High-temperature bending test deflection measuring device and measuring method

A technology of bending test and deflection measurement, which is applied in the field of test system, to achieve the effect of reducing the cost of test construction, ensuring accuracy and reliability, and simple principle

Active Publication Date: 2018-07-31

BEIHANG UNIV

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a non-optical deflection test device suitable for high temperature (room temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

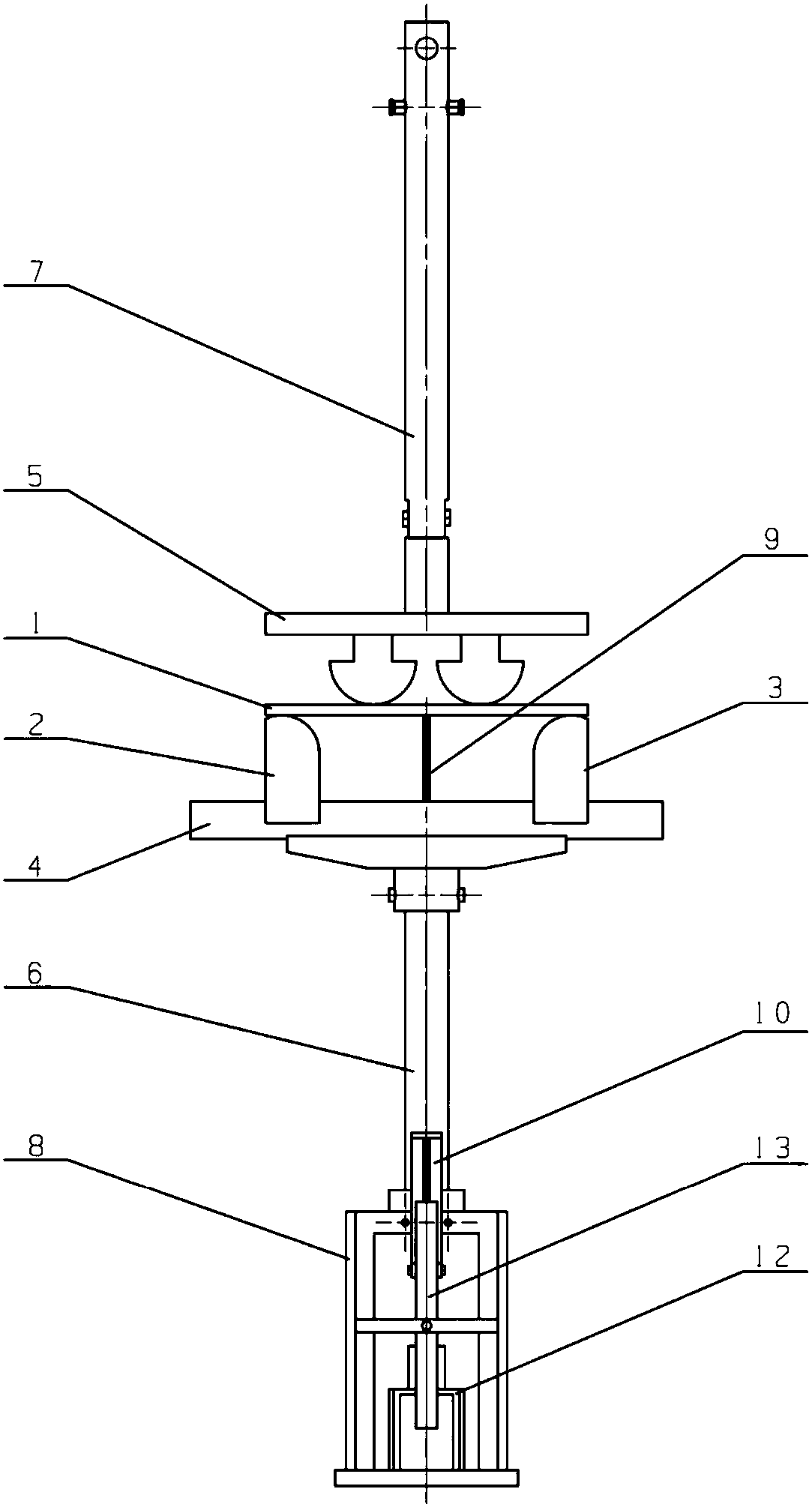

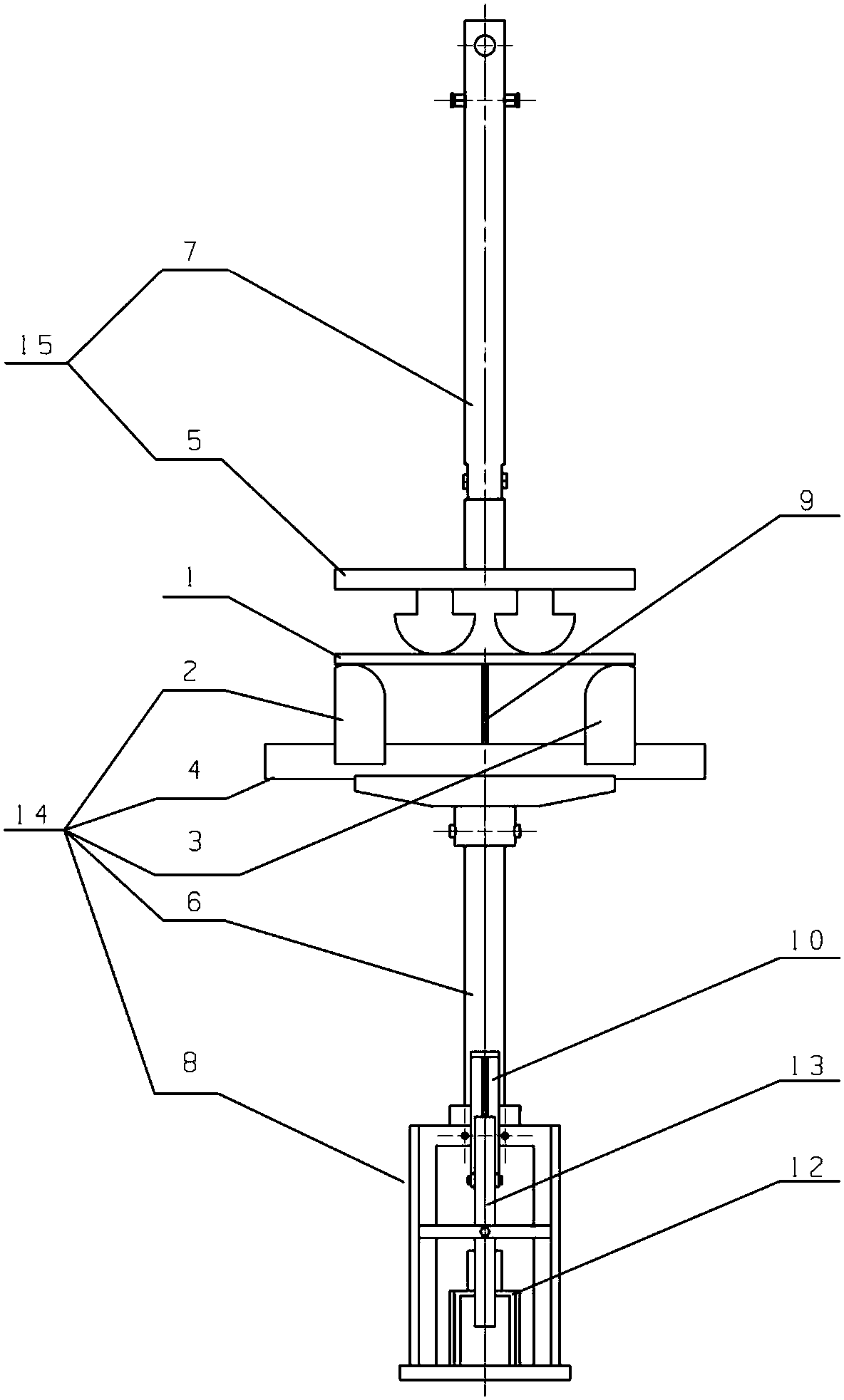

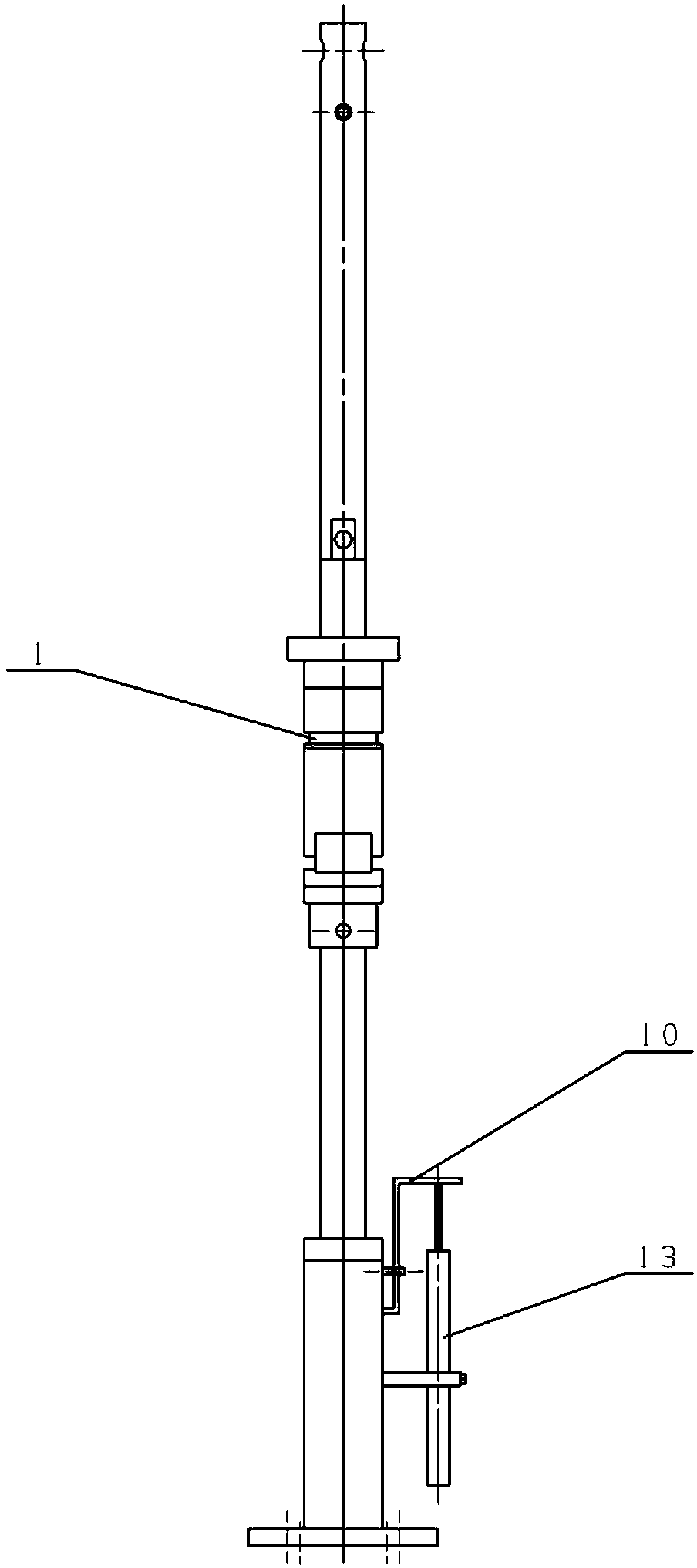

The invention discloses a high-temperature bending test deflection measuring device and a measuring method. An environment box is internally provided with a three-point or four-point bending fixture,and the deflection of a tested sample is transmitted to a displacement sensor outside the environmental box by a measuring extension rod and a Z-shaped frame. The bending fixture includes a first pressure bar assembly and a second pressure bar assembly movable relative to the first pressure bar assembly, the axes of the first pressure bar assembly and the second pressure bar assembly are coincident; the end of the first pressure bar assembly is provided with a first pressure roller and a second pressure roller for supporting test ends of the sample; the second pressure bar assembly is providedwith an upper pressure roller for applying pressure to the sample. The high-temperature bending test deflection measuring device is free from dependence on an optical measuring system, and avoids direct contact with a high temperature component when the displacement sensor is used, thereby effectively ensuring the accuracy and reliability of the high temperature bending test deflection measurement.

Description

technical field [0001] The invention discloses a test system suitable for realizing a material bending test and measuring deflection under a high temperature condition not exceeding 1000°C, and belongs to the technical field of material performance testing. Background technique [0002] Bending test is an important means of testing the mechanical properties of materials. The deflection is one of the core measurement parameters of the bending test. In the normal temperature bending test, the displacement sensing device is usually directly contacted with the sample to measure the bending deflection of the sample. However, in the research and development of aerospace-related materials, the bending test of some materials needs to be carried out in a high-temperature (room temperature to 1000°C) environment. At this time, the displacement sensor cannot be close to the high-temperature sample and cannot effectively measure the bending deflection of the sample. At present, the non-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/20G01N3/02G01B21/32G01D21/02

CPCG01B21/32G01D21/02G01N3/02G01N3/20G01N2203/0023G01N2203/0226G01N2203/0676G01N2203/0682

Inventor 石多奇程震王鹏腾雪峰杨晓光

Owner BEIHANG UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com