Fastening device for fuel cell stack

A fuel cell stack and fastening device technology, which is applied to fuel cells, circuits, electrical components, etc., can solve problems such as complex operation, increased volume and weight of fuel cells, consistent fastening force, and very high requirements for stacking processes, and achieves The length is easy to adjust, the production cost is low, and the effect of force is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

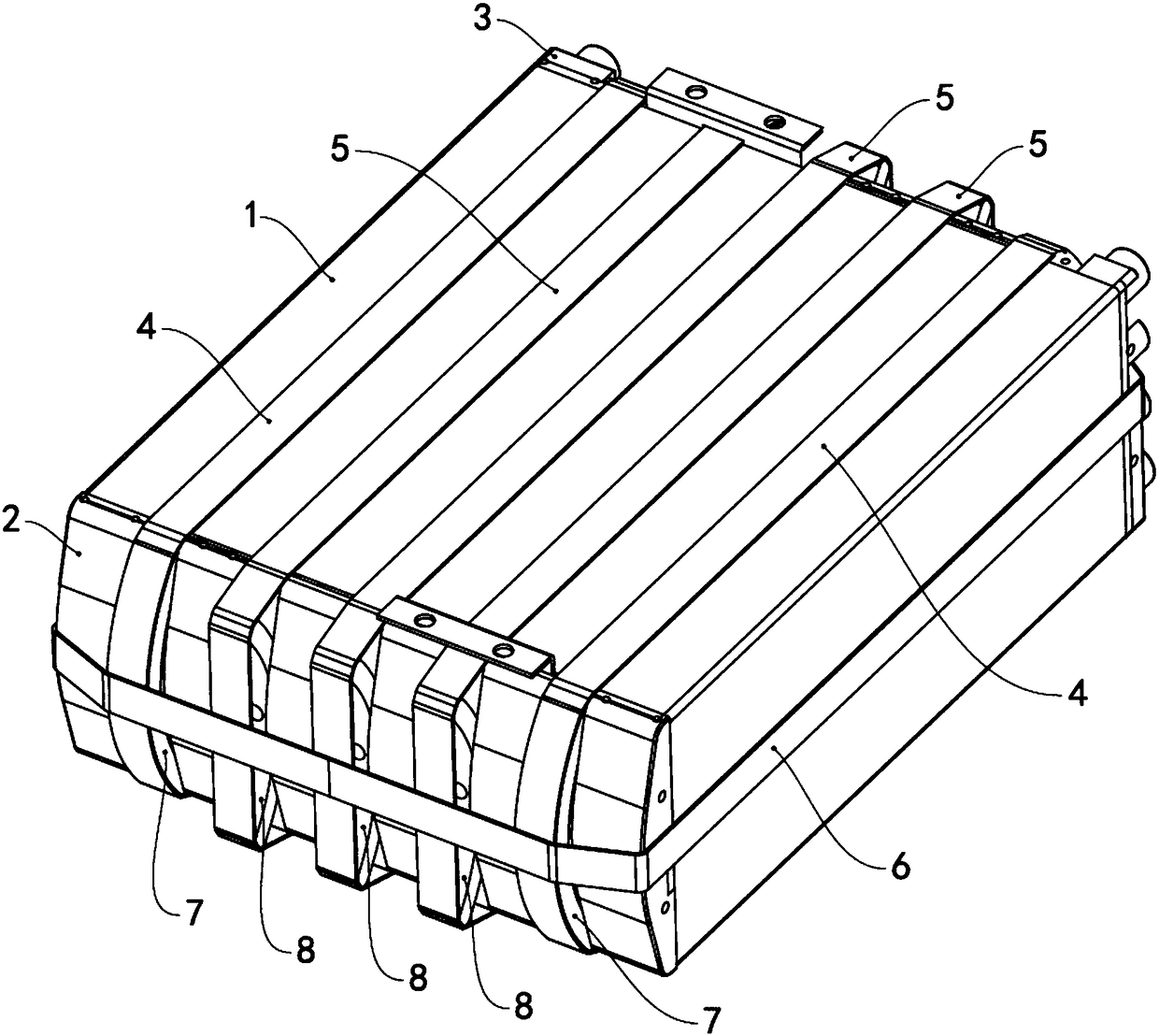

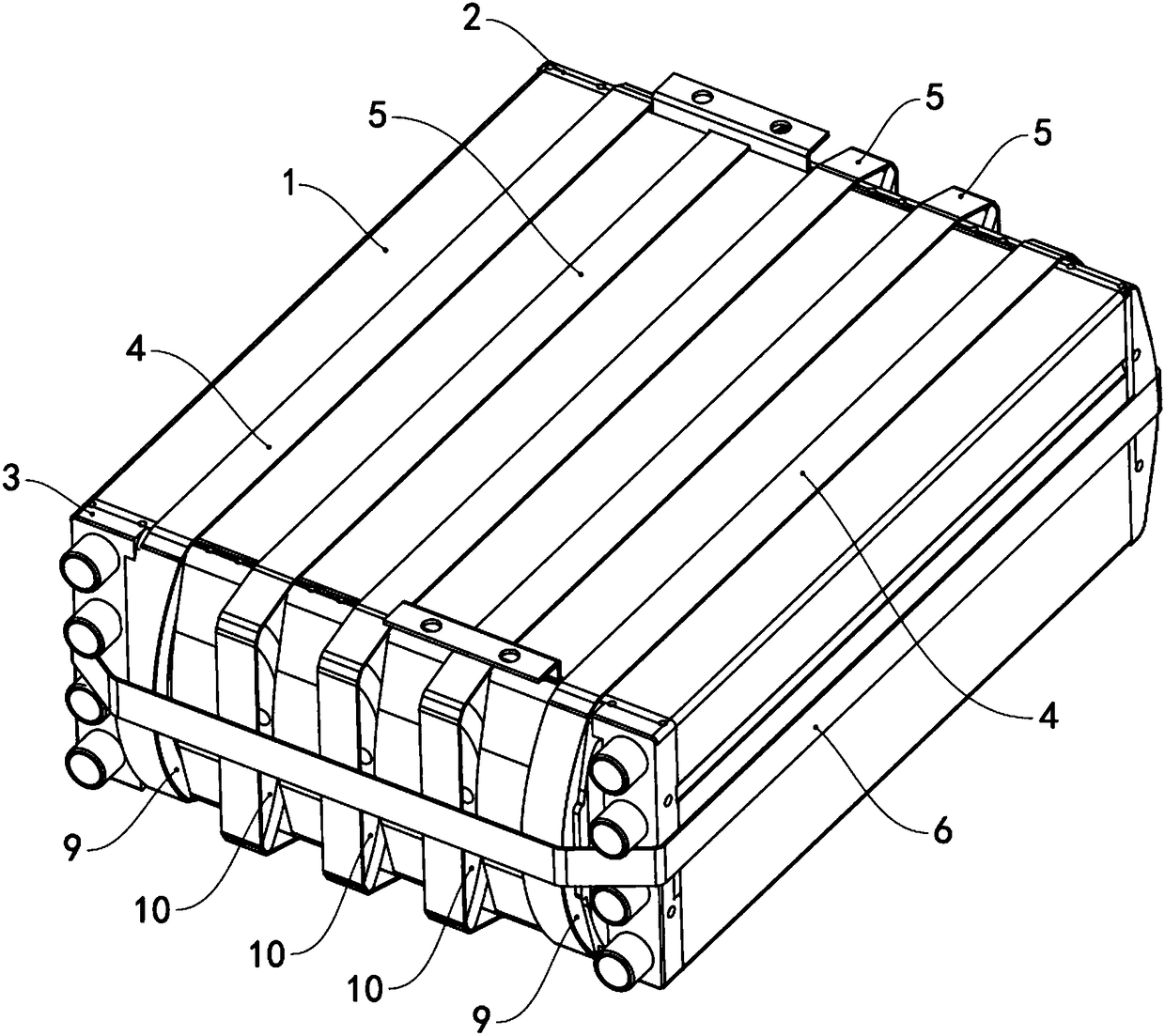

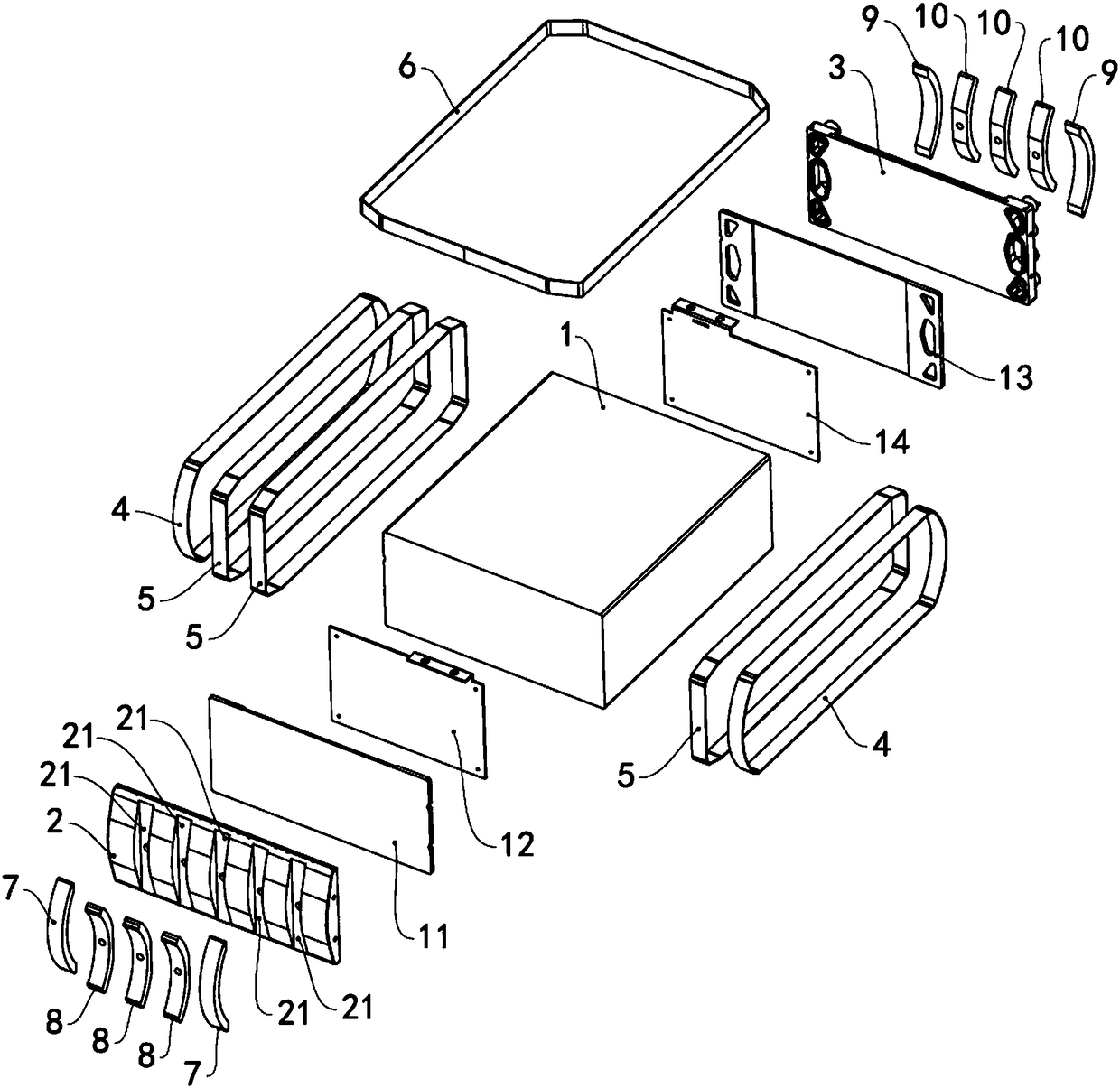

[0023] see Figure 1 to Figure 6 The fastening device of the fuel cell stack includes a front tail plate 2, a rear tail plate 3, a first anti-arc portion 8, a first positive arc portion 7, a second anti-arc portion 10, a second positive arc portion 9, a first tie Belt 5, second strap 4, third strap 6, first current collecting plate 12, first insulating plate 11, second current collecting plate 14 and second insulating plate 13, front tail plate 2 and rear tail plate 3 They are respectively arranged at both ends of the stacking direction of the fuel cell stack 1 . The first insulating plate 11 is located between the front tail plate 2 and the first collector plate 12 , and the first collector plate 12 is connected to one end of the fuel cell stack 1 . The second insulating plate 13 is located between the rear end plate 3 and the second collector plate 14 , and the second collector plate 14 is connected to the other end of the fuel cell stack 1 .

[0024] The arc surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com