Roller chain with greater link joint height

A roller chain, high-level technology, applied in the direction of transmission chain, etc., can solve space problems, limited clearance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

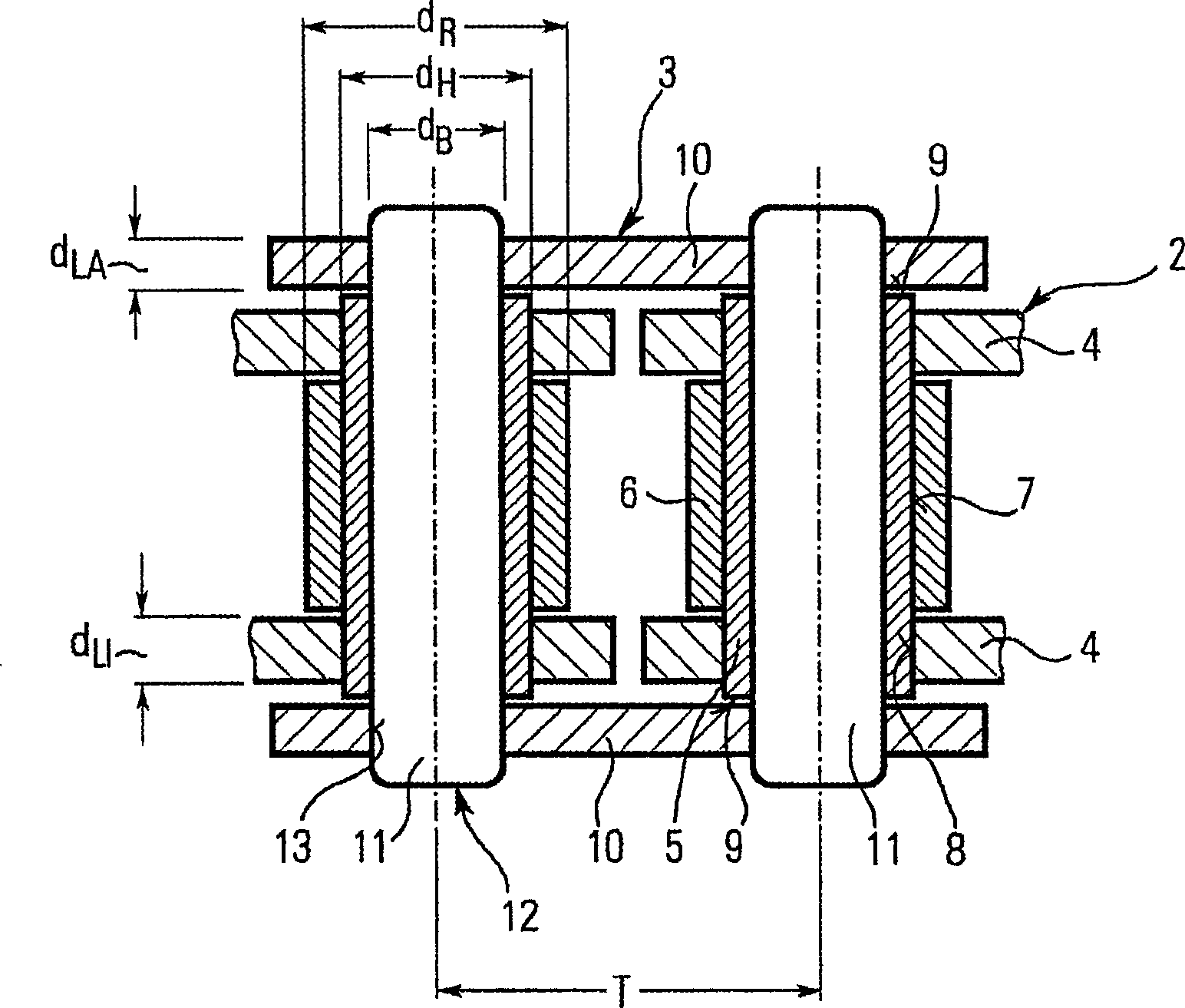

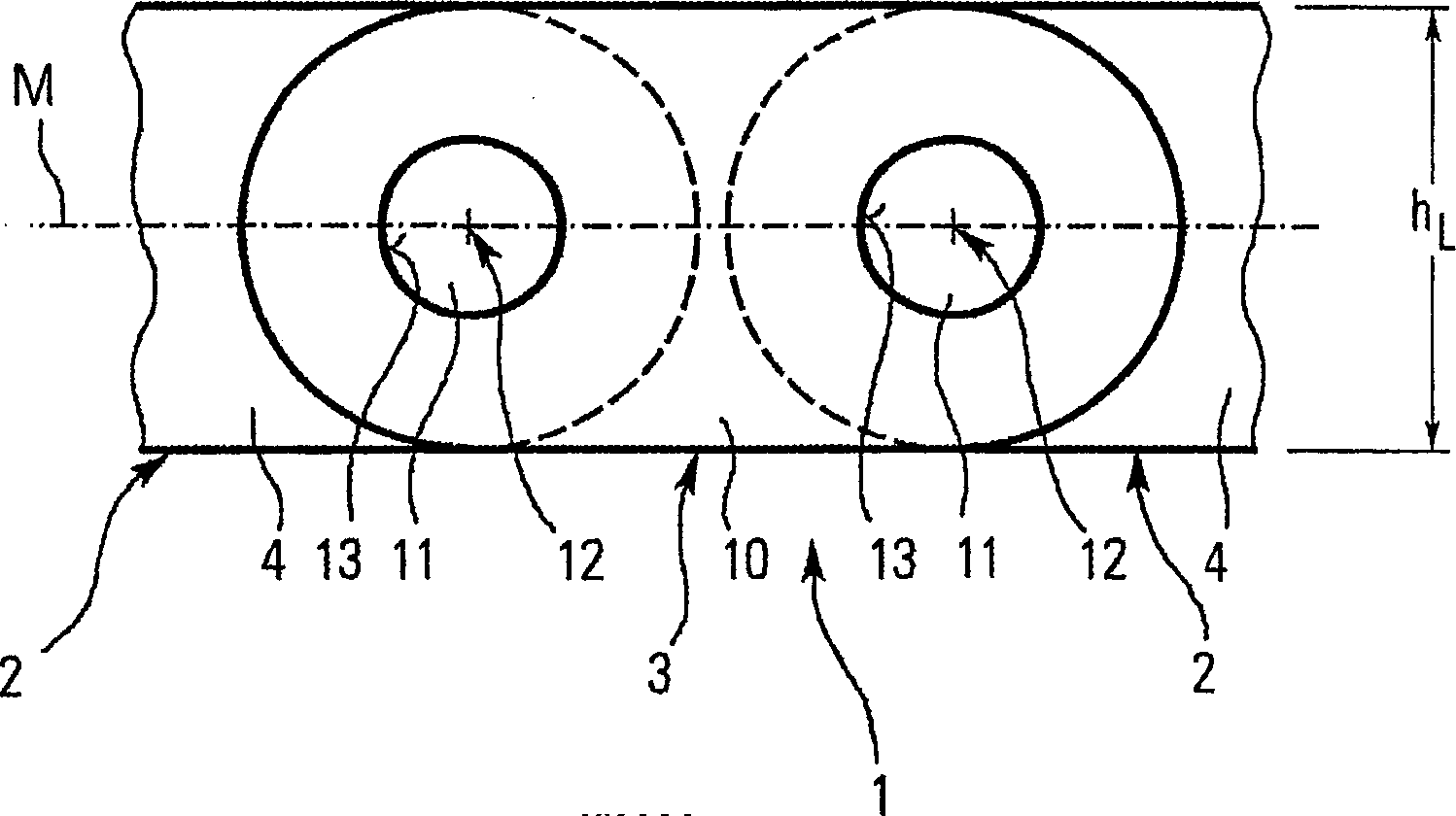

[0021] figure 1 The roller chain shown in consists of alternating inner 2 and outer 3 links.

[0022] Each inner chain link 2 includes: two parallel inner chain plates 4 spaced apart from each other, two parallel connecting sleeves 5 arranged spaced apart from each other and connecting the inner chain plates 4 to each other, and two rollers 6 , in each case one of which is supported for rotation on the outer surface 7 of the connecting sleeve 5 . The connecting sleeve 5 is pressed into the opening 8 of the inner link plate 4 , wherein the face sides 9 of the connecting sleeve 5 protrude slightly beyond the inner link plate 4 . The length of the rollers 6 is slightly shorter than the internal distance between the two inner chain plates 4 .

[0023] Each outer chain link 3 includes two outer chain plates 10 arranged at a parallel distance to each other and two connecting pins 11 arranged at a parallel distance to each other. Each connecting pin 11 passes in each case through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com