Welding-free quick plug type device for electric core multi-module assembly

A welding-free and battery-free technology, which is applied to battery components, batteries, circuits, etc., can solve the problems of reduced safety performance, reduced vehicle use requirements, and reduced overall performance of the battery pack, to compensate for height errors and increase positive poles. Effect of contact force and improvement of link reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

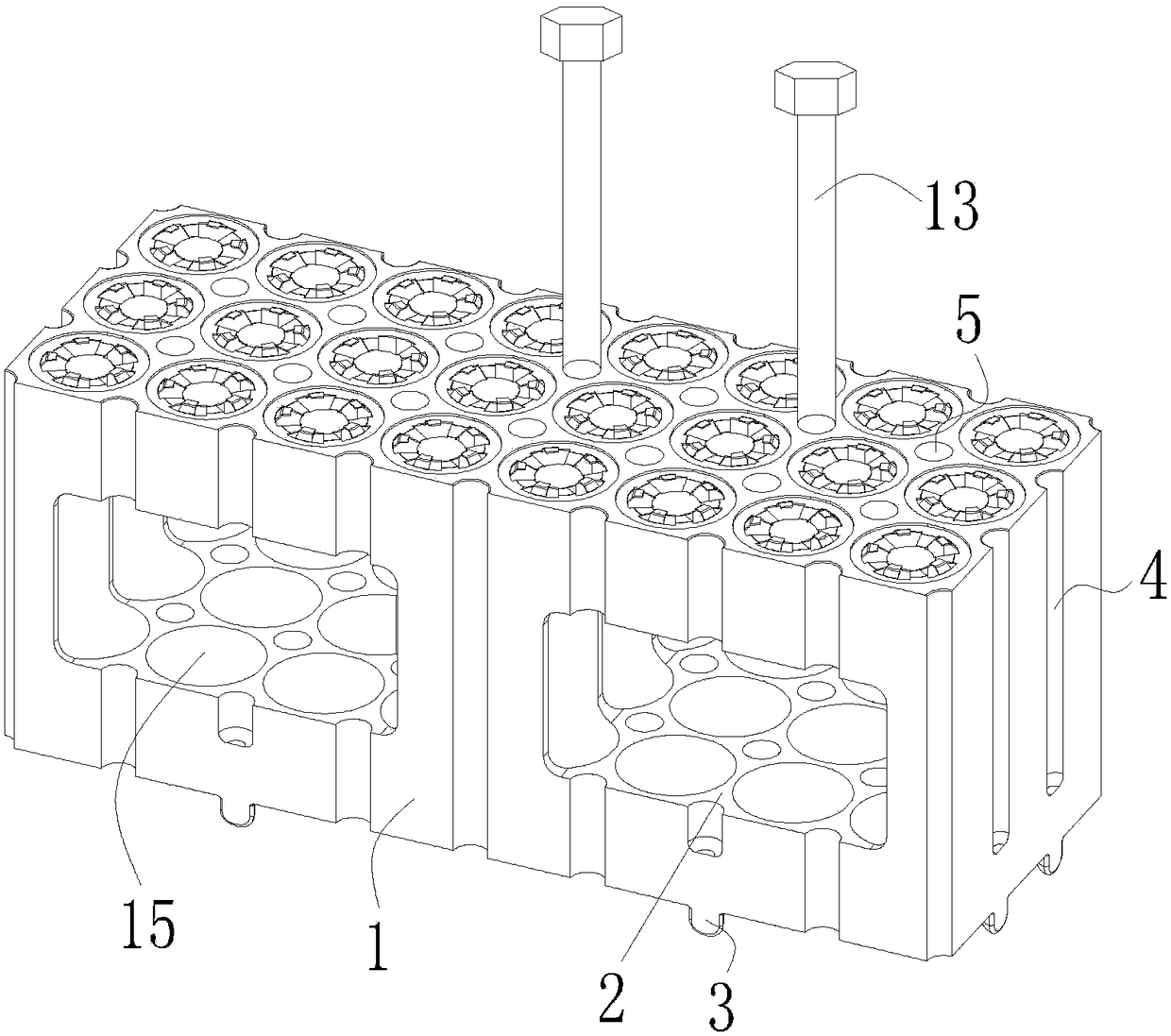

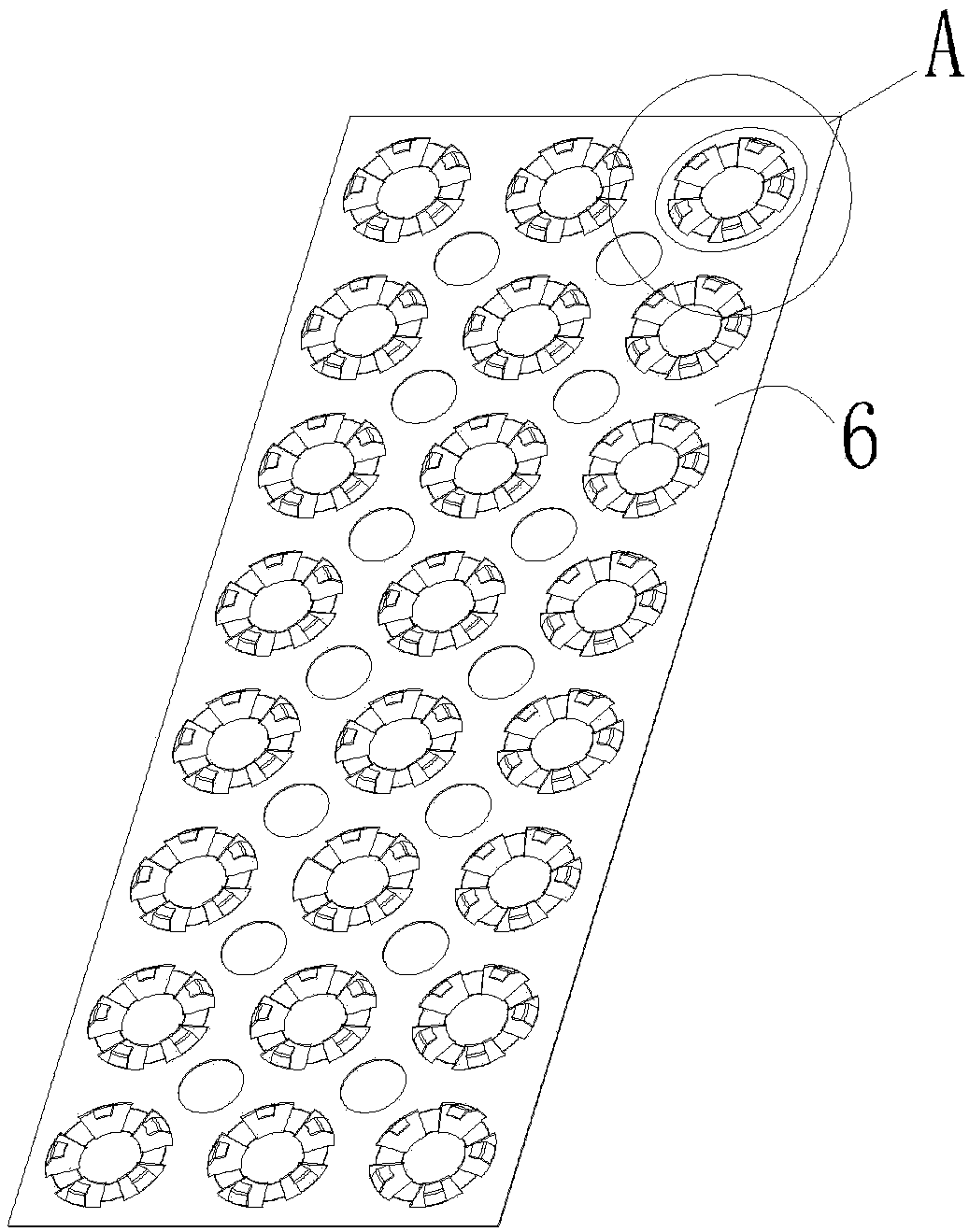

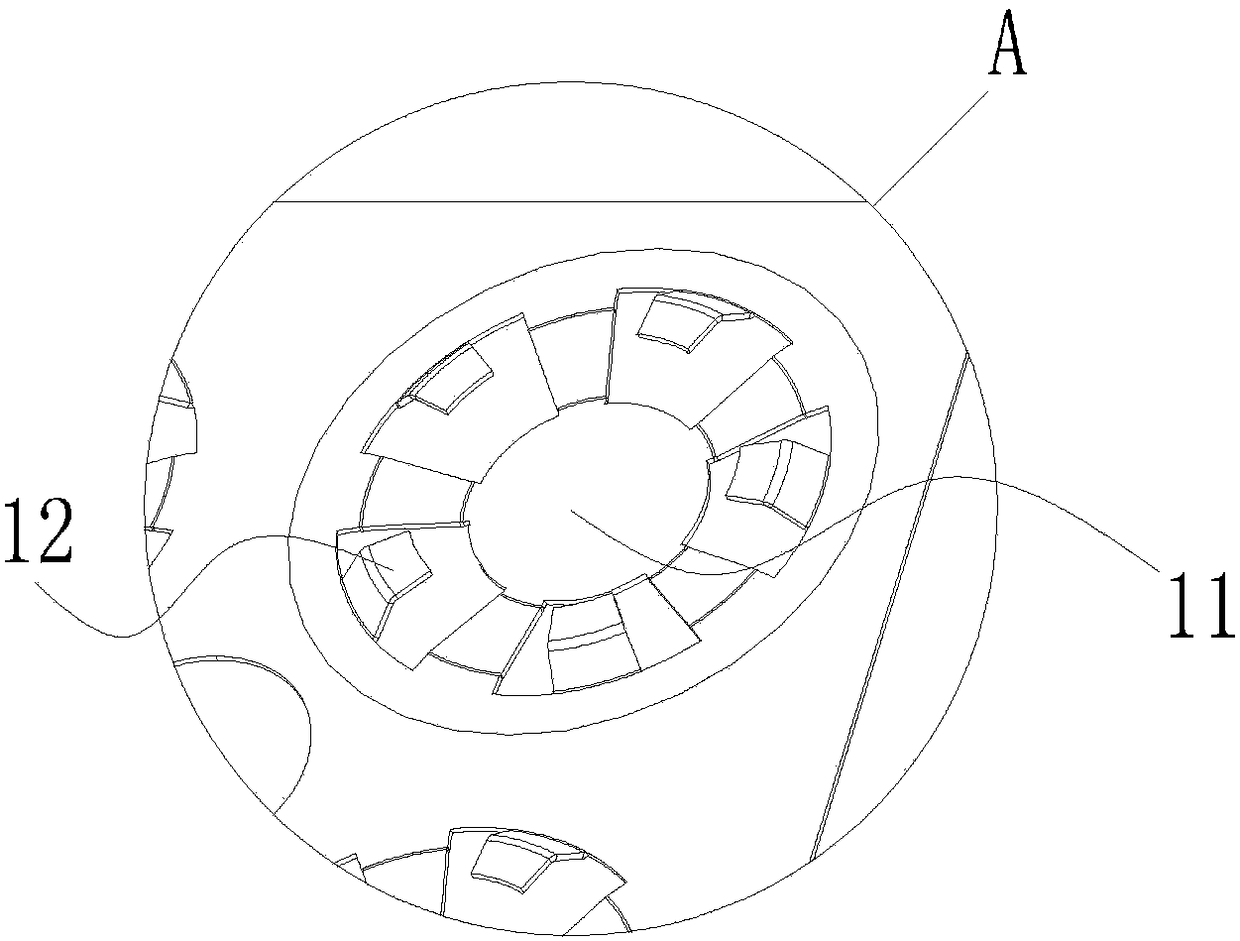

[0020] Specific embodiments of the present invention such as Figure 1 to Figure 6 As shown, a welding-free quick-plug device for battery multi-module assembly includes a housing 1 provided with a plurality of positioning holes 15 for placing batteries, and an upper conductive plate 6 respectively arranged at the upper end and the lower end of the housing 1 And the lower conductive plate 7, the upper conductive plate 6 is provided with a plurality of elastic bosses 11 corresponding to the positions of a plurality of positioning holes 15 and the elastic connecting block 12 surrounding the elastic boss 11, the elastic boss 11 The protruding end points to the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com