Method and device for operating an internal combustion engine in the event of a fault of a crankshaft sensor

A technology of crankshaft sensor and camshaft sensor, which is applied in the direction of valve device, valve driving device, machine/engine, etc., which can solve the problems such as the deterioration of exhaust characteristics of internal combustion engines, and achieve the effect of reducing exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Like features are marked with like reference numerals.

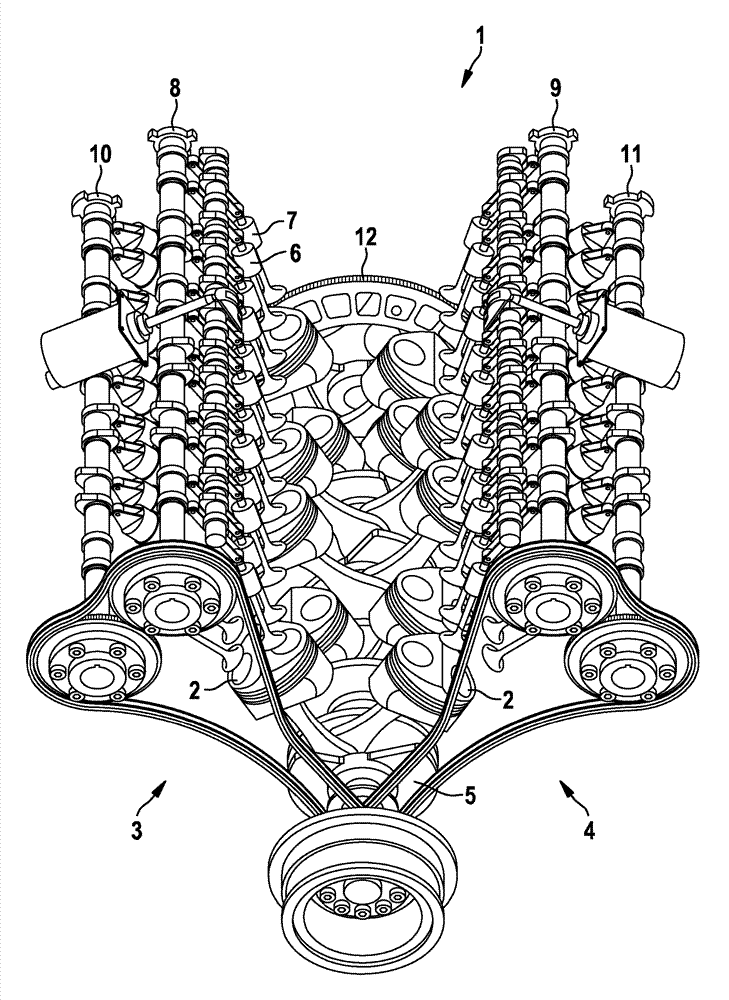

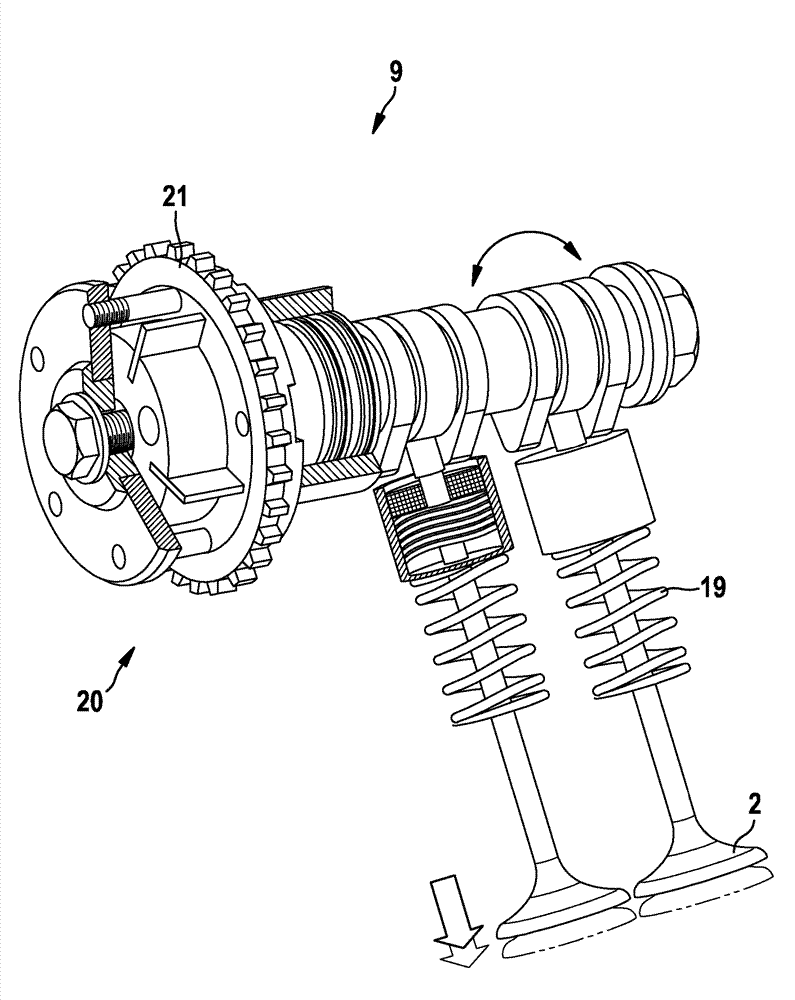

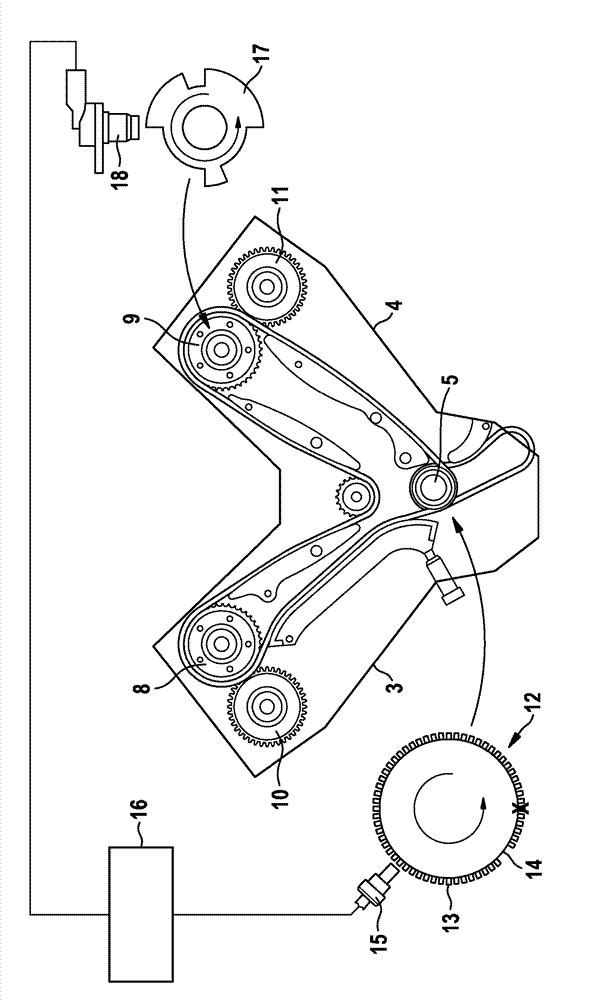

[0020] figure 1 A schematic diagram of a V-shaped internal combustion engine 1 is shown. In this case, cylinders 2 of internal combustion engine 1 are arranged V-shaped in two planes 3 , 4 , wherein crankshaft 5 is positioned at the intersection of these two planes 3 , 4 . Each plane 3, 4 is typically called a bank. Each cylinder 2 is provided with one or more intake valves 6 and exhaust valves 7 . Fresh air and fuel are supplied to the individual cylinders 2 of the internal combustion engine 1 via intake valves 6 , while the combustion products of the cylinders 2 are discharged from the internal combustion engine 1 in the form of exhaust gases via exhaust valves 7 . The intake valve 6 of the first plane 3 of the cylinder 2 is connected to the first camshaft 8 , while the exhaust valve 7 of the first plane 3 is driven by the second camshaft 10 . Similarly, the intake valves of the second plane 4 of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com