Construction method of local deep foundation pit

A construction method and technology of deep foundation pits, which are applied in infrastructure engineering, excavation, artificial islands, etc., can solve problems such as difficult construction of edge angles, long service life of equipment, and slow construction speed, so as to save mechanical workload and save The effect of cement consumption and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper", "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

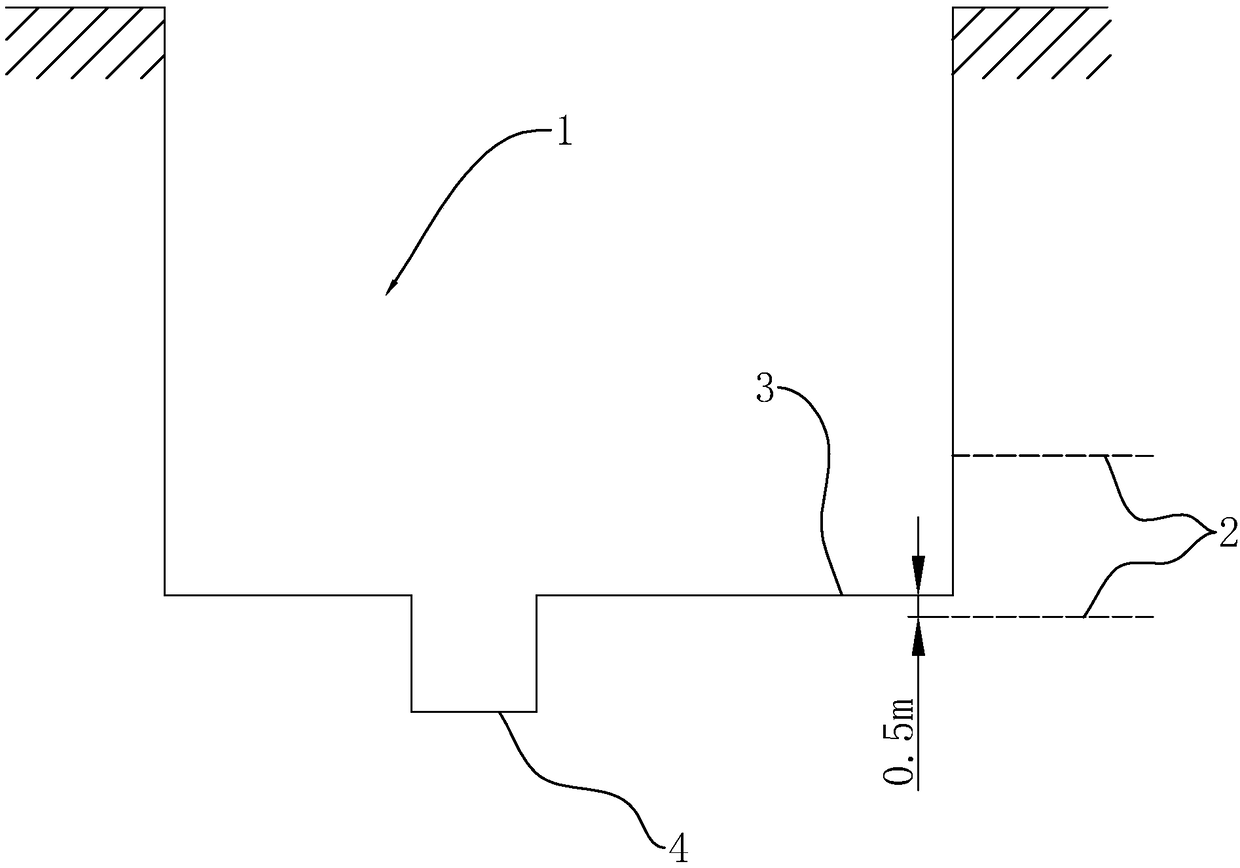

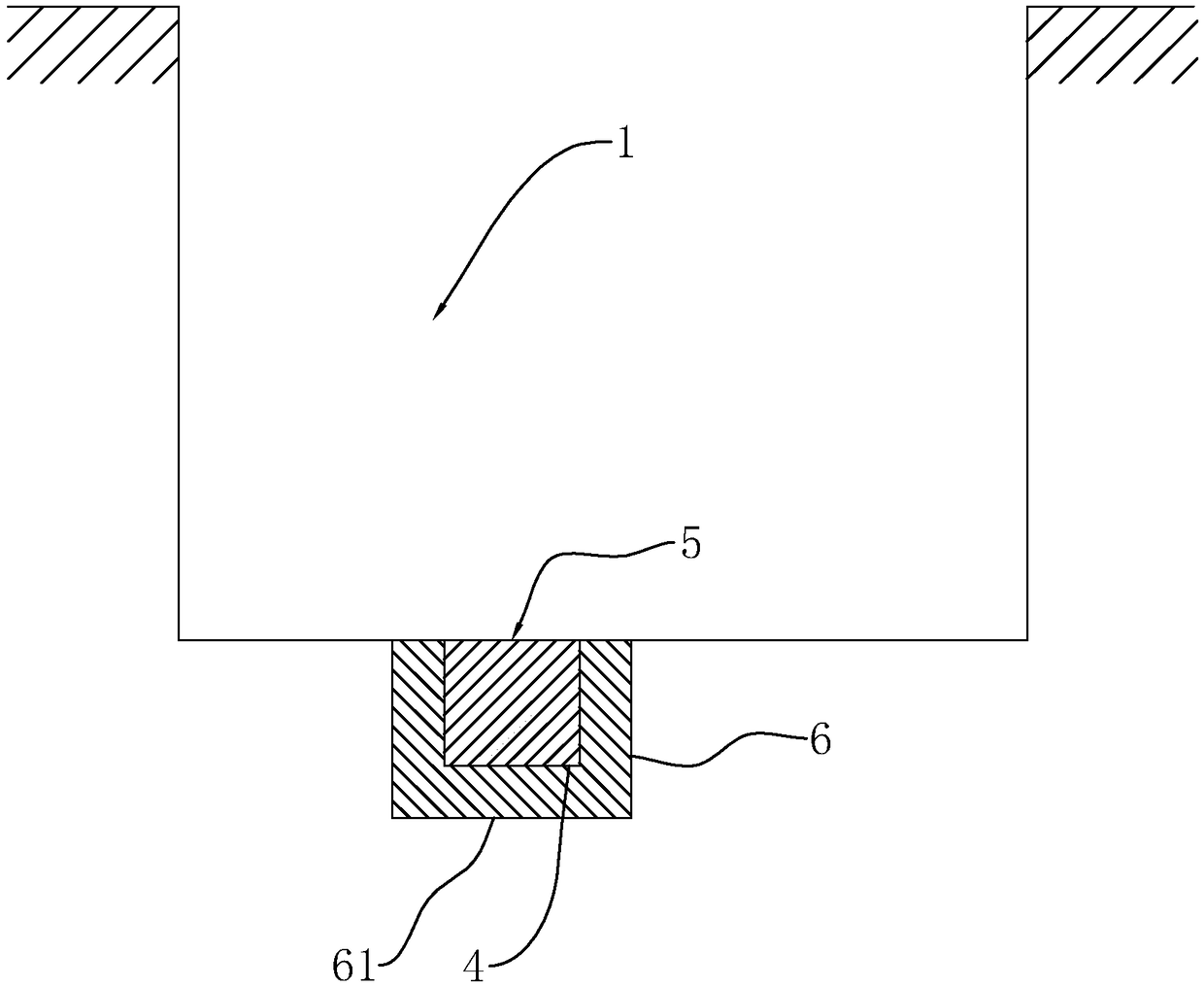

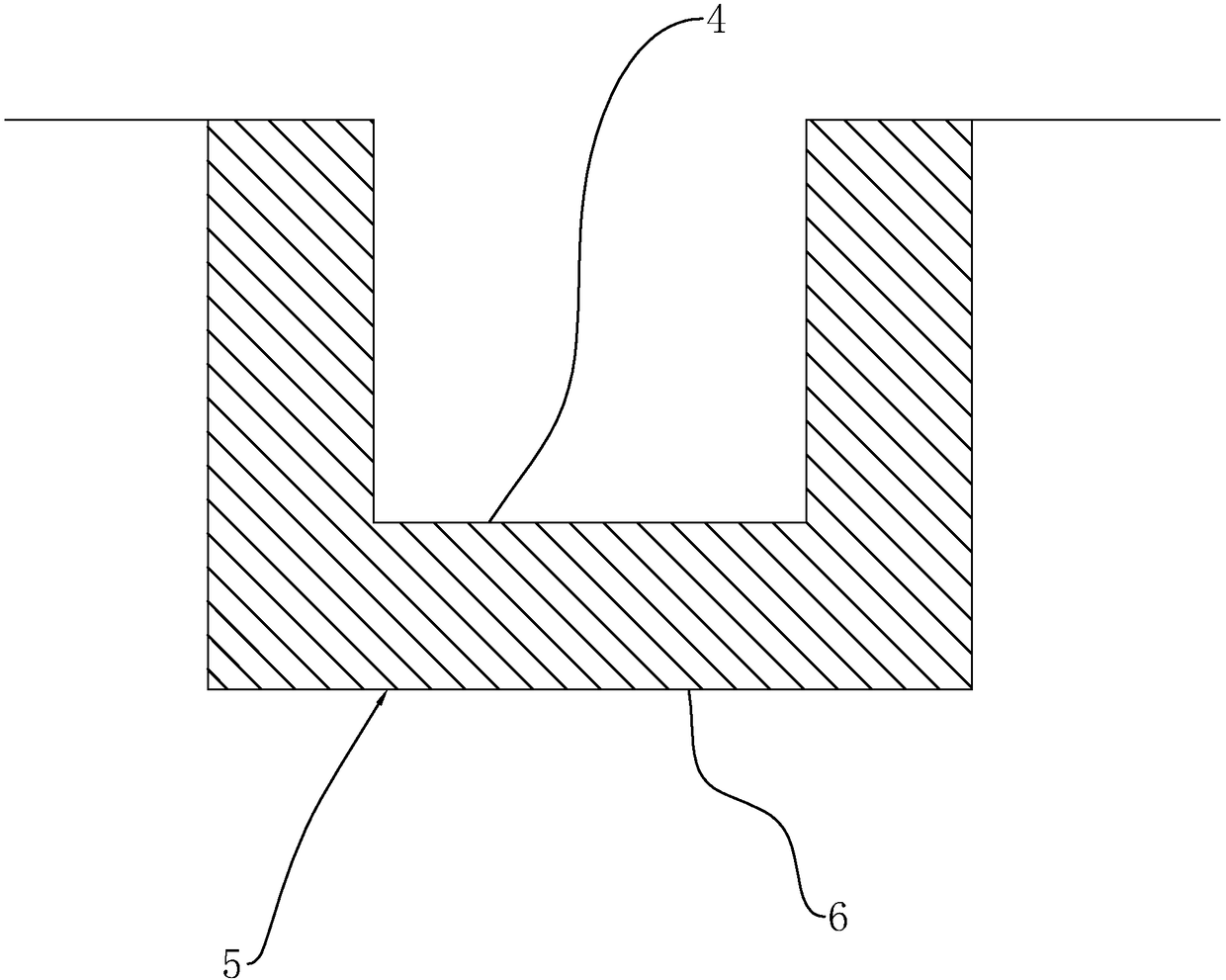

[0040] A construction method for local deep foundation pits, such as figure 2 As shown, the basic principle of this method is: in the excavation position of the local deep foundation pit 4 and the soil body in a certain range around and at the bottom, dry cement is mixed into the cement-soil structure 5 after the cement and the soil are fully mixed. After the soil structure 5 is hardened, a local deep foundation pit 4 is excavated. like image 3 As shown, the hardened cement-soil structure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com