A 100,000-kilowatt reactor core fuel management method

A fuel management and reactor technology, applied in the direction of reactor fuel elements, reactor, nuclear reaction control, etc., can solve the problems of reducing fuel economy, low difficulty of fuel management, uneven fuel consumption, etc., to improve fuel economy, The effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

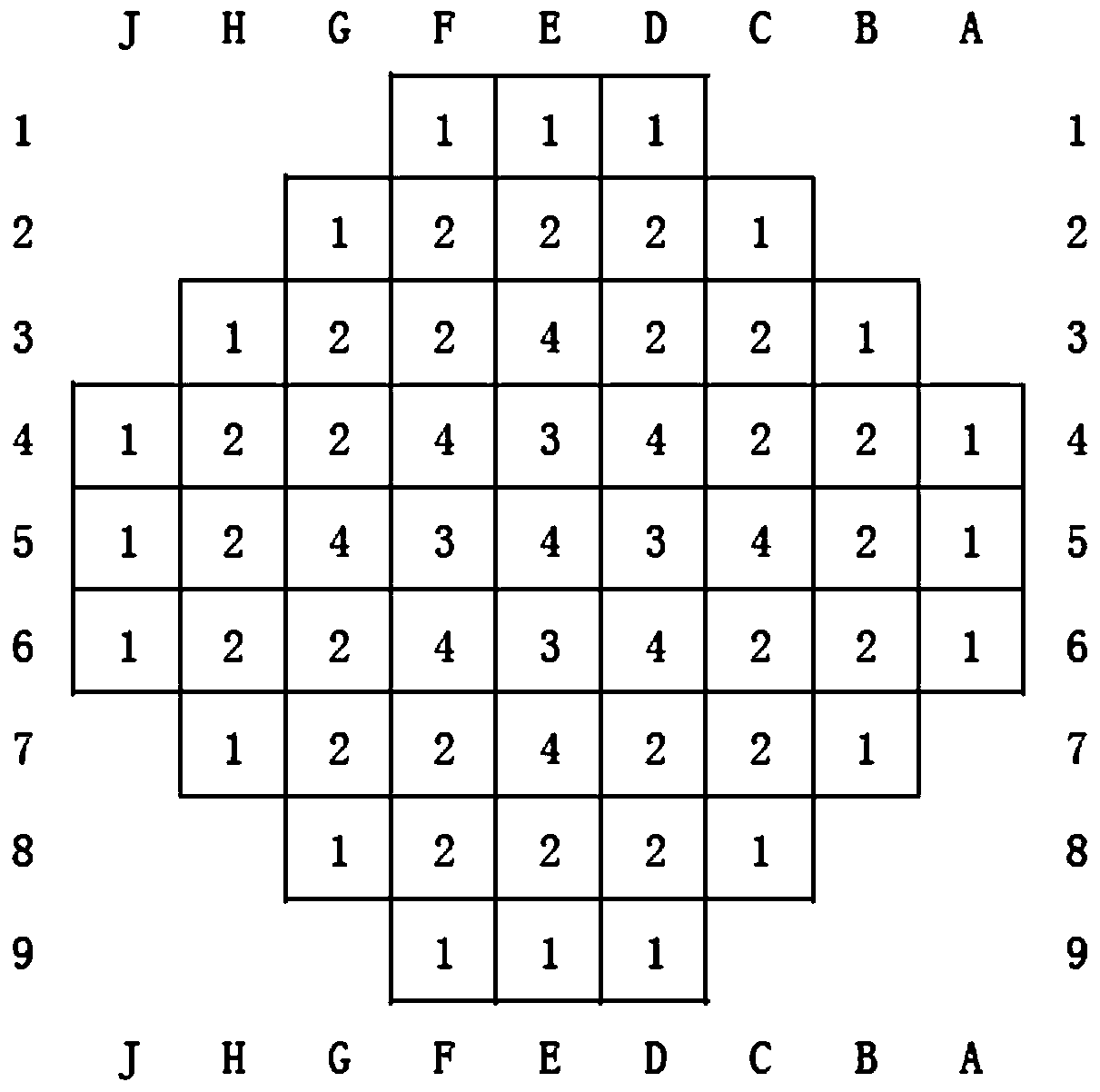

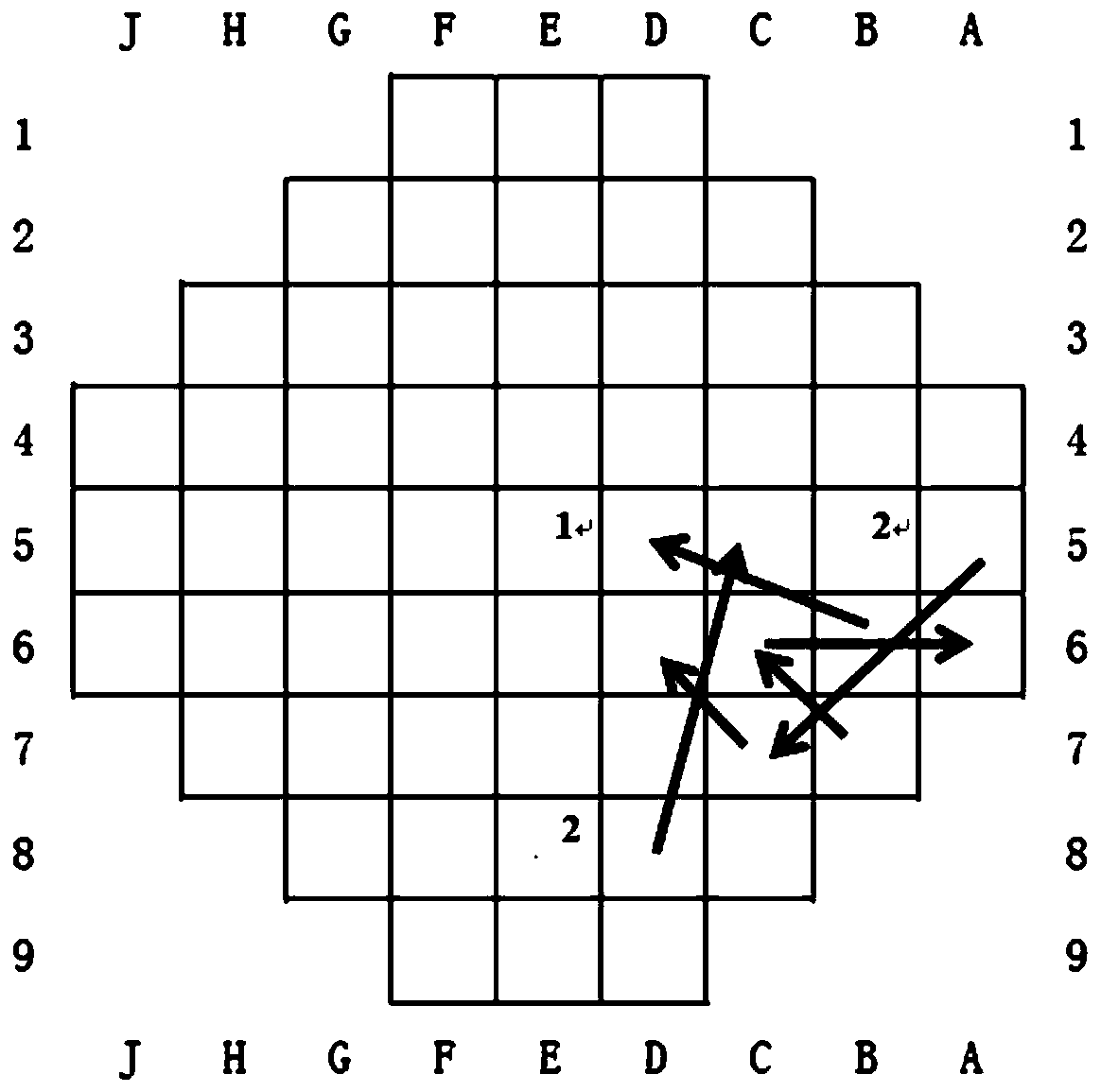

[0022] The invention is aimed at a small pressurized water reactor with pure rod control, thermal power of 300-400MW, electric power of about 100,000 kilowatts, and 57 boxes of square advanced fuel assemblies. Mixing charge with multiple enrichment degrees, using a large amount of integrated burnable poisons, using different mass percentages or different quantities of integrated burnable poisons, and using optimized control rod grouping and rod lifting sequence (including switching adjustment rods and overlapping steps) rod strategy); the reactor does not contain soluble boron, and 9 groups of 49 bundles of control rods are arranged for reactivity adjustment and burnup compensation, so that when all the control rods are lifted out of the core, the core k eff It is equal to 1.001 as the criterion for shutting down and refueling (from the first cycle to the balance cycle); the first cycle lasts 24 months, the second cycle lasts about 17 months, and the subsequent cycle lasts 24 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com