Method for producing eight-membered oxygen ring zeolite and aei-type zeolite

A manufacturing method, technology of oxygen-ring zeolite, applied in chemical instruments and methods, separation methods, crystalline aluminosilicate zeolite, etc., can solve problems such as complicated procedures and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] From the viewpoint of ease of preparation of the pre-reaction mixture and production efficiency, the amount of the aluminum atom raw material (including the above-mentioned specific aluminosilicate zeolite) used is based on the amount of aluminum (Al) in the aluminum atom raw material and The molar ratio of silicon (Si) contained in the raw material mixture is usually 0.02 or more, preferably 0.04 or more, more preferably 0.06 or more, and still more preferably 0.08 or more. The upper limit of the amount of the aluminum atom raw material used is not particularly limited, but from the viewpoint of uniformly dissolving the aluminum atomic raw material in the pre-reaction mixture, the above-mentioned molar ratio is usually 2 or less, preferably 1 or less, more preferably 0.4 or less, More preferably, it is 0.2 or less.

[0077] When an aluminum atom raw material other than the above-mentioned specific aluminosilicate zeolite is used in combination as the aluminum atom raw ...

Embodiment

[0250] Hereinafter, although an Example demonstrates this invention concretely, unless the summary is exceeded, this invention is not limited to a following Example.

[0251] 〔Analysis·Evaluation〕

[0252] Analysis and performance evaluation of the zeolites obtained in the following Examples and Comparative Examples were performed by the following methods.

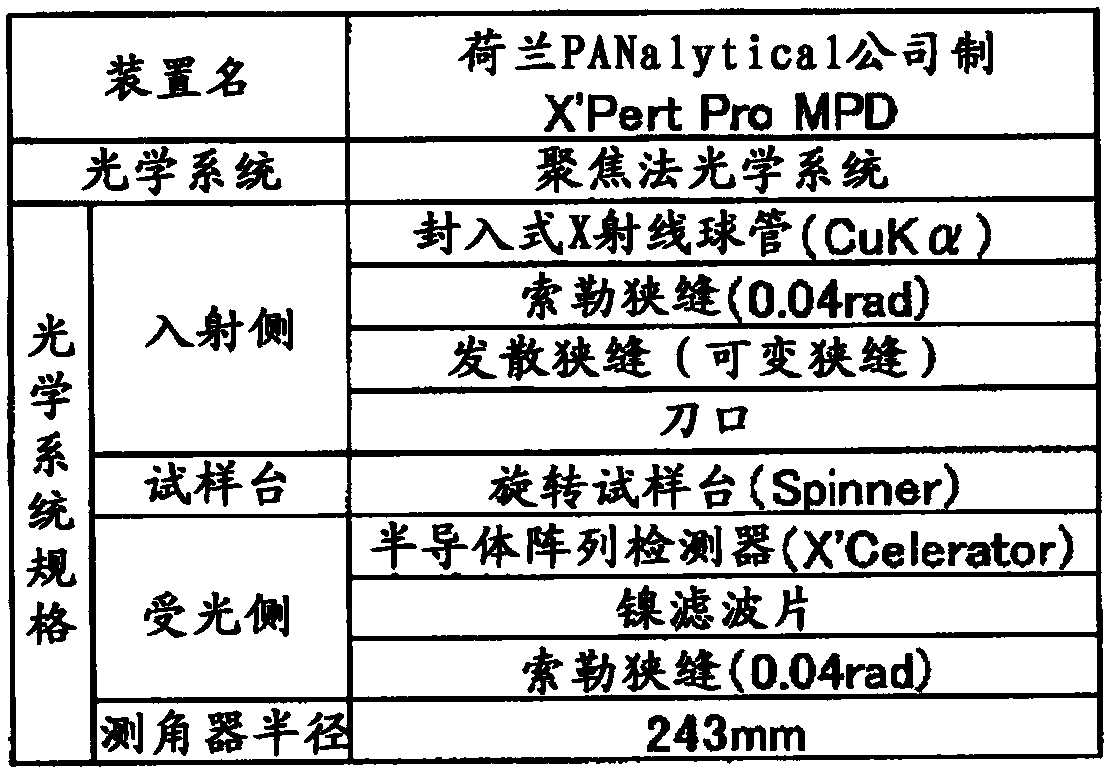

[0253] [Measurement of powder XRD]

[0254]

[0255] About 100 mg of a zeolite sample pulverized manually using an agate mortar was used with a sample holder of the same shape to make the sample amount constant.

[0256]

[0257] The powder XRD measurement device specifications and measurement conditions are as follows.

[0258] [Table 1]

[0259]

[0260]

[0261]

[0262] [Analysis of Cu content and zeolite composition]

[0263] The content of Si and Al in the zeolite used as a standard sample and the elemental analysis of contained copper atoms are as follows.

[0264] After dissolving the zeolite samp...

Embodiment I-1

[0279] 9.083 g of water, 8.415 g of 35% by weight tetraethylammonium hydroxide (TEAOH) (manufactured by SACHEM) and 0.412 g of NaOH (manufactured by Kishida Chemical: 97% by weight) as an organic structure-directing agent (SDA) were mixed. skeletal density 0.871 g of FAU-type aluminosilicate zeolite (silica / alumina molar ratio = 7, USY-7 manufactured by Nikke Catalyst Chemicals Co., Ltd., hereinafter referred to as "FAU-type zeolite") was used as an aluminum atom raw material, and stirred, It dissolves to make a clear solution. To this was added 5.758 g of colloidal silica "Snowtex O-40 (silica concentration: 40% by weight) manufactured by Nissan Chemical Industries, Ltd. as a silicon atom raw material, and stirred again.

[0280] Further, 0.300 g of uncalcined CHA-type zeolite (average particle diameter=0.2 μm, silica / alumina molar ratio=15) was added as a seed crystal, and stirred at room temperature for 2 hours to obtain a pre-reaction mixture.

[0281] The silica / alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com