Hydrostatic coupler and automatic unloading mounting method of gear shaft thereof in working process

A coupler and hydrostatic technology, which is applied in transmission devices, fluid transmission devices, belts/chains/gears, etc., can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

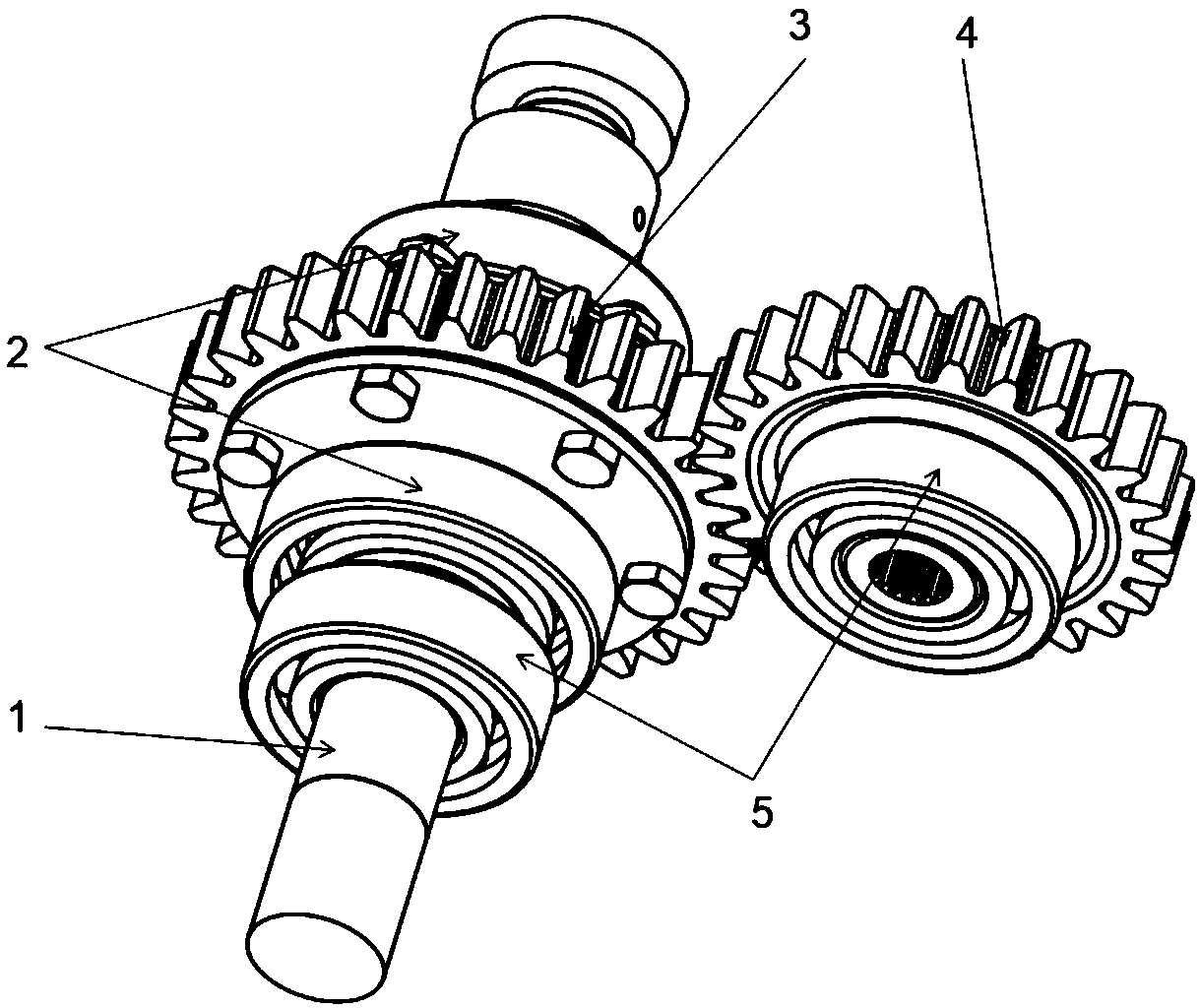

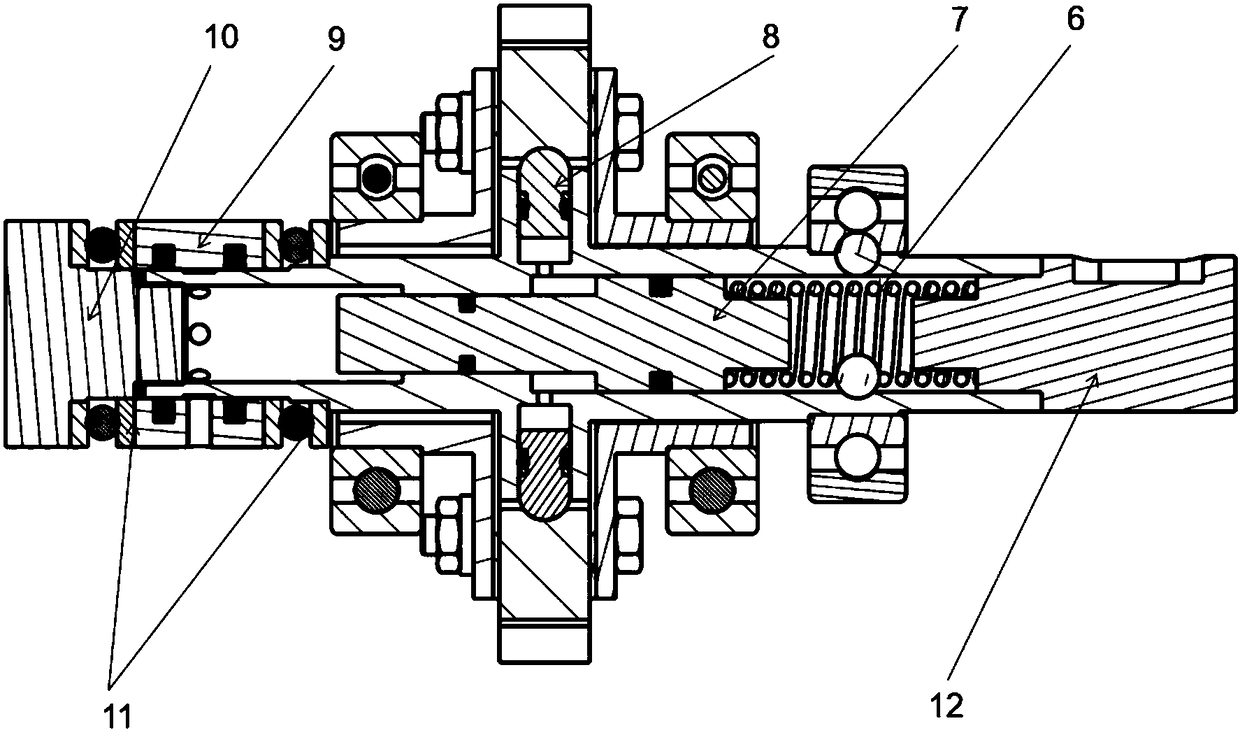

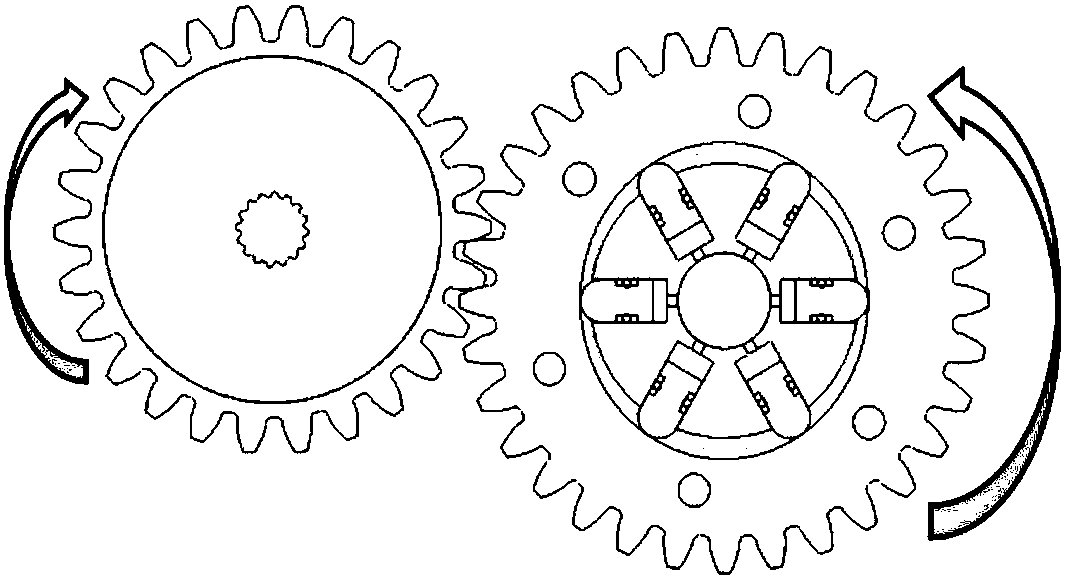

[0026] Example 1, such as Figure 1-2 As shown, this embodiment discloses a hydrostatic coupling, and the coupler includes a drive gear 4 that is installed on the power output shaft of the prime mover and can rotate synchronously with the power output shaft of the prime mover. Driven gear 3, the inner ring of the driven gear is elliptical, a hollow gear shaft 1 connected with the working machine and capable of driving its work is inserted into the inner ring of the driven gear, one end of the gear shaft is covered by the top cover Closed 10, and communicated with the pipeline of the working machine through the pressure supply device 9, the other end is closed by the spring seat 12, the spring 6 installed on the spring seat is connected with the piston 7 in the gear shaft, and the diameter of the piston head Smaller than the diameter of its waist, between the two ends of the gear shaft is a transition section with a smaller inner diameter than both ends. The head of the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com