Quick flushing toilet

A toilet and sprinkler technology, applied in the field of sanitary ware, can solve the problems of unfavorable and fast flushing of the toilet, lack of momentum, energy loss, etc., to prevent water storage and energy loss, reduce energy loss, and shorten the water outlet distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

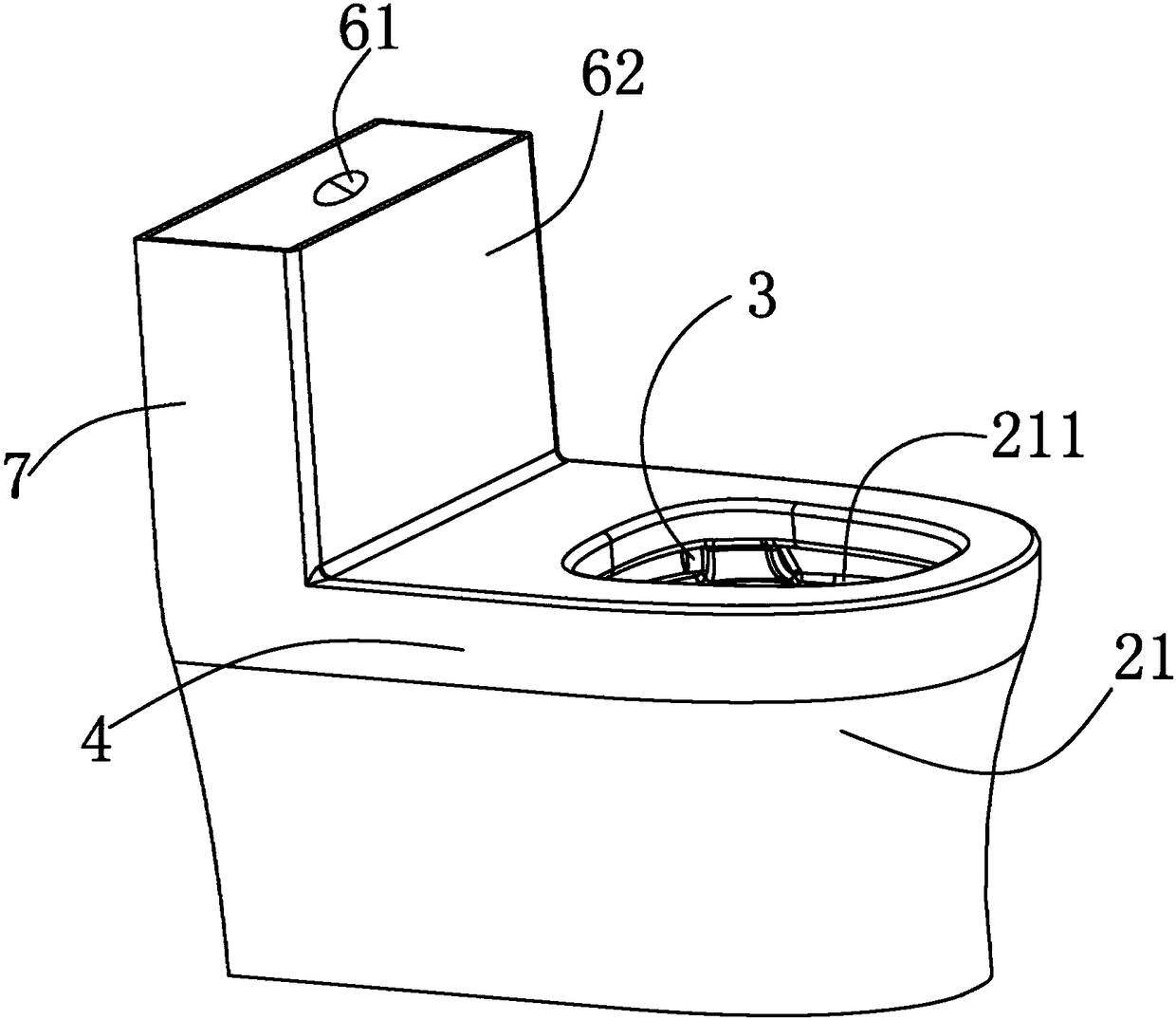

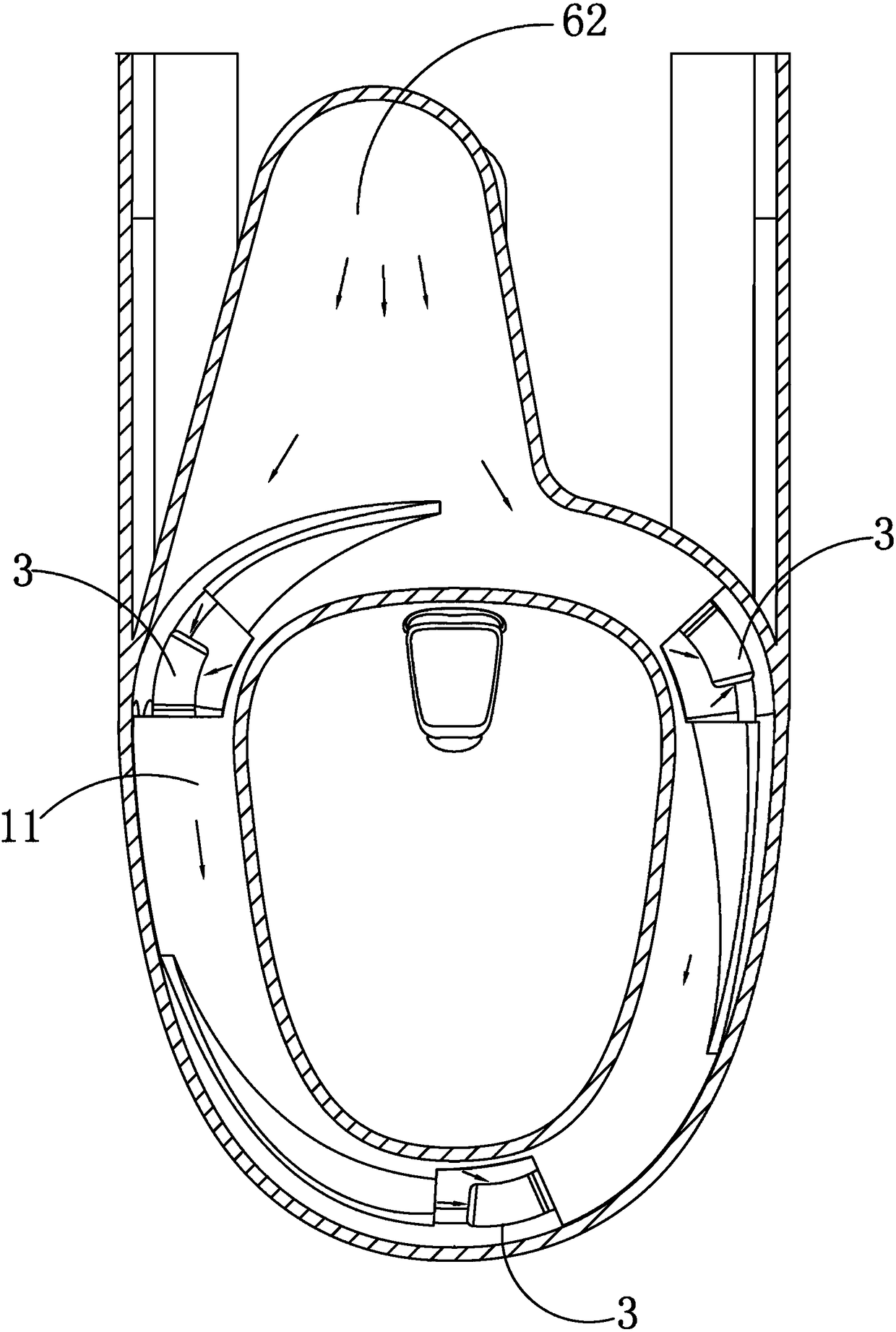

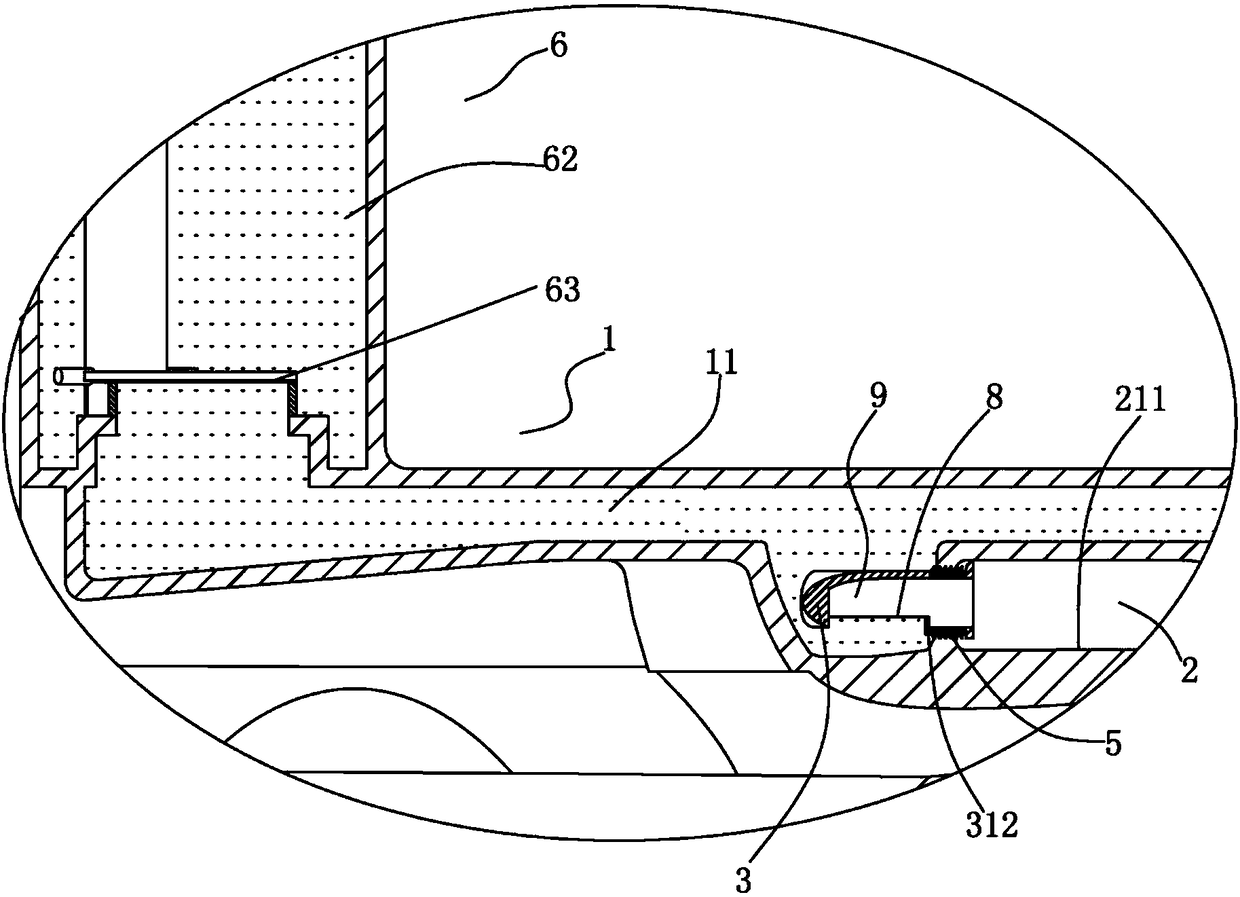

[0053] Specific implementation methods, such as Figure 1 to Figure 8 As shown, the present invention takes a quick-flush component installed in the wash ring water channel of the toilet as an example, which mainly includes the following parts: the water passing part 1, the wash ring water channel 11, the water outlet part 2, the pelvic cavity 21, and the drainage platform 211 , fast flushing part 3, flushing nozzle 31, water inlet 310, water outlet 311, groove 300, water retaining weir 312, limit rib 313, seal 32, flushing seat ring 4, washing ring hole 5, water inlet part 6 , flush button 61, water tank 62 and drain valve 63;

[0054] In actual assembly, from the perspective of the external structure, it includes the toilet body 7 and the quick-flush part 3; the quick-flush part 3 can be used as an accessory, detachably installed in the wash ring hole 5 in the flush seat 4 of the toilet and communicate with the drainage platform 211 set on the inner periphery of the pelvic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com