Tire loose die limiting mechanism and tire loose die

A tire flexible mold and limit mechanism technology, applied in the tire flexible mold limit mechanism and tire flexible mold field, can solve the problems of safety accidents, easily damaged guide strips, limit blocks, etc., to improve the overall service life, reduce Potential safety hazards and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

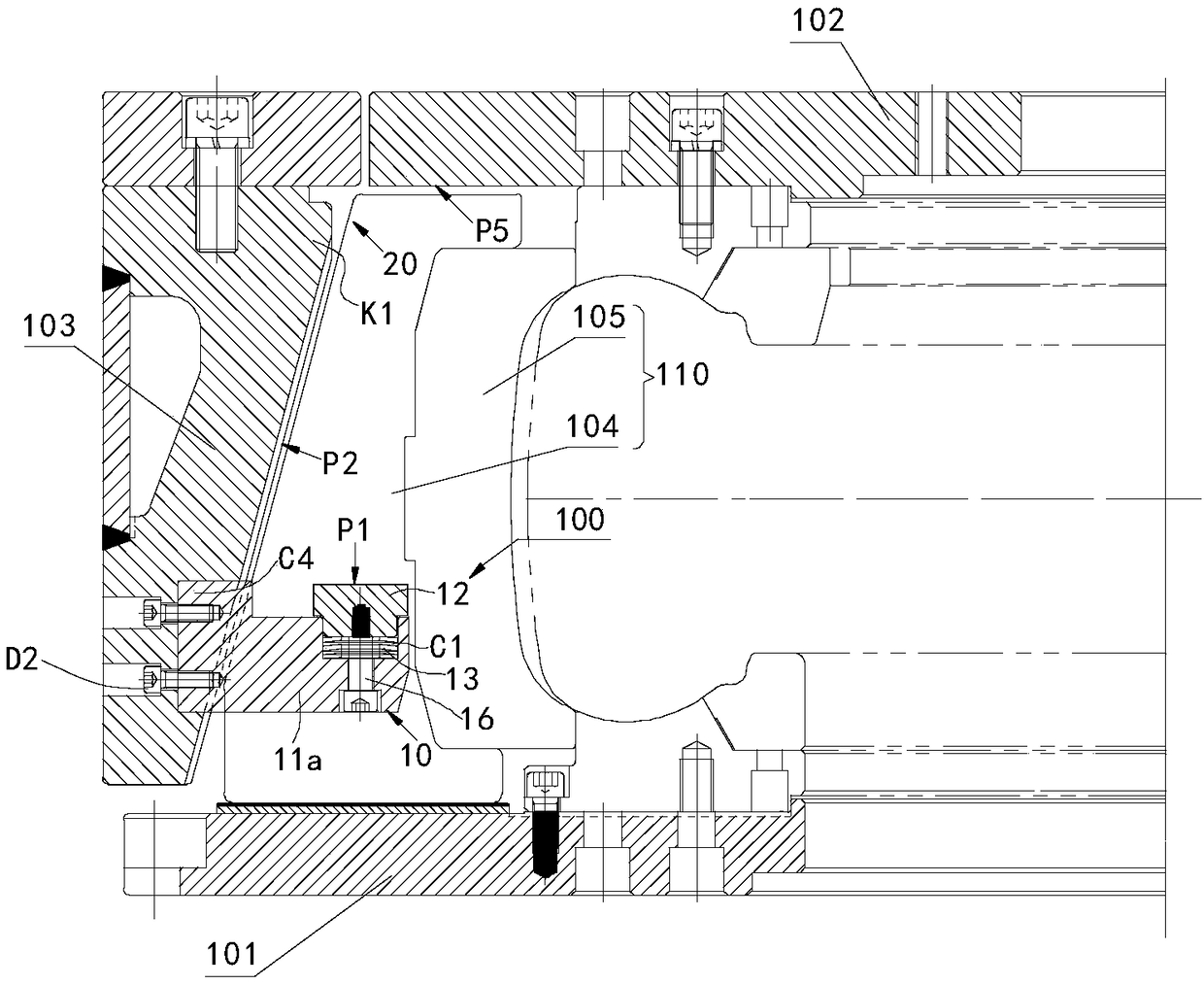

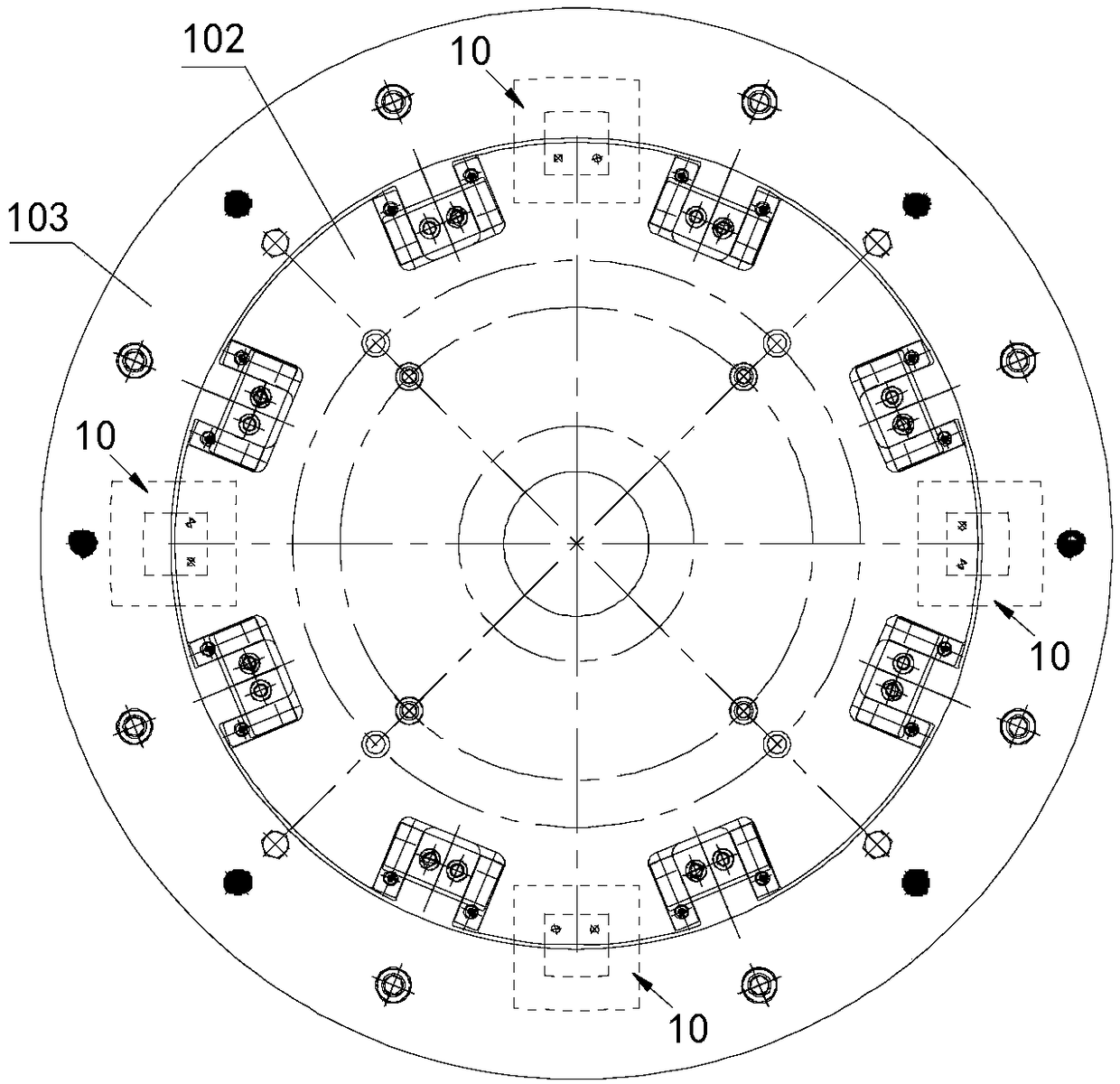

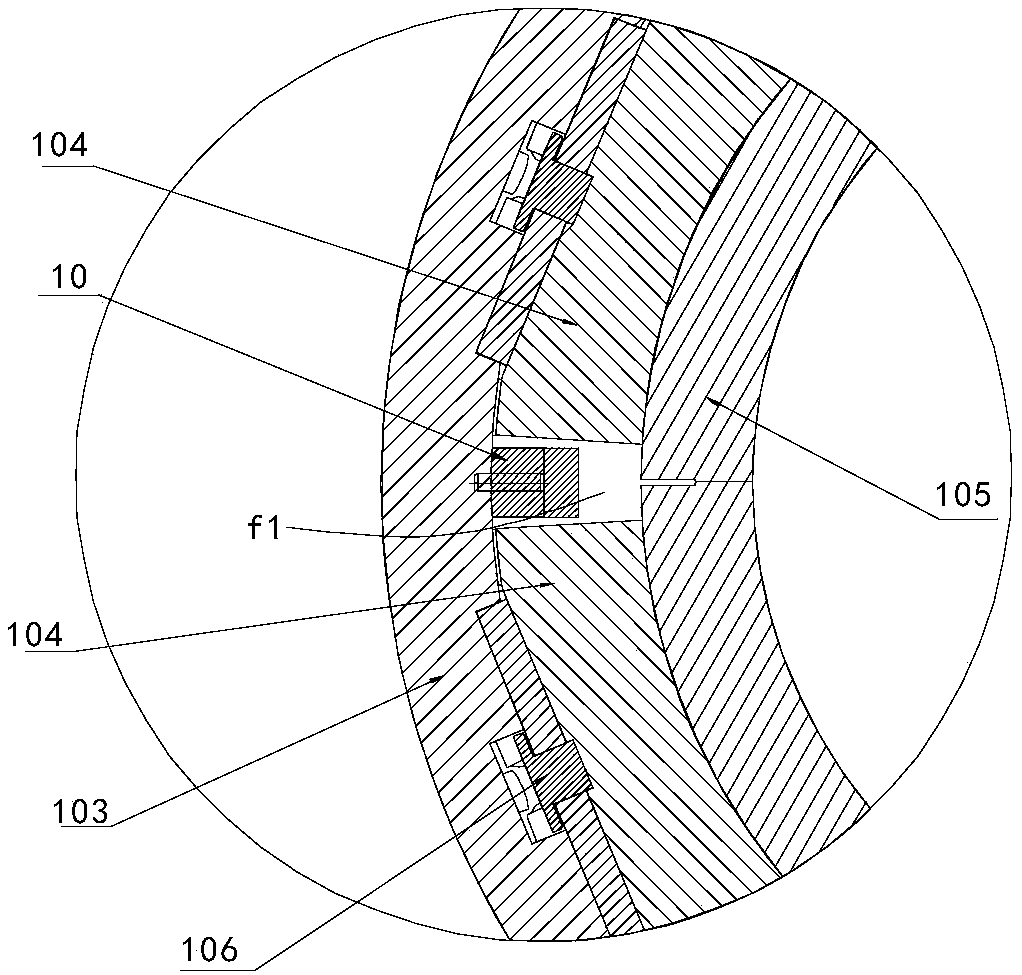

[0074] figure 1 A schematic structural view (half-section display) of an implementation of the tire flexible mold in the embodiment of the present invention is shown in ; figure 2 yes figure 1 top view of image 3 for figure 1 Partial view of the cross-section of the tire flexible mold; Figure 4 for figure 1 Schematic diagram of the mold opening limit. Please refer to figure 1 , figure 2 , image 3 , Figure 4 , The tire movable mold limiting mechanism 100 in this embodiment includes a base 101 , an upper cover 102 , a guide ring 103 , and a plurality of sliding parts 110 . A plurality of sliders 110 are respectively slidably connected to the inner surface P2 of the guide ring 103 and distributed along the inner surface P2 of the guide ring 103 at intervals in the circumferential direction; there is a gap f1 between adjacent sliders 110 . The inner side of the slider 110 is a pattern block 105, which is used to form the pattern on the peripheral surface of the tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com