Energy-saving ventilation system for engineering industry

A ventilation system and industrial technology, applied in the field of energy-saving ventilation systems for engineering industry, can solve the problems that the staff cannot continue to work normally, cannot achieve ventilation, smoke exhaust, and the working environment of the personnel is bad, so as to achieve good ventilation effect and lower temperature , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

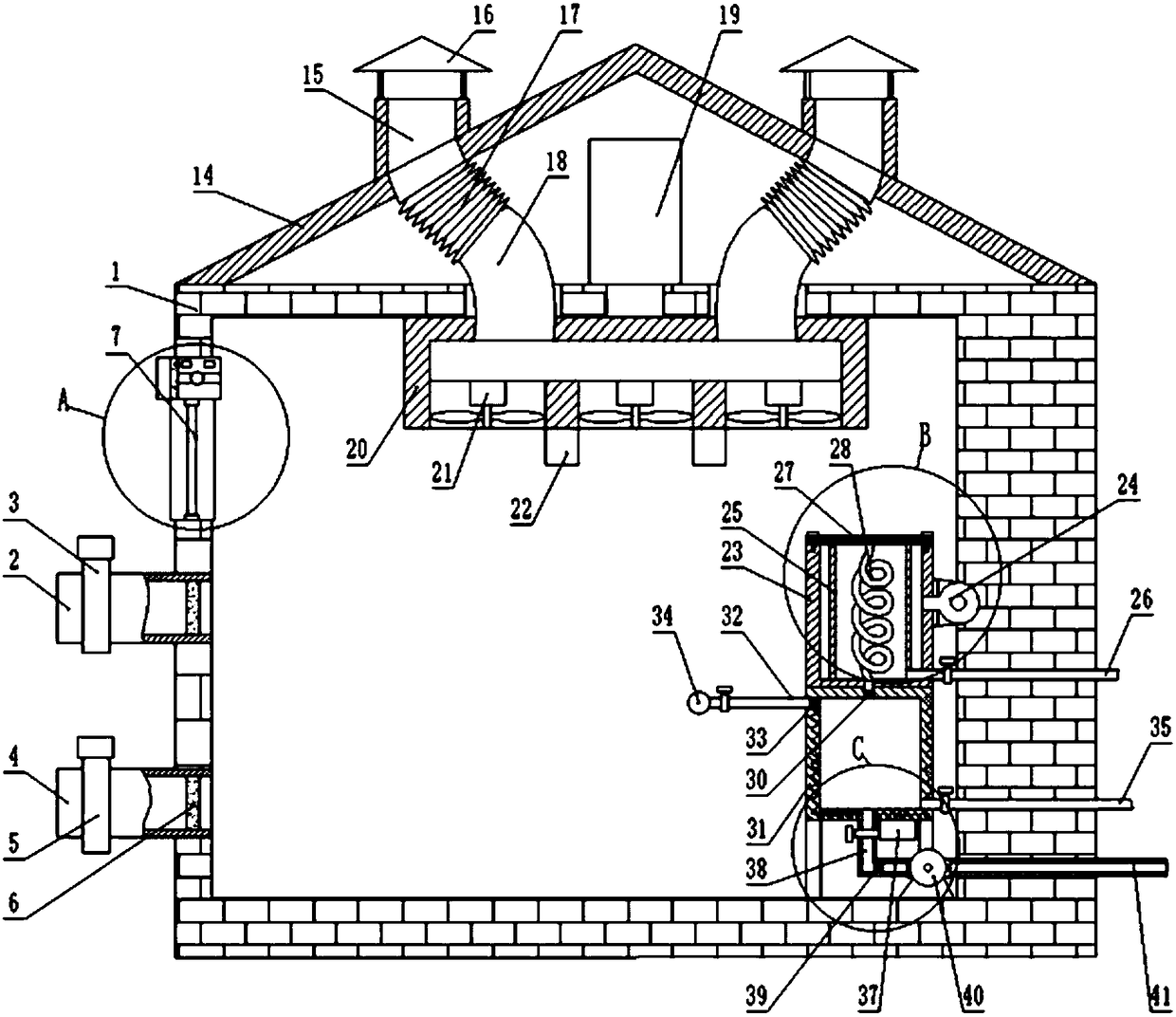

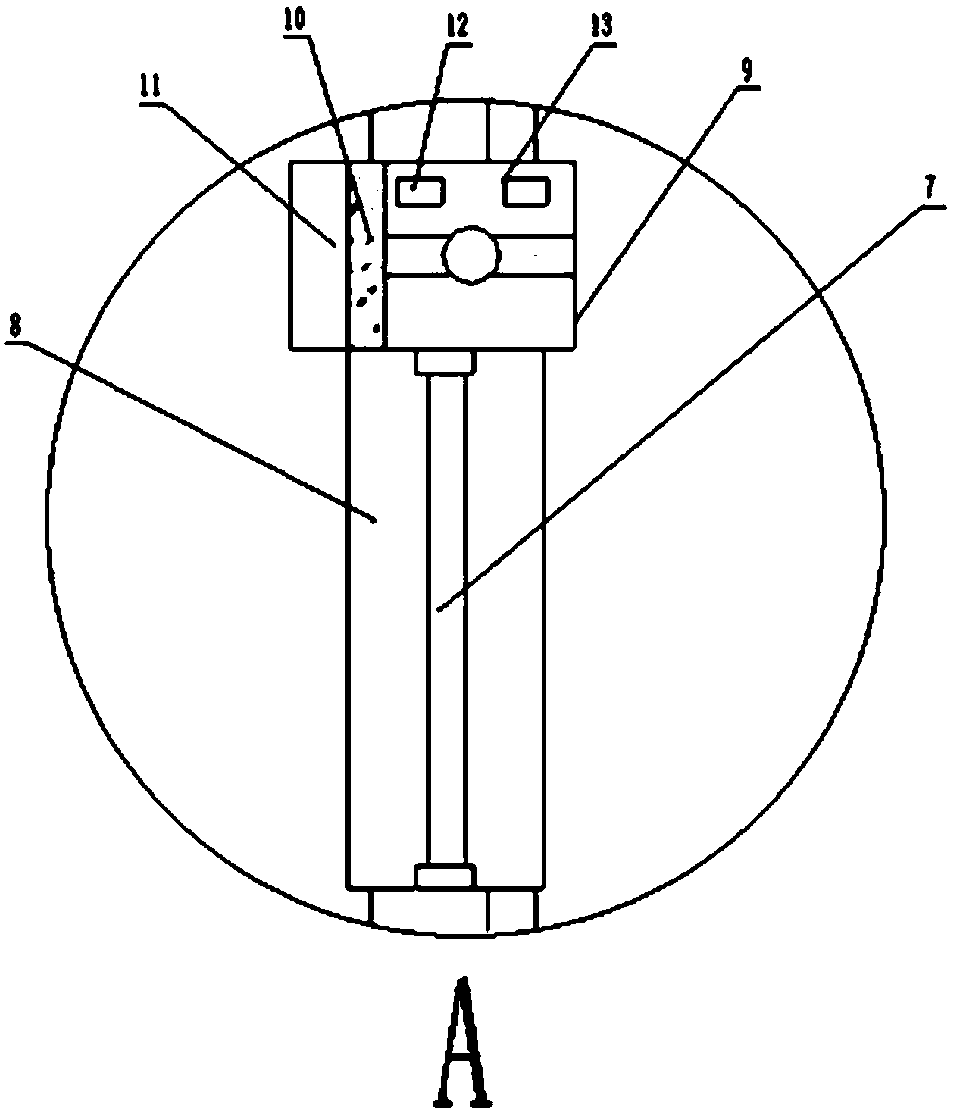

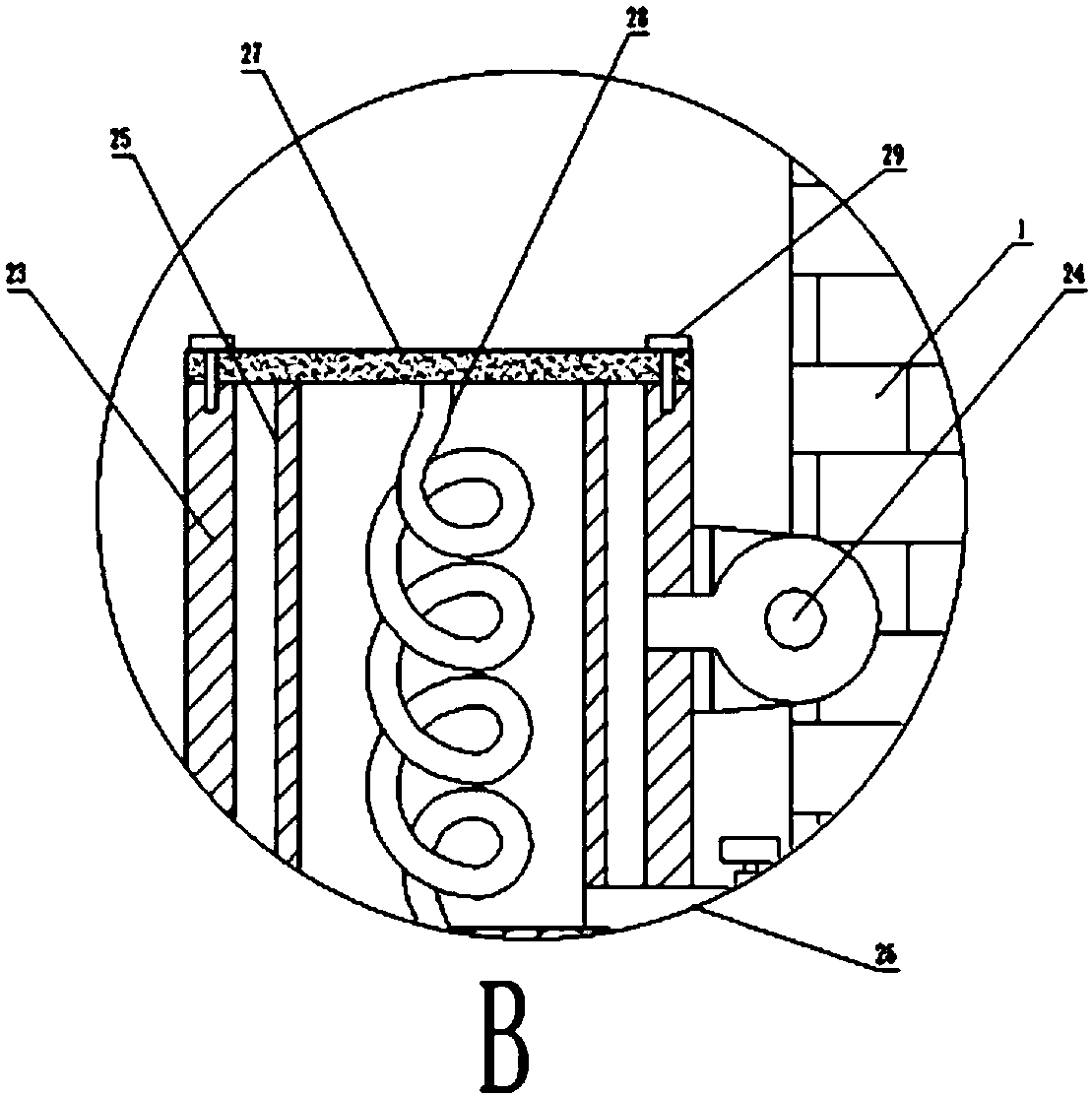

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown, an energy-saving ventilation system for engineering industry, including a factory building 1, the outer wall of the factory building 1 is fixed with an air inlet A2 and an air inlet B4 sequentially from top to bottom, and an electromagnetic control valve A3 is arranged on the air inlet A2. The air inlet B4 is provided with an electromagnetic control valve B5, the air inlet A2 and the air inlet B4 are fixed with a filter screen 6, the inner wall of the factory building 1 is fixed with a cover body 9, and the ceiling 14 of the factory building is fixed with a plurality of Air exhaust port 15, the upper end of the air exhaust port 15 is fixed with a rain cover 16 through a connecting rod, the lower end of the air exhaust port 15 is fixed with a telescopic hose 17 and communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com