Screw pitch adjusting device used for controllable-pitch propeller model and using method of screw pitch adjusting device

A technology of pitch adjustment and propeller, which is applied in the directions of measuring devices, transportation and packaging, and testing of machine/structural components, etc. It can solve the problems of large production quantity, time-consuming process of adjusting the pitch, and no error in adjusting the pitch, etc., to achieve high The effect of pitch angle adjustment accuracy, improved adjustment accuracy, and shortened adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

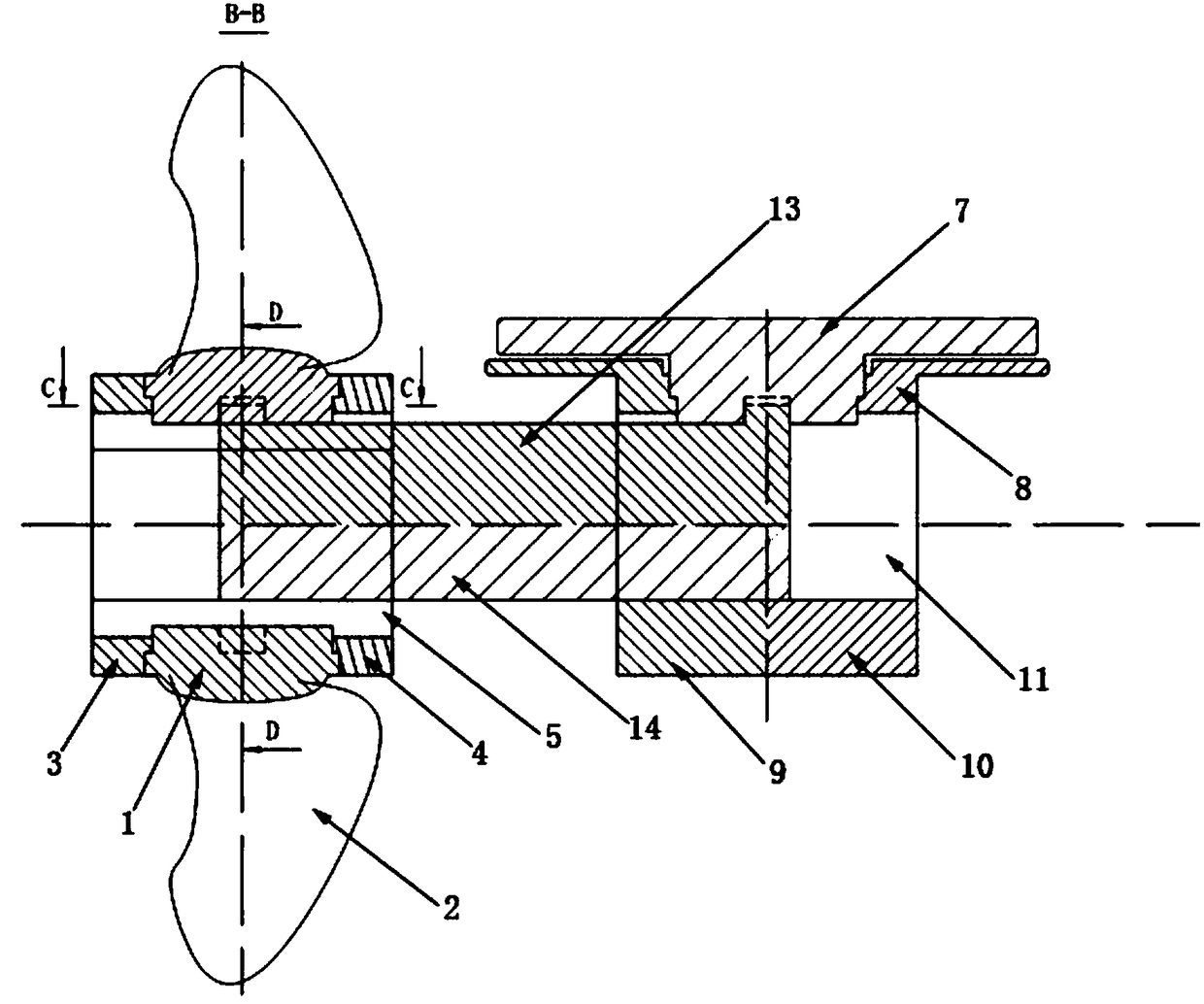

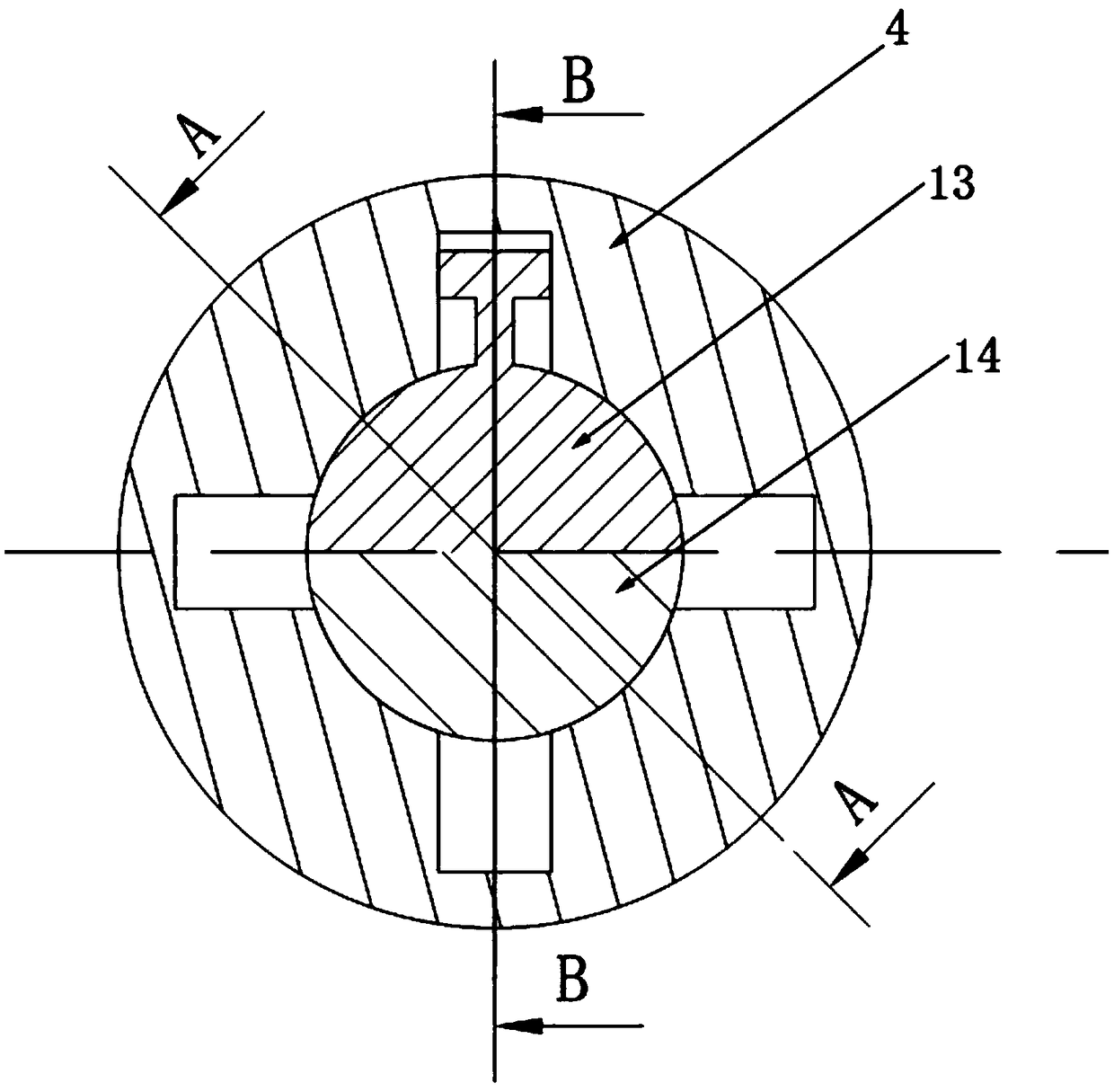

[0039] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 5 As shown, the outer diameter of the fixed dial 8 is larger than the diameter of the adjusting dial 7 .

[0040] In a further embodiment of the present invention, the fixed dial 8 is arranged coaxially with the adjusting dial 7 .

[0041] In a further embodiment of the present invention, the outer circumference of the upper end of the adjusting disc 7 is provided with a circumferential angle scale, which is convenient for determining the rotation angle of the adjusting disc 7 .

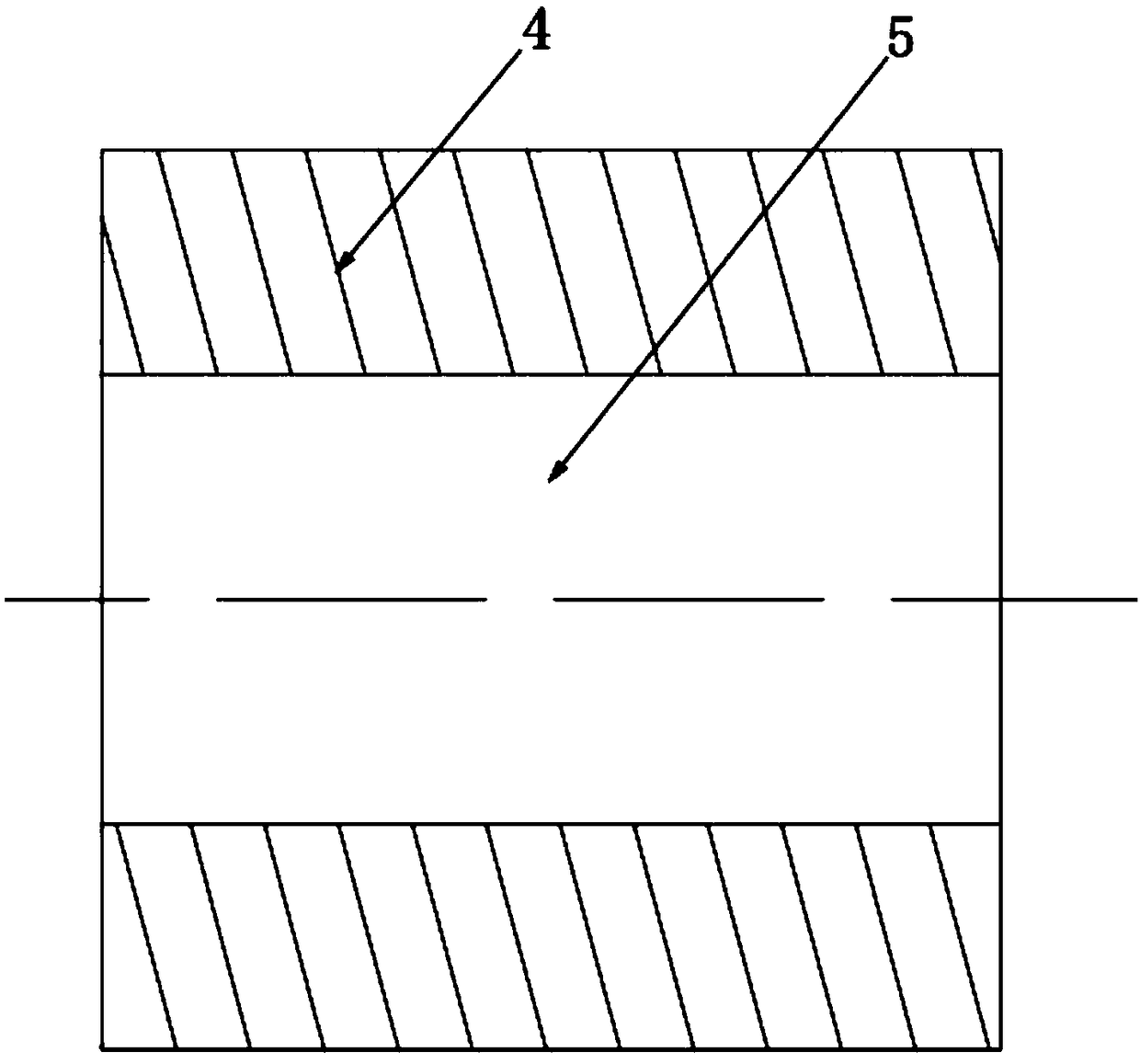

[0042] In a further embodiment of the present invention, the first dummy hub 9 and the second dummy hub 10 are limitedly fitted by keys.

[0043] In a further embodiment of the present invention, the crank disc 1 is fastened to the first propeller hub 3 and the second propeller hub 4 through bolts or other means, so that several blades 2 and several crank discs 1 are connected to the first propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com