Pencil sharpener frame

A pencil sharpener and blade technology, applied in the mechanical field, can solve the problems of reduced cutting force, broken pencil core, high brittleness, etc., and achieve the effect of stable structure, preventing brittle cracking and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

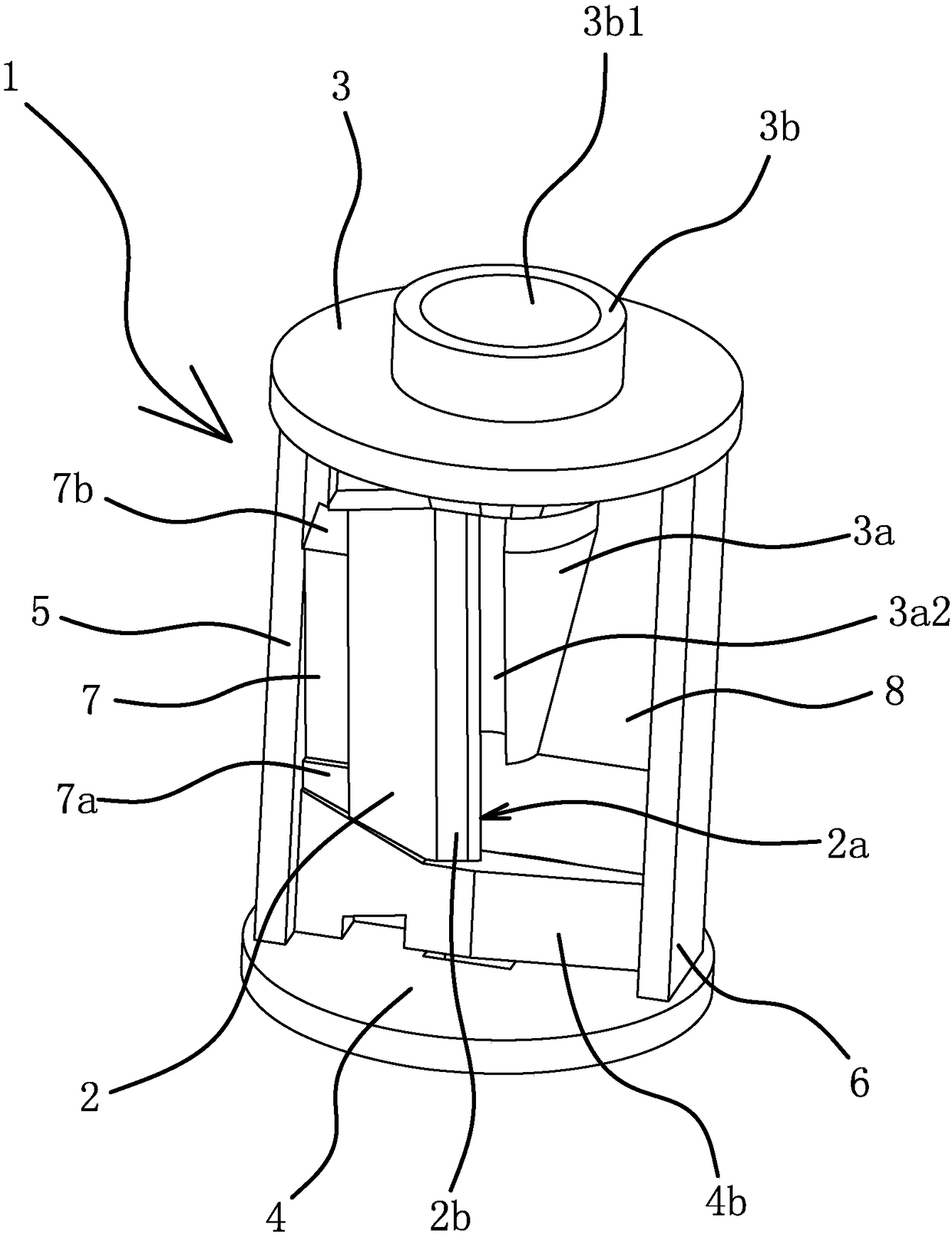

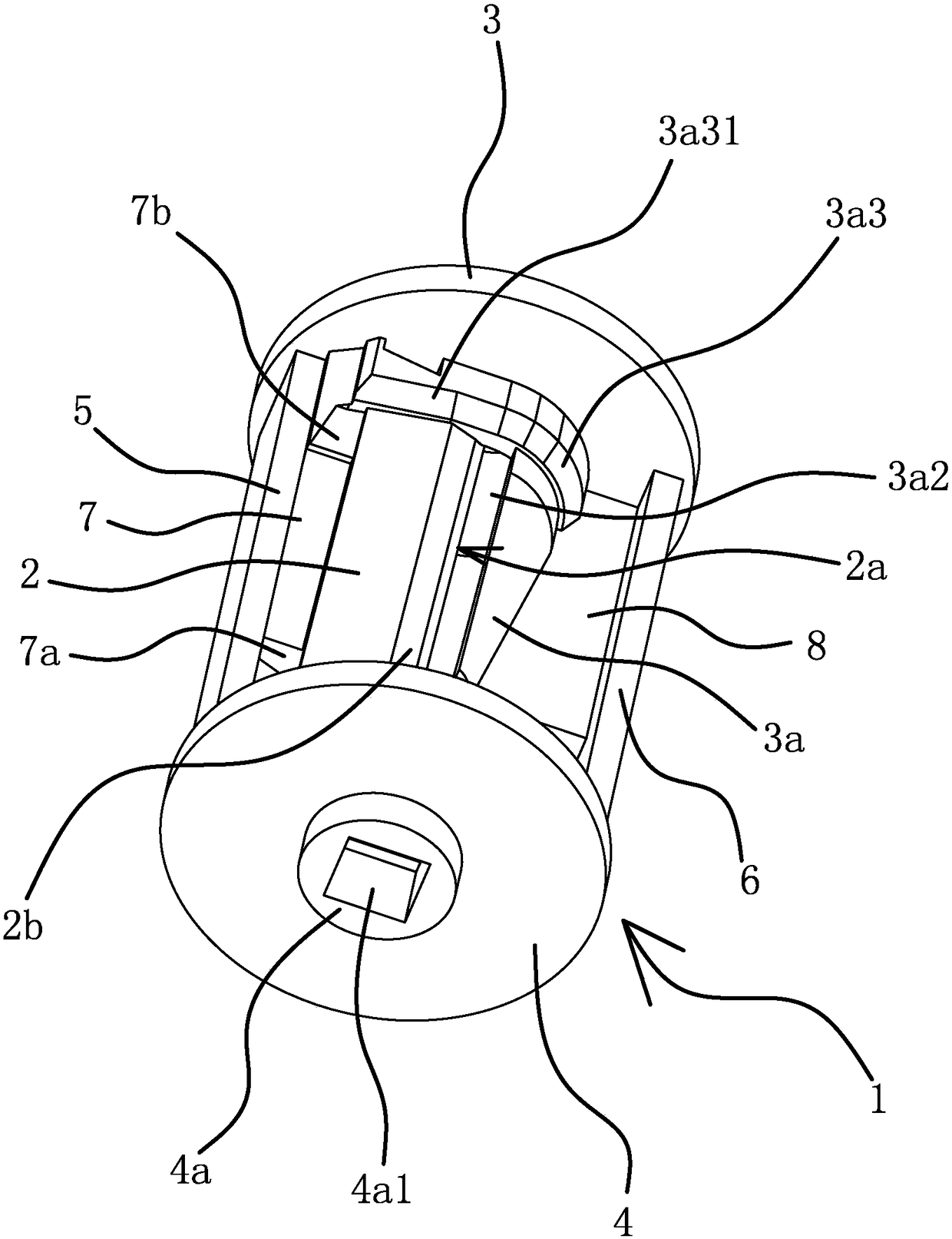

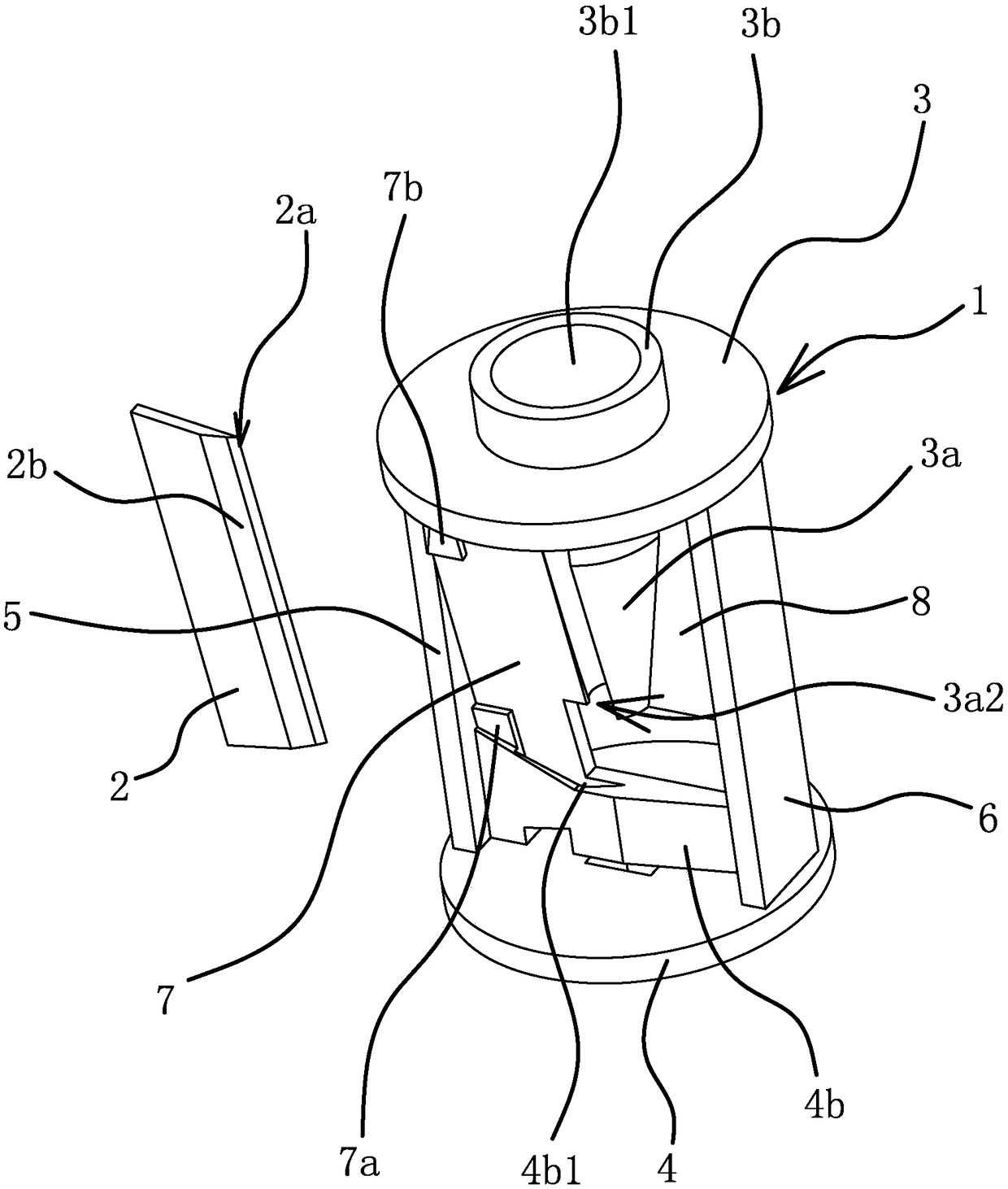

[0047] Such as figure 1 , figure 2 and Figure 6 As shown, a pencil sharpener holder includes a holder body 1 and a blade 2. The blade 2 is made of ceramic material. The frame body 1 has an integrated structure, and the frame body 1 includes a lower plate 4, an upper plate 3 facing the lower plate 4, and a support plate 5 and a support plate 2 that are all fixedly connected between the upper plate 3 and the lower plate 4. 6. The first support plate 5 is set opposite to the second support plate 6 . The lower end surface of the lower plate 4 is provided with a protruding coupling portion 4a, and the coupling portion 4a is provided with a square coupling hole 4a1. The coupling hole 4a1 is mainly for when the pencil sharpener holder is used on the electric pencil sharpener The end of the rotating shaft of the motor can be inserted into the coupling hole 4a1, so that the rotating shaft of the motor can drive the entire pencil sharpener holder to rotate together to cut the penci...

Embodiment 2

[0059] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 12 As shown, in this embodiment, a reinforcing bar 10 is provided between the outer wall of the convex portion 3 a 3 and the outer wall of the positioning portion 4 b, and the inner surface of the reinforcing bar 10 is attached to the outer surface of the blade 2 . By setting reinforcing bar 10 between the outer side wall of the convex part 3a3 and the outer side wall of the positioning part 4b, and making the inner side surface of the reinforcing bar 10 and the outer side surface of the blade 2 fit, the blade 2 made of ceramics can be further improved on the support body 1. The fixed effect on .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com