Commutator and motor

A commutator and commutator segment technology, applied in motor generator connectors, circuits, current collectors, etc., can solve problems such as short circuits, burrs on commutator segments, burrs, etc., to reduce air noise, improve EMC, The effect of avoiding the risk of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

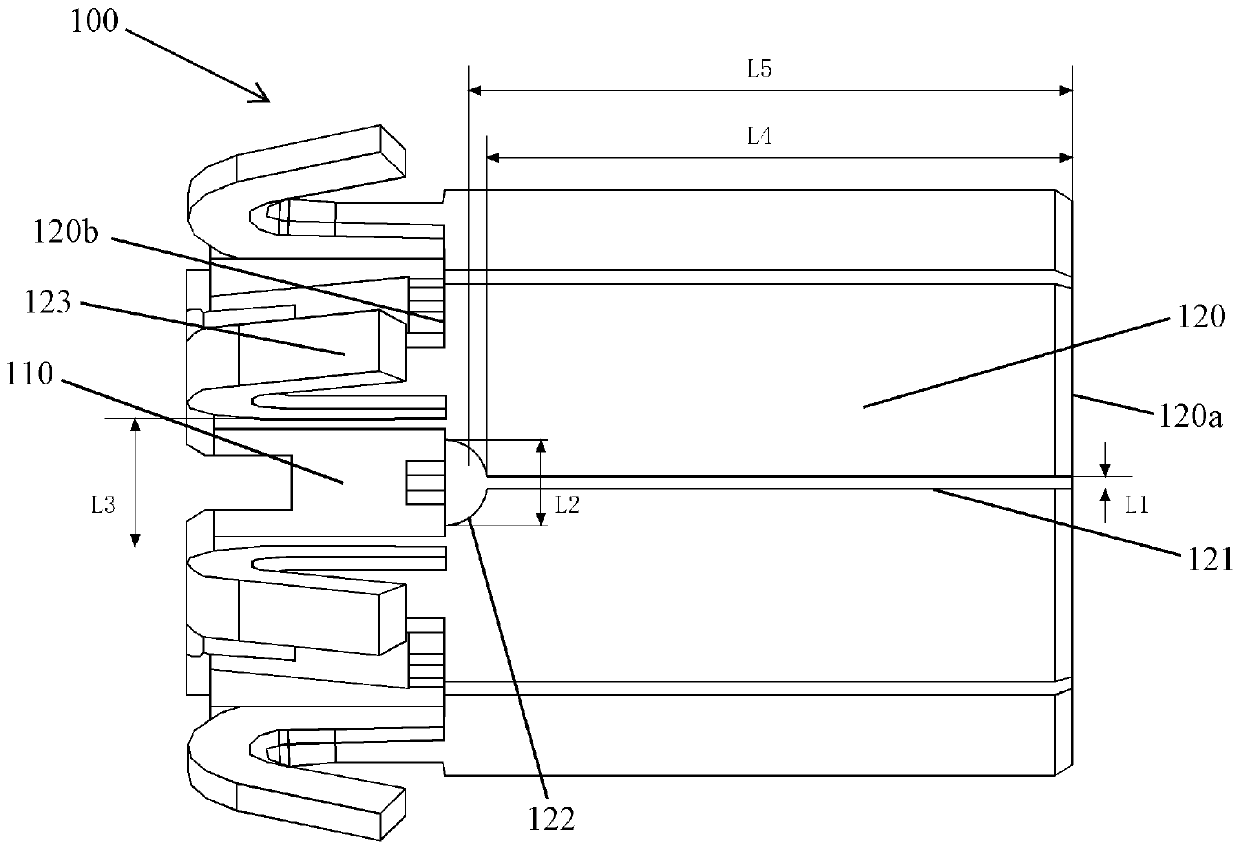

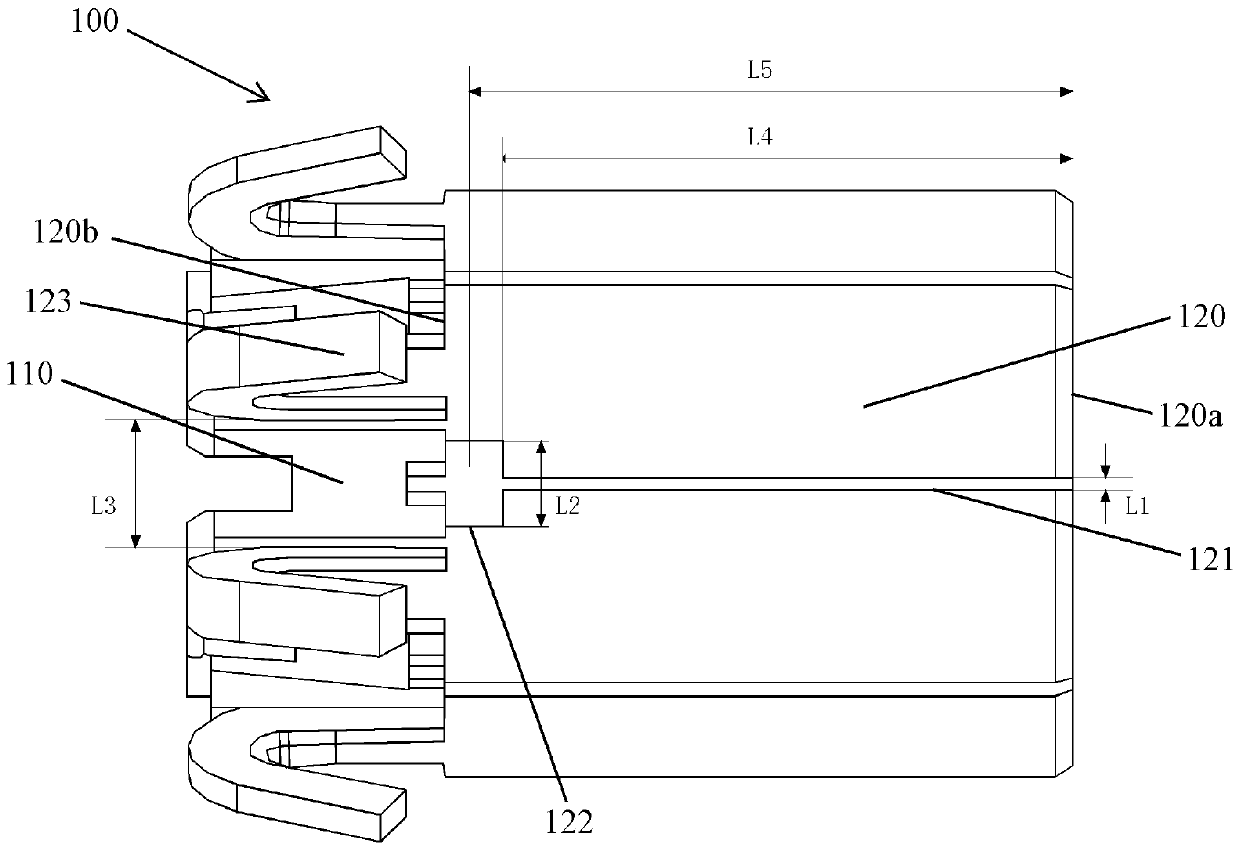

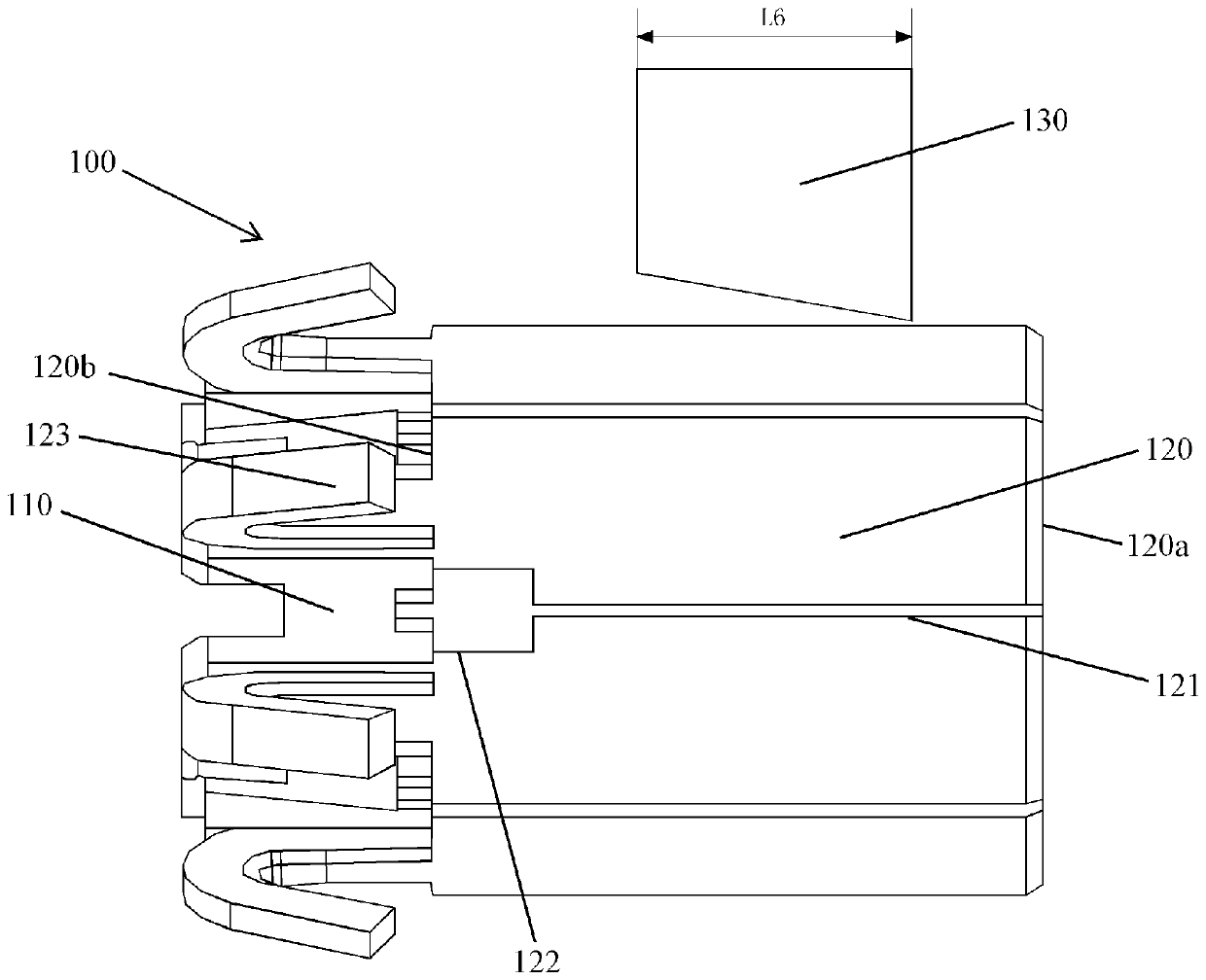

[0013] Please refer to Figure 1 to Figure 4 As shown, it provides multiple embodiments of the commutator according to the present concept. among them, Figure 1 to Figure 2 The basic component composition and the dimensional relationship of key parts of the first embodiment of the commutator are schematically shown. and image 3 and Figure 4 The composition of the basic elements and the dimensional relationships of key parts of the other two embodiments of the commutator are respectively shown.

[0014] See figure 1 and figure 2 The commutator 100 includes a commutator base 110 and a plurality of commutating segments 120. Wherein, a plurality of commutating segments 120 are arranged around the commutator base 110 in the circumferential direction. After the assembling is completed, the plurality of commutating segments 120 are substantially enclosed in a cylindrical structure. There is a gap between adjacent commutating segments 120 along the circumferential direction, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com