Intelligent nitrogen and oxygen sensor and detection method implemented by same

An intelligent nitrogen and oxygen sensor, zirconia technology, applied in the field of sensors, can solve the problems of all NO2, inaccurate measurement values, and current-type nitrogen and oxygen sensors cannot meet the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

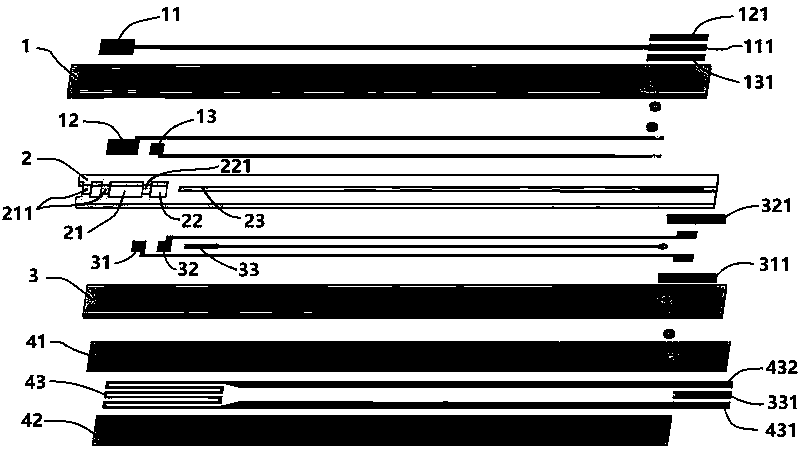

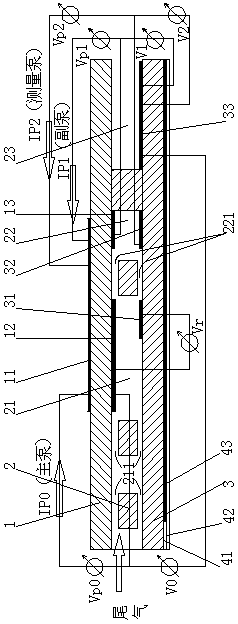

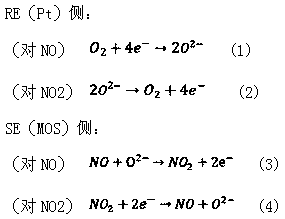

[0021] like figure 1 As shown, it is a sensor chip for smart nitrogen and oxygen sensors, figure 2 Provides an intelligent nitrogen and oxygen sensor with mixed potential and current signal characteristics, which can not only accurately measure the total amount of NOX in the exhaust gas through the current-type working principle, but also detect the ratio of NO / NO2 in the exhaust gas through the mixed potential characteristics, In this way, the respective concentrations of NO and NO2 in the exhaust gas can be accurately calculated.

[0022] The nitrogen and oxygen sensor of the present invention integrates a first measurement cavity, a second measurement cavity, a reference air channel and a heating unit by a three-layer substrate. The special feature is that in addition to the main pump unit, auxiliary pump unit and measuring pump unit, the measurement part also has a mixed potential detection unit, which consists of 6 electrodes; and the heating part consists of 2 electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com