A 7D printing system and printing method thereof

A printing system and host system technology, which is applied to other home appliances, 3D object support structures, and electrical components to assemble printed circuits, etc., can solve the problems of many equipment, complex systems, poor sealing, etc. Fewer parts and improved short-circuit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will be described in detail in conjunction with the accompanying drawings and specific embodiments. The following embodiments are used to illustrate the present invention, but not to limit the scope of the present invention.

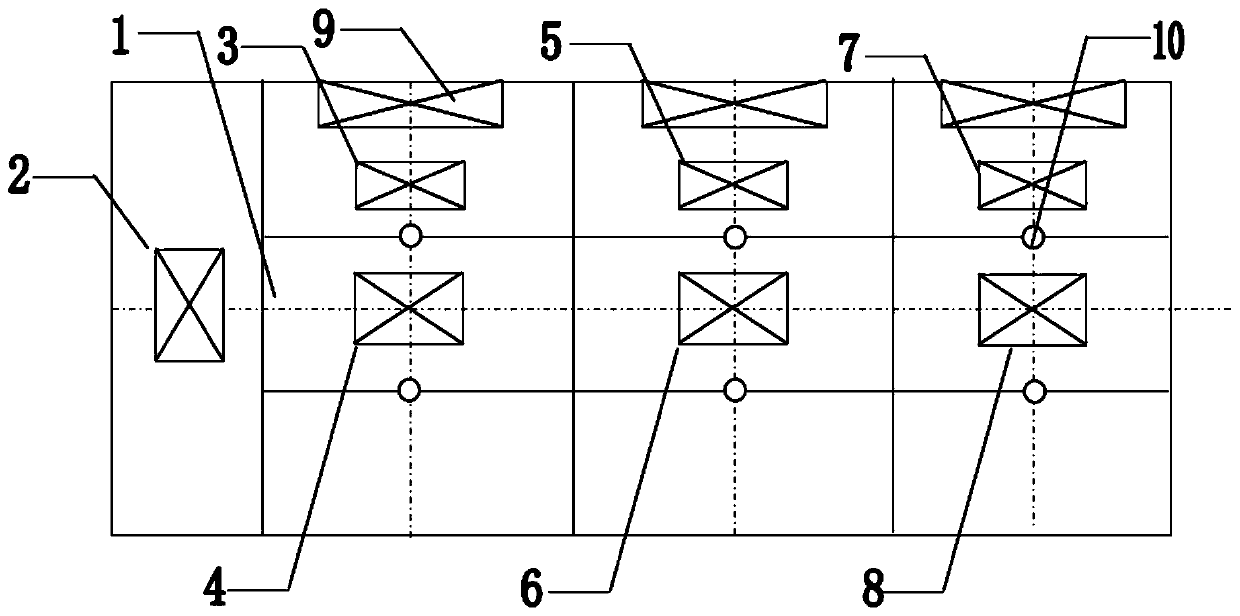

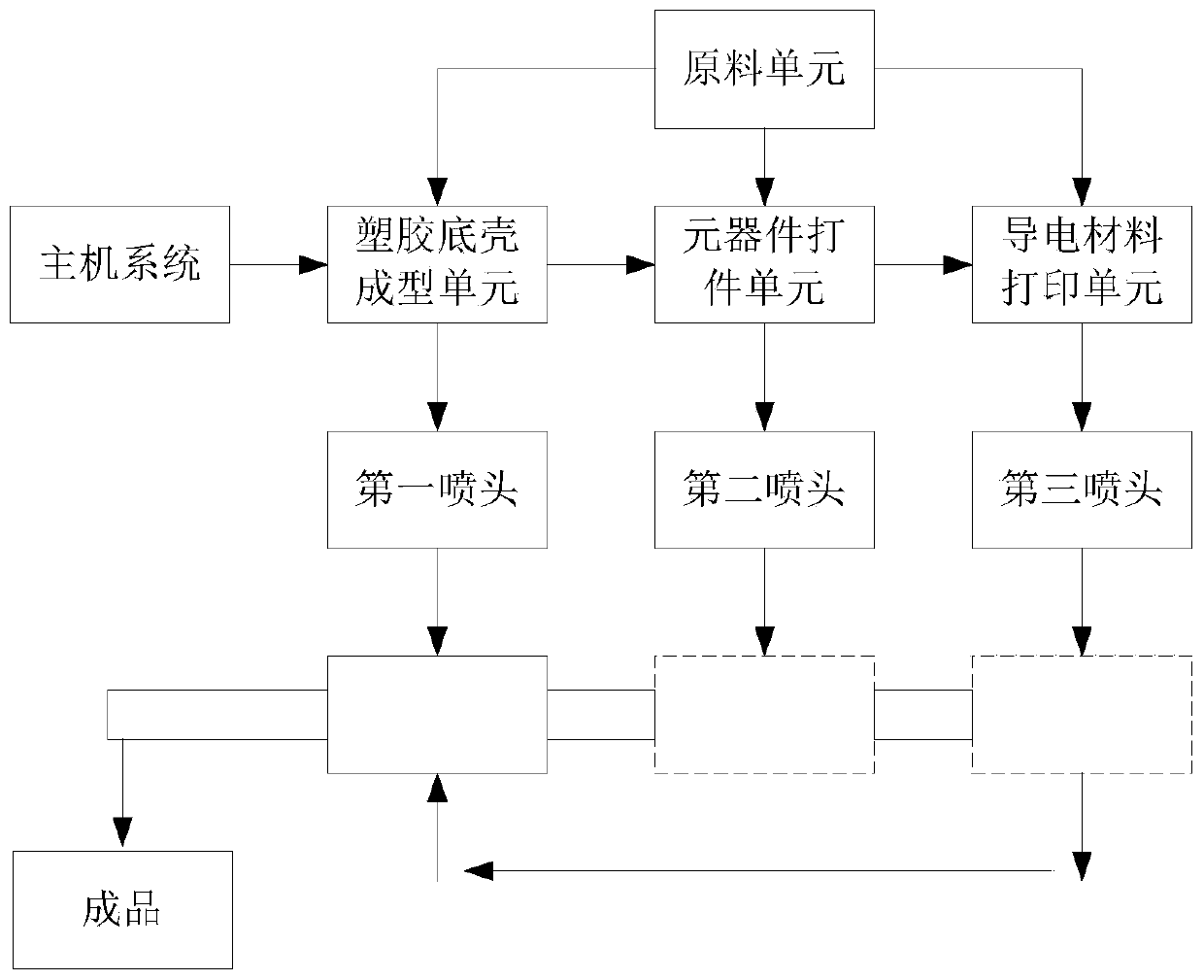

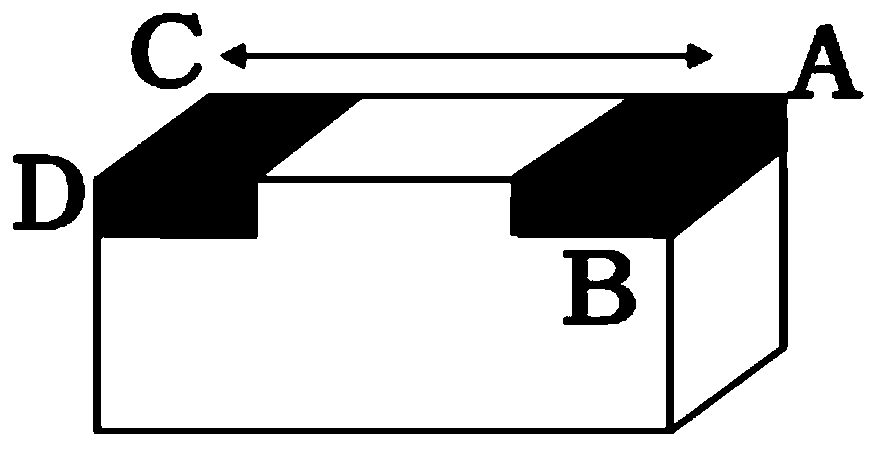

[0032] refer to figure 1 , figure 2 As shown, a 7D printing system includes a raw material unit 9, a plastic bottom shell forming unit 3, a component printing unit 5, a conductive material printing unit 7, and a host system 2; wherein:

[0033] The raw material unit 9 is used to store various insulating materials and circuit printing materials;

[0034] The plastic bottom shell molding unit 3 is connected to the host system 2, and is used to print the insulating material in the raw material unit into a casing of an electronic product;

[0035] The component printing unit 5 is connected to the host system 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com