Low-noise high-speed floating acoustic test device in water tank

An acoustic test and low-noise technology, applied in fluid dynamic tests, measuring devices, transportation and packaging, etc., can solve the problems of unavoidable dragging system, high lower limit frequency, high cost, etc. Effect of device noise cancellation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

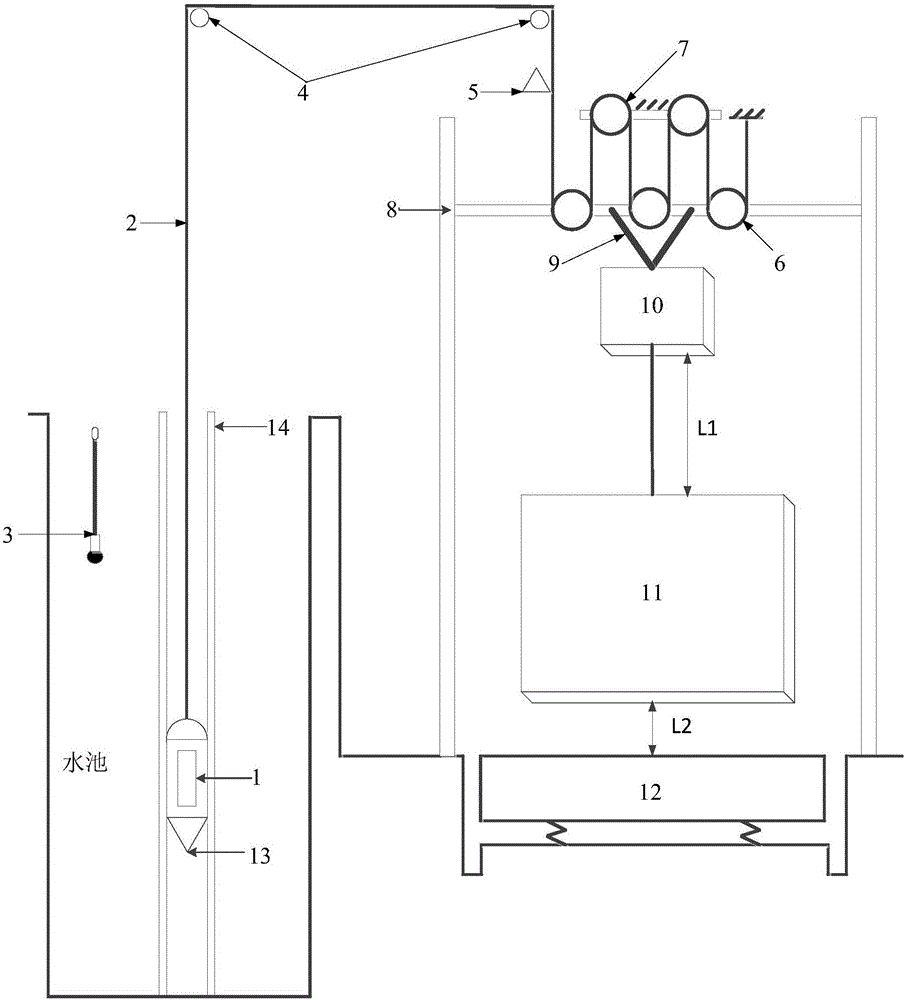

[0022] Such as figure 1 As shown, a low-noise high-speed floating acoustic test device in a pool, the test device includes a test model 1, a soft cable 2, an underwater acoustic measurement device 3, two fixed pulleys 4, an induction speedometer 5, a movable pulley block 6, Fixed pulley block 7, guide mechanism I8, connector 9, weight I10, weight II11 and vibration damping mechanism 12;

[0023] The mass of the weight I10 is less than that of the weight II11, and the outer surfaces of the weight I10 and the weight II11 are covered with rubber plates; the flexible cable 2 is laid with a hydrophobic material; the test model 1 has data collection records instrument to record the attitude, vibration and self-noise generated during the floating process of the test model; the guide mechanism I8 is composed of a horizontal rod and two vertical rods, and the two ends of the horizontal rod are slidingly matched with the two vertical rods and respectively connected with the two vertical...

Embodiment 2

[0031] Embodiment 2, on the basis of Embodiment 1, the test model is fixedly installed inside the streamlined underwater structure 13, and the streamlined underwater structure 13 is fixedly connected with the flexible cable 2, and then the floating test is carried out.

Embodiment 3

[0032] Embodiment 3, on the basis of Embodiment 1, the guide mechanism II14 is fixedly installed in the pool, and the test model 1 is installed inside the streamlined underwater structure 13; the guide mechanism II14 is composed of two vertical rods perpendicular to the water surface, and the guide mechanism The two vertical rods in II 14 are respectively in contact with the streamlined underwater structure 13, and the streamlined underwater structure 13 is fixedly connected with the flexible cable 2; then the floating test is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com