Saw blade locking device

A technology for locking devices and saw blades, applied in the direction of locking fasteners, threaded fasteners, connecting components, etc., can solve the problems of troublesome disassembly and assembly, inconvenience of keeping attention at all times, etc., and achieves convenient use and high safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

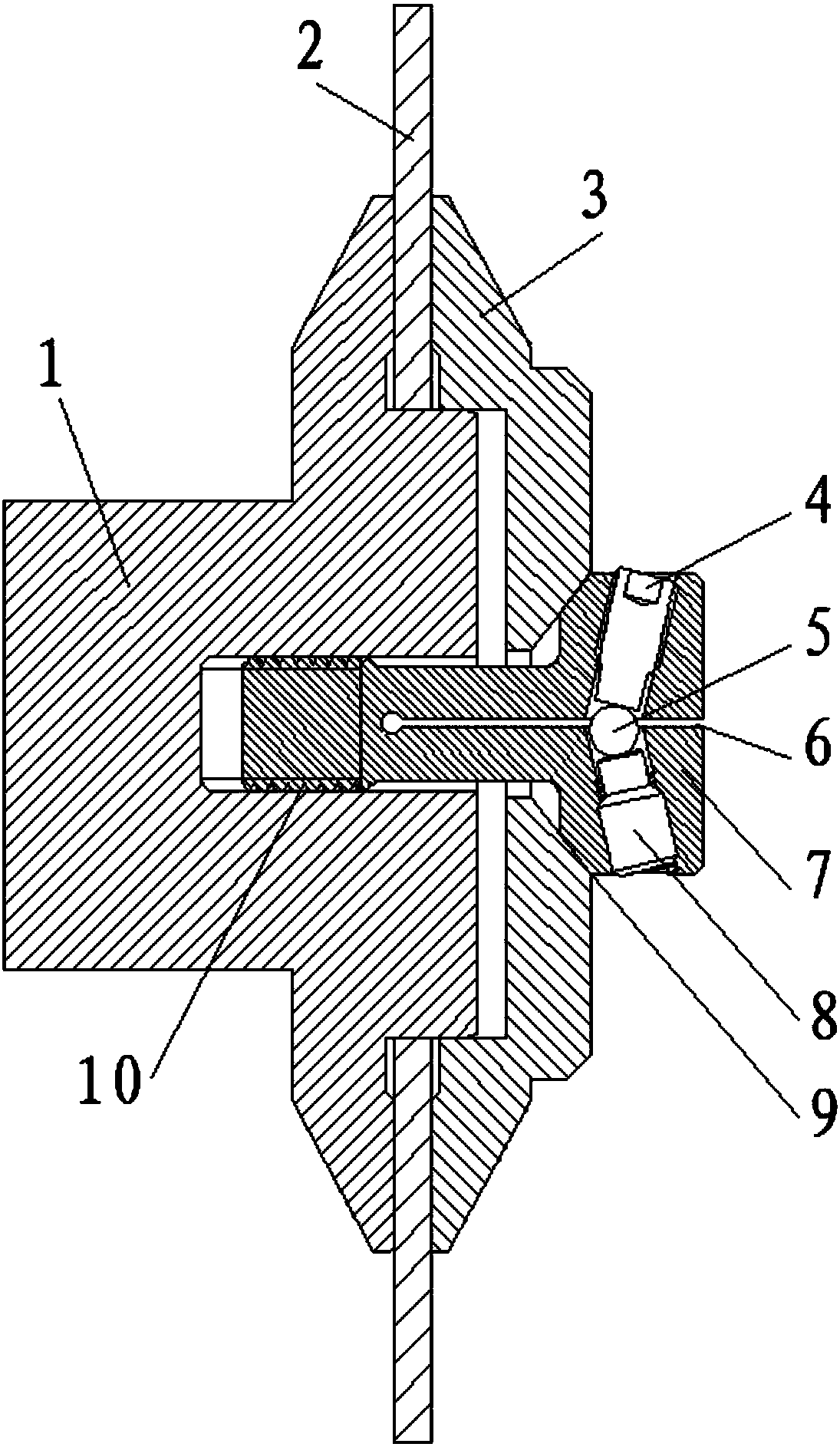

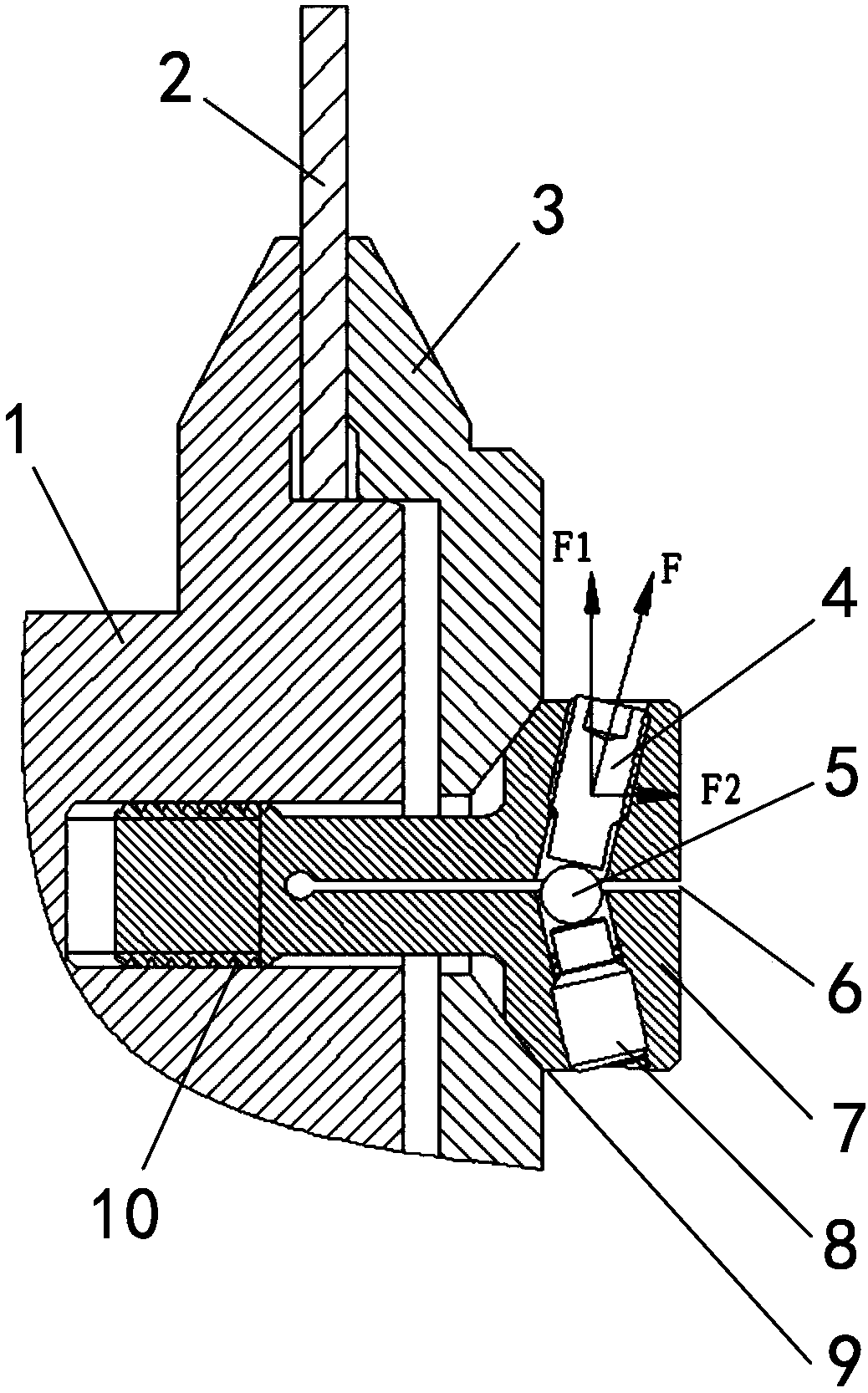

[0015] refer to figure 1 , figure 2 , The present invention is a saw blade locking device, comprising a pressing screw. One side of the compression screw is the threaded part 10 detachably connected to the saw shaft 1, and the other side of the compression screw is the expansion part 7 of the compression flange 3, and the expansion part 7 is provided with a compression slope 9 in contact with the flange 3, The compression screw is provided with a number of expansion grooves 6 that separate the expansion part 7 in the axial direction, and each expansion groove 6 is evenly distributed around the center of the expansion part 7, and the expansion part 7 is provided with a device for adjusting the radial expansion size of the expansion part 7. Adjustment components. The adjustment assembly includes a support ball 5 at the junction of each expansion groove 6 and several screws that are threaded and evenly distributed on the expansion part 7 , and the heads of each screw contact t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com