Gas lift and pump lift combined lifting well drilling device without marine riser and parameter design method of well drilling device

A riser and drilling technology, applied to drilling equipment and methods, driving devices for drilling in boreholes, drilling equipment, etc., can solve the problems of increasing drilling costs and risks, reduce power, improve reliability, and improve parameters Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

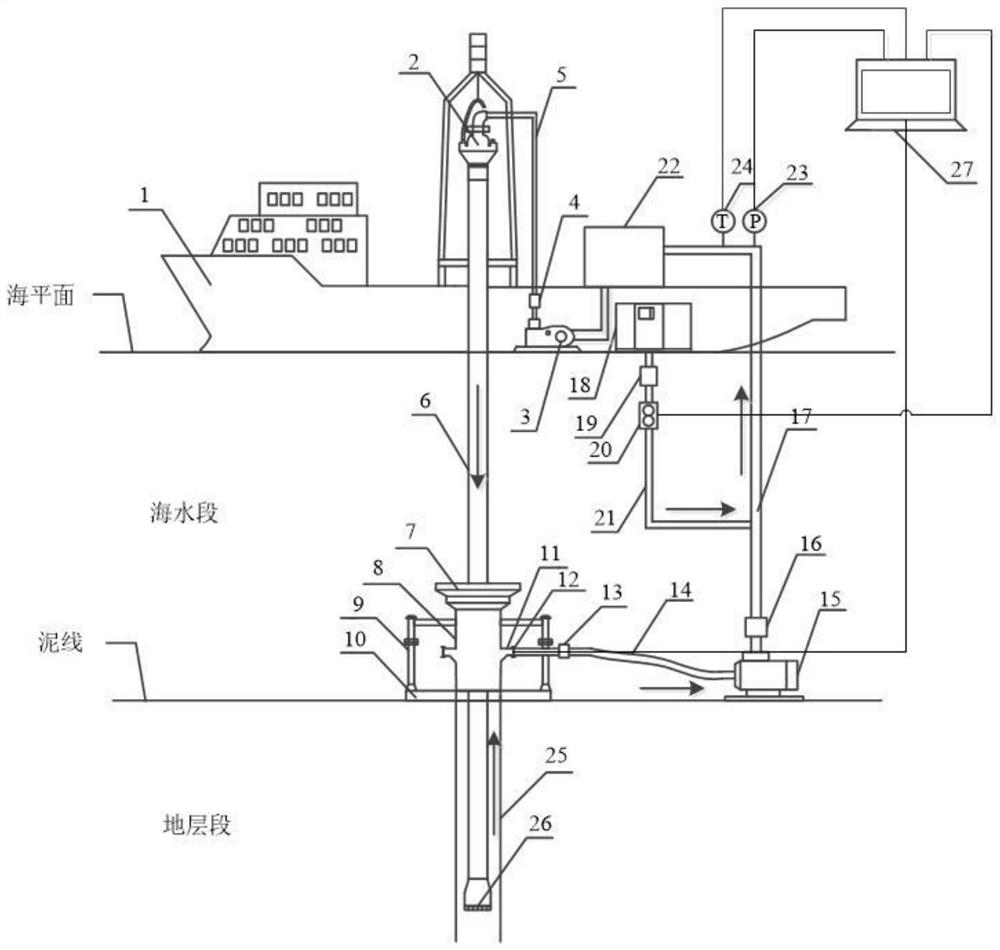

[0110] A drilling device with riserless gas lift and pump lift combined lift, such as Figure 1-2 As shown, it includes a drilling vessel 1, a drilling fluid injection system, a subsea drilling fluid suction system, a drilling fluid lifting system, a surface drilling fluid processing device 22, a data monitoring system and a data processing system;

[0111] The drilling fluid injection system is installed on the drilling ship 1. During drilling, the drilling fluid is pumped into the drill pipe 6 through the drilling fluid injection system to form a flow circulation in the wellbore to achieve the purpose of breaking the rock; the wellbore includes the drill pipe 6 and the casing 25, which are surrounded by The air is the annular part between the wellbore and the drill pipe. The subsea drilling fluid suction system is used to divert the cuttings and drilling fluid returned from the annular space to realize the sealing between the wellbore and the seawater; the drilling fluid is l...

Embodiment 2

[0115] A drilling device without riser gas lift, pump lift combined lift, as described in Embodiment 1, the difference is that the drilling fluid injection system includes a mud pump 3, a first flow control valve 4, a drilling fluid connected in sequence After injection into pipeline 5 and top drive 2, the drilling fluid stored in the mud tank is sucked by the mud pump 3, and then injected into the pipeline 5 along the drilling fluid under the action of the pump, and then sent into the drill pipe 6 through the top drive 2. The rod 6 flows to the drill bit 26 to achieve the purpose of assisting rock breaking.

[0116] The subsea drilling fluid suction system is installed on the subsea wellhead, and its functions are mainly to straighten down the drilling tool, provide an interface for the drilling fluid return line 14, and isolate the top of the annulus and the surrounding environment. The subsea drilling fluid suction system includes a subsea mud suction device 7, an external ...

Embodiment 3

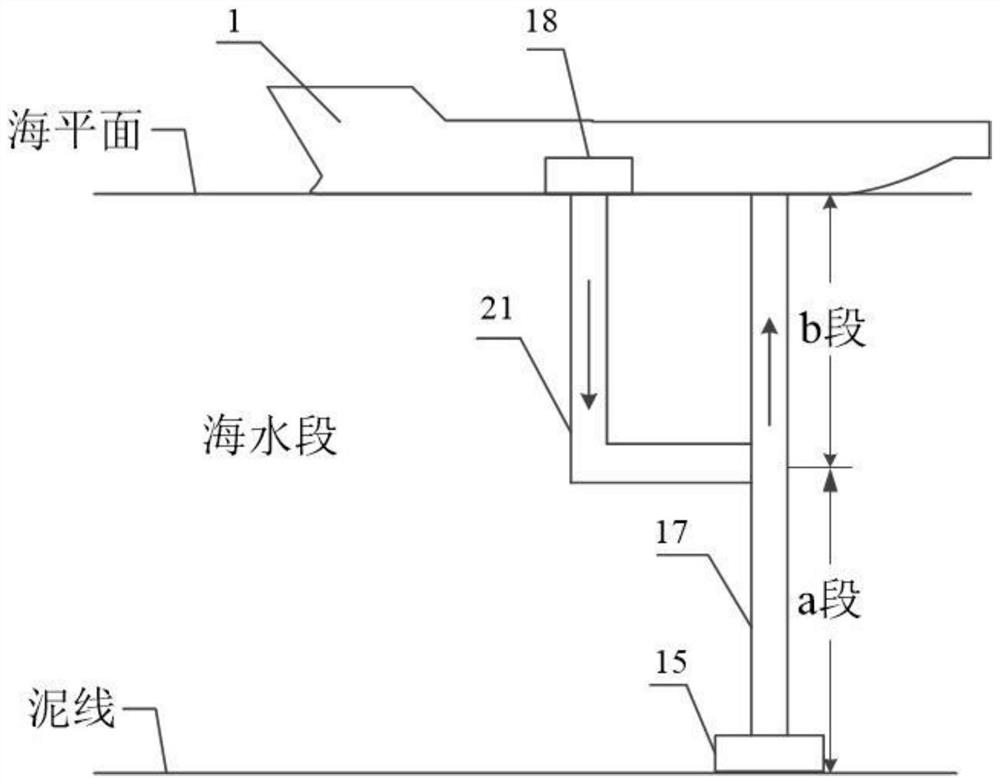

[0118] A drilling device without riser gas lift, pump lift combined lift, as described in Embodiment 2, the difference is that the pump lift system includes a subsea lift pump 15, a third flow control valve 16 and a drilling fluid upward return Pipeline 17, the subsea lifting pump 15 is installed on the seabed, and is used to provide power for the upturning cuttings and drilling fluid. The inlet of the subsea lifting pump 15 is connected with the drilling fluid return line 14 of the subsea drilling fluid suction system, and the outlet is connected to the drilling fluid return line 14. The drilling fluid return line 17 of the three flow control valve 16 is connected, and the end of the drilling fluid return line 17 is connected to the sea surface drilling fluid processing device 22;

[0119] The gas lift system includes an air compressor 18, a fourth flow control valve 19, a gas flow meter 20 and a gas injection line 21. The air compressor 18 is installed on the drilling ship 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com