Large mirror-surface stainless steel suspended-ceiling installing structure

A mirror stainless steel, installation structure technology, applied in the direction of the ceiling, building components, building structures, etc., can solve the problems such as surface unevenness, and achieve the effect of solving surface unevenness and quickly leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

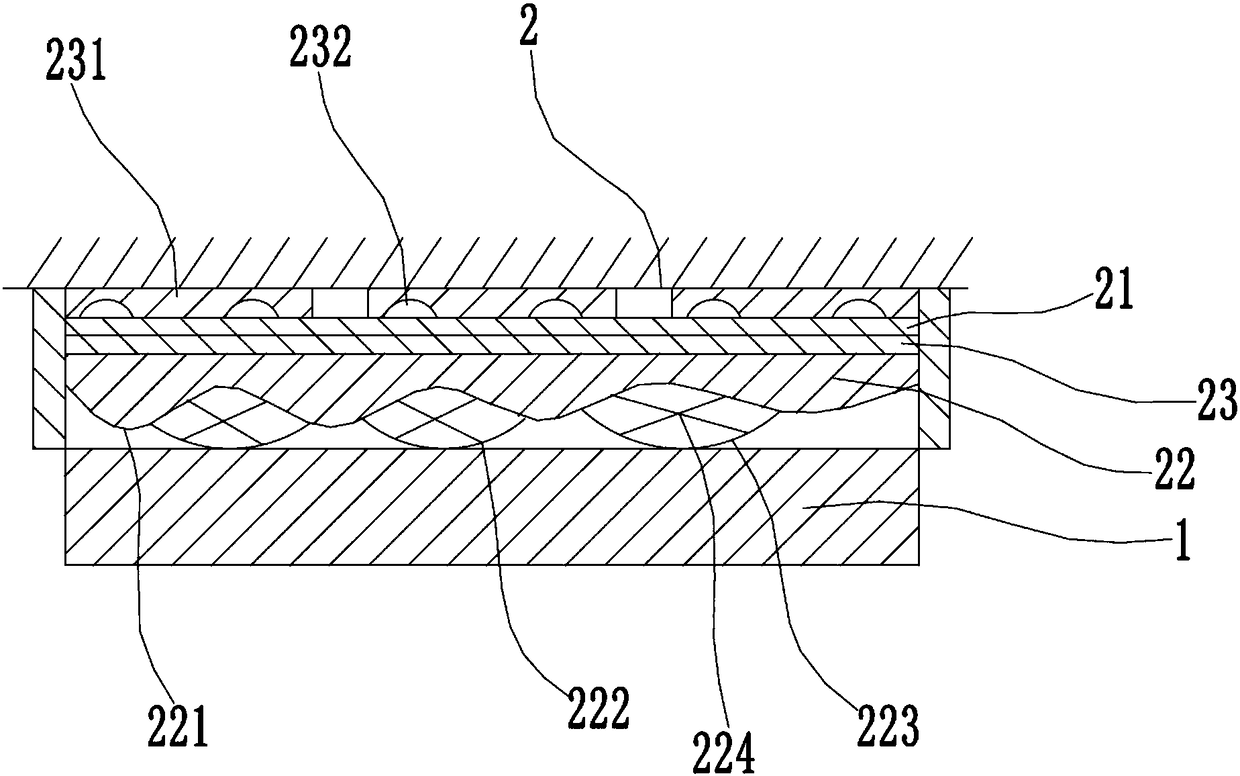

[0015] see figure 1 , the figure shows a large-volume mirror stainless steel ceiling installation structure provided by the embodiment of the present invention, which includes a plurality of stainless steel ceiling panels 1, a first backing plate 21 is fixedly installed on the wall top surface 2, and the first backing plate 21 is set There is an elastic cushion layer 22, the elastic cushion layer 22 has a wave-shaped surface 221, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap