Magnetic gear structure capable of improving production efficiency

A production efficiency, magnetic gear technology, applied in the direction of permanent magnet clutches/brakes, electrical components, electromechanical devices, etc., can solve the problems of troublesome manufacturing process of the modulation ring, the need to strengthen the modulation ring, and the complex assembly structure of the modulation ring, etc., to achieve guaranteed Rigidity and integrity, ingenious design, ingenious shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

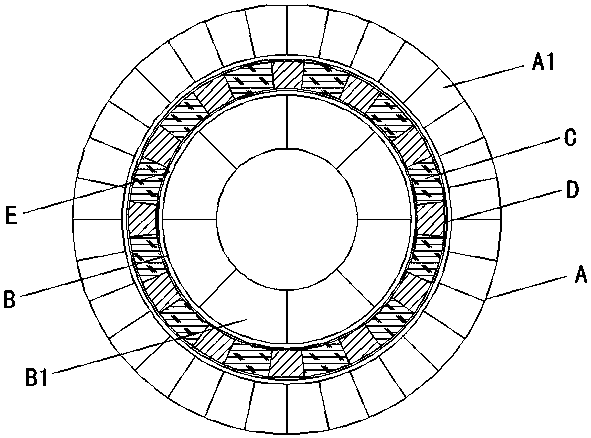

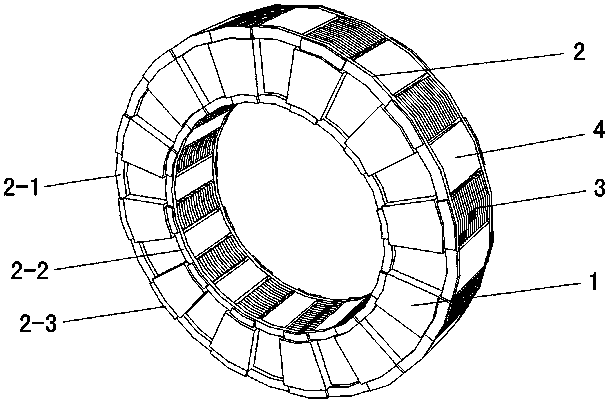

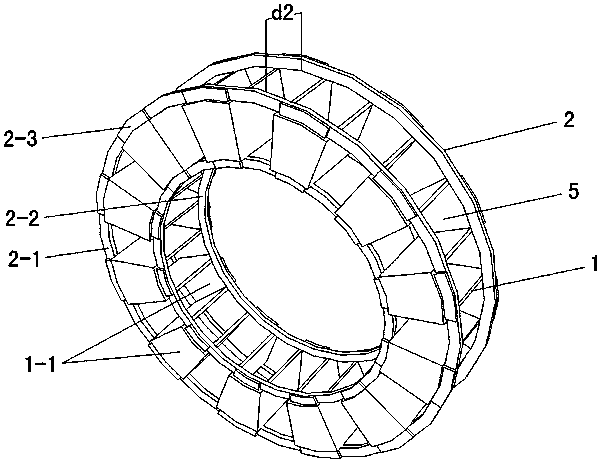

[0015] Specific implementation mode one: as Figure 1~Figure 7 As shown, the present invention discloses a magnetic gear structure capable of improving production efficiency, including an outer rotor A, an inner rotor B and a modulation ring C, the modulation ring C is fixed, and the outer rotor A rotates coaxially Outside the modulation ring C, there is an outer air gap D between the outer rotor A and the modulation ring C. The inner rotor B rotates coaxially inside the modulation ring C, and an inner air gap is set between the inner rotor B and the modulation ring C. Gap E, the outer rotor A is spliced and pasted into a large ring shape by a plurality of sector-shaped permanent magnet blocks-A1, the plurality of sector-shaped permanent magnet blocks-A1 are radially magnetized, and every two adjacent sector-shaped permanent The magnetic poles of block 1 A1 are opposite, and the inner rotor B is spliced and pasted into a small ring shape by a plurality of sector-shaped per...

specific Embodiment approach 2

[0016] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of Embodiment 1. Each of the sector-shaped permanent magnet block A1 and sector-shaped permanent magnet block 2 B1 is made of NdFeB material.

specific Embodiment approach 3

[0017] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of Embodiment 1 or Embodiment 2, and the air gaps of the outer air gap D and the inner air gap E are both 0.2-0.4 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com