Electric accelerated concrete corrosion test device and method for simulating two-way tension and compression

A test device and a technology of concrete specimens, which are applied in the field of simulation tests, can solve problems such as the inability to study electric acceleration of hydraulic concrete dissolution, and achieve the effect of preventing the intercommunication and leakage of the positive and negative poles, with significant advantages and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

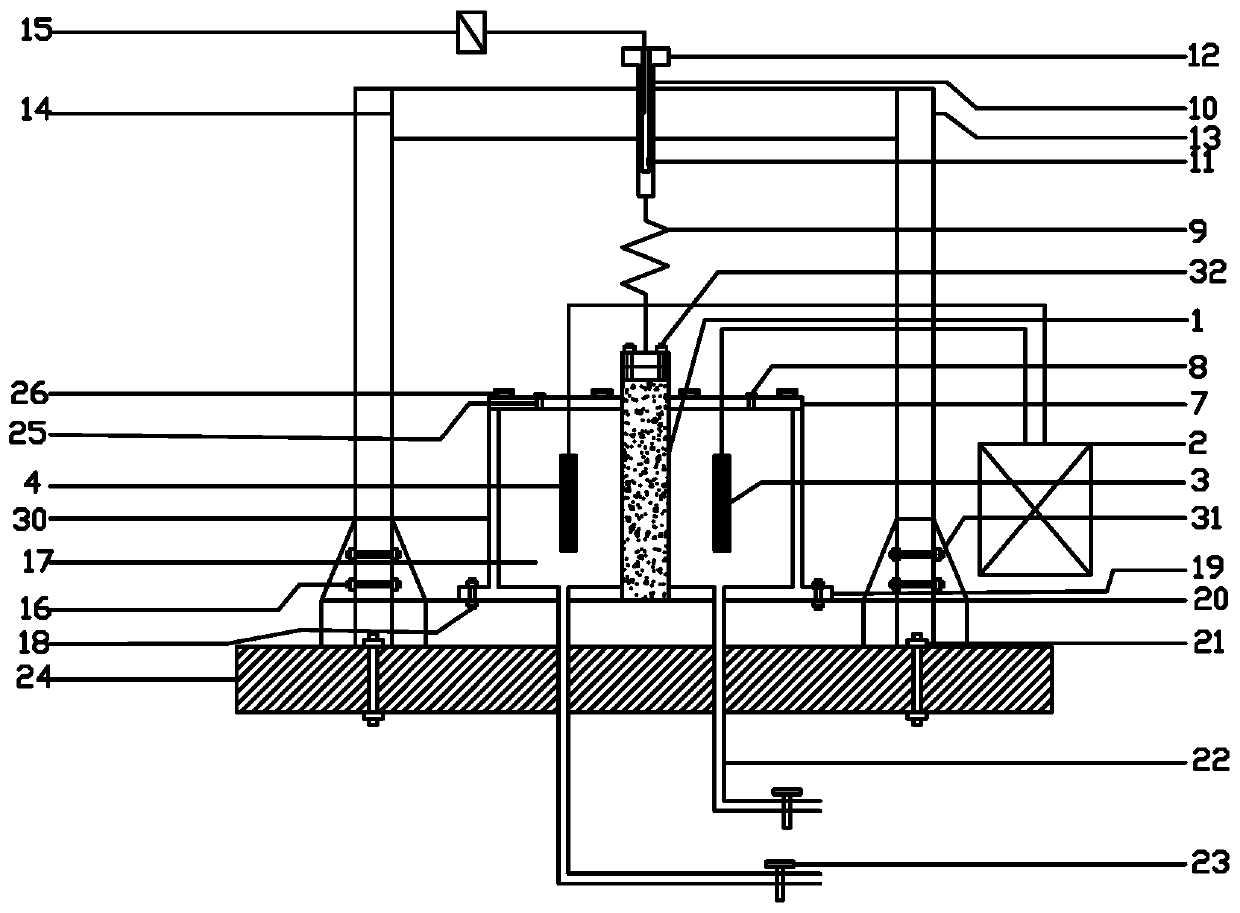

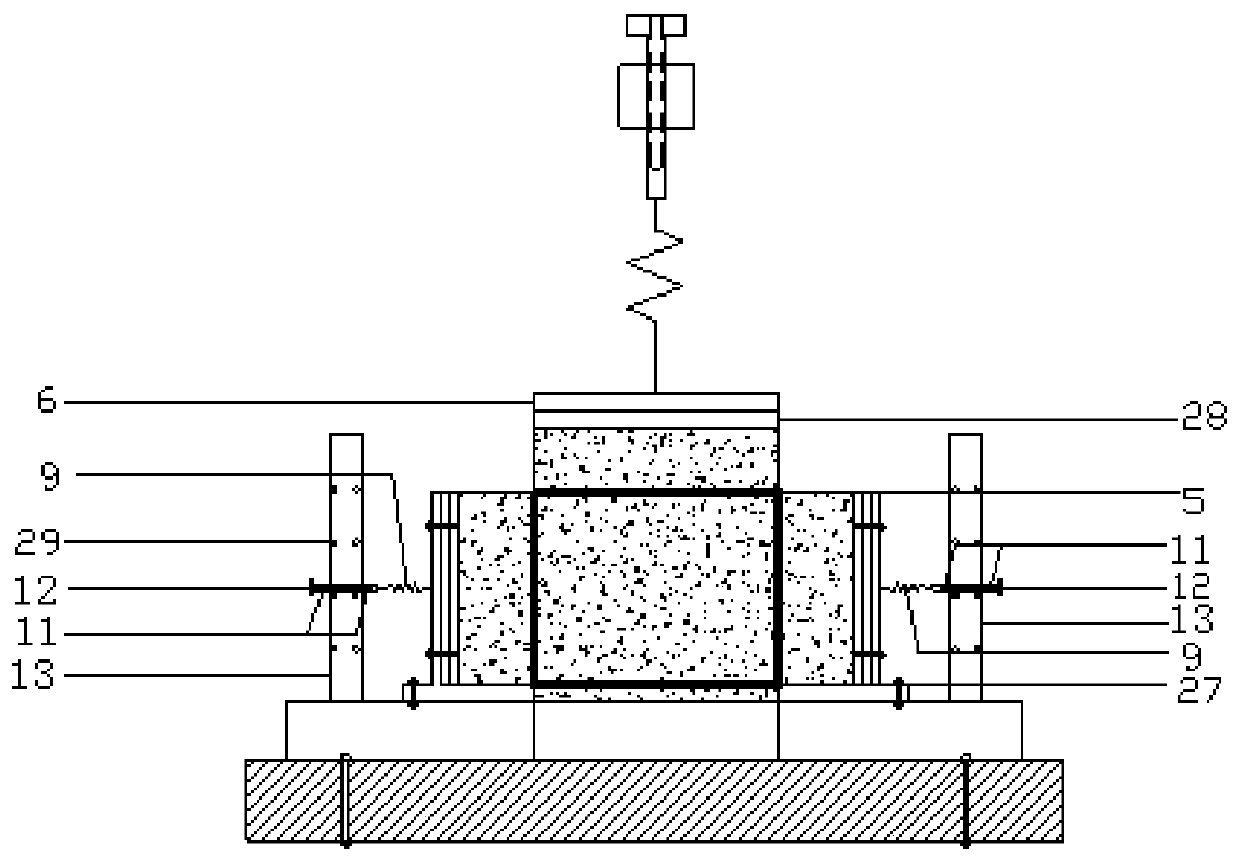

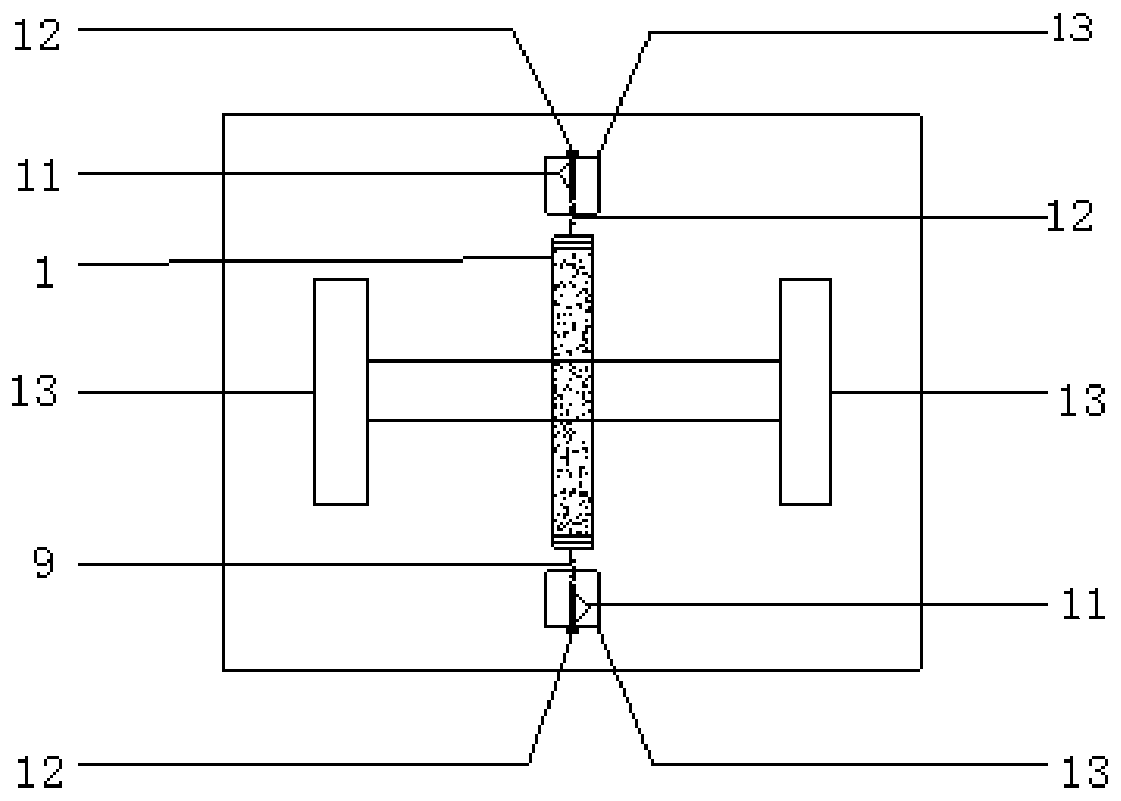

[0040] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0041] Such as Figure 1-Figure 3 As shown, the present invention includes the following technical features: 1 is a concrete test piece, 2 is a rectifier, 3 is an anode electric plate, 4 is a cathode electric plate, 5 is a water-stop rubber at the top of an electrolysis chamber, 6 is a tensile steel plate, and 7 is an electrolytic Chamber top cover, 8 is water inlet sealing rubber cover, 9 is high stiffness spring, 10 is hollow screw, 11 is strain gauge, 12 is vertical nut, 13 is I-beam reaction force frame, 14 is reaction force frame plus Rib, 15 is the strain collection box, 16 is the fixing bolt of the triangular steel plate, 17 is pure water, 18 is the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com