A leather pressing equipment for leather production and processing

A technology for laminating equipment and leather goods, applied in raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur processing, small raw hide/large raw hide/leather/fur mechanical processing, etc. Worker injury rate, inability to improve safety and other issues, to achieve the effect of improving safety and reducing injury rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

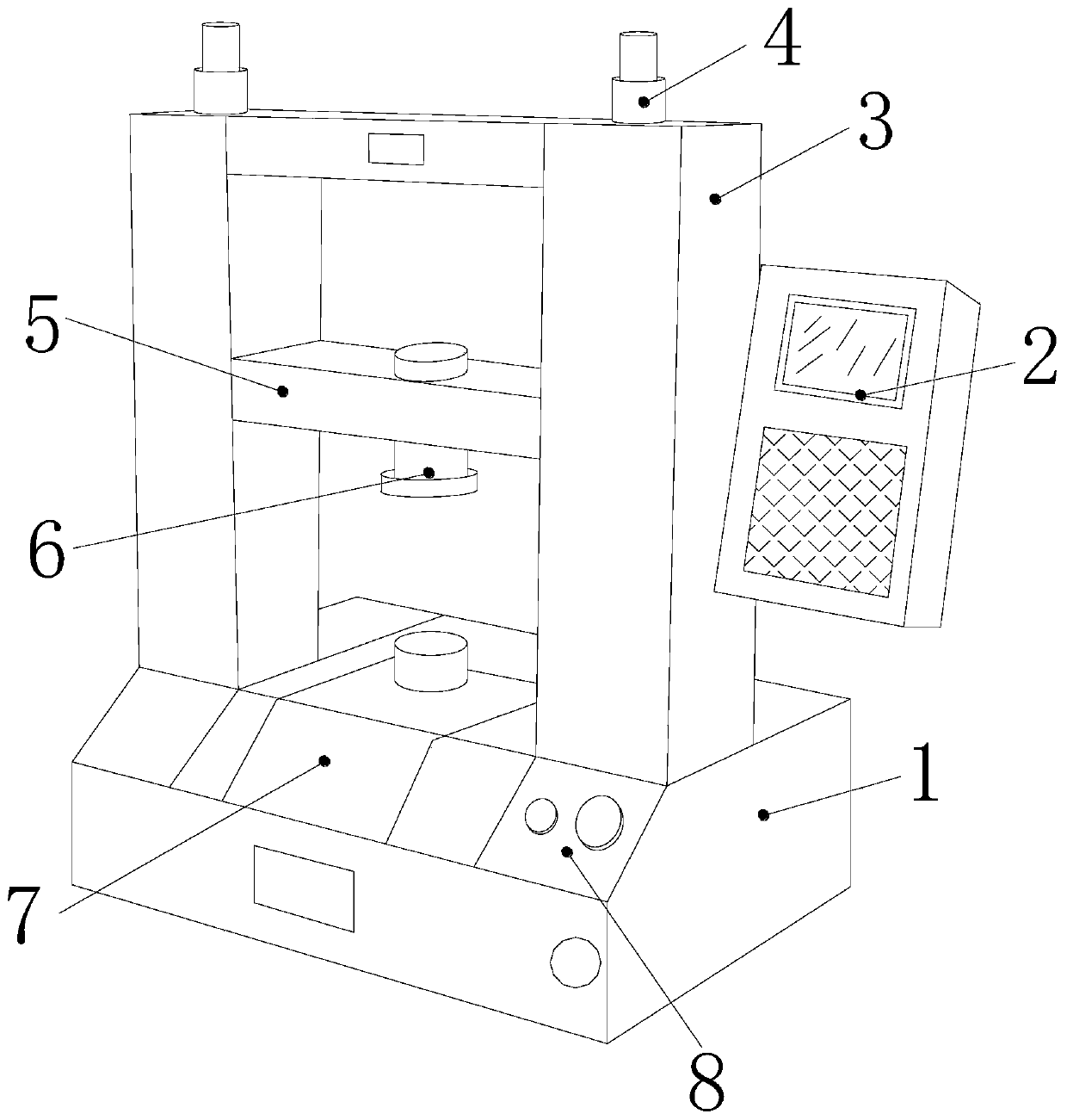

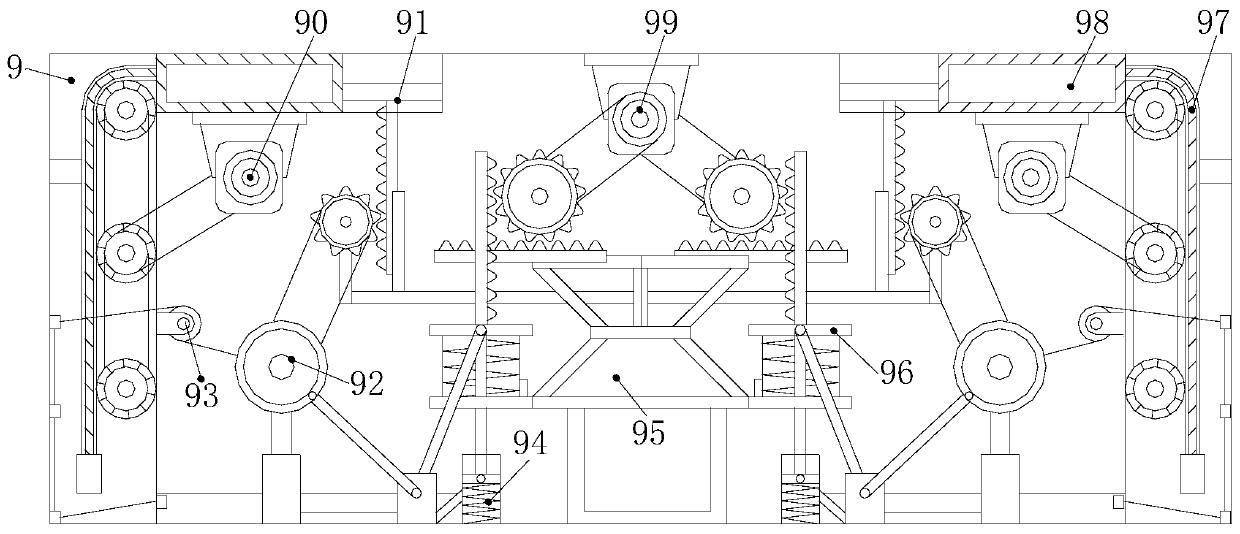

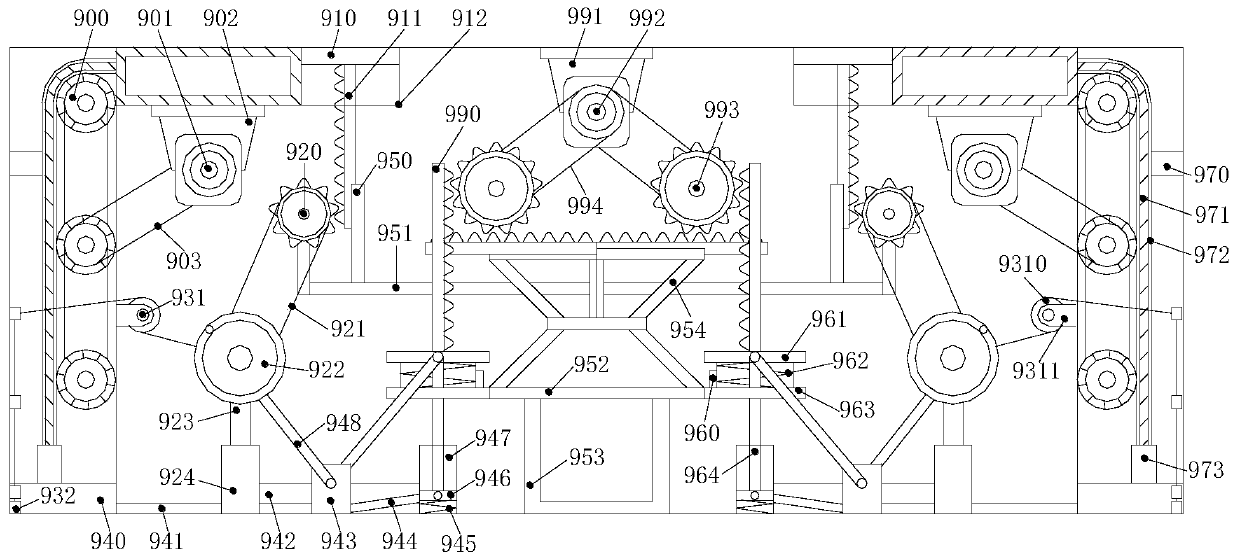

[0025] see Figure 1-Figure 3, the present invention provides a leather goods pressing equipment for leather goods production and processing: its structure includes a machine base 1, a data controller 2, a frame 3, a manual knob 4, a pressing lifting frame 5, a pressing column 6, a pressing Pillar base 7, switch control board 8, internal safety device 9, described machine base 1 is provided with slope, described machine base 1 is vertically connected with frame 3, and described frame 3 is inverted U-shaped structure, and described data control The device 2 is obliquely installed in the middle of the side of the frame 3, the manual knob 4 is connected with the internal safety device 9, the manual knob 4 is provided with a group, the manual knob 4 is located at the upper end of the frame 3, and the frame 3 It is movably connected with the pressing lifting frame 5, the pressing lifting frame 5 is located on the hollow structure of the frame 3, the pressing lifting frame 5 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com