A-INS precision measurement piecewise linear fitting method aiming at track irregularity inspection

A track irregularity, A-INS technology, applied in track, measuring instrument, track maintenance, etc., can solve data waste and other problems, achieve simple calculation, ensure accuracy and reliability, and ensure measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

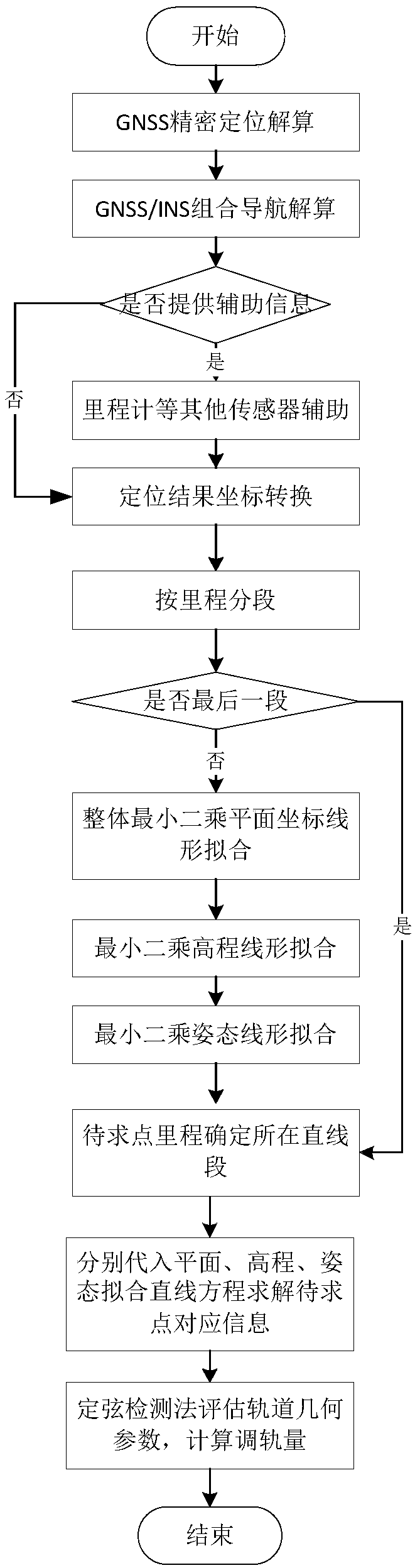

[0039] The following will combine figure 1 , providing a specific embodiment of the present invention, the specific steps are as follows:

[0040] S100A-INS system integrated navigation and positioning.

[0041] This step further includes sub-steps:

[0042] S110 uses GNSS precise positioning to obtain GNSS precise positioning results.

[0043] GNSS (Global Navigation Satellite System) can provide an absolute position reference, and GNSS precise positioning can achieve centimeter-level absolute positioning accuracy. Generally, the coordinate system of GNSS precise positioning results is the earth-centered ground-fixed coordinate system WGS84, and the sampling frequency is generally 1HZ. For GNSS precise positioning, the GNSS precise positioning algorithm can use real-time carrier differential positioning (RTK) method or precise point positioning (PPP) method. Specifically, firstly, the GNSS satellite carrier, GNSS pseudo-range observations and ephemeris data are collected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com