Flexible heating cable

A heating cable, flexible technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of heating cable damage, heating cable bending, low power, etc., to improve heat production capacity, enhance tensile strength, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

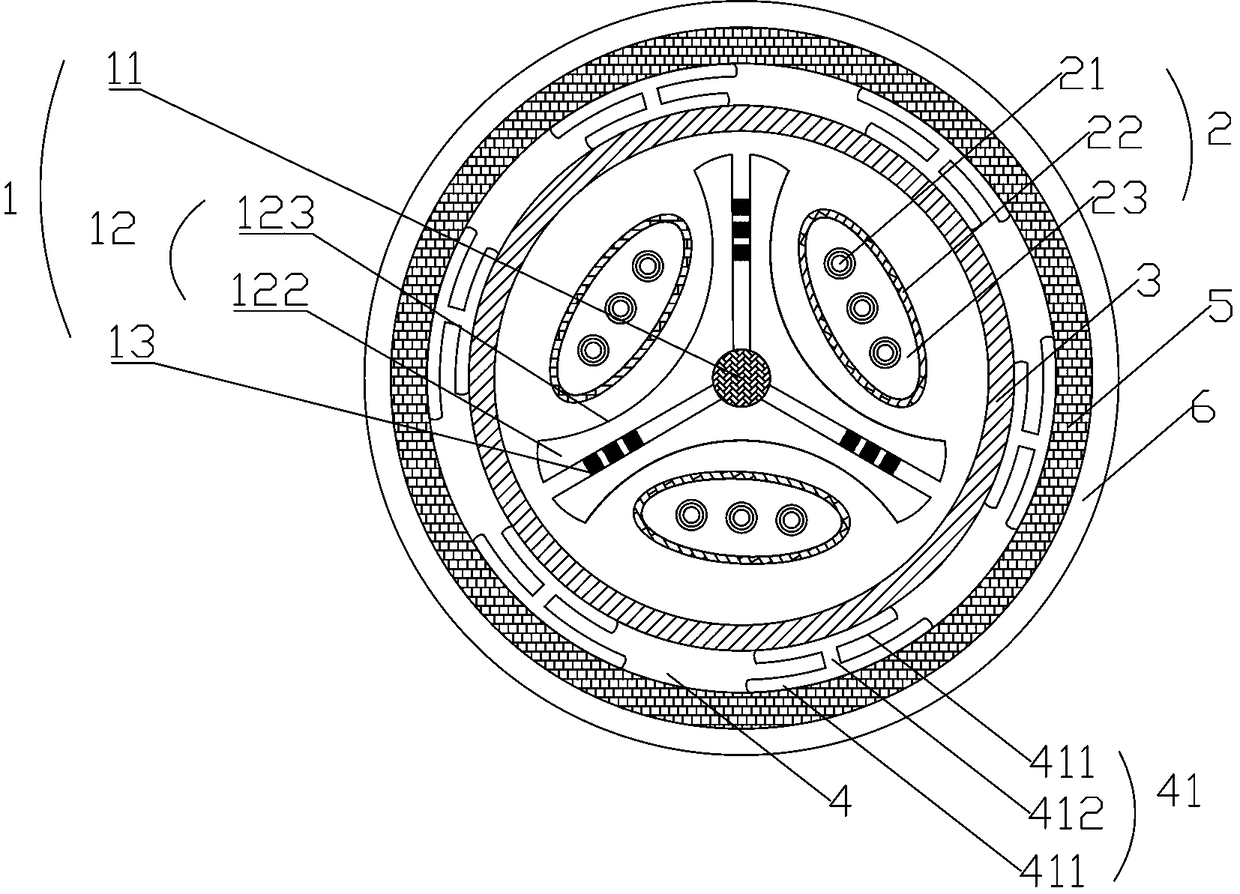

[0022] Such as figure 1 As shown, the flexible heating cable includes three heating units 2, each heating unit 2 includes three heating conductors 21 and a metal heating outer wall 22, and a magnesium oxide filler 23 is filled between the heating conductors 21 and the metal heating outer wall 22. The heating units 2 are divided by the central dividing device 1, and the central dividing device 1 plays a role of support and isolation in the entire flexible heating cable. Because the flexible heating cable integrates three heating units 2 in one cable, it improves the flexible heating cable. Therefore, in order to ensure that each heating unit 2 does not interfere with each other, a central dividing device 1 is provided. The central dividing device 1 includes a reinforcing core 11 and a dividing part 12, and the reinforcing core 11 and the dividing par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com