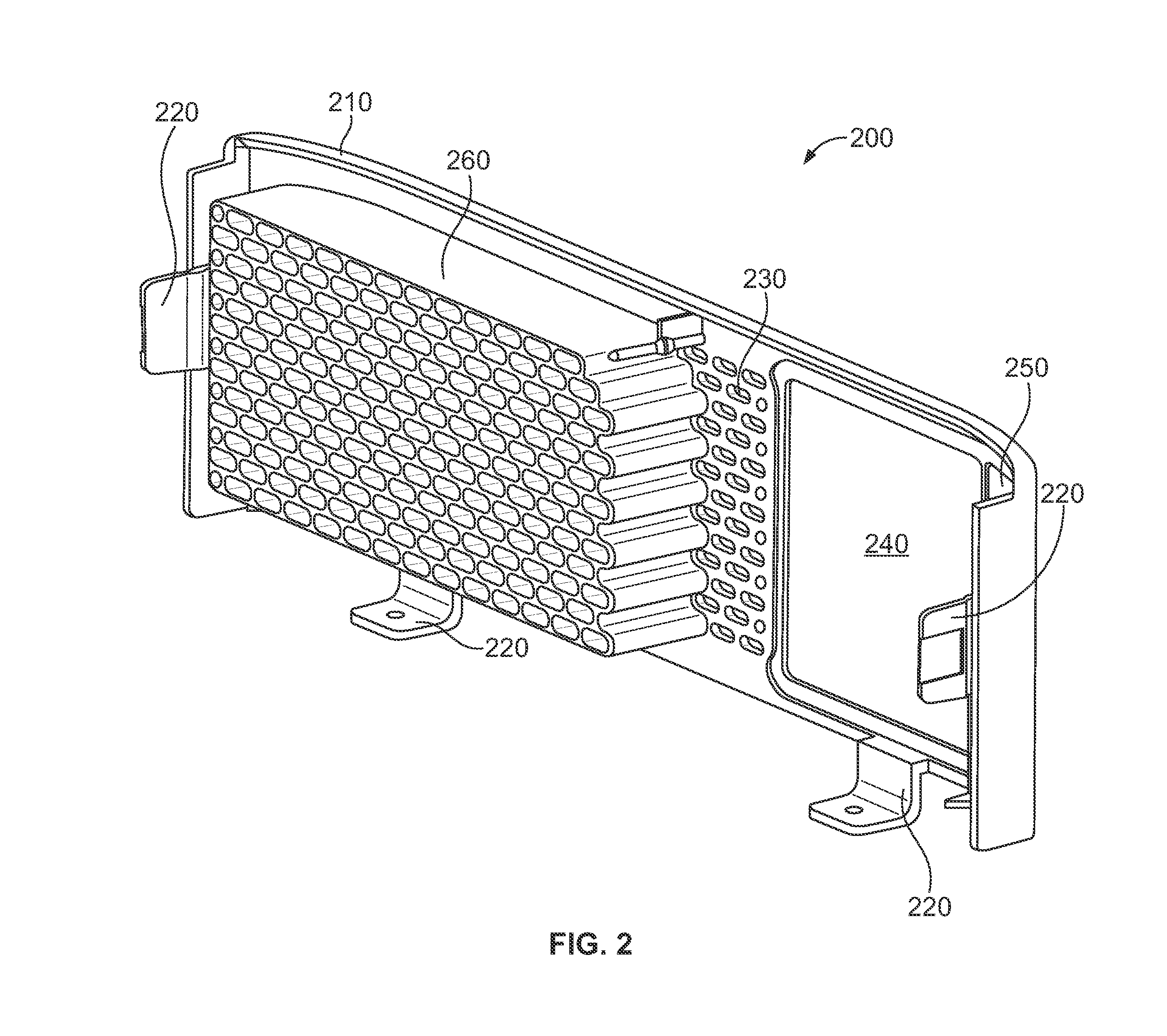

Noise-Reducing Air Inlet Grille for an Appliance

InactiveUS20140014436A1Reducing eliminating formationReduce dropNoise reduction installationsLighting and heating apparatusEngineeringAirplane

An air inlet grille for an appliance onboard an aircraft includes a screen having an inside-facing surface and an outside-facing surface, a plurality of airflow openings formed within the screen between the inside-facing surface and the outside-facing surface, and a plurality of tubes disposed on the inside-facing surface of the screen where openings on one end of the plurality of tubes are aligned with the plurality of airflow openings. A length of the plurality of tubes is at least twice a diameter of the plurality of airflow openings with which the plurality of tubes is aligned.

Owner:BE AEROSPACE INCORPORATED

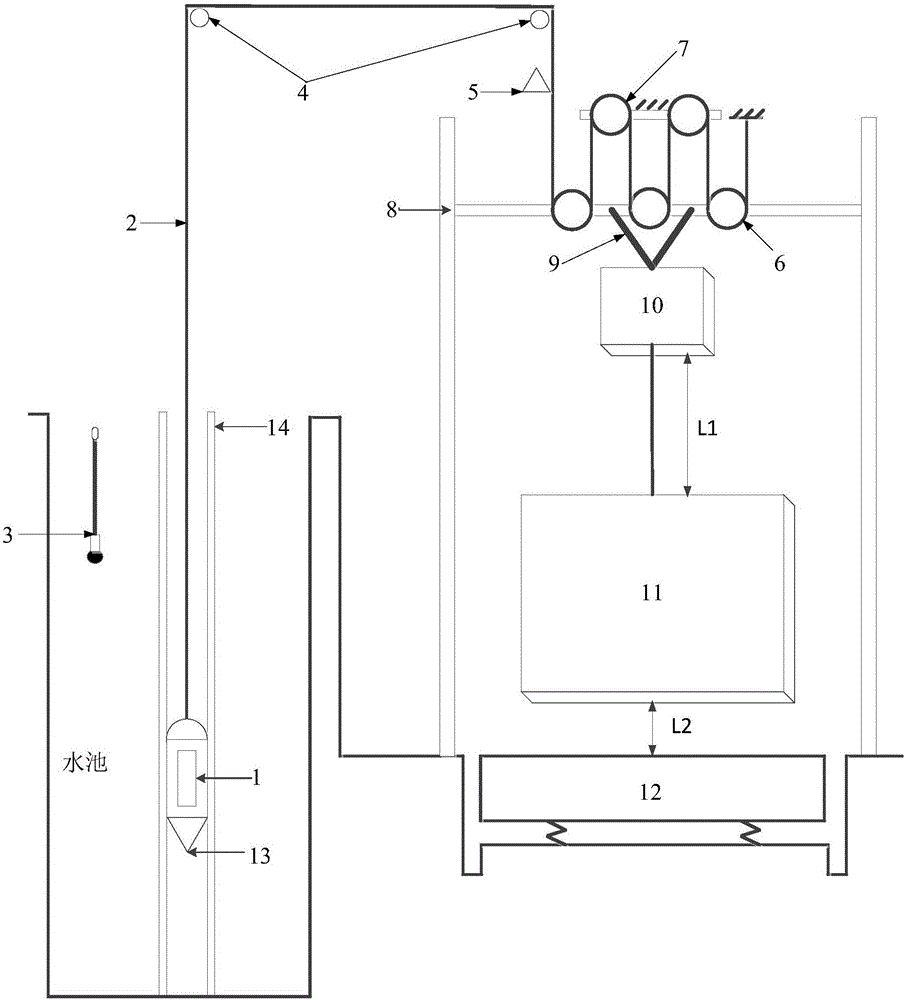

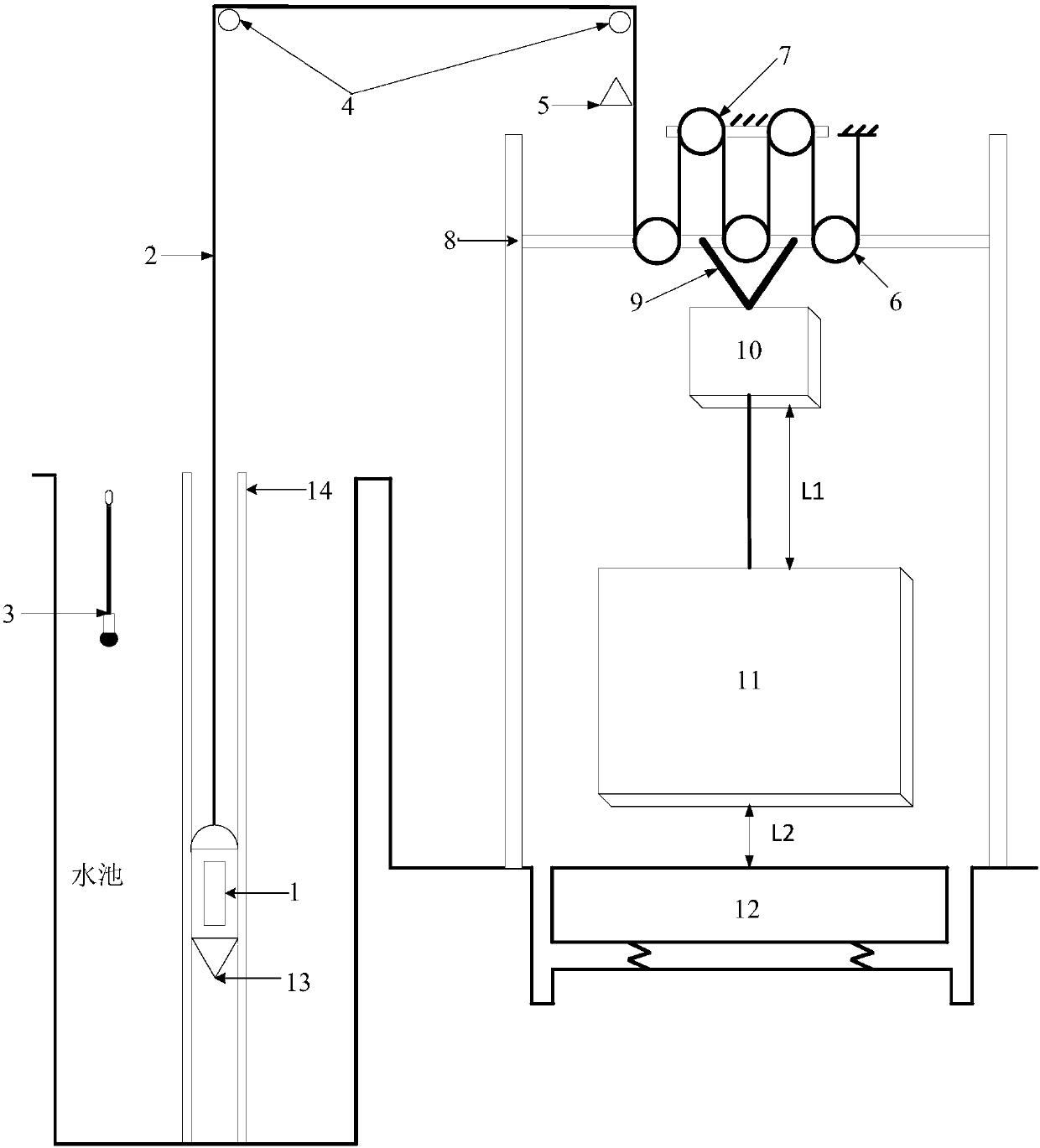

Low-noise high-speed floating acoustic test device in water tank

ActiveCN106184662ANoise reduction of mechanical equipmentAvoid randomnessHydrodynamic testingUnderwater equipmentEngineeringFlexible cable

The invention relates to a low-noise high-speed floating acoustic test device in a water tank, and belongs to the technical field of underwater aircraft hydrodynamic noise control. The test device comprises a test model, a flexible cable, an underwater acoustic measuring device, two fixed pulleys, an induction type speedometer, a movable pulley unit, a fixed pulley unit, a guide mechanism I, a connector, a weight I, a weight II and a shock absorbing mechanism. When the weight II descends to the shock absorbing mechanism by the aid of the gravity of the weight II, the accelerated speed acquired by the test model under the action of the pulley units is far higher than that of the weight II, and the test model reaches floating speed needed by tests. However, the resistance of a test system is overcome by the gravity of the weight I, the test model keeps the needed speed and floats at constant speed until the weight I descends to contact with the weight II, the test model exactly floats out of a water surface, and near-field noise and free far-field noise characteristics of the test model are acquired by analyzing data recorded by the underwater acoustic measuring device and an internal data acquisition recorder of the test model.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Rotor processing method capable of reducing motor vibration and noise

InactiveCN103023232AReduce structure noiseReduce vibration intensityManufacturing stator/rotor bodiesCentering/balancing rotorsDynamic balanceMotor vibration

The invention provides a rotor processing method capable of reducing motor vibration and noise. The processing method is characterized by including step one, performing coarse grinding on a bearing retainer of a motor and an external circle of an iron core; step two, performing a first dynamic balance correction; step three, performing a second fine grinding on the rotor; and step four, performing a second dynamic balance correction. Grinding and dynamic balance correction are performed twice for the rotor processing, compared with grinding and dynamic balance correction which are performed once, the motor vibration severity is improved by at least one standard grade, structural noise is reduced by 3-5dB, different motors have different specific circumstances, air noise is reduced due to reduction of the vibration severity and the structural noise, and therefore vibration and noise reduction effects are obvious.

Owner:SHANGHAI ELECTRICAL APP RES INST +1

Laser scanning unit including a shield

ActiveUS7271941B2Reduce air noiseOptical resonator shape and constructionPrintingLaser scanningLight beam

A laser scanning unit is provided comprising: a housing; a scanning device; a first pre-scan assembly generating a first light beam and directing the first light beam toward the scanning device; a second pre-scan assembly generating a second light beam and directing the second light beam toward the scanning device; a first post-scan assembly receiving the first light beam reflected from the scanning device and causing a first portion of the first light beam to scan along a first scan path; and a second post-scan assembly receiving the second light beam reflected from the scanning device and causing a first portion of the second light beam to scan along a second scan path. The first post-scan assembly further reflects a second portion of the first light beam in a direction away from the first scan path. A shield is associated with the housing for blocking the second portion of the first light beam reflected by the first post-scan assembly during at least a portion of the scan of the first portion of the first light beam along the first scan path so as to prevent the second portion of the first light beam from entering the second post-scan assembly.

Owner:LEXMARK INT INC

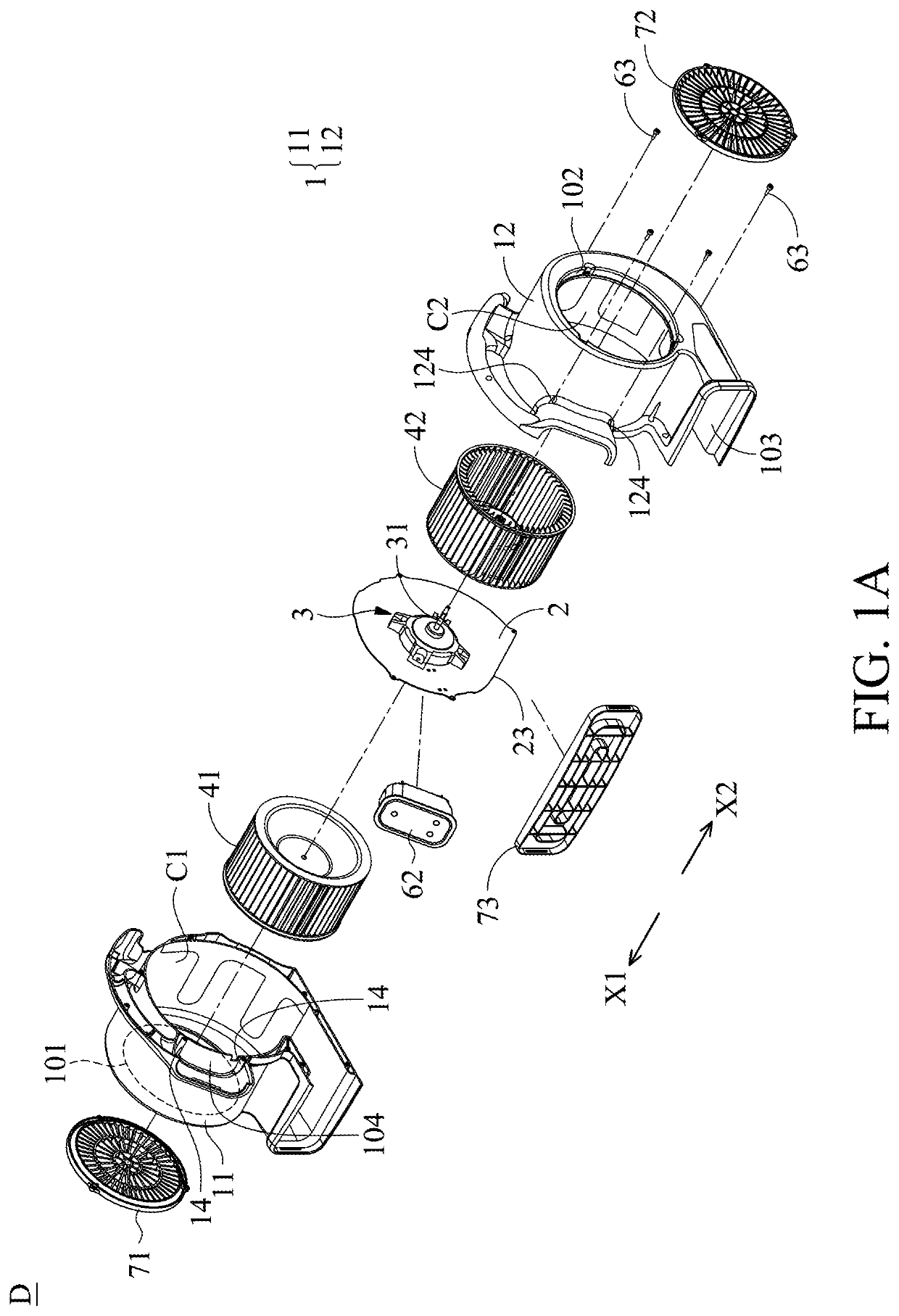

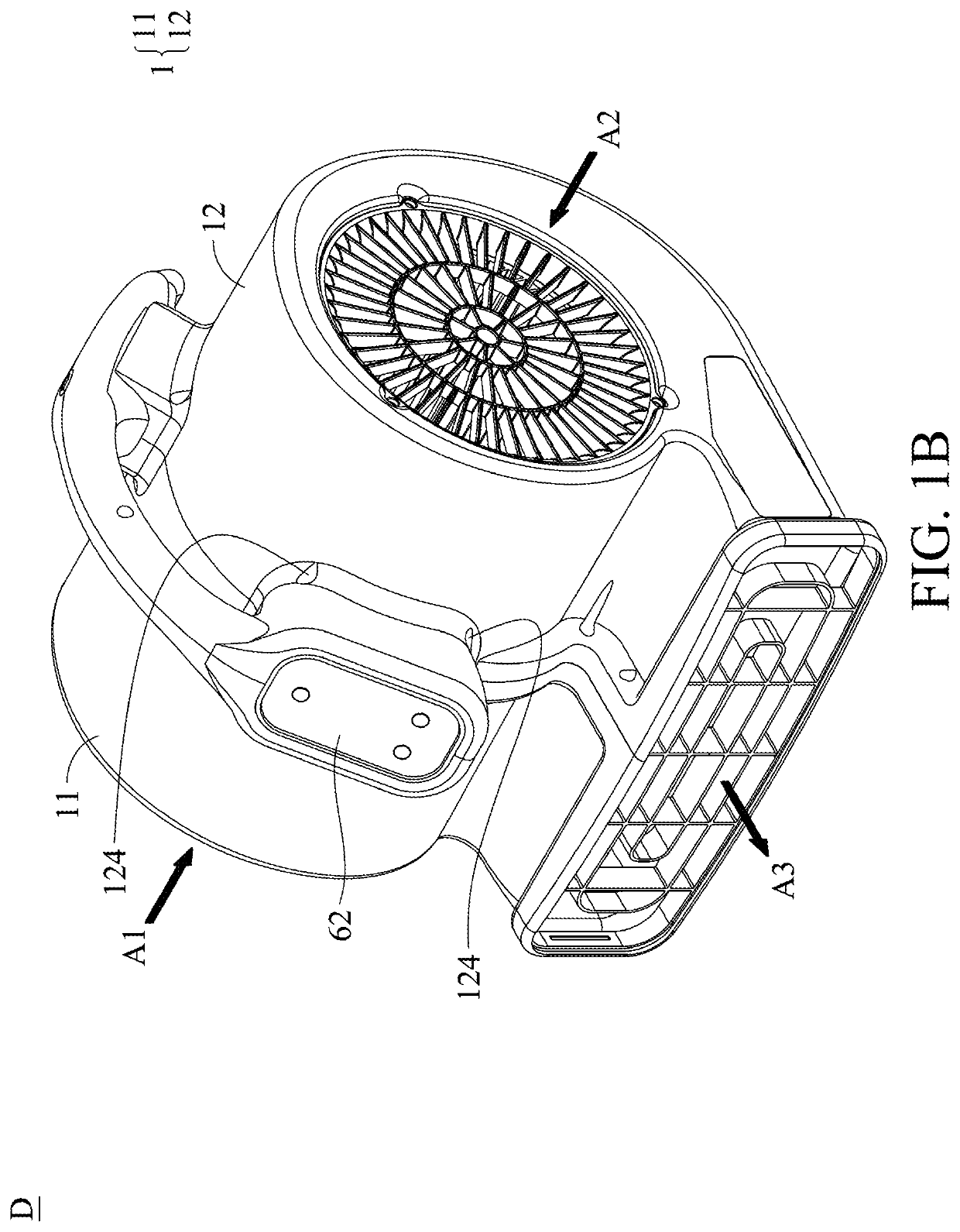

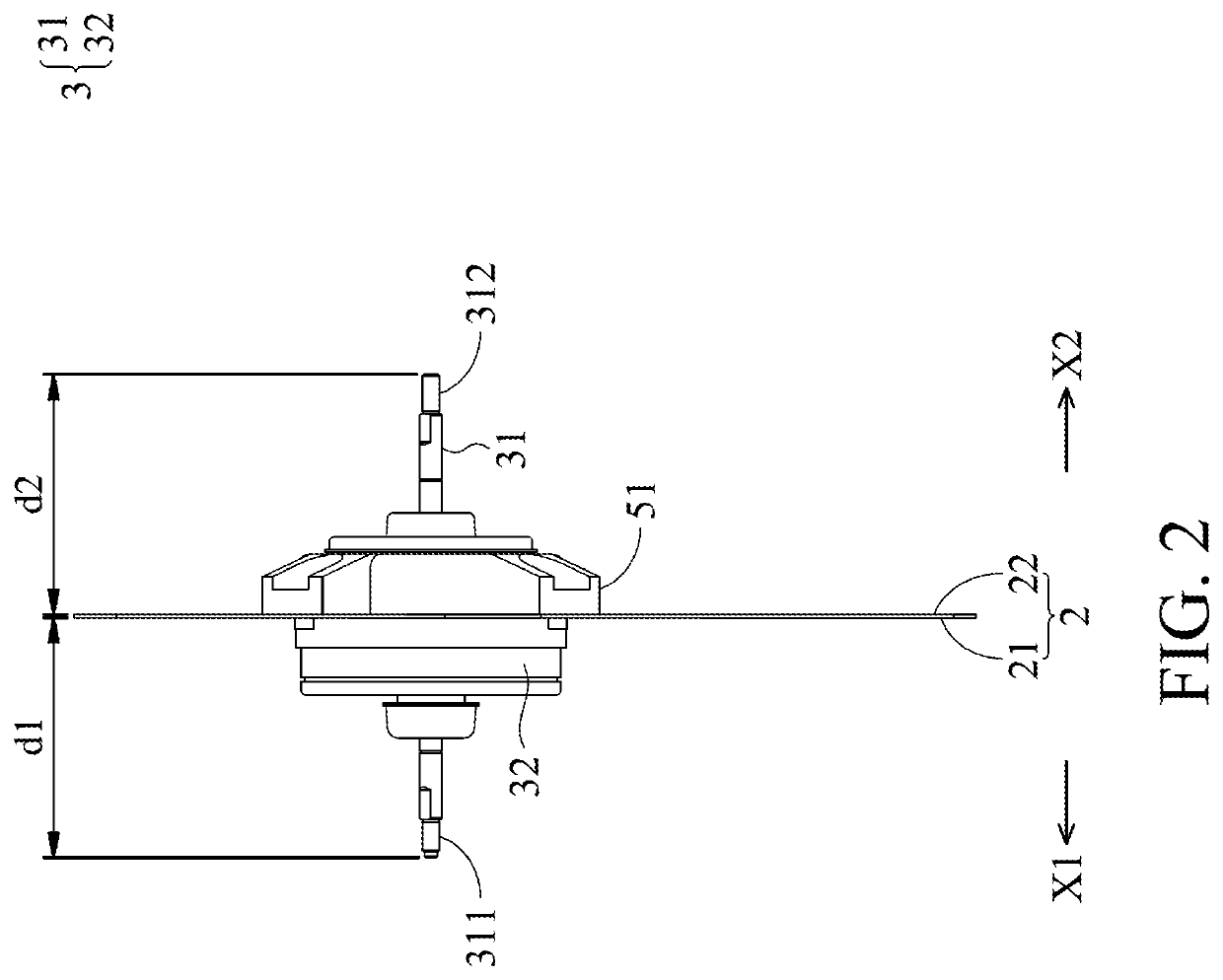

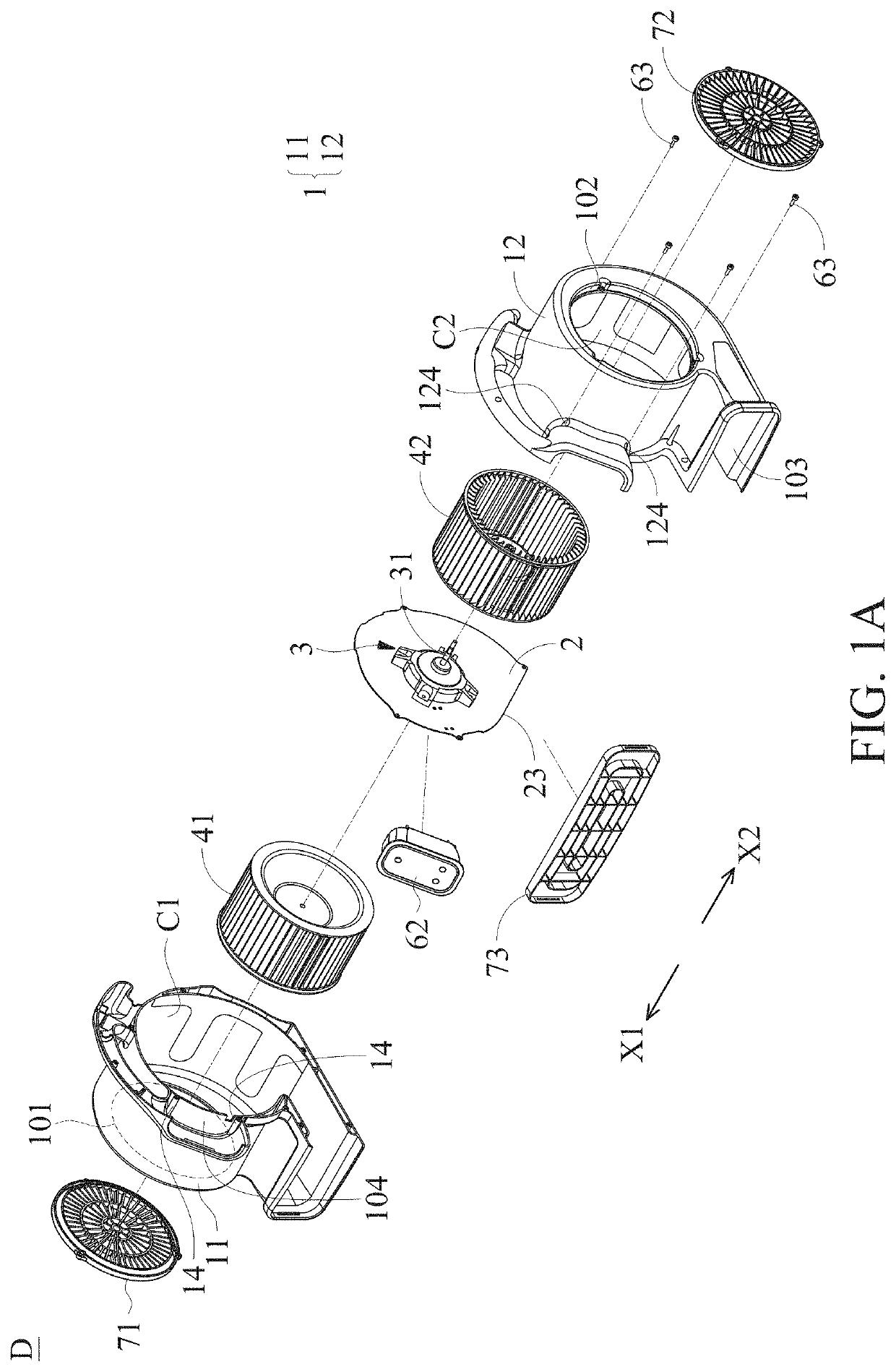

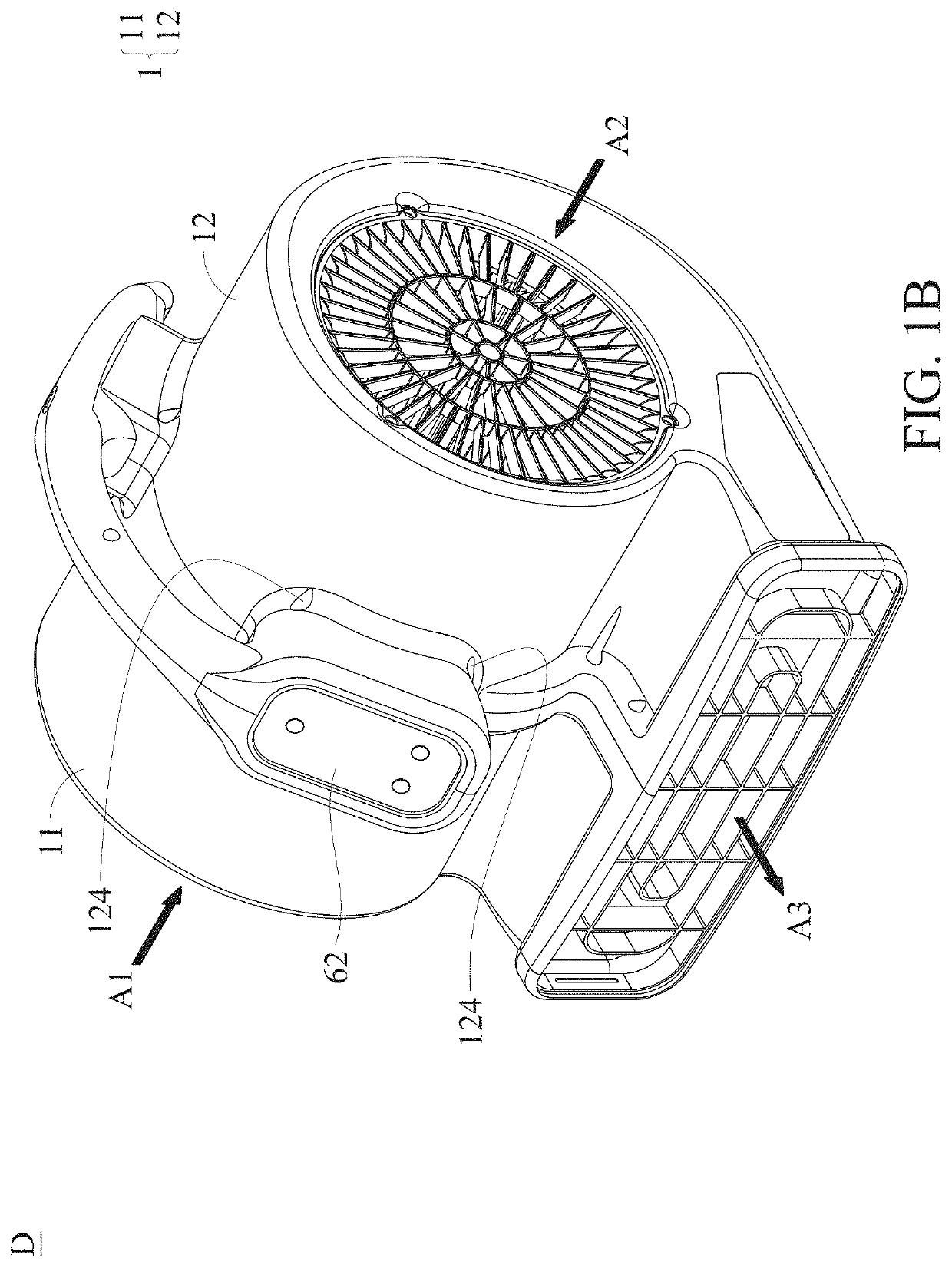

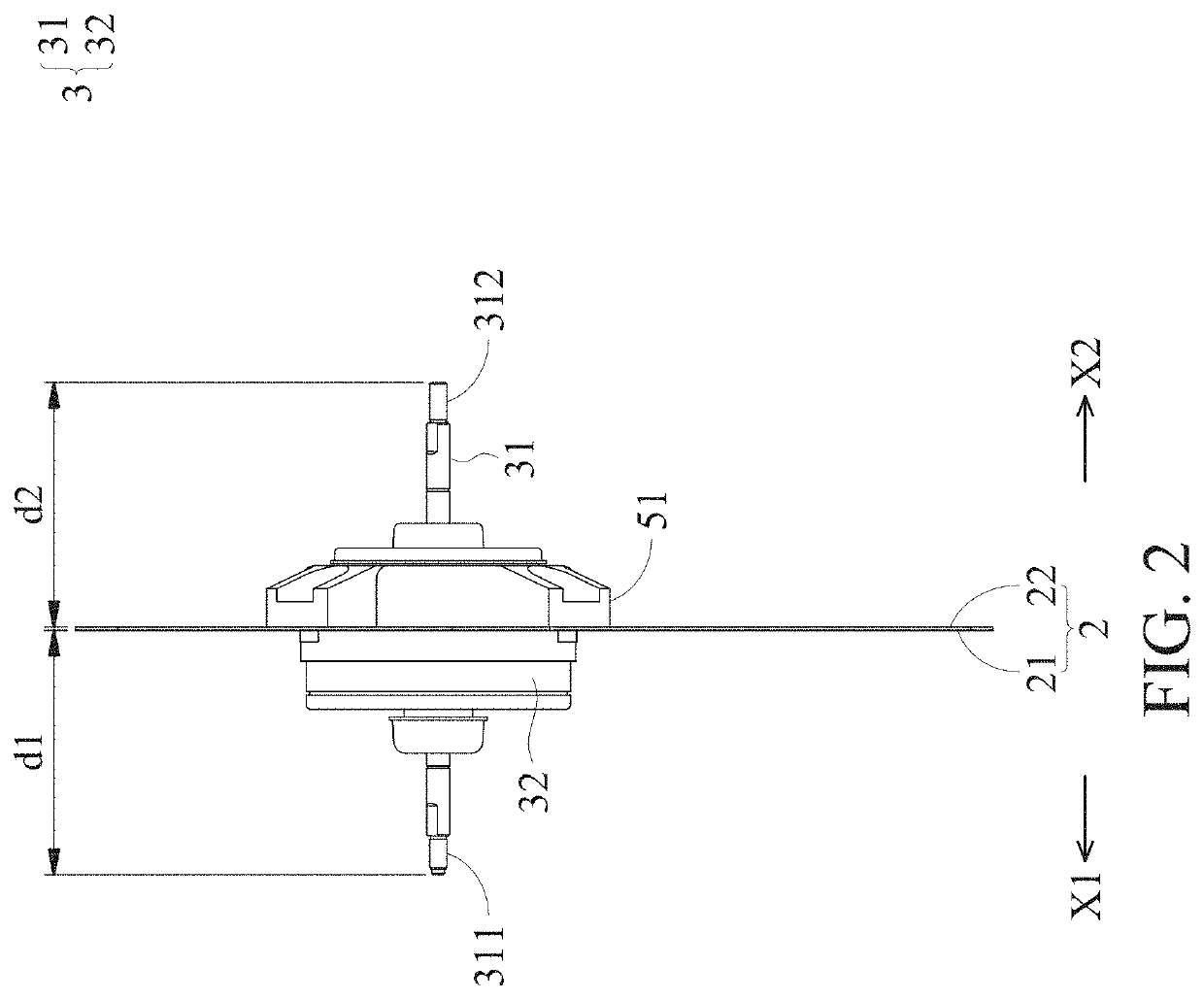

Air mover

ActiveUS11041508B2Easy to carryUniform weightPump componentsPump installationsElectric machineEngineering

Owner:DELTA ELECTRONICS INC

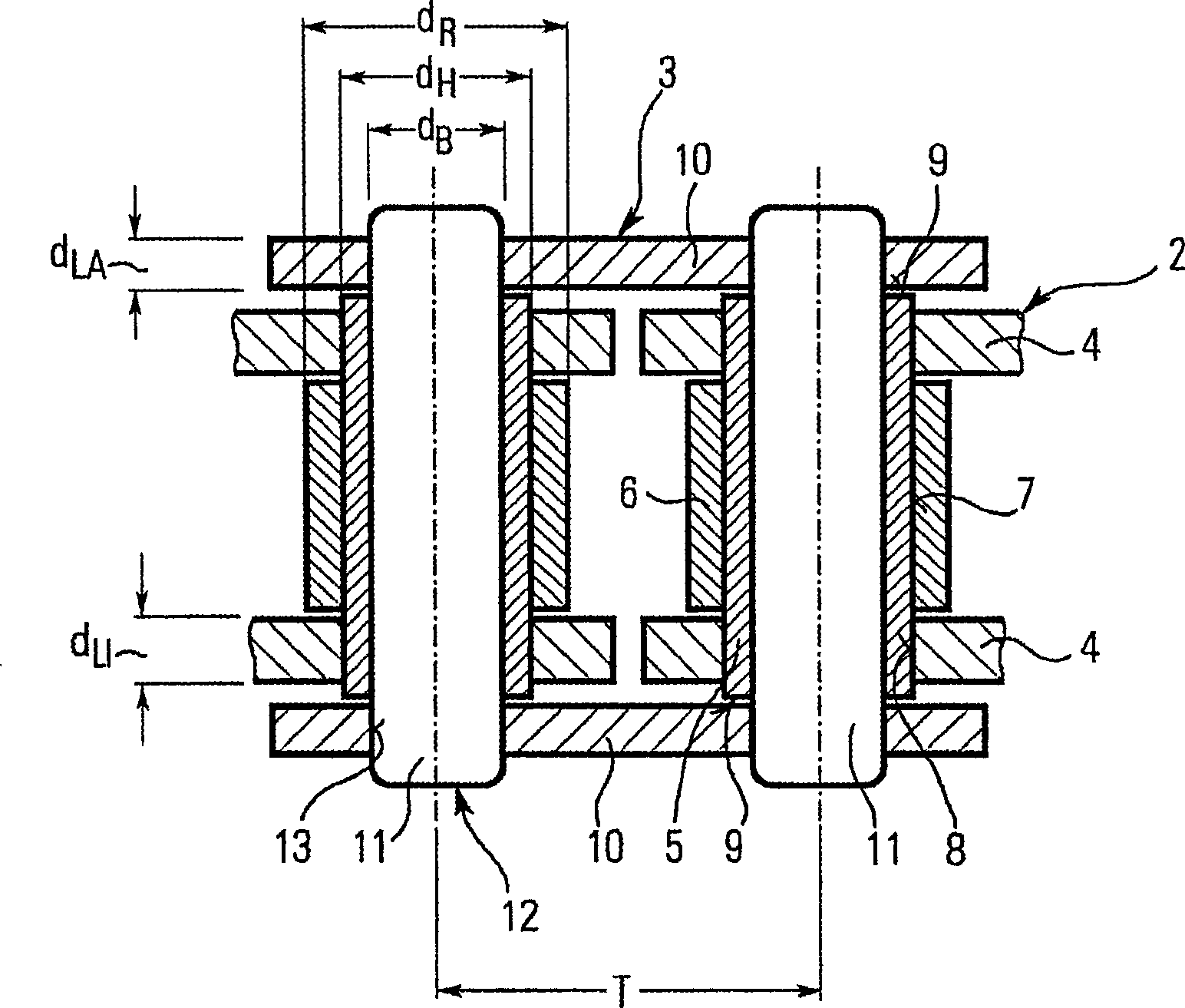

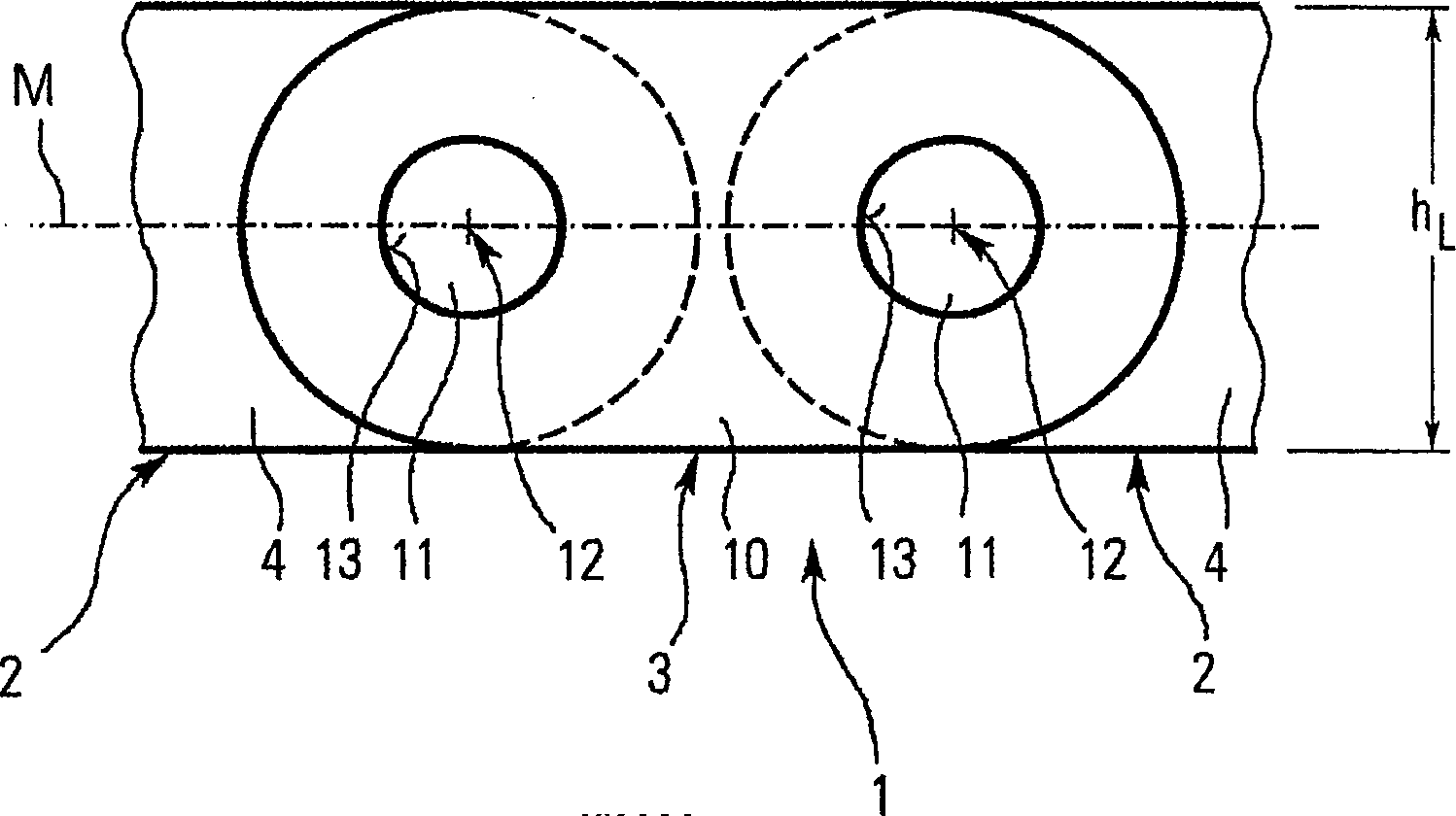

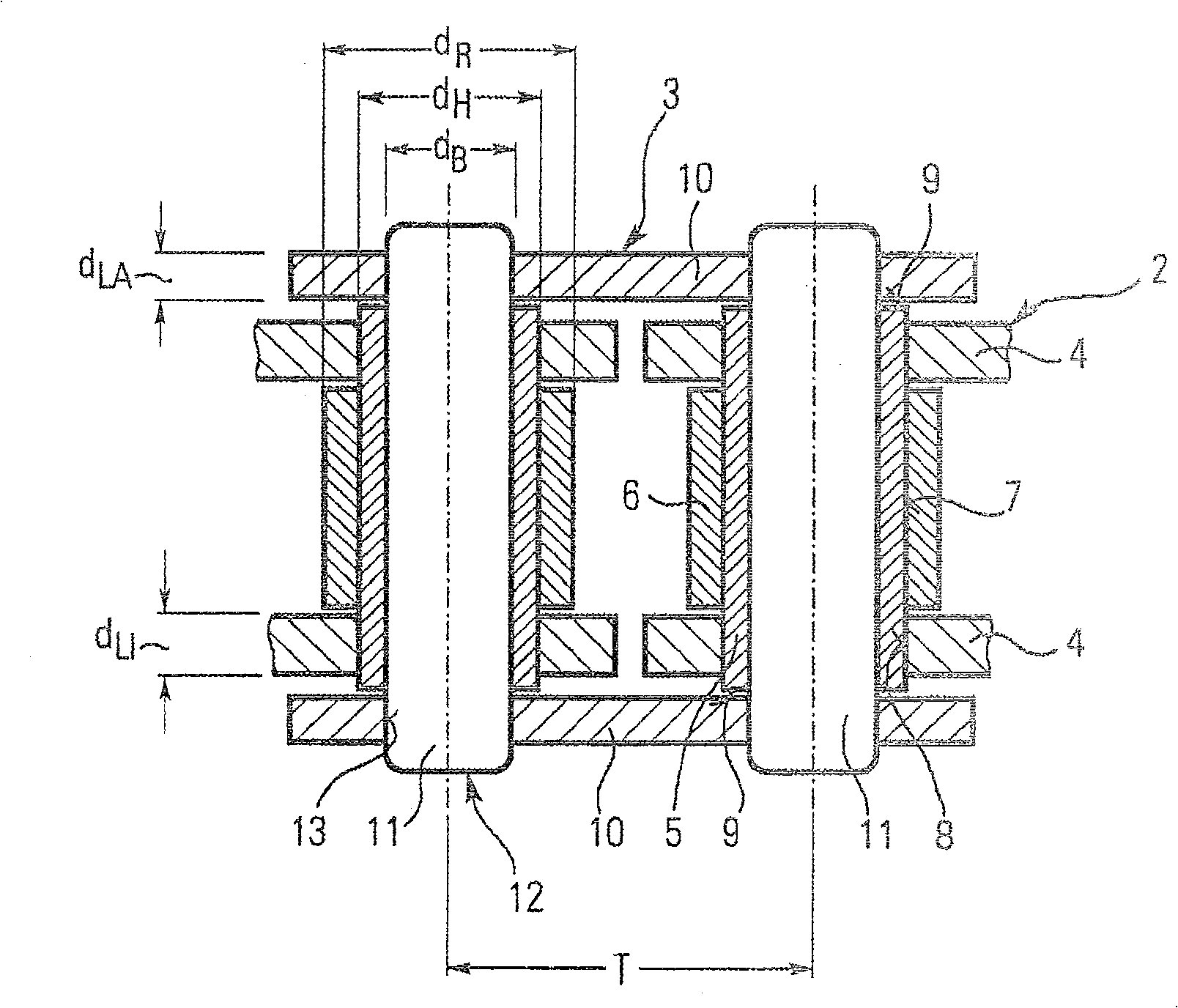

Roller chain with greater link joint height

ActiveCN1755162AReduce air noiseReduce structure-borne noiseDriving chainsMetallic materialsRoller chain

A roller chain of a metallic material, with alternating inner and outer chain links which are respectively joined together via a chain joint, whereby the outer chain links comprise two parallel outer plates, joined together by means of two parallel joint pins, and the inner chain links comprise two parallel inner plates, joined together by means of two parallel joint sleeves, a joint pin of an outer chain link extends in each case through a joint sleeve of an inner chain link to form a chain joint and a rotatable roller is arranged on the outer surface of the joint sleeve, whereby a size ratio of the height of the outer and inner plates to the external diameter of the roller is greater than 1.4, and a size ratio of the mean thickness of the inner plate to the mean thickness of the outer plate is greater than 1.1.

Owner:JOH WINKLHOFER & SOHNE

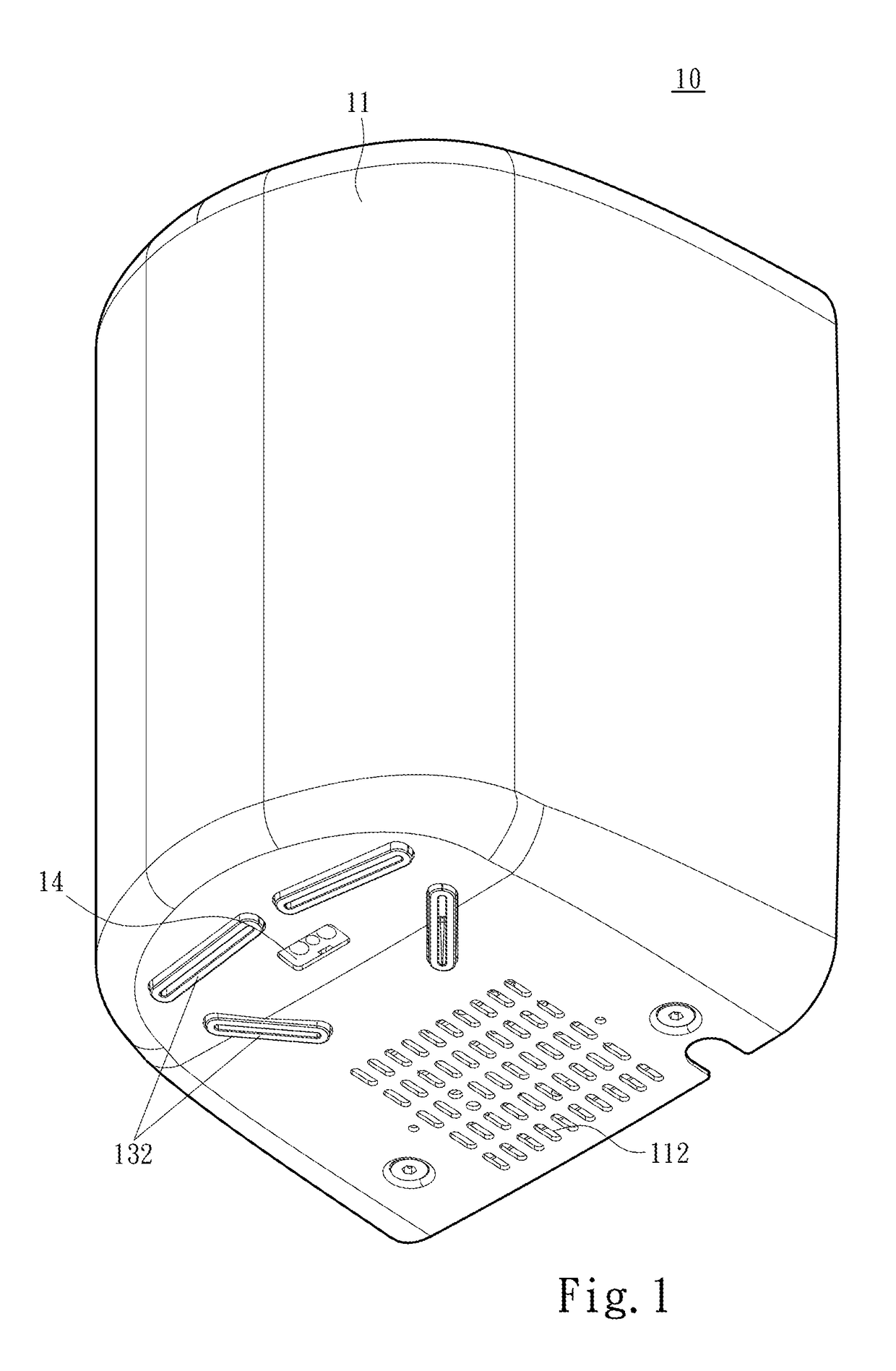

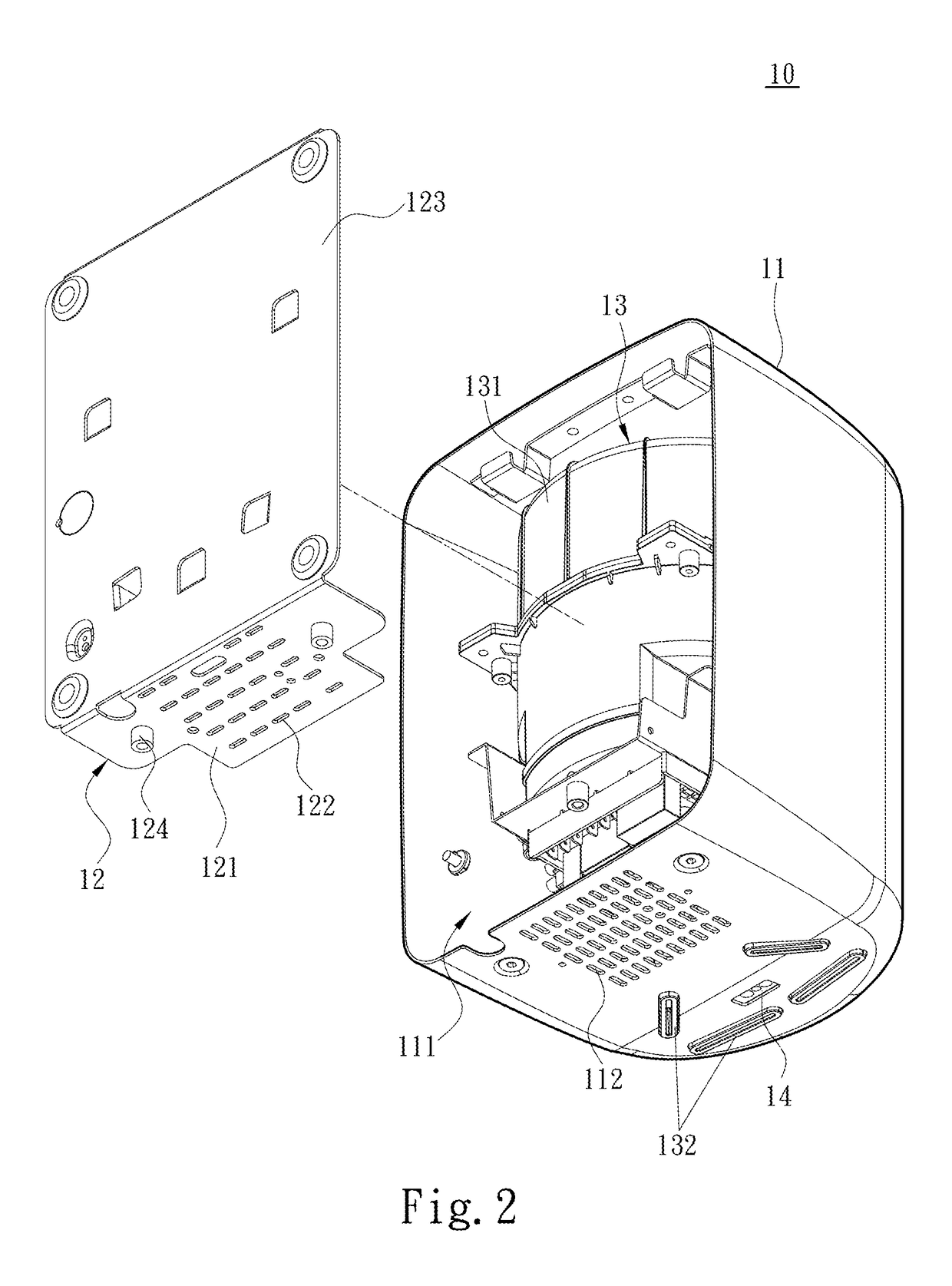

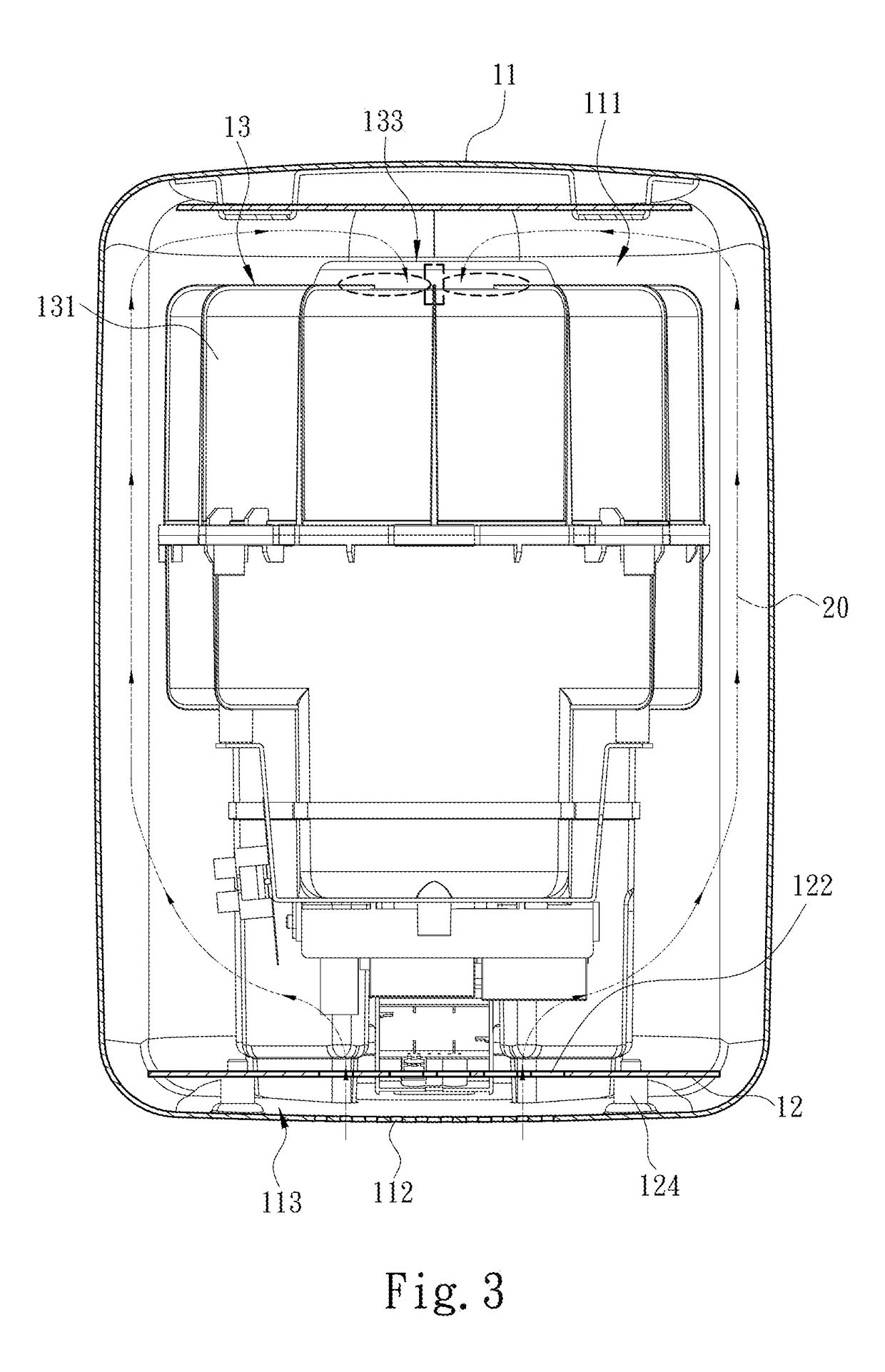

Hand dryer with reduced air-intake noise

ActiveUS10165908B1Reduce noiseReduce air noiseDrying gas arrangementsDomestic applicationsAcoustic waveEngineering

A hand dryer with reduced air-intake noise includes a housing, a flow-guide plate, and an air supply module. The housing includes an accommodating space and a plurality of narrow air inlets. The flow-guide plate is disposed inside the accommodating space, but the flow-guide plate is not contacted with the housing. The flow-guide plate includes a plurality of narrow air guide holes. The air supply module is disposed inside the accommodating space, and includes a blower that extracts air inside the accommodating space to generate a drying air flow after being started and an air-guide piece connected to the blower to receive the drying air flow. An interval between the narrow air inlet and the narrow air guide hole interferes with transmission of a sound wave formed by the air flowing between the narrow air inlet and the narrow air guide hole, so that generated noise can be greatly reduced.

Owner:HOKWANG IND

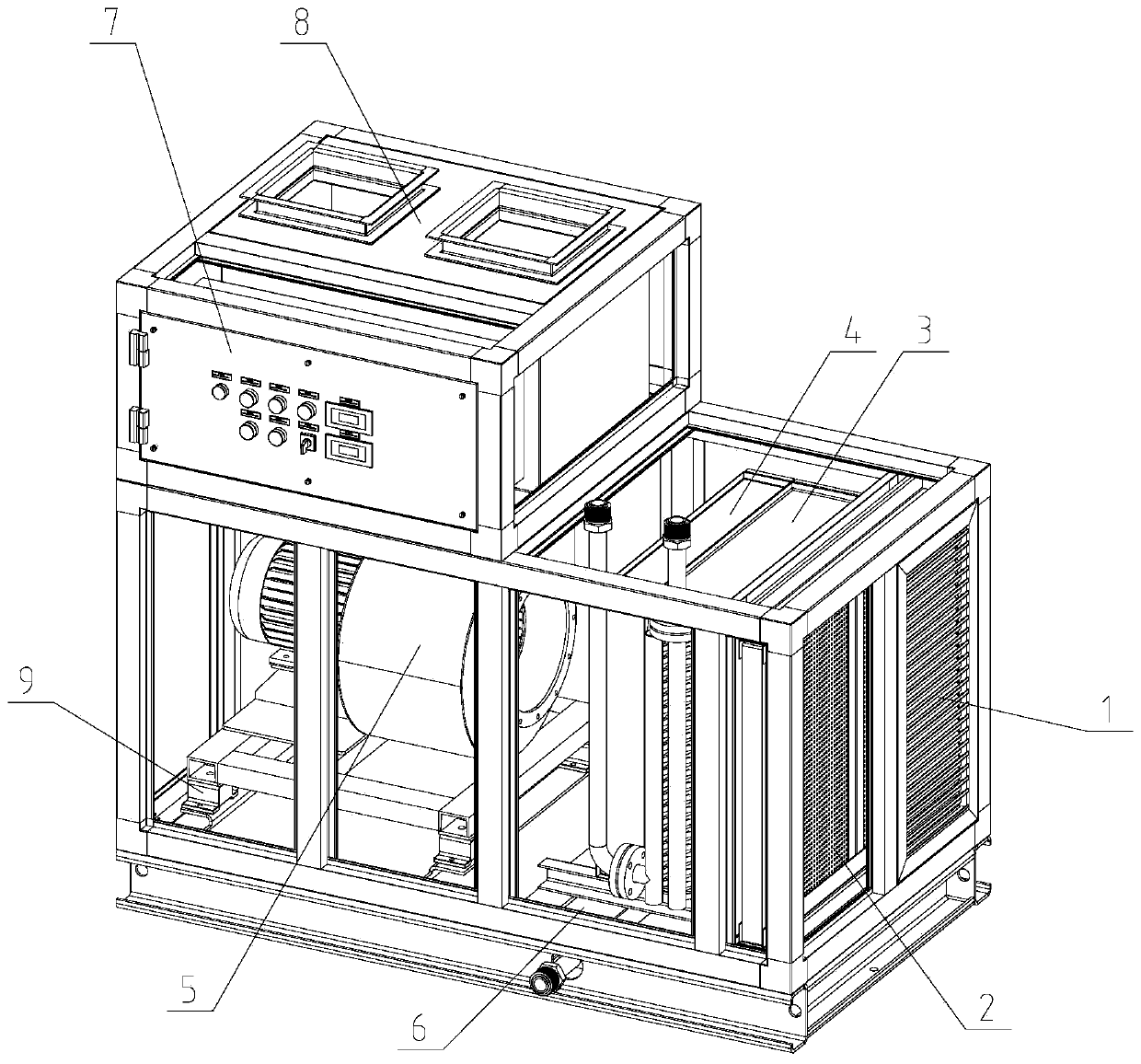

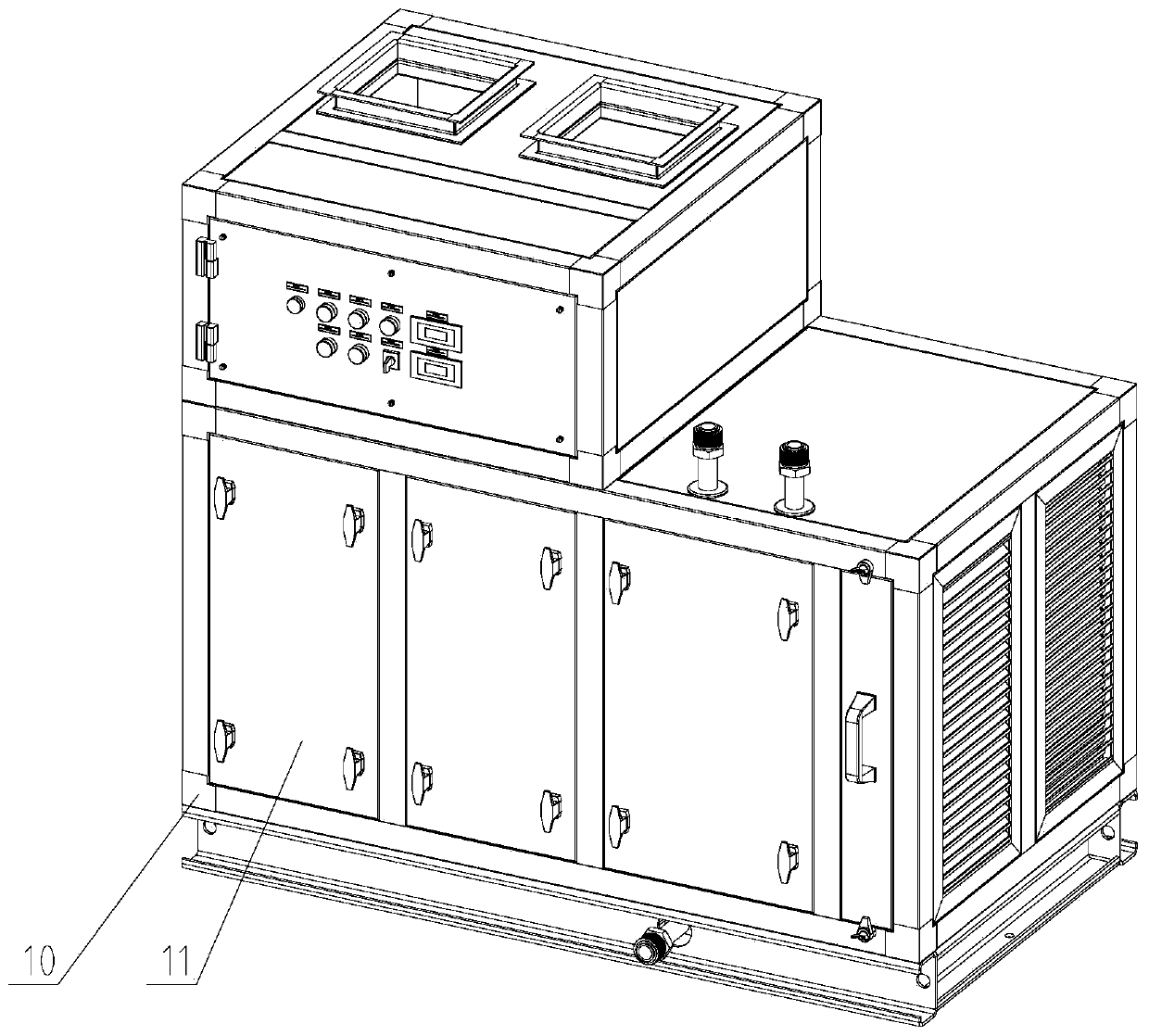

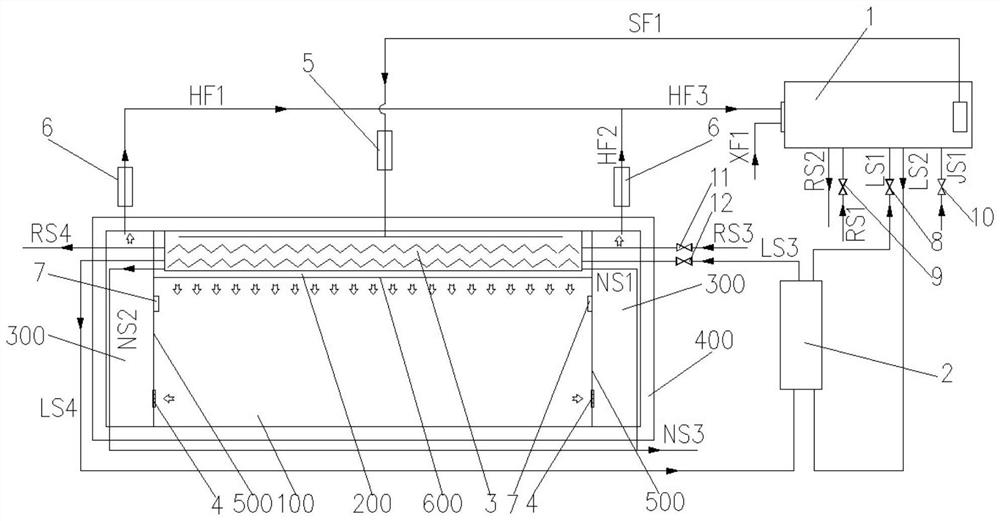

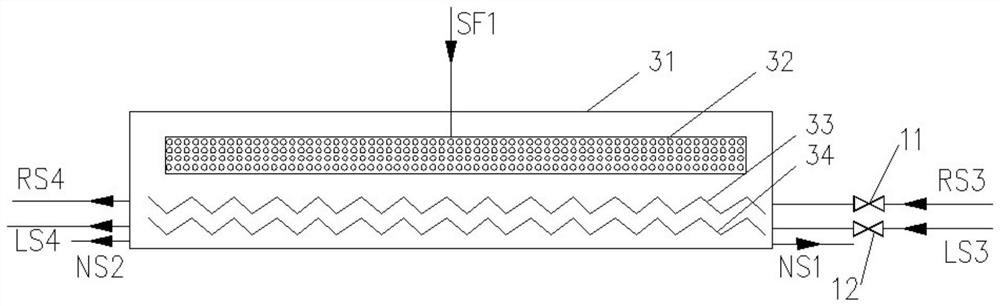

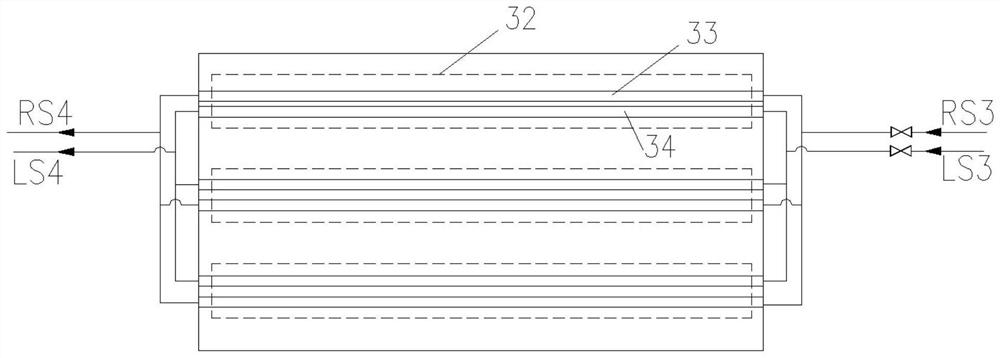

Integrated air-conditioning station for naval vessels

InactiveCN110469921AImprove space utilizationImprove uniformityMechanical apparatusLighting and heating apparatusLow noiseAir filter

The invention discloses an integrated air-conditioning station for naval vessels, belongs to the field of air-conditioning refrigeration, and relates to a low-noise and integrated air-conditioning station using low-temperature fresh water as a refrigerant medium and used for a ventilation air-conditioning system. When the integrated air-conditioning station supplies air, the high-temperature and high-humidity air sequentially passes through a muffling air return opening, an air filter, an air heat exchanger, a dehydrator, an air conditioner fan and an air outlet plenum chamber to form the low-temperature and low humidity air to be supplied outside through an air outlet for ventilating and air conditioning. The muffling air return opening adopts a multi-layer grid structure with the surfacemade of rough and pitted sound absorption materials, and air noise is continuously attenuated through refraction, scattering and nonlinear propagation of sound. The integrated air conditioning station for the naval vessels is low in vibration noise, uniform in air supply and high in pressure head, and air supply static pressure and air supply uniformity are effectively improved.

Owner:CHINA SHIP DEV & DESIGN CENT

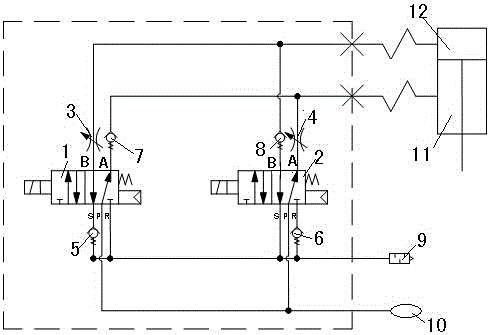

Air-saving and low-noise valve quick switch pneumatic system

ActiveCN104632748BLow instantaneous air supply requirementLow gas consumptionOperating means/releasing devices for valvesServomotor componentsLow noiseEngineering

Owner:SHANGHAI MARINE EQUIP RES INST

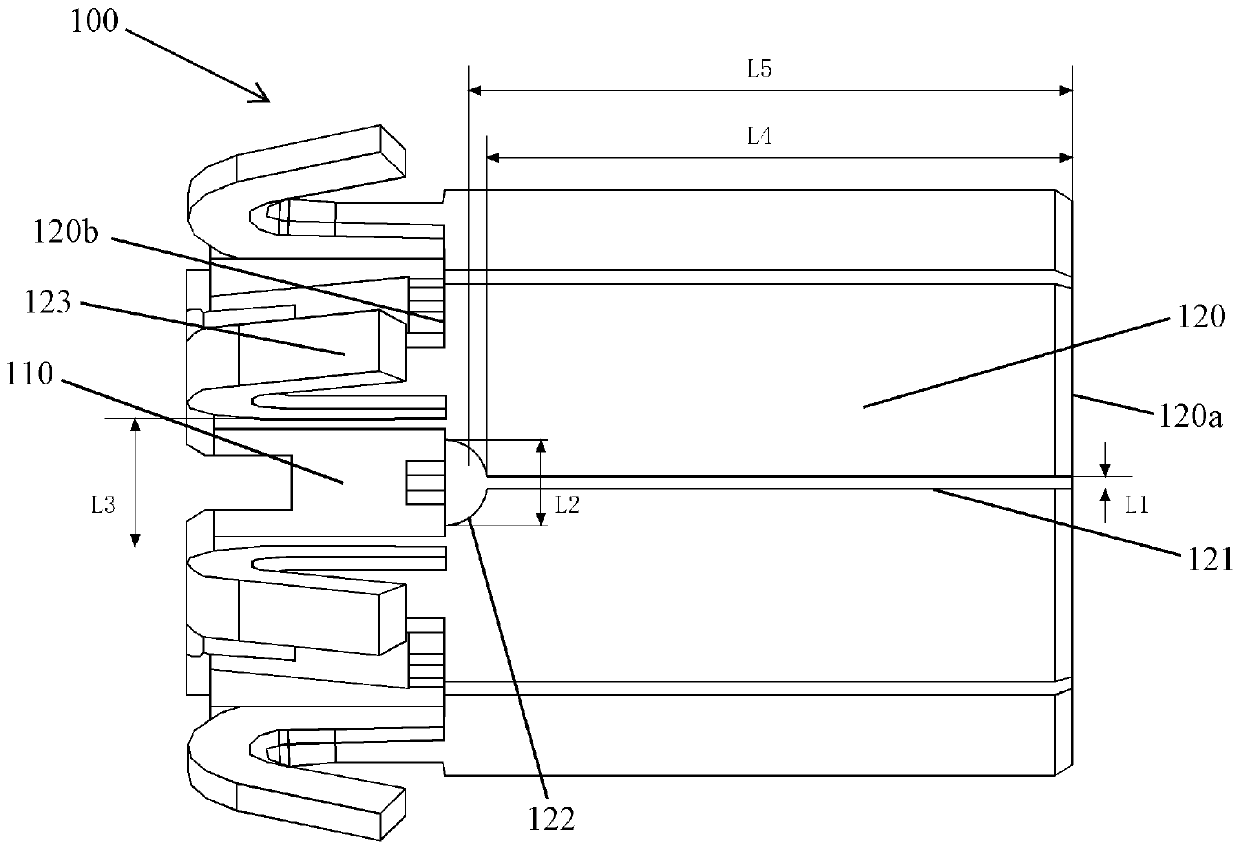

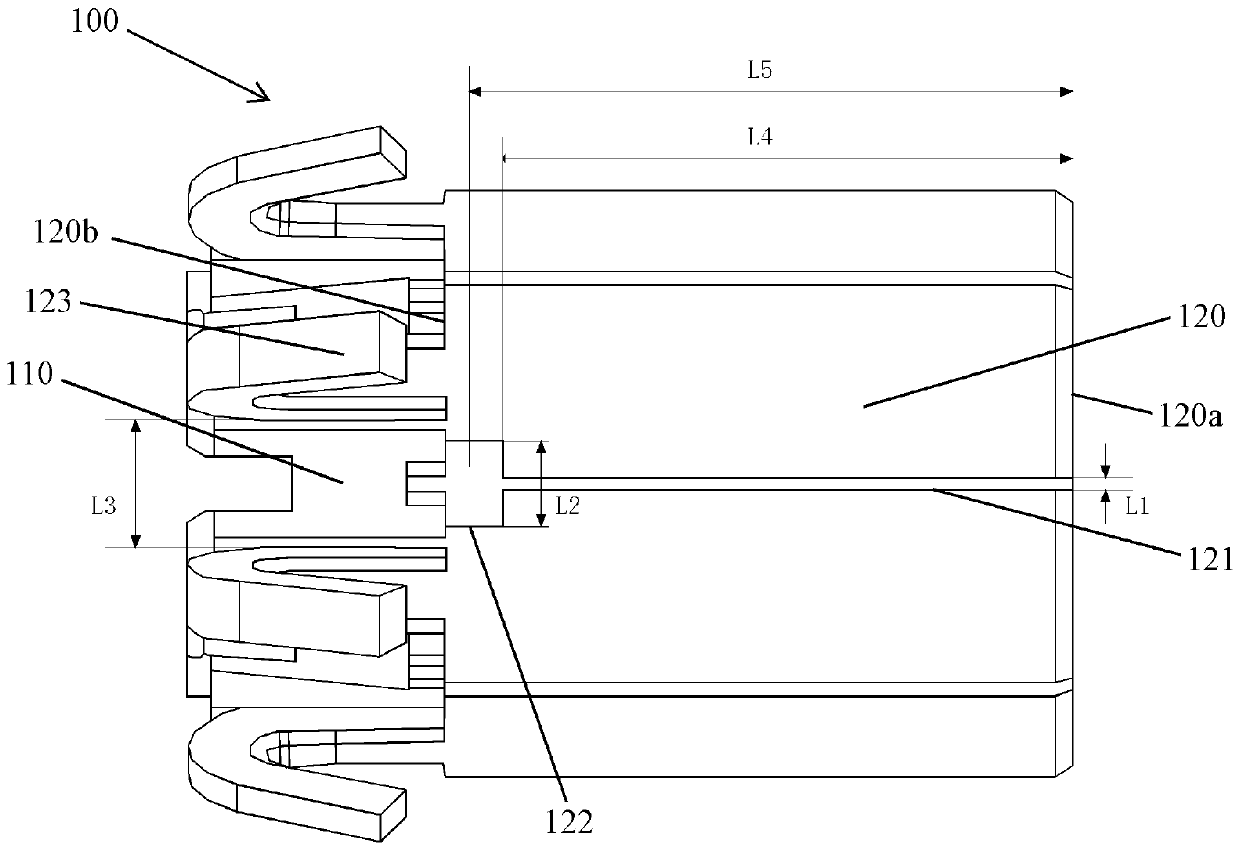

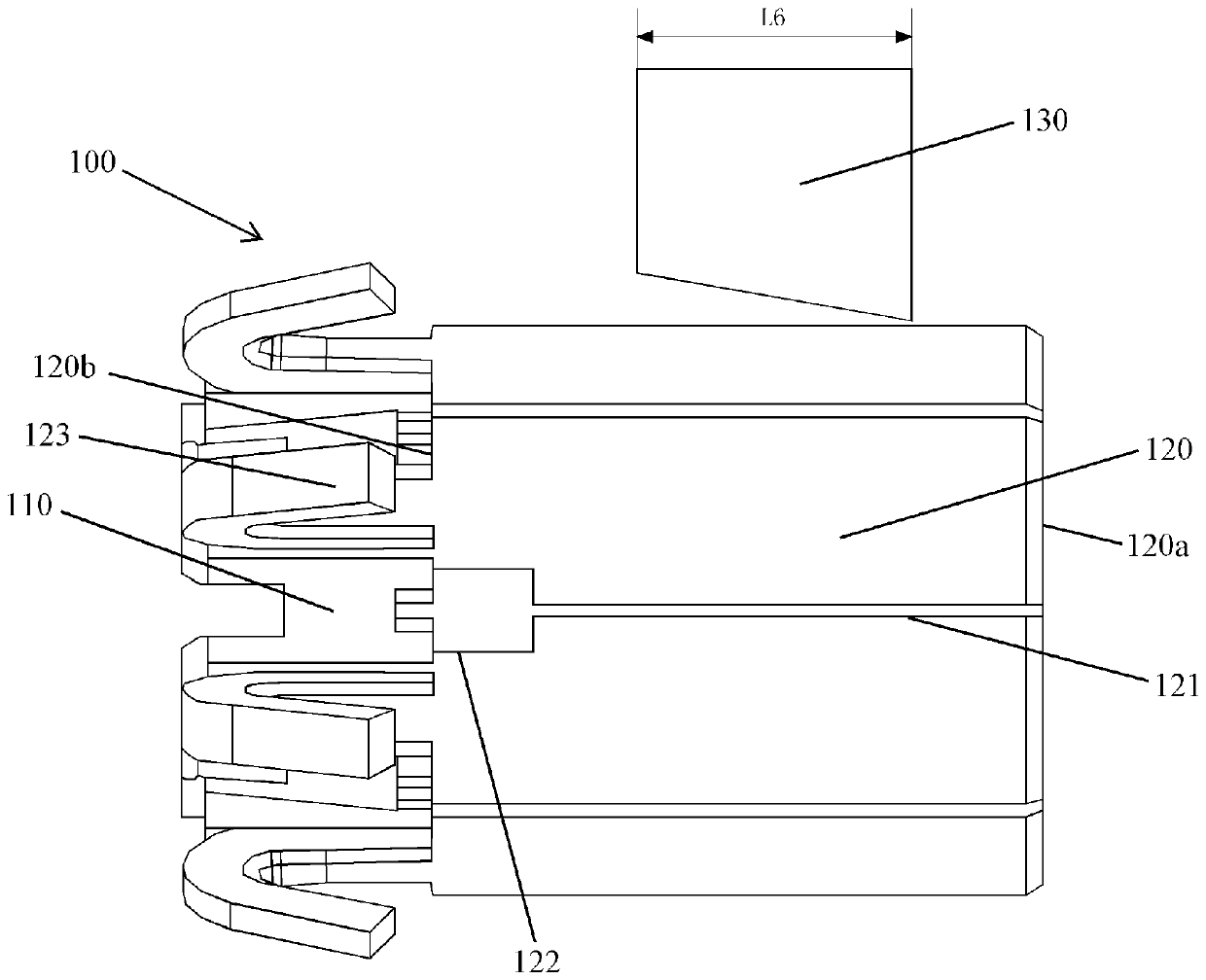

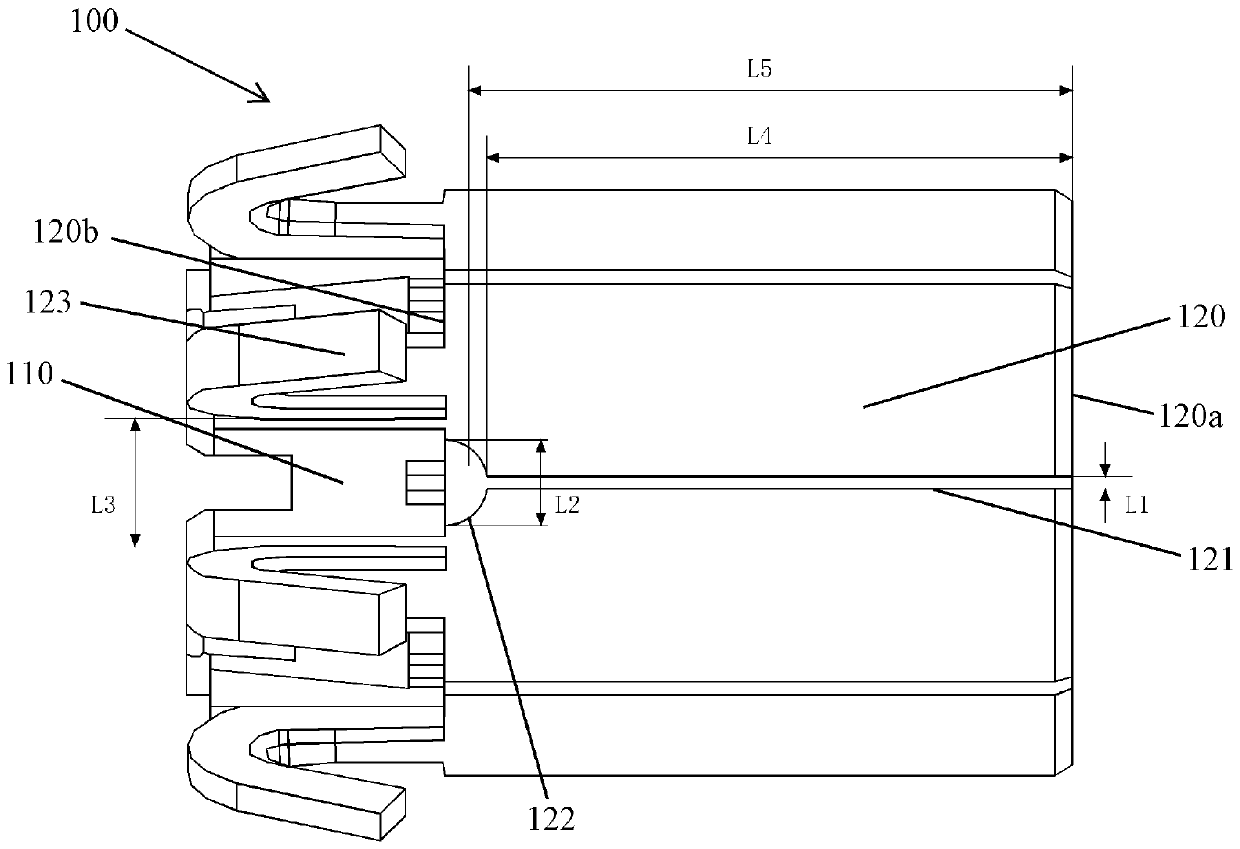

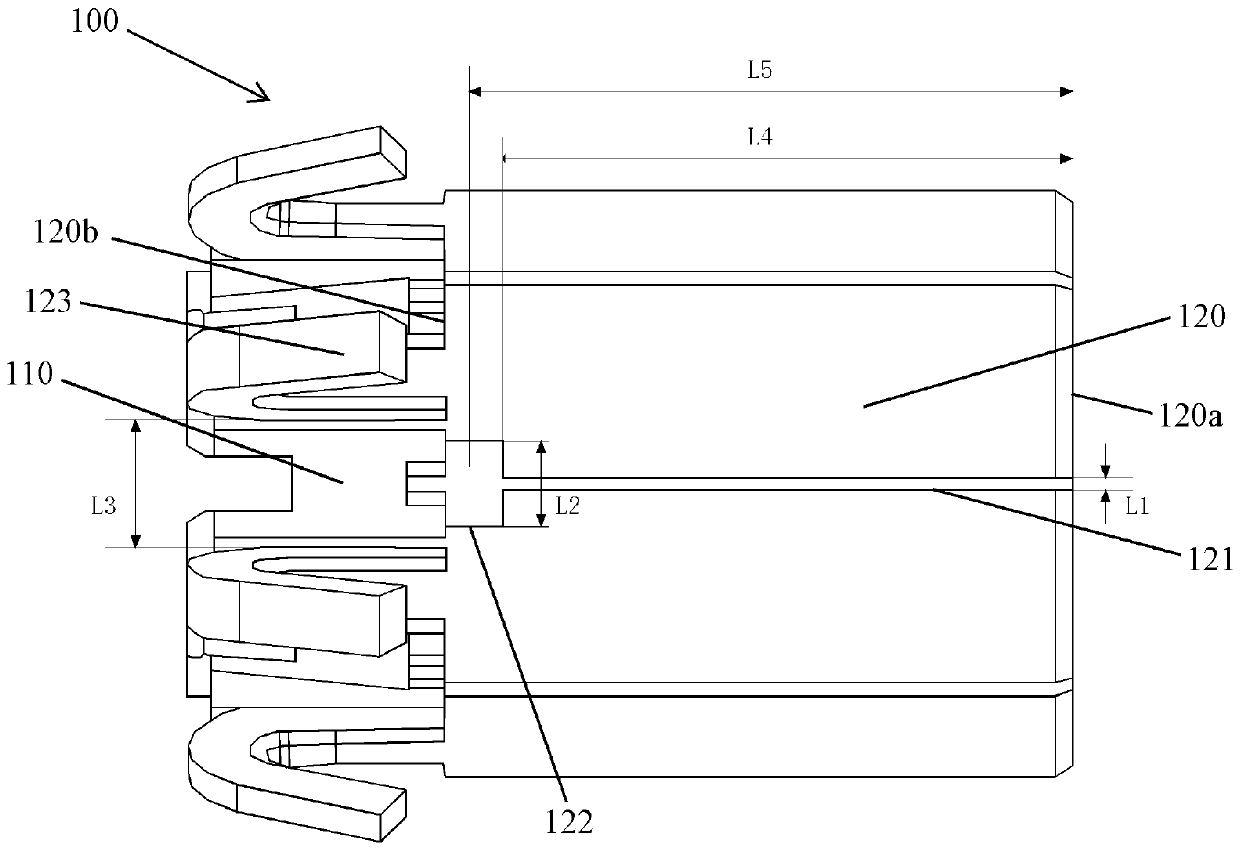

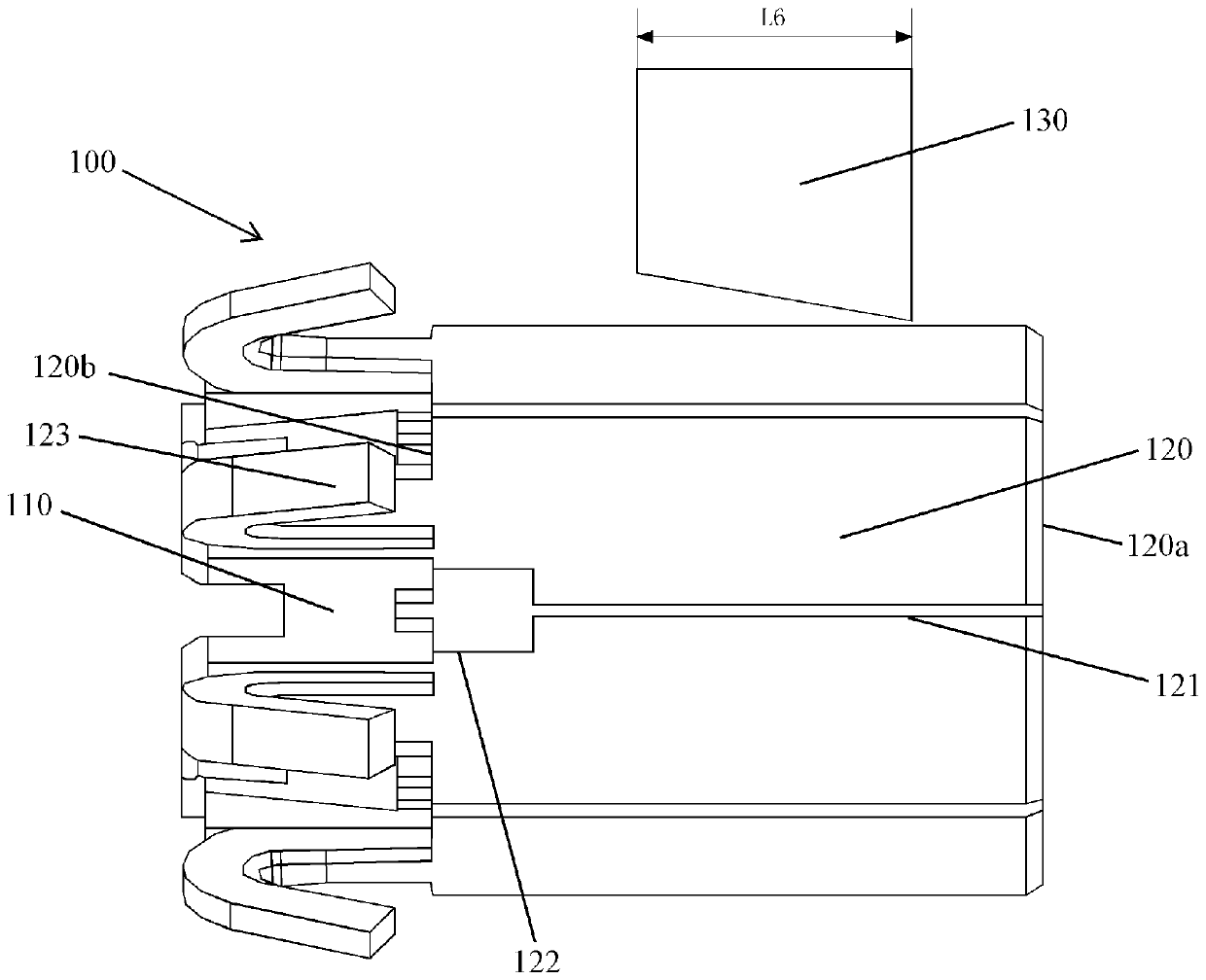

Commutator and motor

ActiveCN110086057AImprove performanceAvoid the risk of short circuitsRotary current collectorDynamoelectric machine connectorsCommutatorShort circuit

The invention provides a commutator and a motor. The commutator comprises a commutator base body and a plurality of commutator segments, wherein the plurality of commutator segments are arranged around the commutator base body along the circumferential direction, and the adjacent commutator segments are provided with a first gap section and a second gap section therebetween which are adjacent to each other along the circumferential direction; each commutator segment is provided with a winding wiring portion at the second end along the axial direction, and the first end of the commutator segment along the axial direction is away from the winding wiring portion; the width L2 of the second gap section between the second ends of the adjacent commutator segments is greater than the width L1 ofthe first gap section between the first ends; and the width L2 of the second gap section is less than the width L3 of the spacing between the winding wiring portions of the adjacent commutator segments. According to the technical scheme of the invention, the setting of the width-varying gap between the adjacent commutator segments increases the spacing of burr-prone areas during the processing process so as to avoid the risk of short circuits one the one hand; and on the other hand, the working area of the commutator is kept to have a narrow spacing, thereby improving the EMC, reducing the airnoise and vibration, and enabling the motor performance to be more stable.

Owner:BOSCH AUTOMOTIVE PROD CHANGSHA

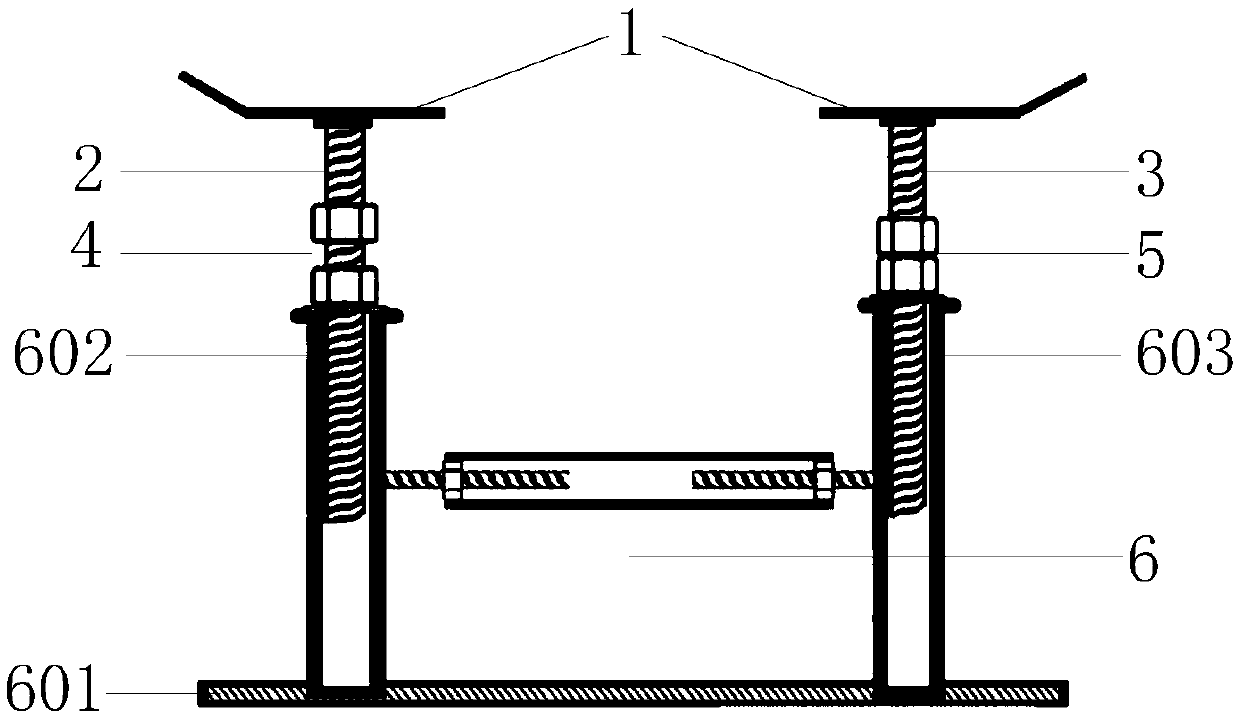

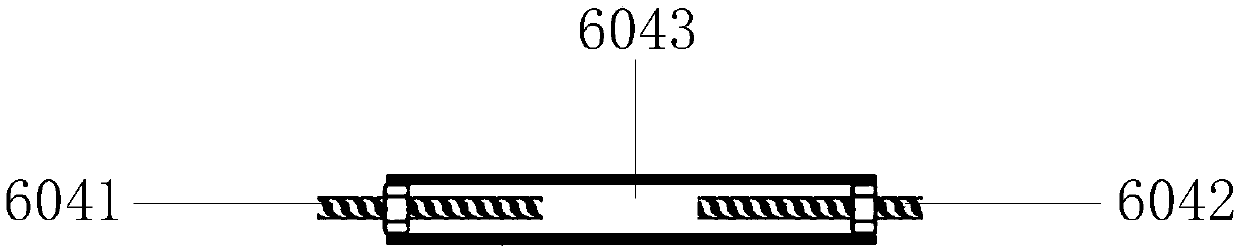

Valve body support and assembling method

InactiveCN110886936APrevent sinkingPrevent leakageStands/trestlesStructural engineeringMechanical engineering

The invention relates to a valve body support and belongs to the technical field of oil exploitation. A first vertical screw rod and a second vertical screw rod in the valve body support are connectedwith a first support component. The vertical screw rod is sleeved with a first set of locking nuts, and the second vertical screw rod is sleeved with a second set of locking nuts. A second support component comprises a bottom guide groove, a first vertical support pipe, a second vertical support pipe and a width adjustment part. The first vertical support pipe and the second vertical support pipeare located in the bottom guide groove and movably connected with the bottom guide groove. The width adjustment part is connected with the first vertical support pipe and the second vertical supportpipe. The second end of the first vertical screw rod is inserted into the first vertical support pipe. The first set of locking nuts is used for locking the first vertical screw rod. The second end ofthe second vertical screw rod is inserted into the second vertical support pipe, and the second set of locking nuts is used for locking the second vertical screw rod. According to the valve body support, a valve body can be stably supported, the valve body is prevented from sinking or floating, and the safety is improved.

Owner:PETROCHINA CO LTD

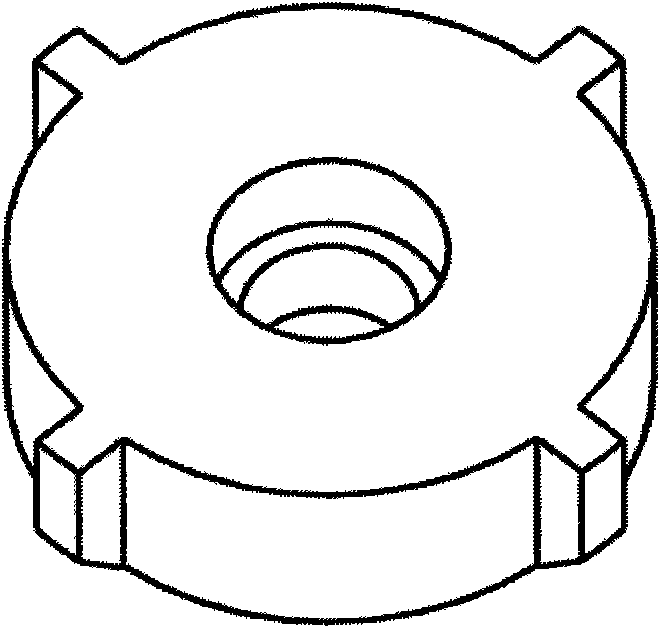

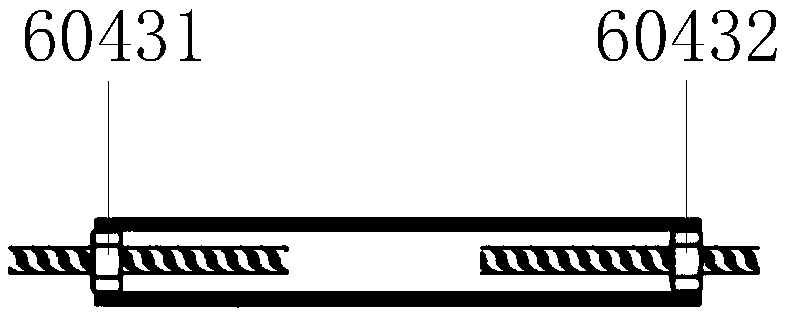

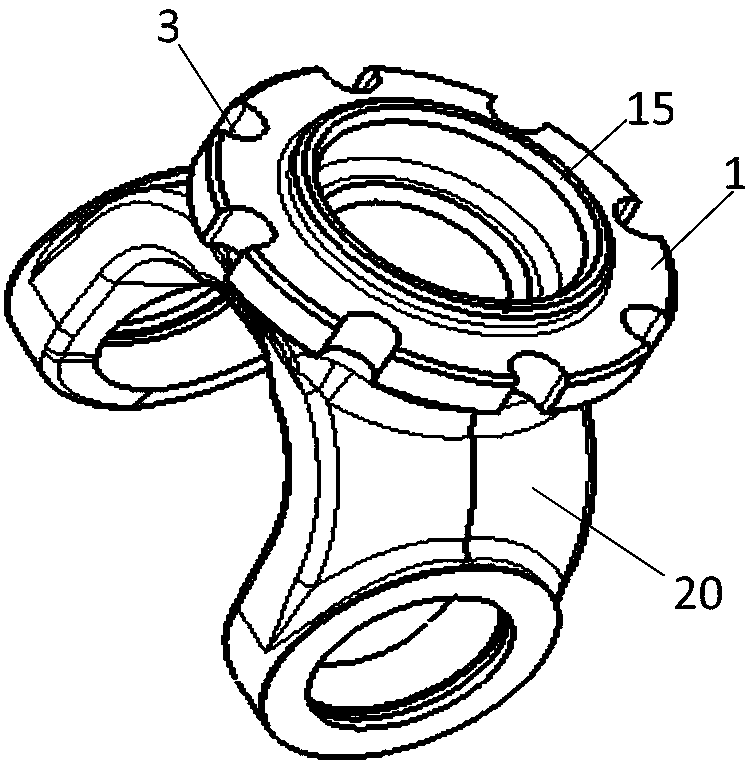

Connecting device for transmission shaft and input shaft

The invention discloses a connecting device for a transmission shaft and an input shaft. The connecting device comprises a first flange, a second flange, pin bodies and a limiting ring. The first flange is in transmission connection with the transmission shaft. Multiple first through grooves are formed in the outer circumference of the first flange. The second flange is in transmission connectionwith the input shaft, and multiple second through grooves are formed in the outer circumference of the second flange. The second through grooves are in one-to-one correspondence with the first throughgrooves. One end of each pin body is located in the corresponding first through groove, and the other end of each pin body is located in the corresponding second through groove. An annular limiting groove is formed in the inner wall of the limiting ring. The limiting ring is arranged on the first flange and the second flange in a sleeving manner. One end face of the first flange and one end faceof the second flange abut against the two side walls of the annular limiting groove correspondingly. By means of the connecting device, the air resistance formed in the transmission process can be reduced; transmission efficiency can be improved; and the air noise can be reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

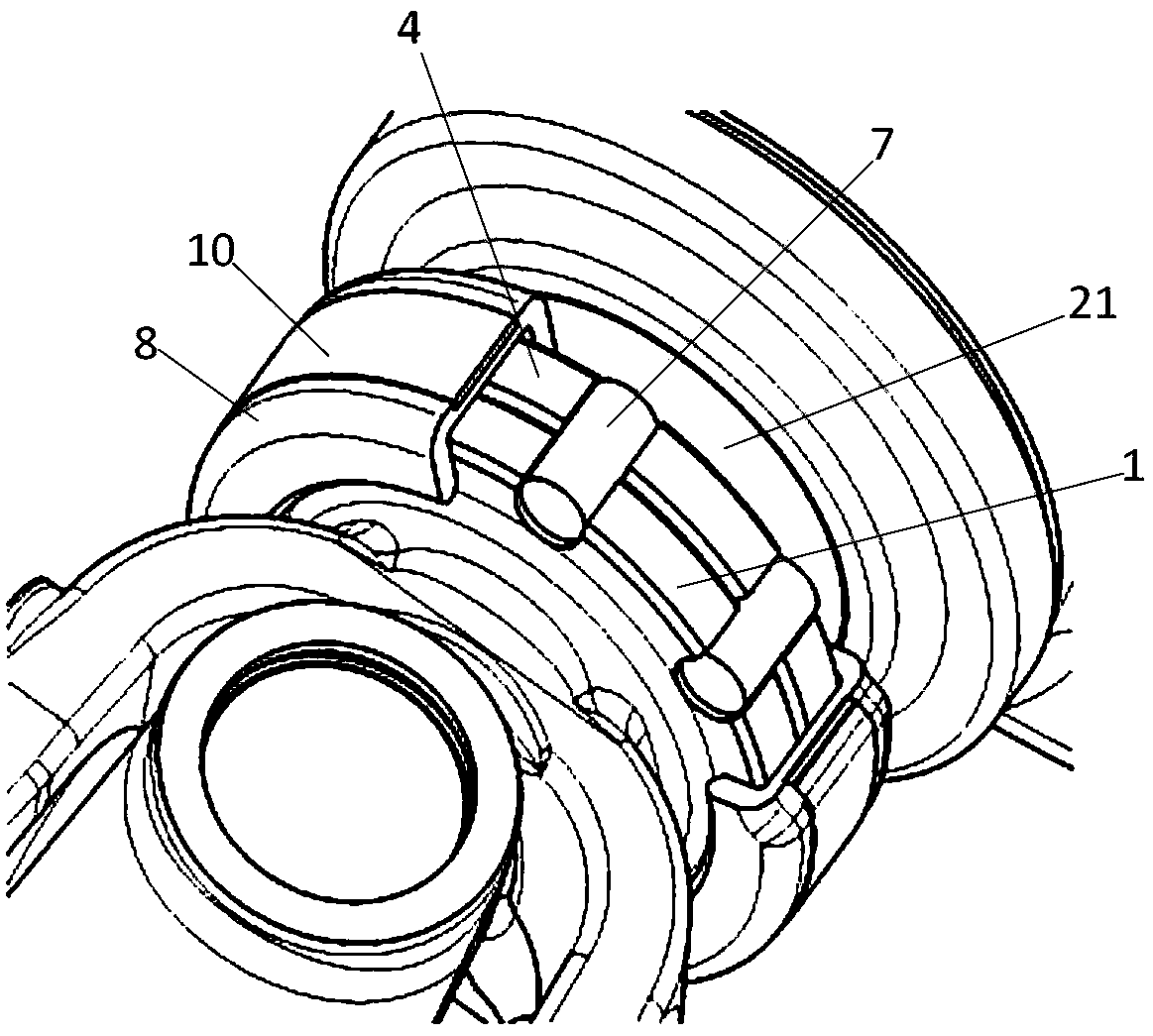

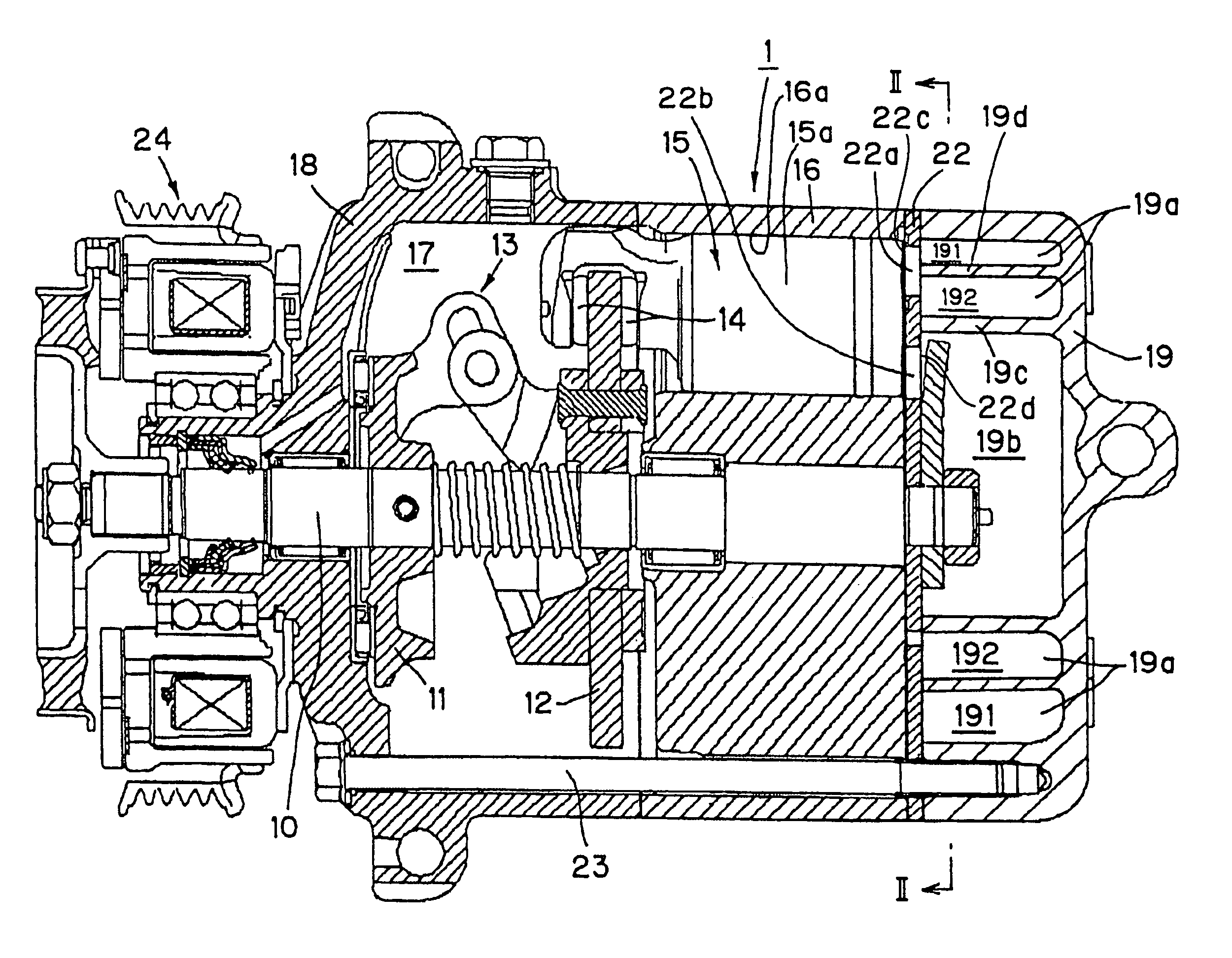

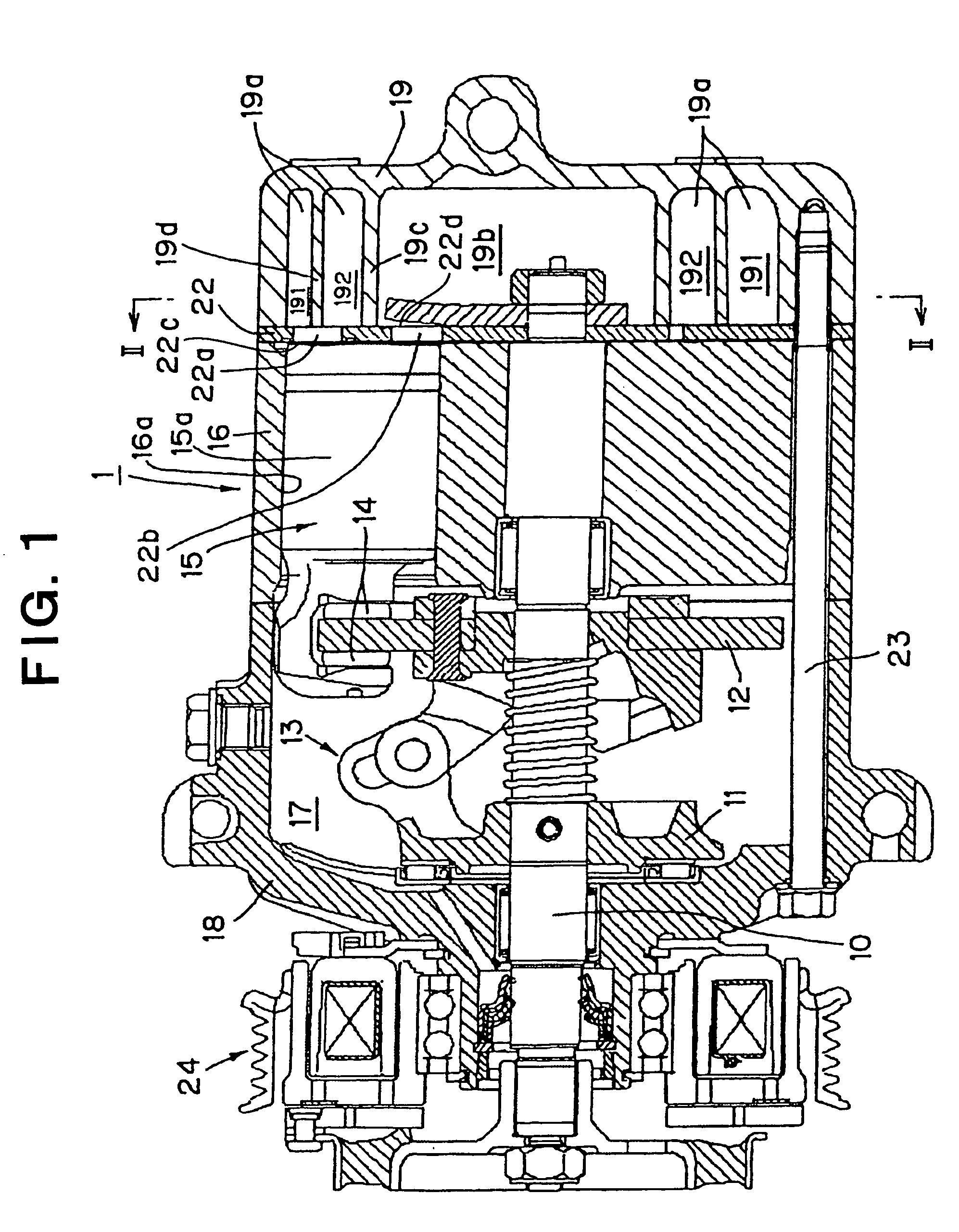

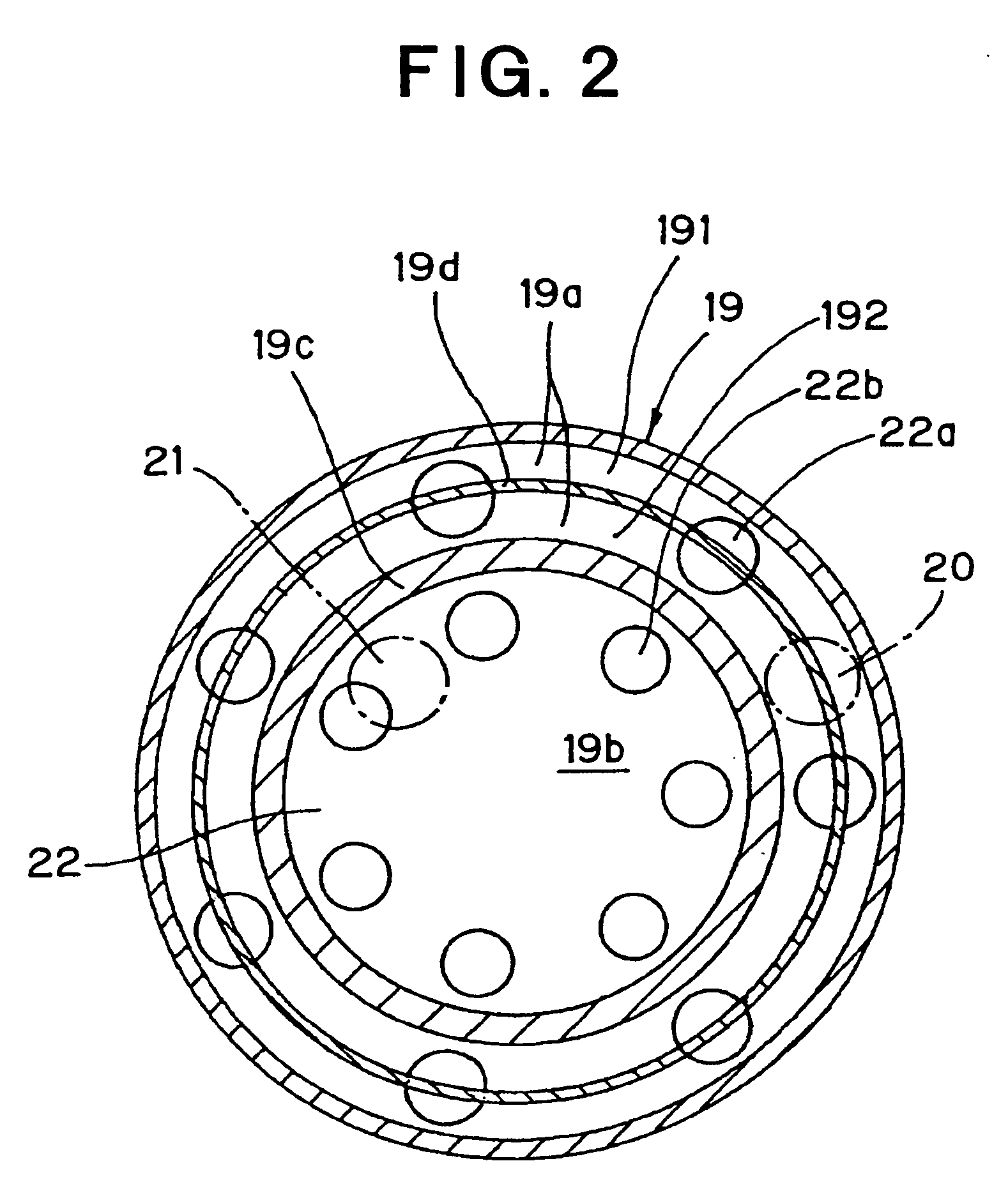

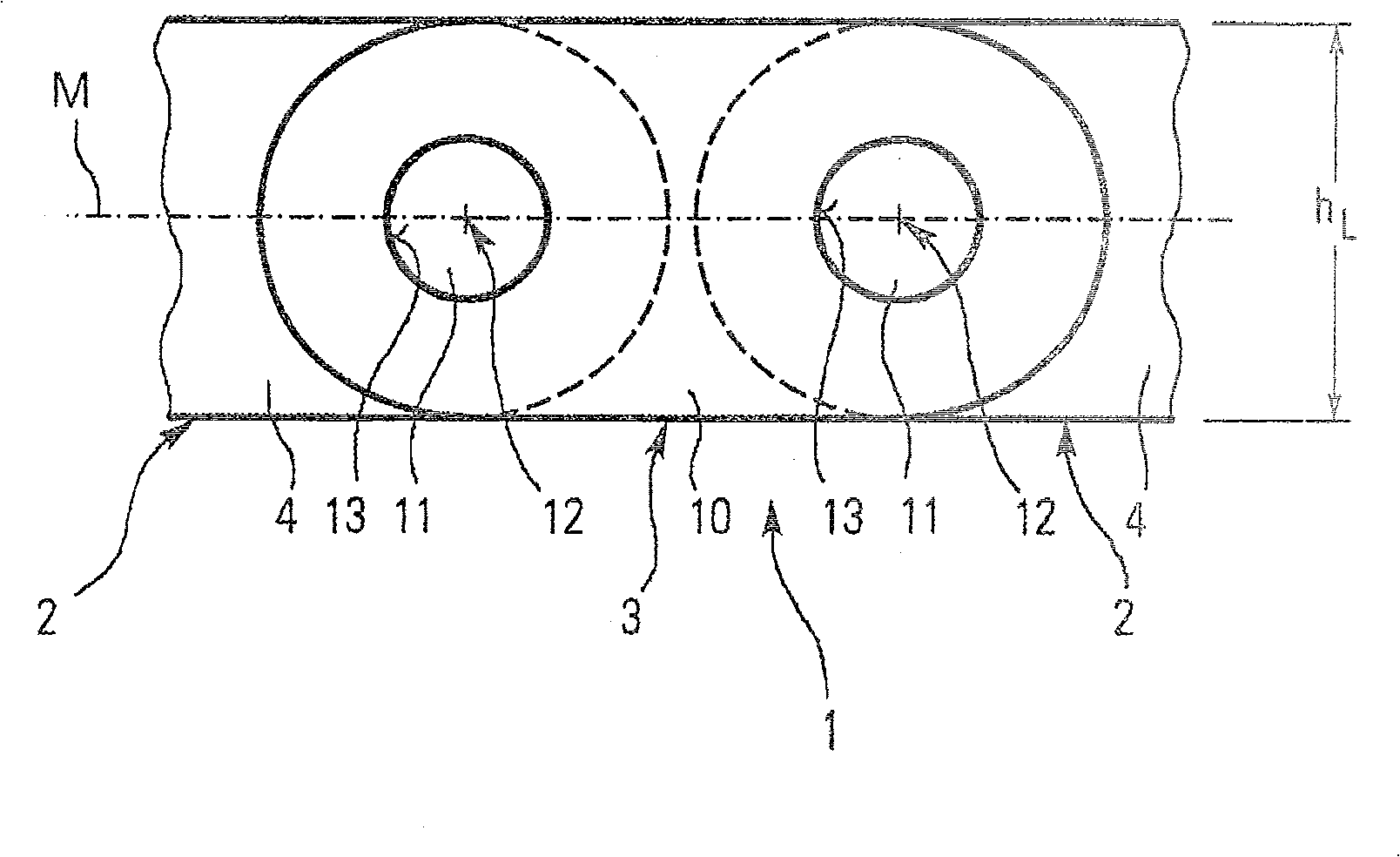

Multi-cylinder, reciprocating compressors for air conditioning systems mounted in vehicles

InactiveUS20060034704A1Suppresses above-described vibration and noiseReduce vibration levelsPositive displacement pump componentsMulti-stage pumpsIn vehicleCylinder block

A multi-cylinder reciprocating compressor for an air conditioning system mounted in a vehicle includes a columnar cylinder block with cylinder bores, a front head provided at one side of the cylinder block to form a crank chamber, a rear head provided at the other side of the cylinder block, a valve plate interposed between the cylinder block and the rear head, a discharge chamber formed in the rear head, and a suction chamber formed in the rear head having an annular shape and positioned radially outside of the discharge chamber. The suction chamber is divided into first and second, annular chambers by a partition wall extending in a circumferential direction. As a result of this configuration, the pulsation of refrigerant generated in the annular suction chamber may be reduced, and the vibration and noise of the air conditioning system may be reduced.

Owner:SANDEN CORP

Roller chain with greater link joint height

ActiveCN100547261CImprove fatigue strengthIncreased durabilityDriving chainsCouplingMetallic materials

Owner:JOH WINKLHOFER & SOHNE

Air mover

PendingUS20210277904A1Easy to carryUniform weightPump componentsPump installationsElectric machineEngineering

Owner:DELTA ELECTRONICS INC

Air conditioning system of low-temperature laboratory

PendingCN114313200AAccurate adjustmentImprove comfortAuxillariesVessel ventillation/heating/coolingTemperature controlEngineering

The invention provides an air conditioning system of a low-temperature laboratory. The air conditioning system comprises an air conditioning device, a temperature control unit, a refrigerating device, an electric control box, a temperature and humidity sensor and the like. The temperature and humidity sensor is used for monitoring the temperature and humidity in the low-temperature laboratory in real time, when the real-time temperature and humidity deviate from preset values, the electric control box regulates and controls an electromagnetic valve in the air conditioning device and also regulates and controls an electromagnetic valve in the temperature control unit at the same time, and temperature and humidity regulation and control are more accurate through two times of regulation and control. Meanwhile, under the action of the air supply cavity and the air supply pore plate, air flow is stably supplied into a working area of the low-temperature laboratory, and an air return opening of the air return cavity is formed in the bottom, so that an air flow organization type of top air supply and lower air return is formed, and the constancy of the temperature is ensured. Compared with an existing air cooler cooling mode, the indoor constant-temperature constant-humidity and low-noise design environment is achieved, and high comfort of personnel is guaranteed.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Commutator and motor

ActiveCN110086057BImprove performanceAvoid the risk of short circuitsRotary current collectorDynamoelectric machine connectorsElectric machineControl theory

The invention provides a commutator and a motor. The commutator comprises a commutator base body and a plurality of commutator segments, wherein the plurality of commutator segments are arranged around the commutator base body along the circumferential direction, and the adjacent commutator segments are provided with a first gap section and a second gap section therebetween which are adjacent to each other along the circumferential direction; each commutator segment is provided with a winding wiring portion at the second end along the axial direction, and the first end of the commutator segment along the axial direction is away from the winding wiring portion; the width L2 of the second gap section between the second ends of the adjacent commutator segments is greater than the width L1 ofthe first gap section between the first ends; and the width L2 of the second gap section is less than the width L3 of the spacing between the winding wiring portions of the adjacent commutator segments. According to the technical scheme of the invention, the setting of the width-varying gap between the adjacent commutator segments increases the spacing of burr-prone areas during the processing process so as to avoid the risk of short circuits one the one hand; and on the other hand, the working area of the commutator is kept to have a narrow spacing, thereby improving the EMC, reducing the airnoise and vibration, and enabling the motor performance to be more stable.

Owner:BOSCH AUTOMOTIVE PROD CHANGSHA

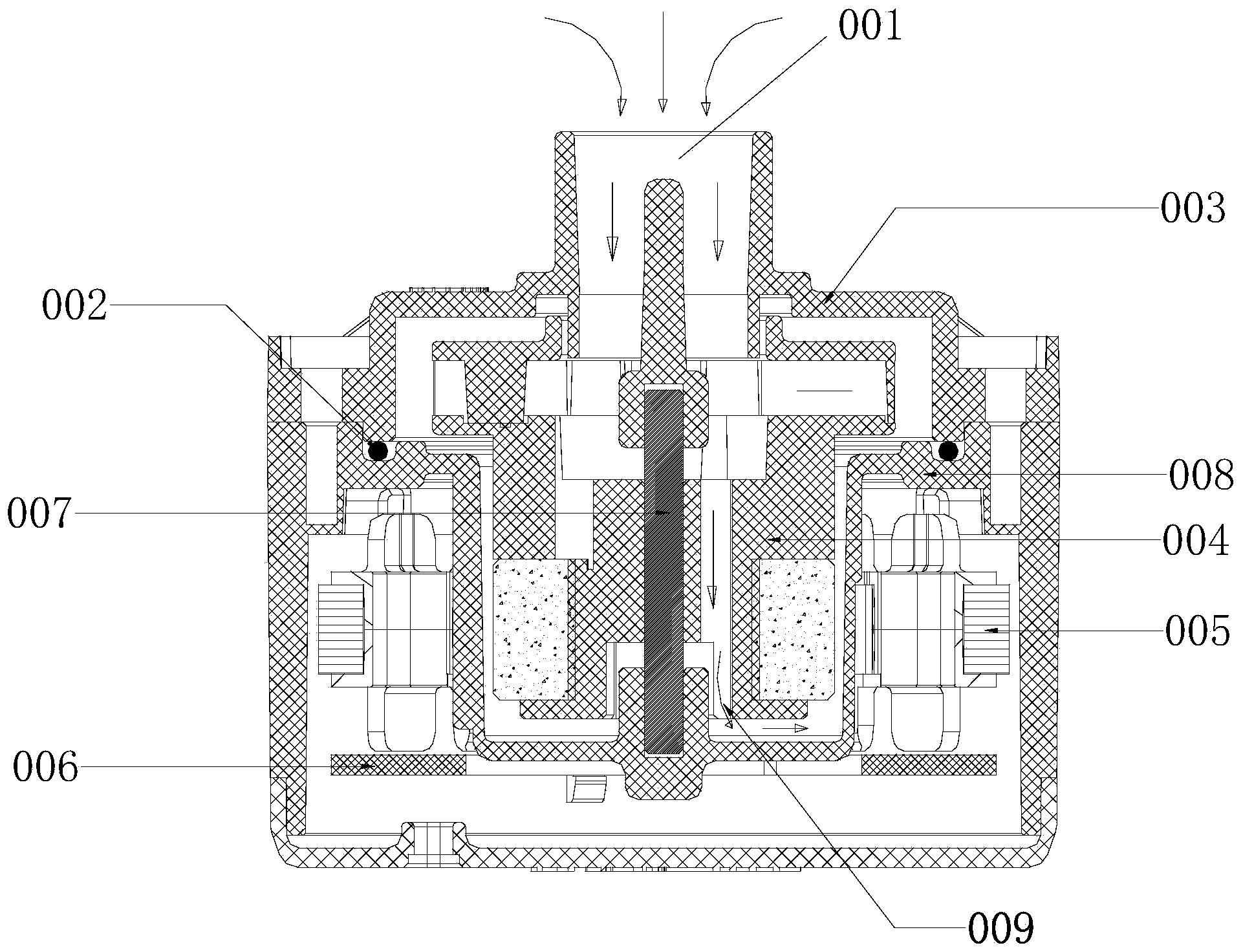

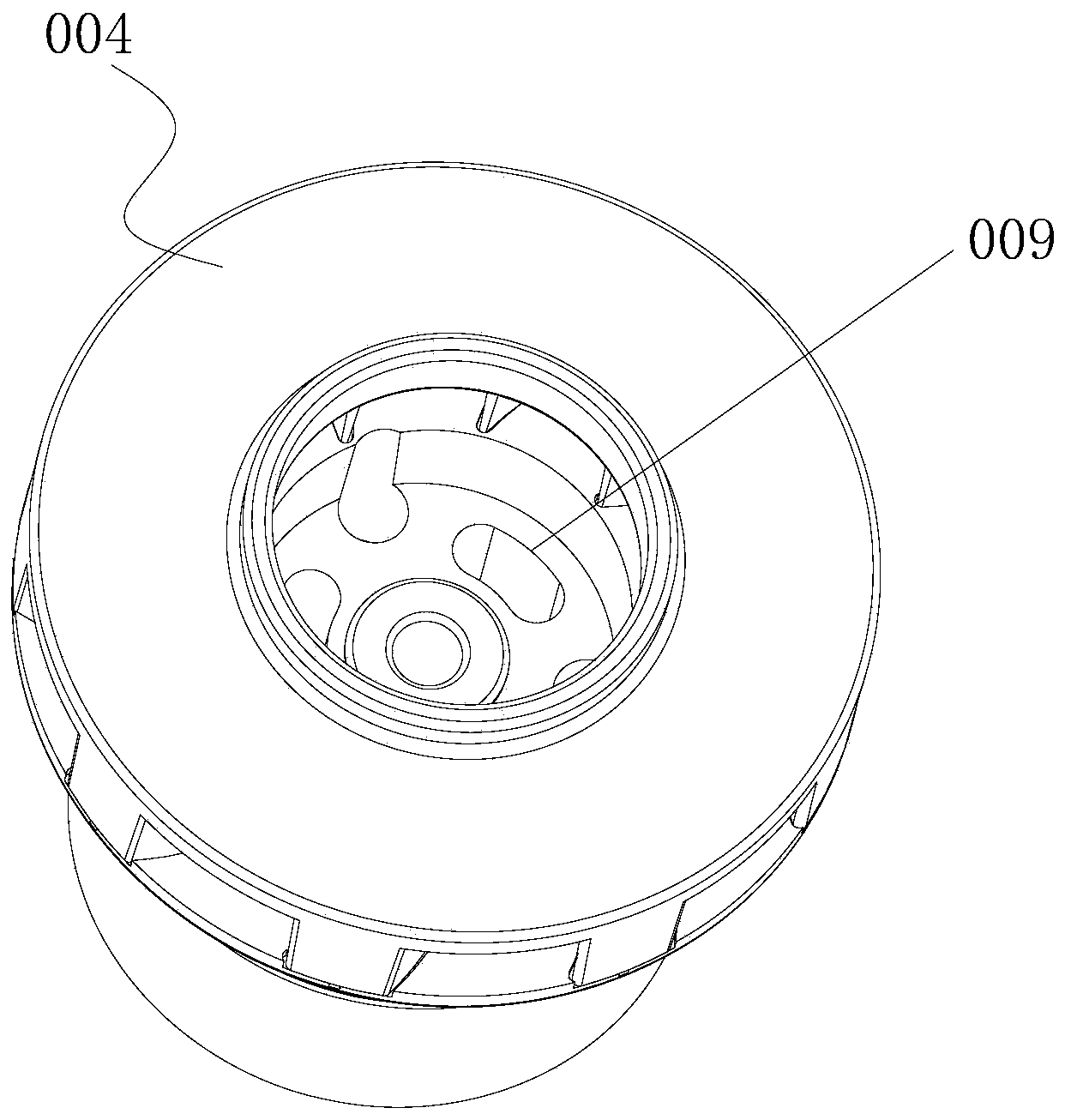

Direct-current brushless mute water pump

InactiveCN103629119AReduce frictional resistanceReduce air noisePump componentsPump installationsPump headMechanical abrasion

The invention discloses a direct-current brushless mute water pump, which comprises a water pump main body, wherein a rotor, a stator and a pump head are arranged inside the water pump main body, the rotor and the stator are mutually connected with each other, the pump head is fixed on the upper part of the water pump main body, a pump cavity is formed between the rotor and the stator, the center of the rotor is provided with a central shaft, the central position, adjacent to the upper part of the central shaft, of the pump head is provided with a water inlet, a water inlet passage is formed between the central shaft and the rotor, a plurality of groups of balance pores are arranged in the water inlet passage, the pump cavity can be instantaneously fully filled with the water by adopting the design of the balance pores, and the negative pressure is generated in the water inlet, so that the rotor is imbalanced, the rotor and the stator are mutually balanced, the rotor is enabled to work under the freedom state, the friction resistance force between the rotor and a mechanical member in work can be reduced, and no mechanical abrasion noise is realized when the water pump works; since the pump cavity is rapidly filled with the water, the air inside the water passage can be thoroughly emptied in a short time, the air noise generated by the rotation of the air in the pump cavity can be lowered, more than 80 percent of noise pollution can be reduced, and the direct-current brushless mute water pump has broad market prospect.

Owner:东莞市深鹏电子有限公司

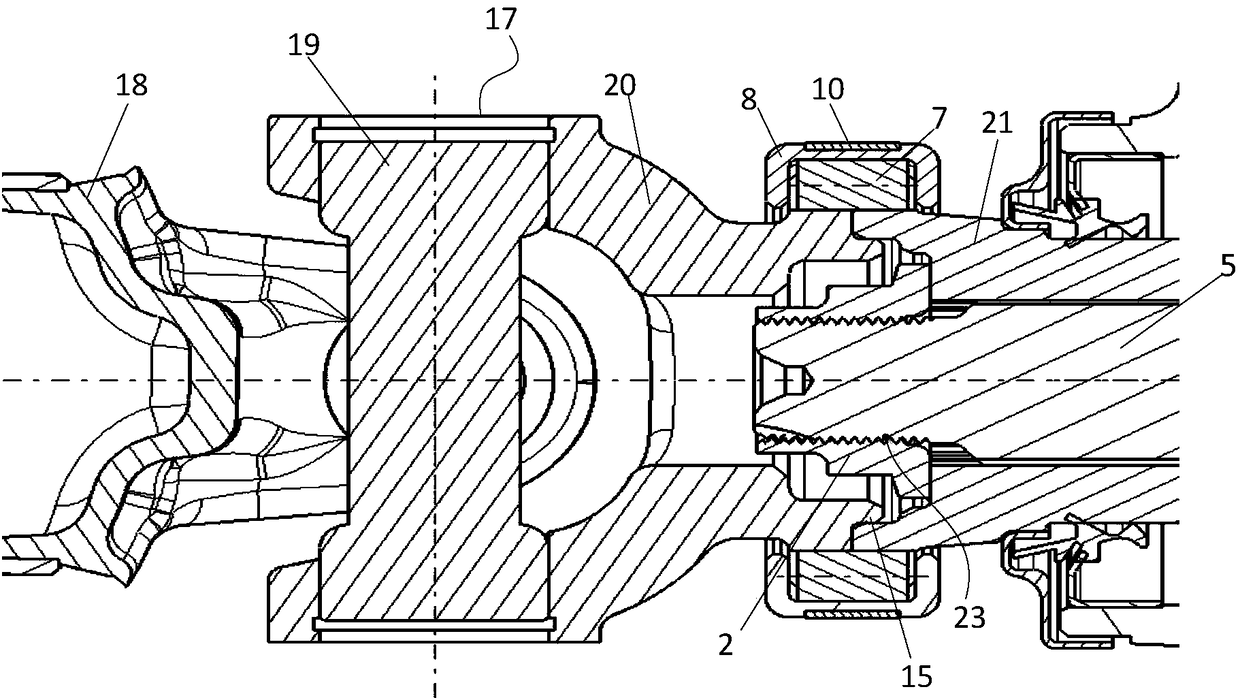

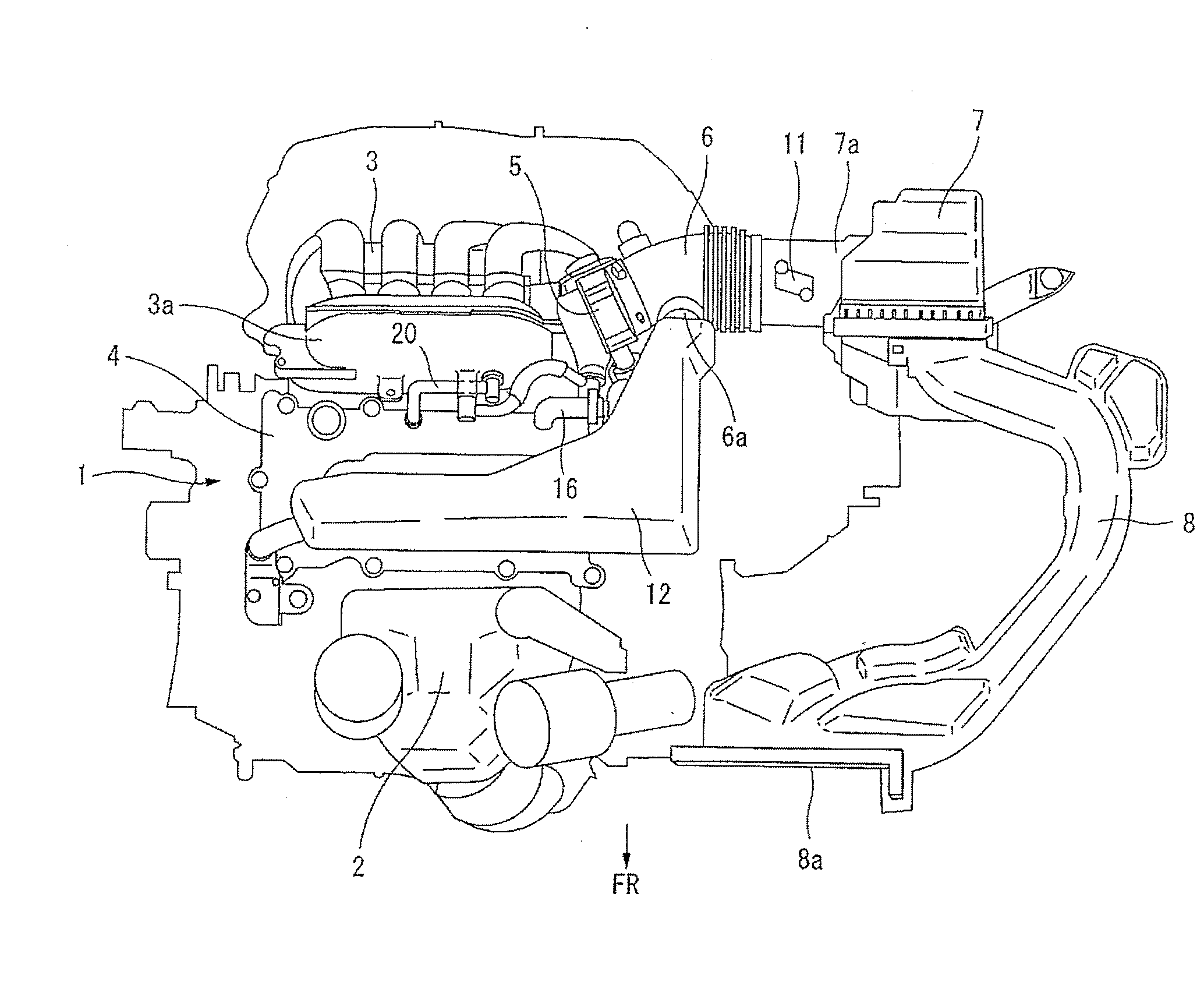

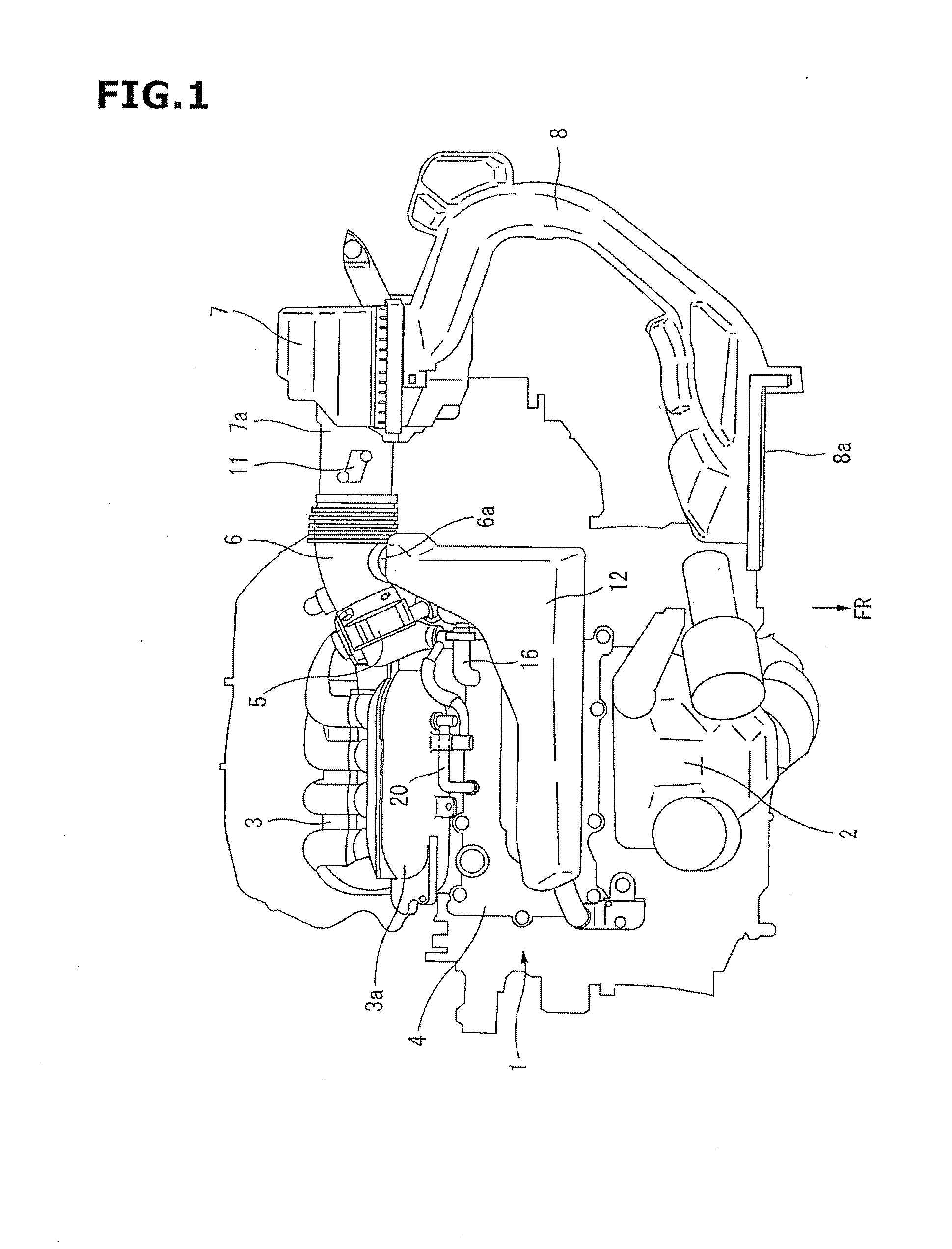

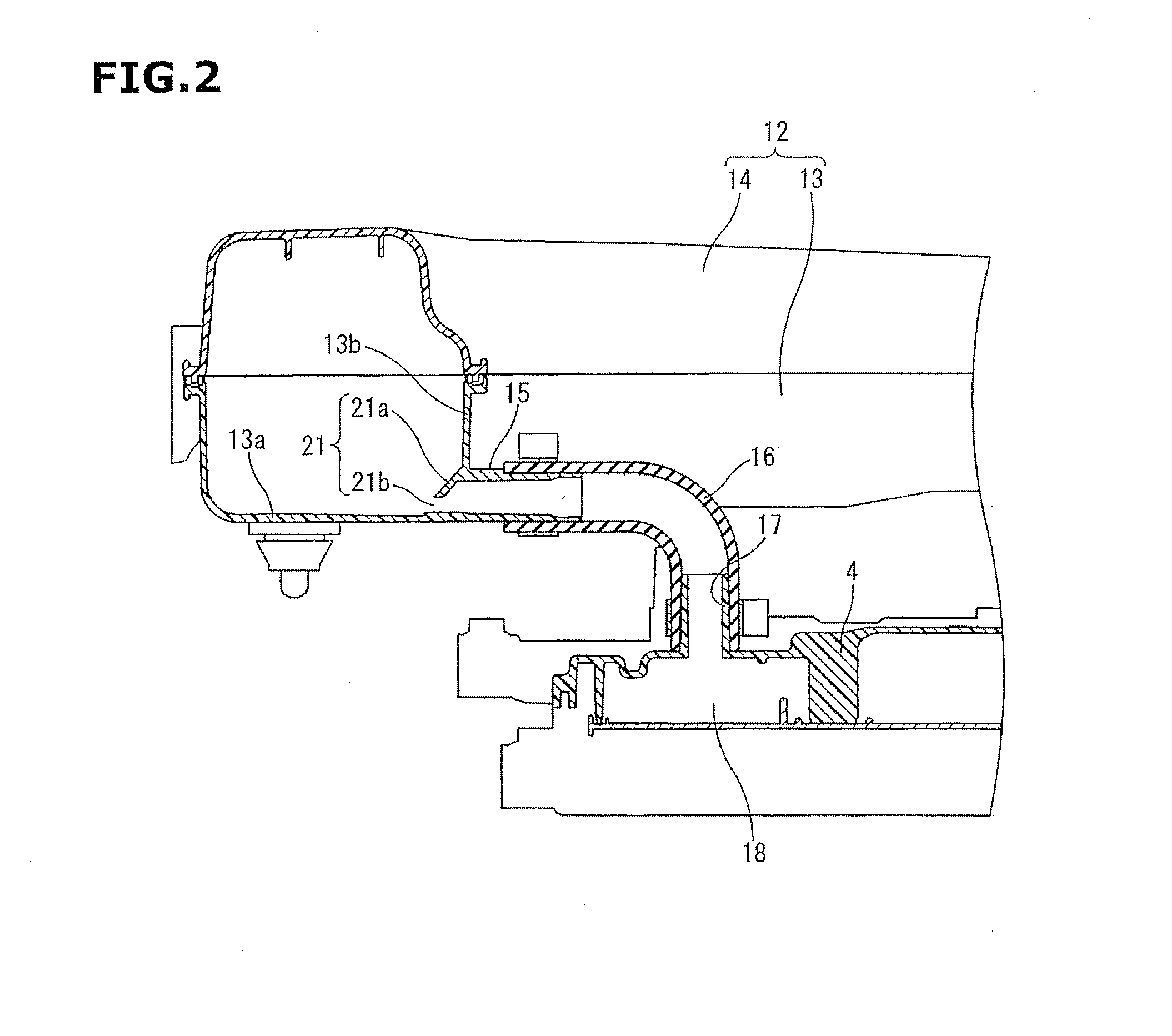

Blow-by gas treatment device for internal combustion engine

ActiveUS20160160802A1Reduce intake noiseReduce pressure pulsationInternal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineCylinder head

A resonator (12) for reducing intake air noise is connected to an intake air duct (6) connecting a throttle chamber (5) and an air cleaner case (7). This blow-by gas treatment device is equipped with a fresh air introduction passage comprising a fresh air introduction hose (16), and, a blow-by gas passage comprising a blow-by gas hose (20), with the fresh air introduction hose (16) connecting a cylinder head cover (4) and the resonator (12). A connector part (15) of the resonator (12) to which the fresh air introduction hose (16) is connected is provided with an orifice (21) formed integral with a lower body (13) formed of a synthetic resin, as a part thereof. Pulsation is effectively reduced by the throttling effect of the orifice (21) and the expansion effect of the resonator (12).

Owner:NISSAN MOTOR CO LTD

A low-noise and high-speed floating acoustic test device in a pool

ActiveCN106184662BCancel noiseReduce noiseHydrodynamic testingUnderwater equipmentNoise controlLow noise

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

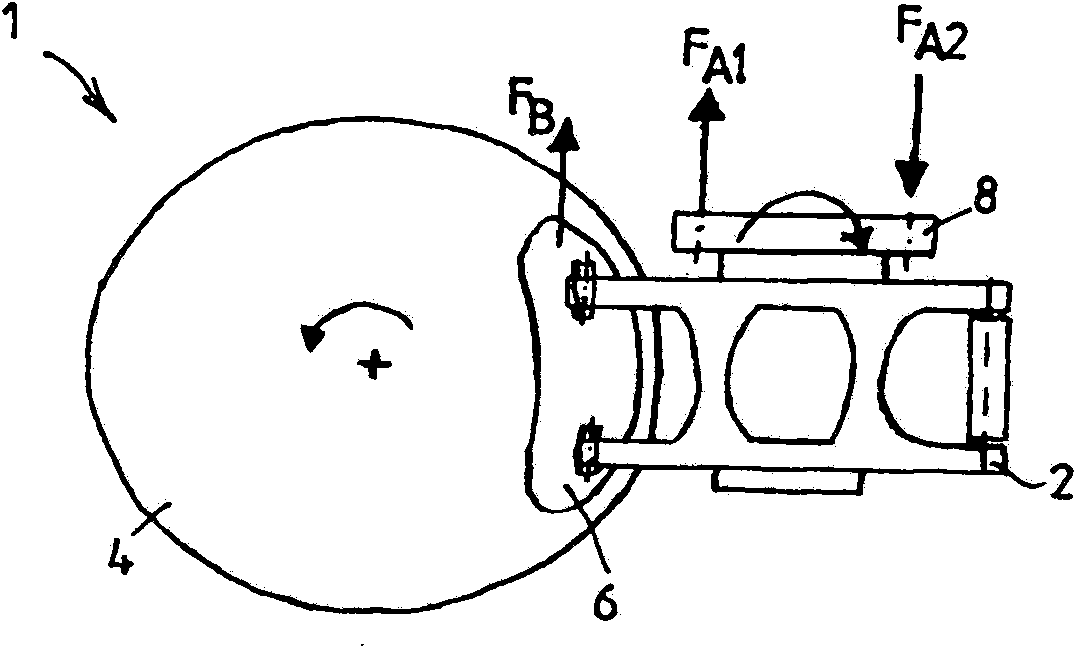

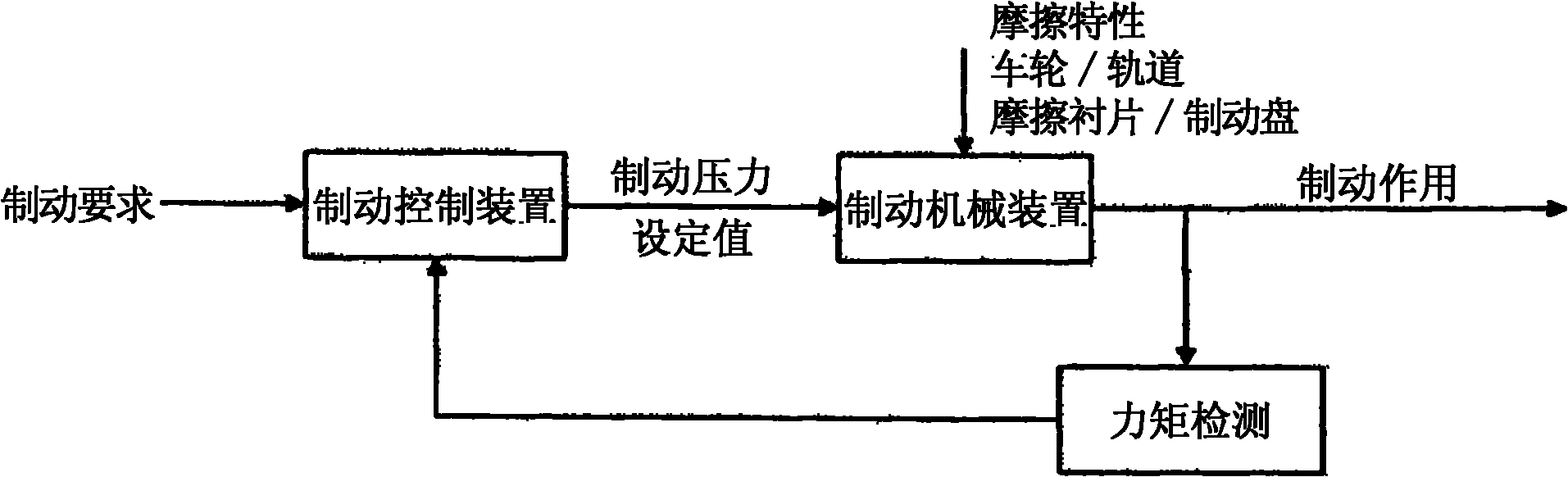

Brake system of rail vehicle with reduced stick-slip effect and control method thereof

ActiveCN102256844BBraking torque monitoringChange the pressing pressureBraking componentsActuatorBrake lining

The invention relates to a brake system (1) of a rail vehicle, having at least one brake actuator (2) comprising at least one brake disk (4) and at least one brake lining (6), which interacts with said brake disk (4), for generating a braking force in response to a braking demand. The invention provides at least one sensor device in order to measure at least one variable which represents jerky sliding motion, arising from the braking demand, between the brake disk (4) and the at least one friction lining (6), and to output a signal dependent on the measured variable to a control device which is designed so as to adapt the braking force generated by the brake actuator (2) as a function of a deviation of the measured variable from a predefined value or value range of the variable.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

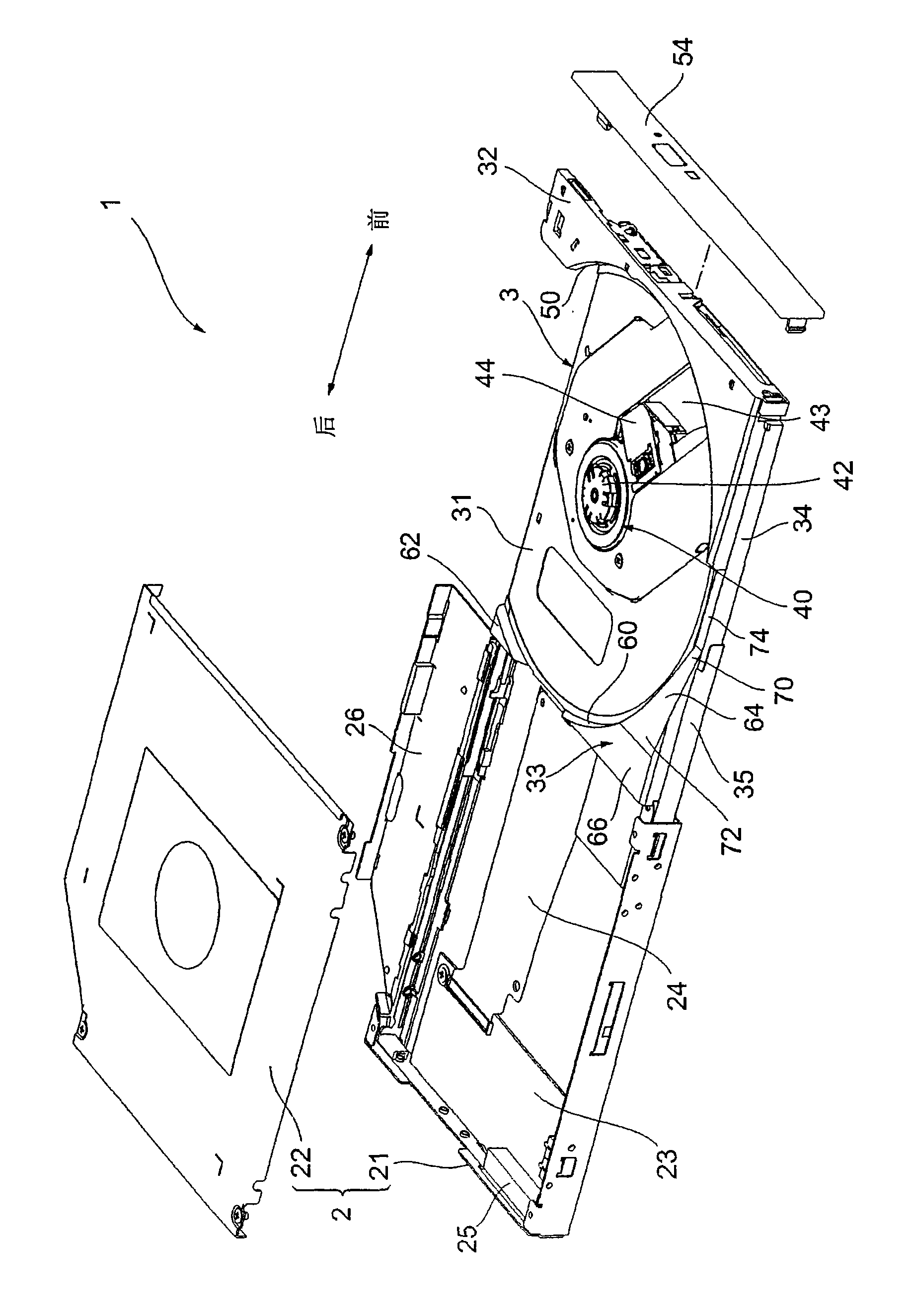

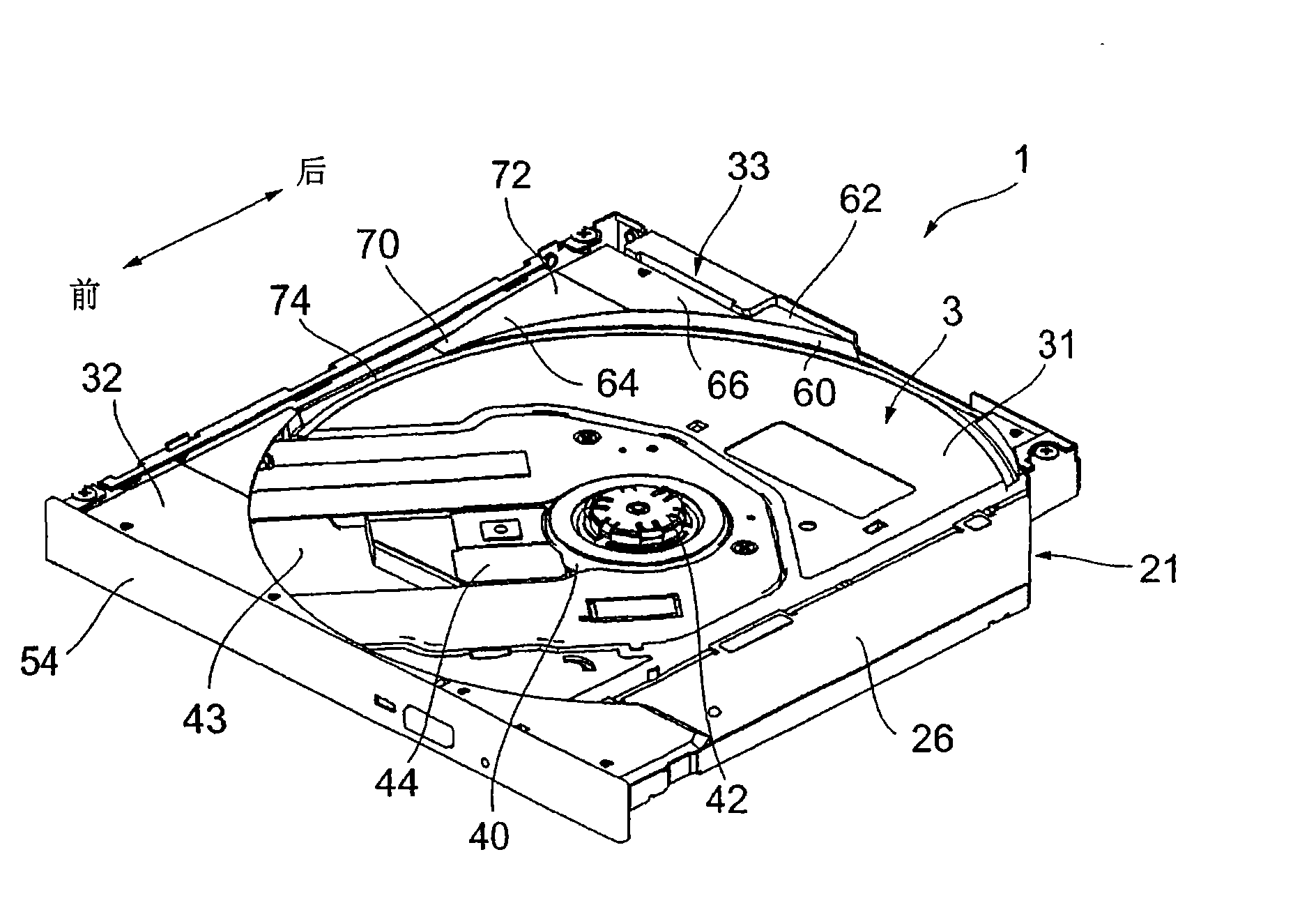

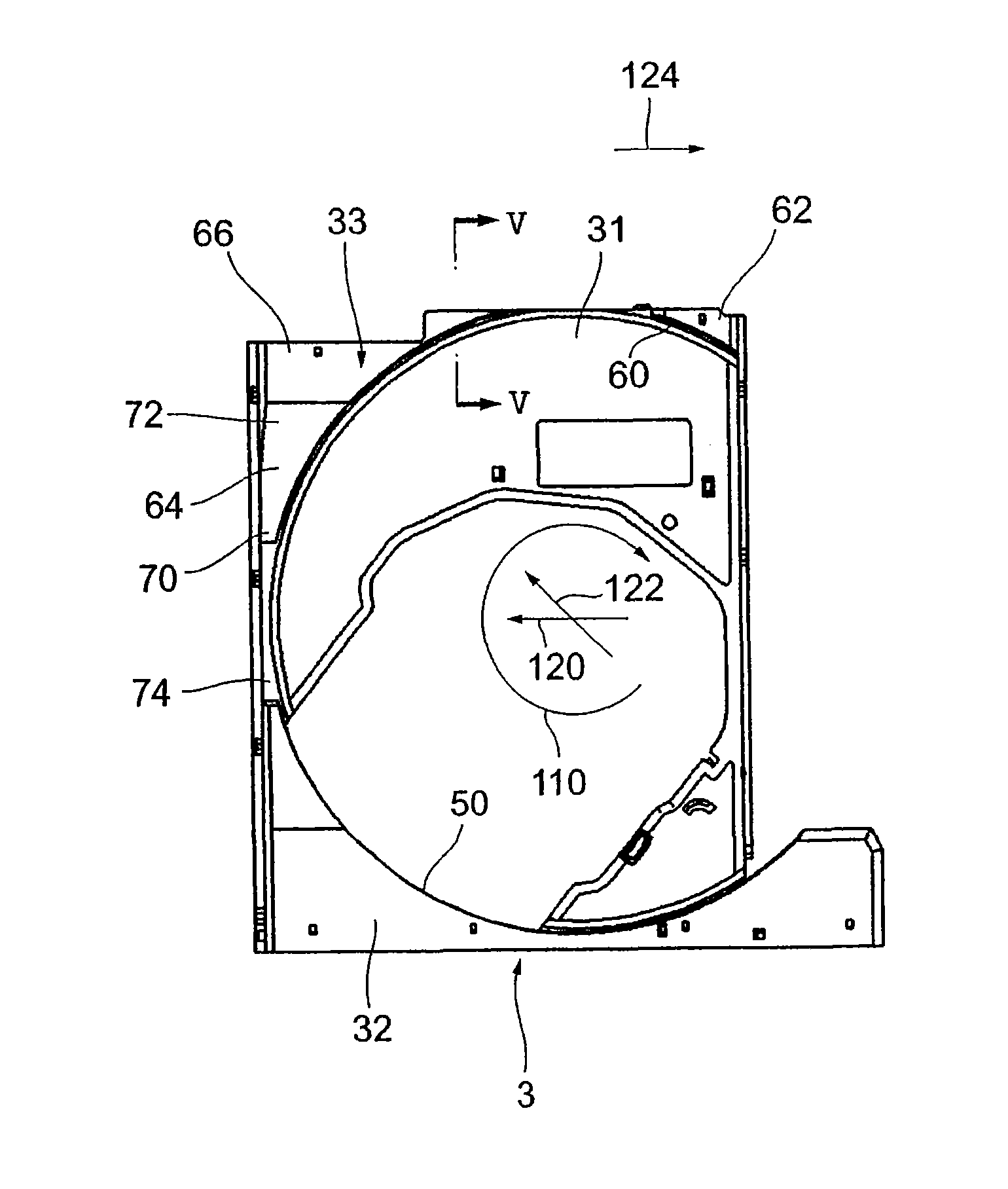

Tray of optical disk device and optical disk device including the same

ActiveCN101640050AReduce air noiseRecord information storageRecord carrier contruction detailsEngineeringOptical disc

A tray of an optical disk device and an optical disk device including the tray are provided. In a tray rear portion (33) located at a higher level than a tray bottom portion (31), a first tapered surface (60) as a draft taper and a second tapered surface (64) sloping more gently than the first tapered surface (60) are formed. An upper end (72) of the second tapered surface (64) is located fartherfrom a center of rotation of an optical disk (100) than a lower end (70), and thus air in a peripheral portion of the optical disk (100) generated during rotation of the disk is introduced along the tapered surface (64) to a rear.

Owner:HITACHI-LG DATA STORAGE

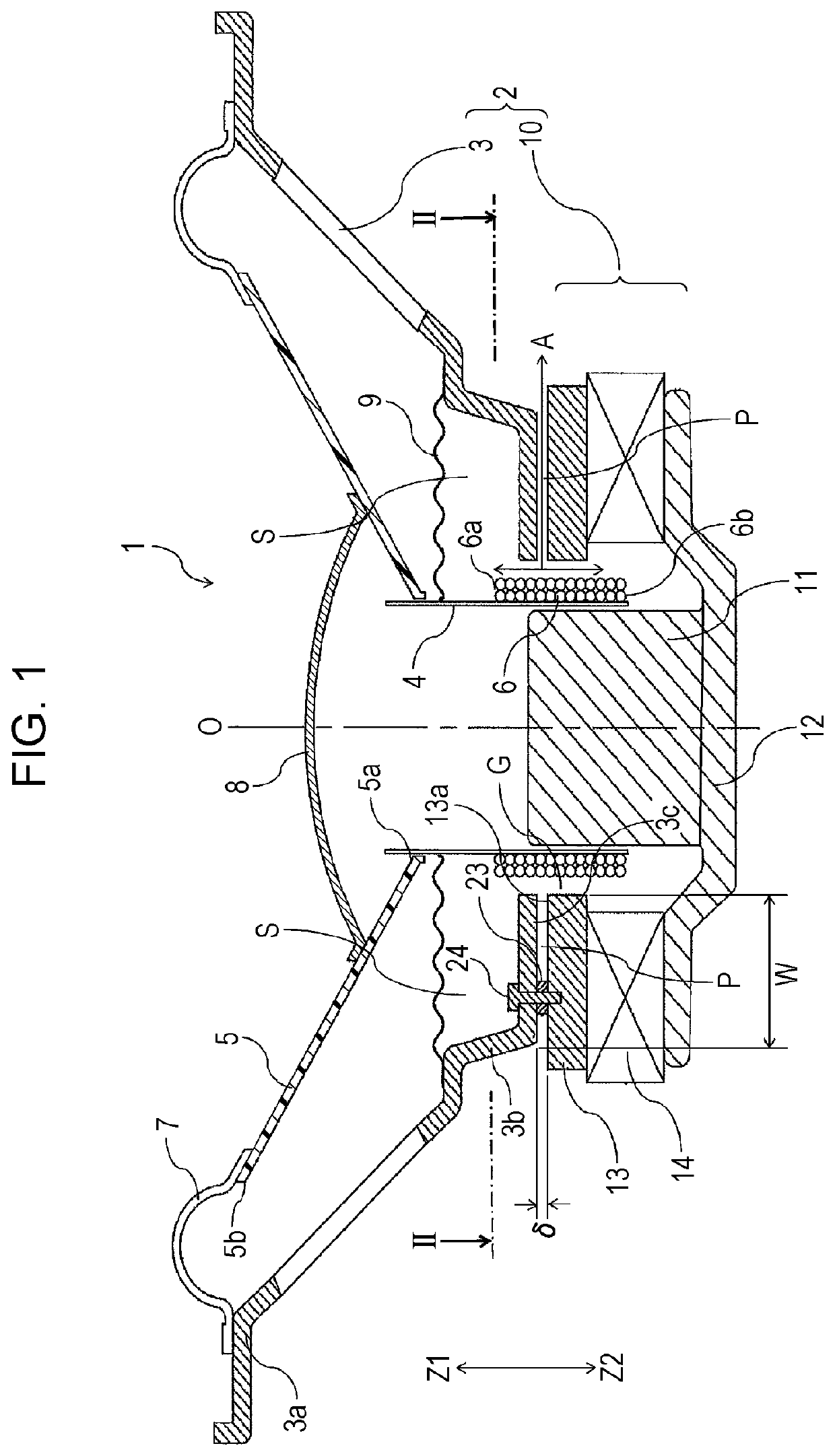

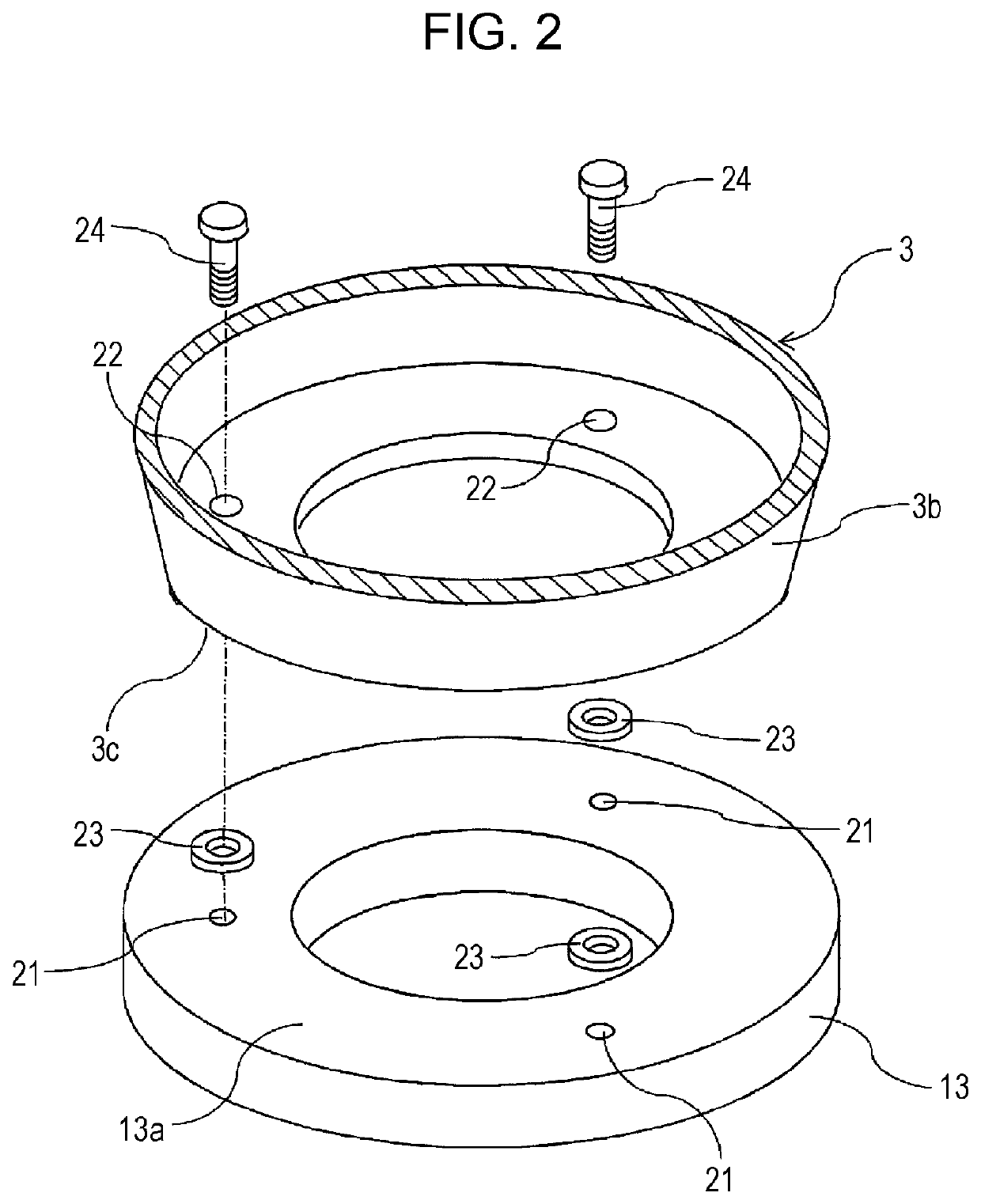

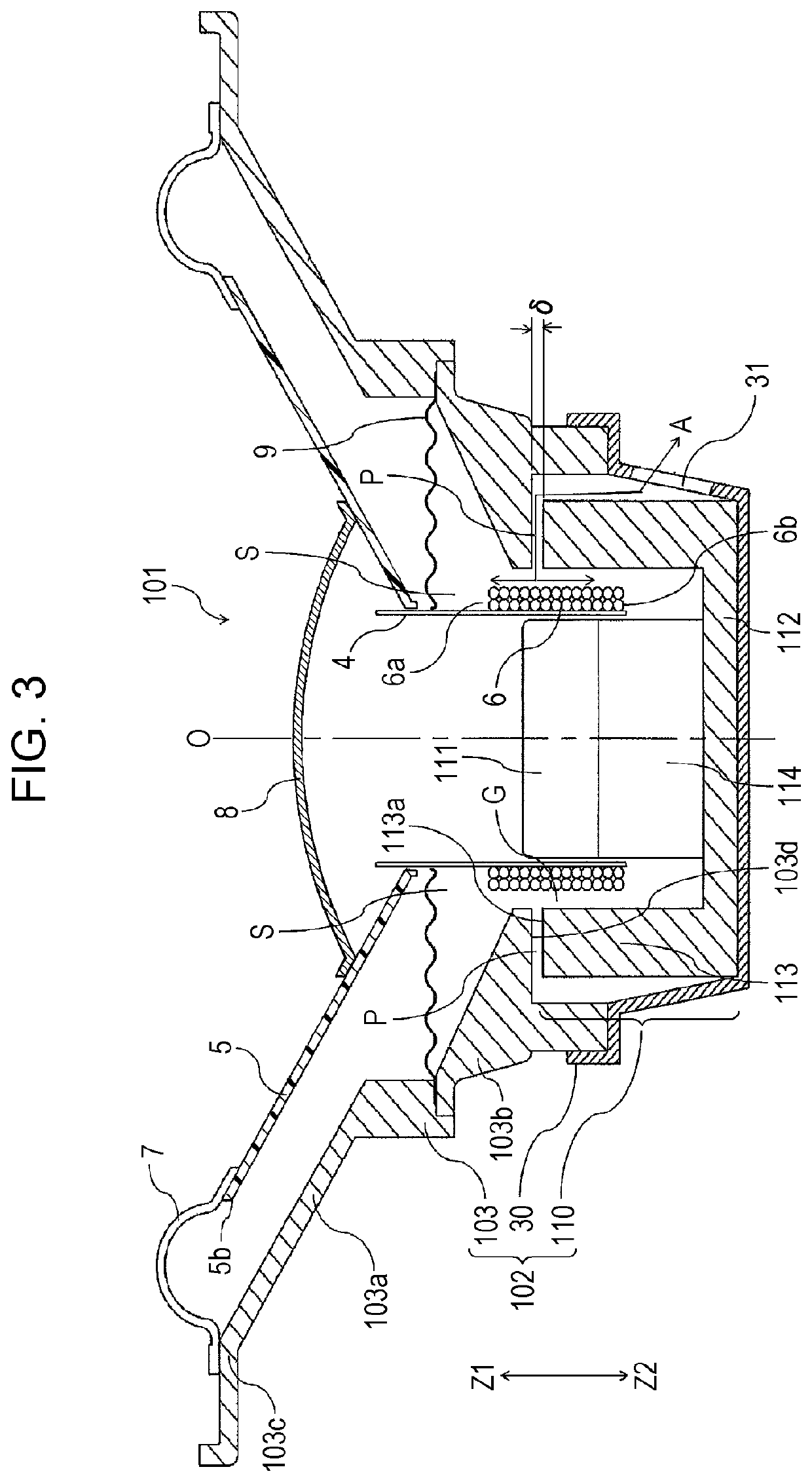

Speaker

ActiveUS10595130B2Sufficient heat dissipating effectReduce air noiseLoudspeakersPlane diaphragmsBobbinLoudspeaker

A speaker includes spacers that are disposed between a front end portion of a top yoke, which serves as a first member, and a back end portion of a back portion of a frame, which serves as a second member, to form a gap that defines an air passage. When a bobbin and a vibrating plate vibrate in a front-back direction, an airflow through the air passage, which faces a voice coil, is formed between the space around a magnetic gap and the outside. Accordingly, the voice coil is cooled over the entire circumference thereof.

Owner:ALPINE ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com