Powder feeding type circulating cooling nozzle and K-TIG special welding gun

A technology of circulating cooling and powder feeding, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of many structural parts, high assembly difficulty, and high maintenance cost, and achieves reduction of bonding, assembly process, and improvement. The effect of powder feeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030]实施例一

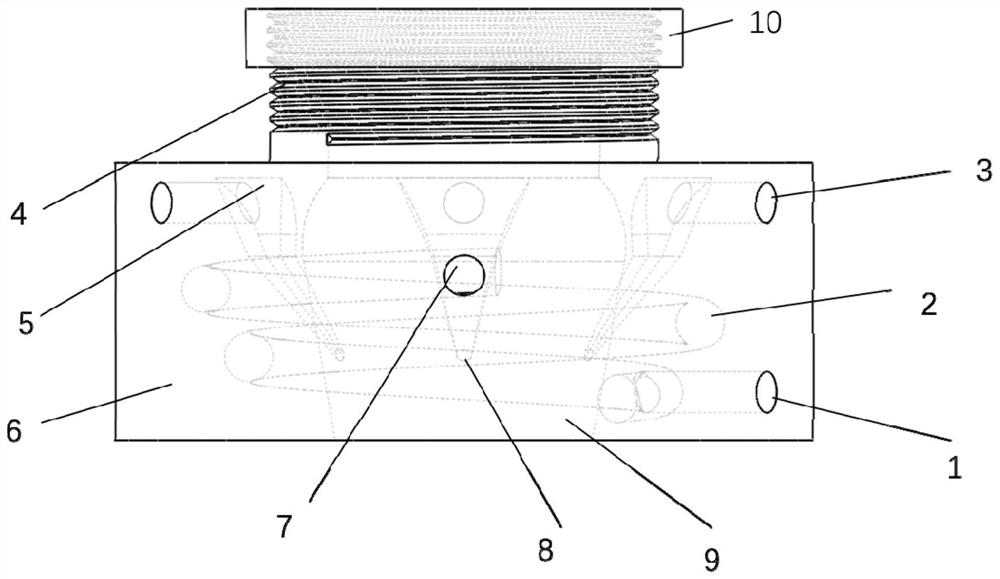

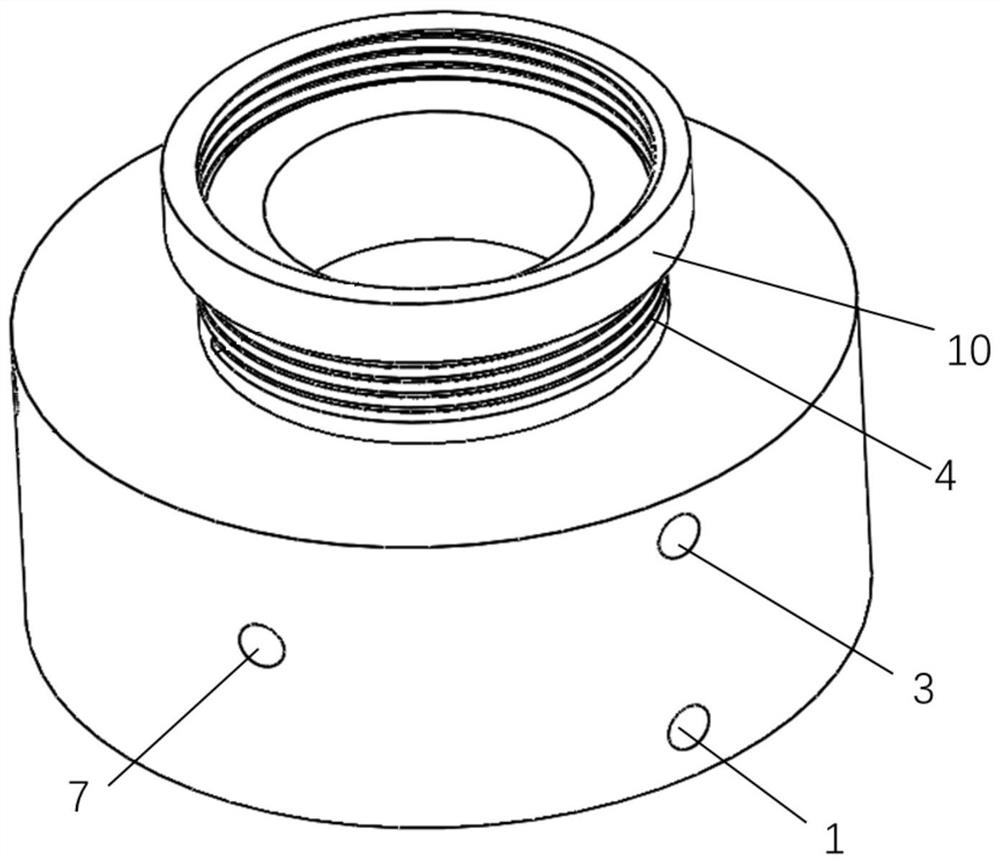

[0031]如图1~图5所示,一种送粉式循环冷却喷嘴,包括喷焊结构,喷焊结构包括喷焊主体和连接头,喷焊主体和连接头固定连接;喷焊主体内设有钨针空腔、冷却通道和送粉通道,钨针空腔呈圆柱状或圆台状,连接头内设有连接空腔,连接空腔与钨针空腔连通;送粉通道包括入粉口和出粉口,入粉口位于喷焊主体的外侧表面,出粉口位于钨针空腔的内侧壁,从而送粉通道通过出粉口连通钨针空腔,冷却通道呈螺旋旋线形,冷却通道环绕于钨针空腔的外侧。

[0032]连接空腔的端部边沿设有倒圆角。

[0033]送粉通道的数量为多个,多个送粉通道绕钨针空腔的轴线呈圆周阵列排布。

[0034]送粉通道包括依次连接的入口段、过渡段和喷粉段,入口段、过渡段和喷粉段依次连接,喷粉段的一端连接过渡段,出粉口设于喷粉段的另一端,从喷粉段的一端到另一端,喷粉段的横截面逐渐缩小。喷粉段呈收束状,用作粉末流的收束,加大粉末流的动量,使粉末流可以冲破保护气气屏,汇聚于钨针尖端下部的一点。

[0035]过渡段包括依次连接的第一侧面、第二侧面、第三侧面和第四侧面,第一侧面为内侧凹进的曲面,第三侧面为内侧凸起的曲面;第一侧面的一端和第三侧面的一端相交于一条曲线,第一侧面的另一端和第三侧面的另一端均连接收束段,第二侧面和第四侧面均为平面,入口段的一端位于过渡段的第三侧面处。过渡段用于改变粉末的流动方向。

[0036]多个喷粉段的中心线相交于钨针空腔的轴线上的一点。

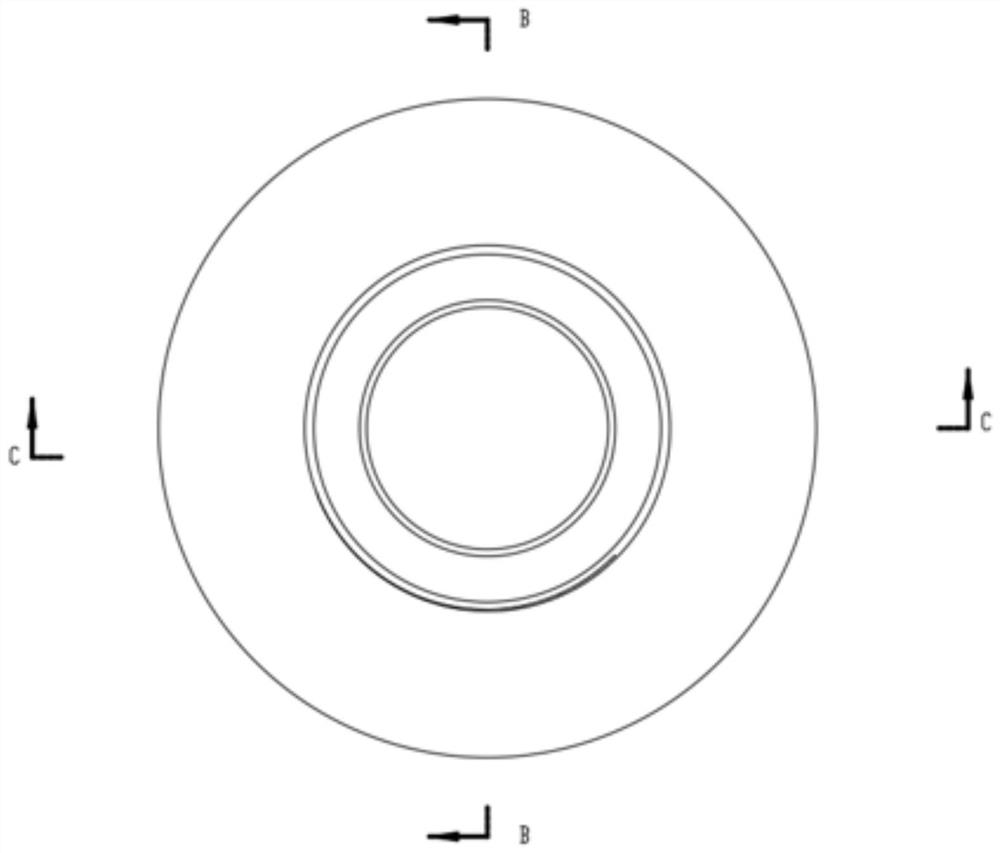

[0037]冷却通道为圆锥螺旋线形。

[0038]冷却通道的截面为直径5~8mm的圆形,冷却通道的锥度角为32°,圈数为1.87圈,螺距为7mm。每个送粉通道的外侧都有两次水流通过,保证冷却效果的均匀性和快速性。

[0039]冷却通道包括进水口和出水口,进水口和出水口均位于喷焊主体的外侧表面,进水口相对于出水口远离连接头。工作时,冷却水通过外侧壁下部的进水口进入冷却通道,经过倒锥螺旋形的冷却通道对喷焊结构进行冷却,从外侧壁上部的出水口流出,并通过外部的冷却系统进行回收,达到循环冷却的效果。

[0040]还包括固定环,连接头的外侧设有外螺纹,连接头通过外螺纹连接固定环。

[0041]固定环为圆环形结构,固定环的厚度为3mm。

[0042]出粉口的上端和下端为弧形线,出粉口的两侧为直线,出粉口的各边线的长度均为2~3mm。

[0043]本实施例可用于TIG焊接等非熔化极惰性气体保...

Example Embodiment

[0045]实施例二

[0046]如图6~图7所示,一种K-TIG专用焊枪,包括一种送粉式循环冷却喷嘴。可焊接的同时进行喷粉,通过这种创新的金属焊接方式改变材料力学性能。

[0047]装配上述K-TIG专用焊枪时,通过固定环连接枪体和喷焊结构。

[0048]本实施例未提及部分同实施例一。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com