Carding machine with a device for adjustment of the carding gap

A technology of carding machine and gap, applied in the field of carding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

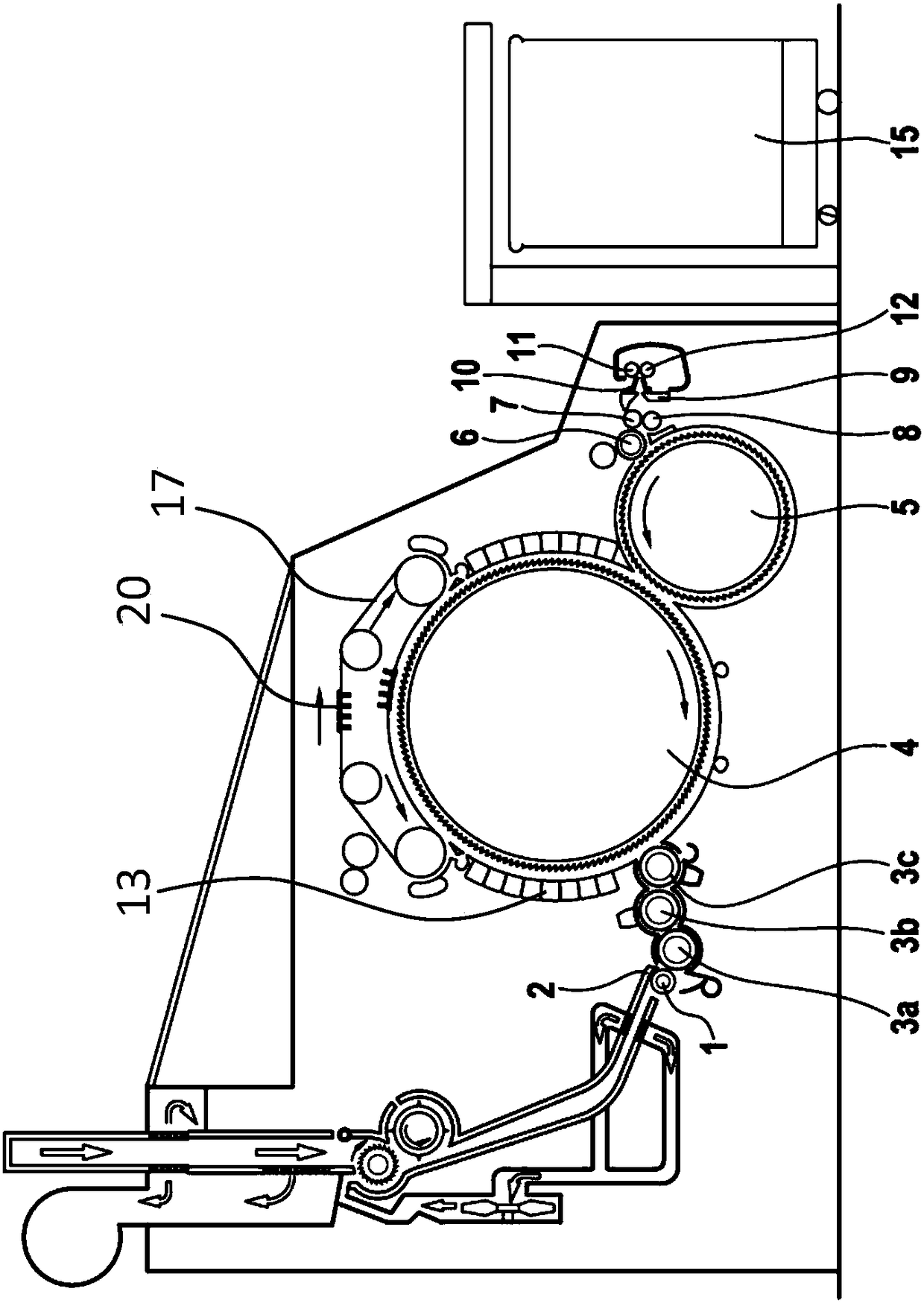

[0025] figure 1 A card according to the prior art is shown in which loose fibers are guided via slides to feed roller 1 , feed table 2 , via a plurality of licker-in rollers 3 a , 3 b , 3 c to drum 4 or cylinder. The fibers of the loose fibers are parallelized and cleaned on the cylinder 4 by means of the stationary carding elements 13 and the endless flat strips 20 arranged on the revolving flat 17 . The resulting fiber fluff is then conveyed via a doffer 5, a take-off roller 6 and a plurality of pressure rollers 7, 8 to a web guiding element 9, which reforms the fiber fluff by means of a bell mouth 10 into a fiber sliver, The fiber strand is passed via take-off rollers 11 , 12 to a downstream processing machine or can 15 .

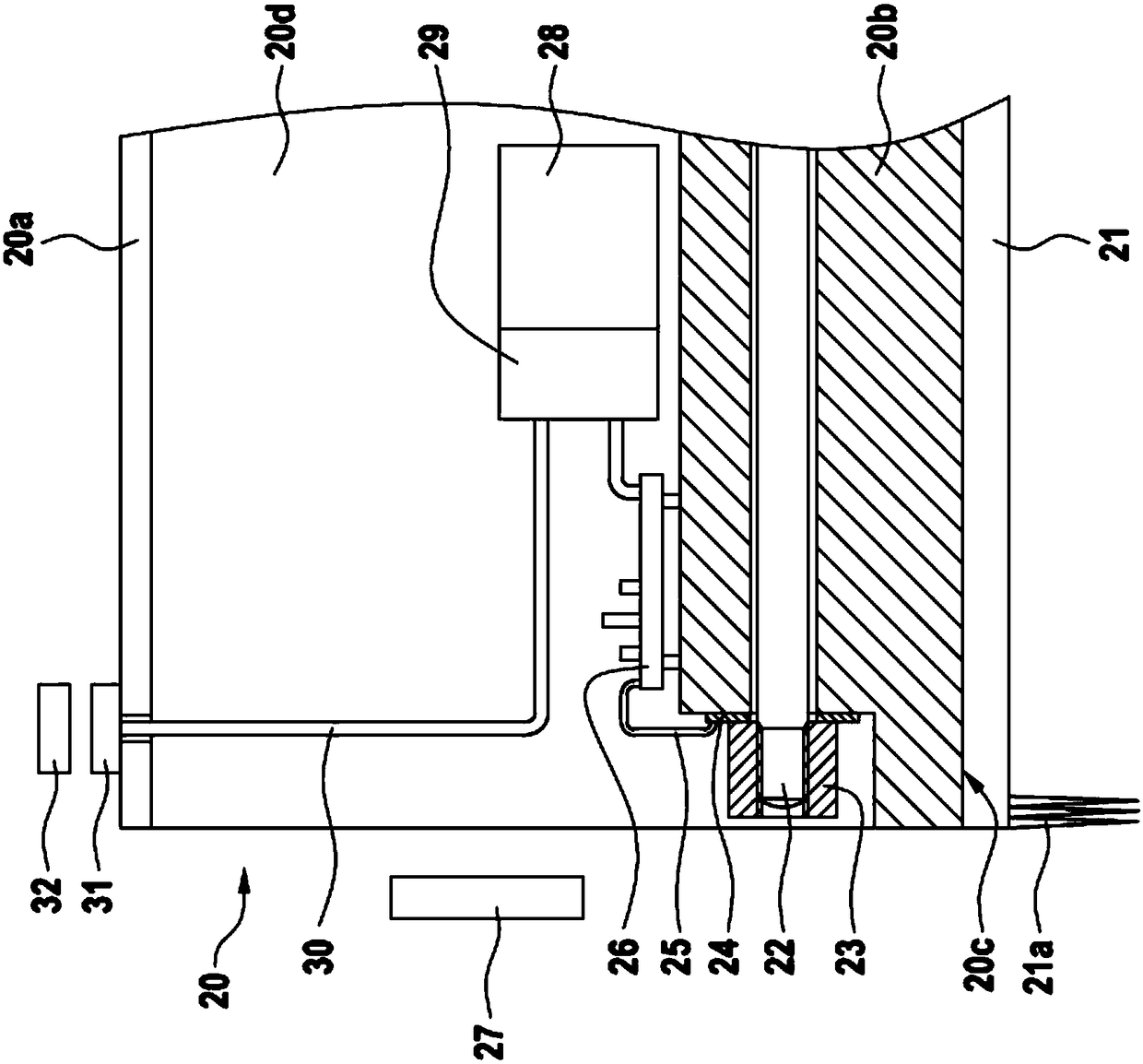

[0026] figure 2A cross section is shown through the flat strip 20 which is arranged on the revolving flat 17 and runs around. The cover strip 20 can be made of extruded aluminum and comprises a cover back 20a, a carrier 20b and a cover bottom 20c. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com