High-strength armored cable

A kind of armored cable, high-strength technology, applied in the direction of power cable, insulated cable, cable/conductor manufacturing, etc., can solve the problems of installation, transportation trouble, not easy to break, open, inconvenient use, etc., to increase the resistance Compression capacity and weighing capacity, the effect of increasing the compression area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

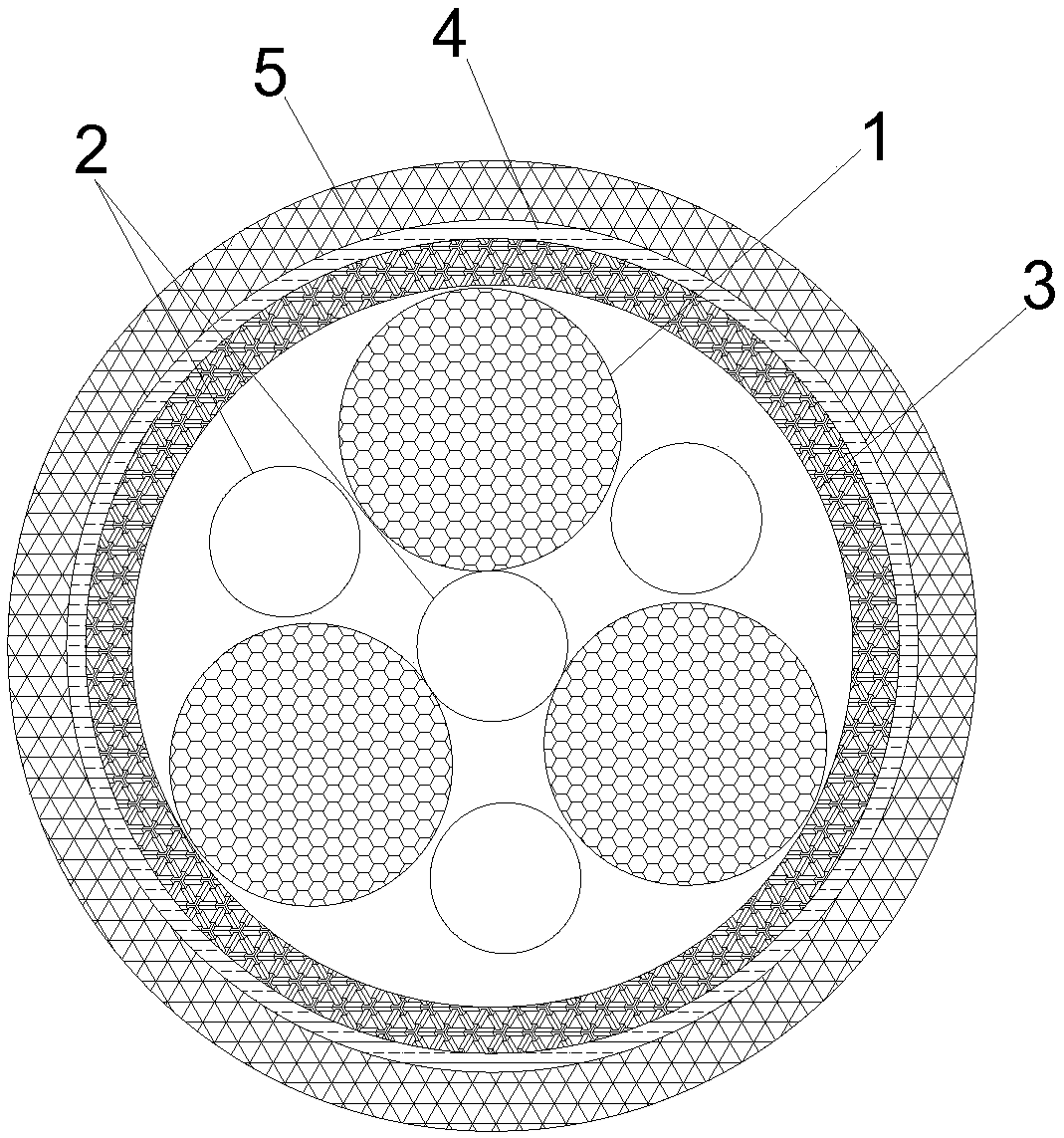

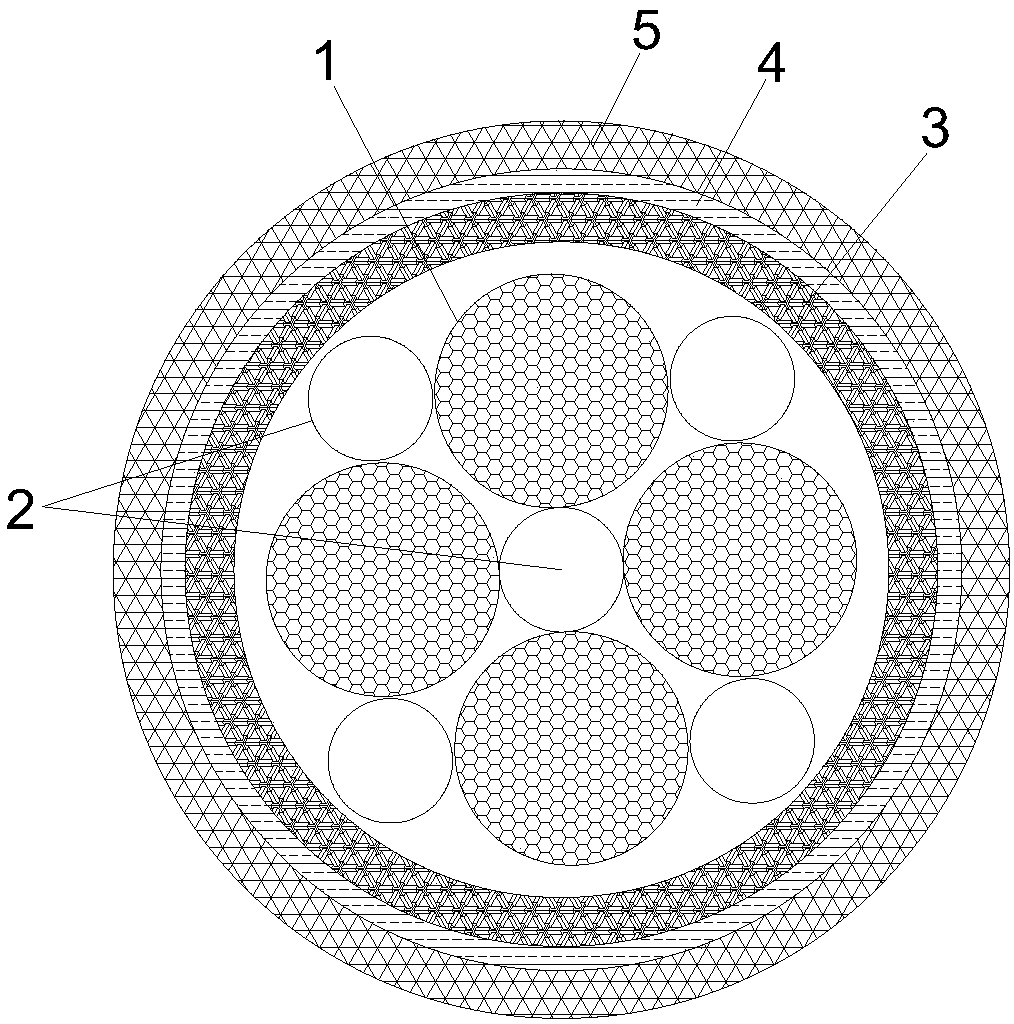

[0049] Such as figure 1 as well as figure 2 As shown, a high-strength armored cable includes a cable core wire 1, a polyester fiber rope 2 is arranged beside the cable core wire 1, and the polyester fiber rope 1 and the cable core wire 2 are wrapped with an armor layer 3. A sheath layer 5 is provided outside the armor layer 3, and an isolation layer 4 is provided between the armor layer 3 and the sheath layer 5;

[0050] The cable core wires 1 are provided with 3-5 strands, twisted together;

[0051] The polyester fiber rope 2 is located between adjacent cable core wires 1, and the polyester fiber rope 2 is wound with the cable core wire 1;

[0052] The ratio of the diameter of the cable core wire 1 to the diameter of the polyester fiber rope 2 is 1: (0.4-0.7);

[0053] The sheath layer 5 is made of rubber material.

Embodiment 2

[0055] The preparation method of the armor layer is:

[0056] Ⅰ Grinding 15-23 parts by weight of foaming agent and passing through a 120-200 mesh sieve;

[0057] ⅡCrush and grind 100-110 parts by weight of aluminum alloy ingots into granules, then mix them uniformly with 8-15 parts by weight of ceramic balls, 10-12 parts by weight of magnesium powder, and 4-10 parts by weight of silicotungstic acid, and put them into the melting furnace, and Completely melt in an inert gas atmosphere, then inhale the blowing agent under negative pressure, and continue to stir to obtain a uniform mixture of aluminum liquid;

[0058] Ⅲ Pour the molten aluminum mixture in Ⅱ into the mold, push it into the foaming furnace, and keep it warm at 680-700°C for a period of time;

[0059] Ⅳ mold cooling, enter the cooling system to cool to obtain the foamed aluminum material;

[0060] The foaming agent is one of titanium hydride and zirconium hydride;

[0061] The aluminum alloy is aluminum alloy (5...

Embodiment 3

[0065] The isolation layer is made of the following materials by weight,

[0066] 19 parts of polyethylene resin, 3 parts of sodium hydroxide, 3 parts of isocyanate, 5 parts of diethylene glycol butyl ether, 1 part of tributoxyethyl phosphate, 4 parts of modified bentonite, 4 parts of lignosulfonic acid, stearic acid 4 parts of calcium, 9 parts of anti-aging agent IPPD, 30 parts of deionized water;

[0067] The preparation method of the modified bentonite is as follows: grind the bentonite and pass through a 300-400 mesh sieve, then bake it at a temperature of 45°C for 30 minutes, and then add 0.8 times its mass of pure water at 60°C, at 60°C After stirring and mixing at a constant temperature for 1 hour, add dioctyl azelate, and lower the temperature to 40°C, continue stirring and mixing for 1.5 hours, then dry and regrind to obtain modified perlite;

[0068] The mass ratio of described dioctyl azelate to bentonite is 1:3.9;

[0069] The preparation method of the isolation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap