A shaft assembly locking and positioning mechanism

A technology of locking and positioning and locking mechanism, which is applied in the directions of internal accessories, assembling machines, containers of machines, etc., can solve the problems of not being able to realize the function of double-axis locking and positioning at the same time, unable to adapt to complex vibration environment, and large stress at the positioning place. , to achieve the effect of simple and compact overall structure design, good environmental adaptability, good axial and radial mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

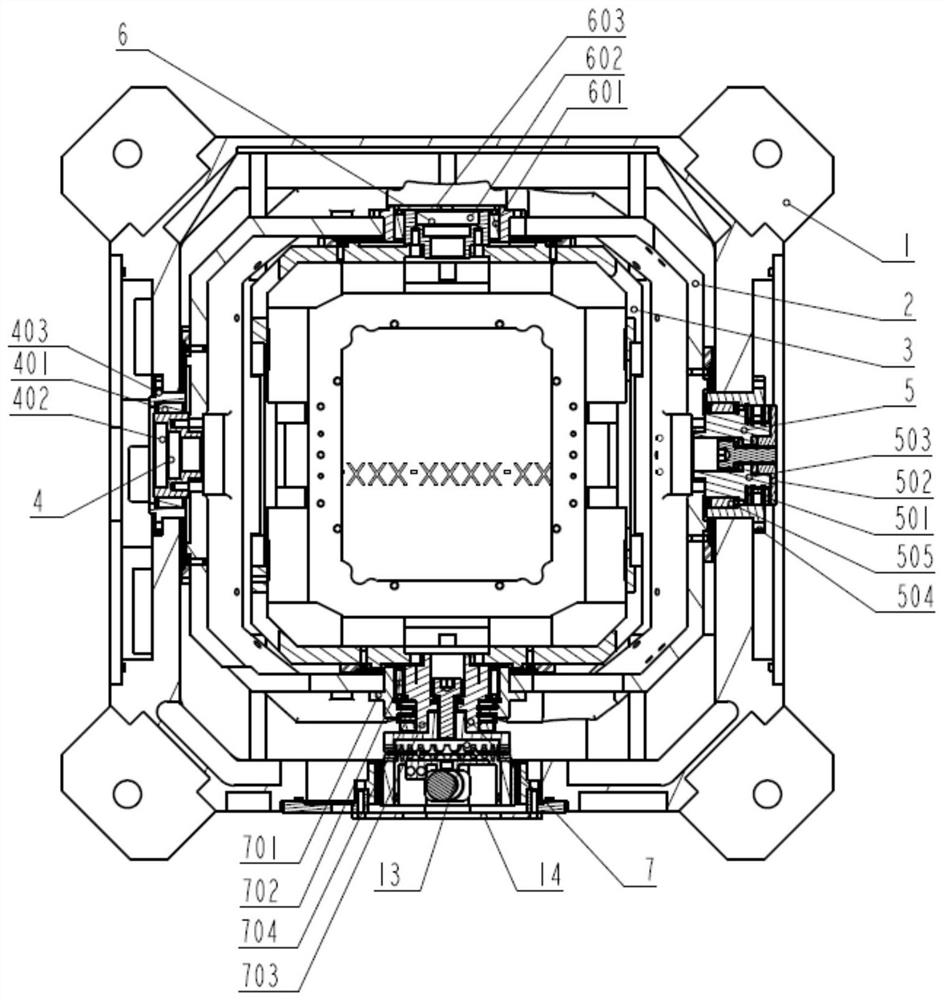

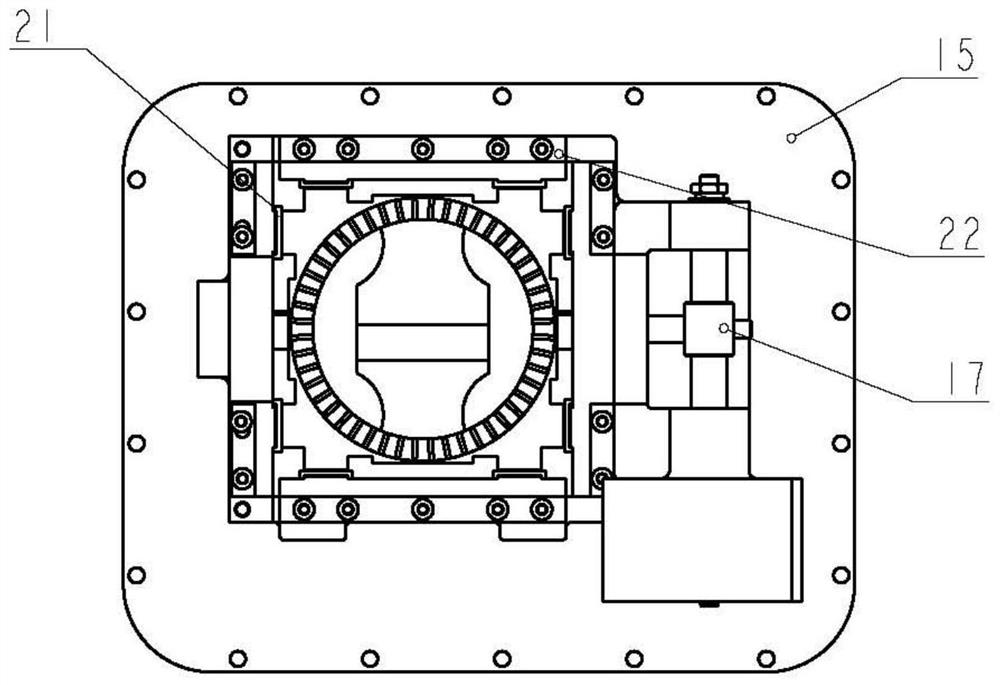

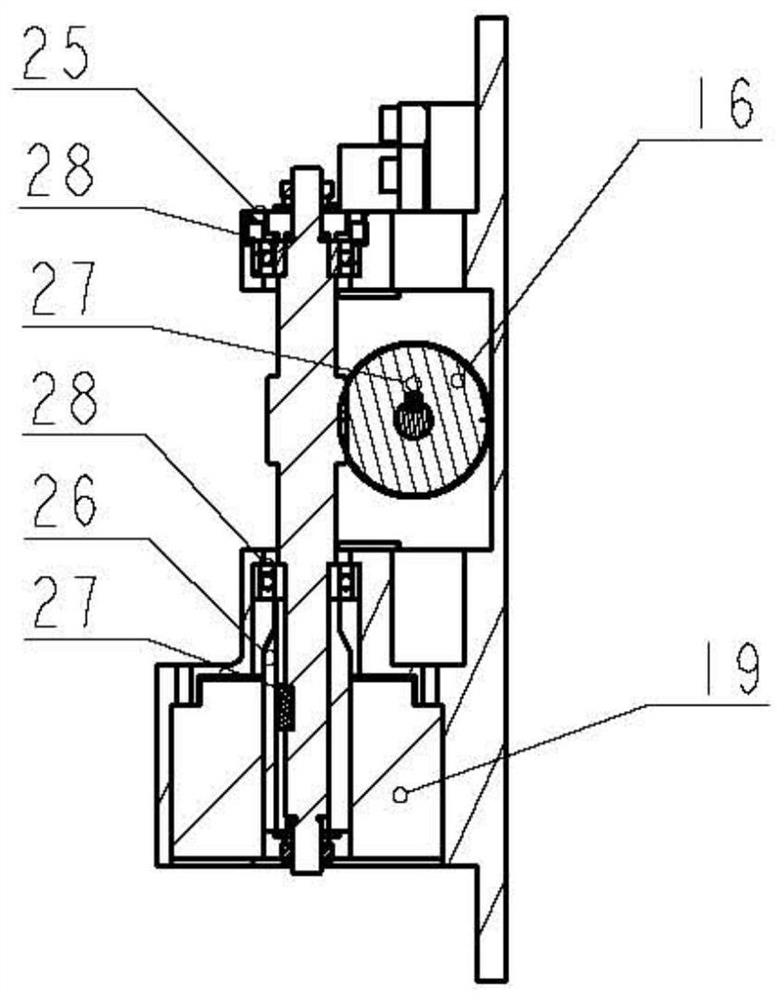

[0025] A shaft assembly locking and positioning mechanism, such as figure 1 As shown, it includes an outer box 1, an outer rotating frame 2, an inner rotating frame 3, a first traveling shaft assembly 4, a restraining shaft assembly 5, a third traveling shaft assembly 6, a locking shaft assembly 7, The fixed-end toothed plate 13 and the locking mechanism 14, the outer rotating frame 2 is connected to the inner side of the outer box body 1 through the first floating shaft assembly 4 and the restraining shaft assembly 5 respectively, and the inner rotating frame 3 is connected through the The third traveling shaft assembly 6 and the locking shaft assembly 7 are connected to the inner side of the outer rotating frame 2, such as figure 2 As shown, the fixed-end sprocket 13 is installed on the outside of the outer rotating frame 2 and locks the outer rotating frame 2 and the inner rotating frame 3 rotated to the designated position by engaging with the locking mechanism 14, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com