Chamfering equipment for automobile top window sunshade curtain cross beam

A technology for automobile sunroofs and sunshades, which is applied in metal processing equipment, drilling/drilling equipment, feeding devices, etc., can solve the problems of uneven surface of chamfers, inability to process both ends at the same time, low processing efficiency, etc. The effect of overall cost, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

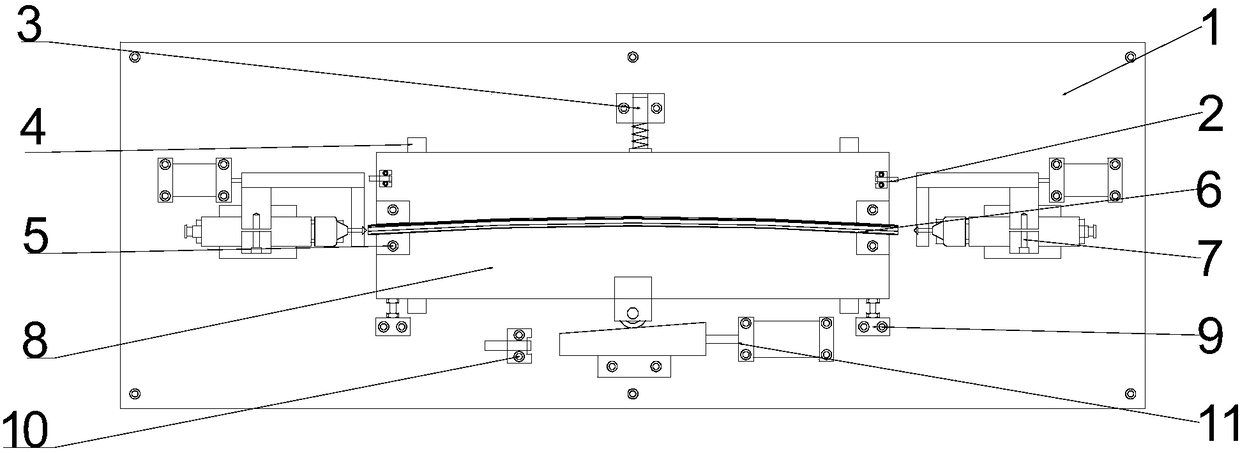

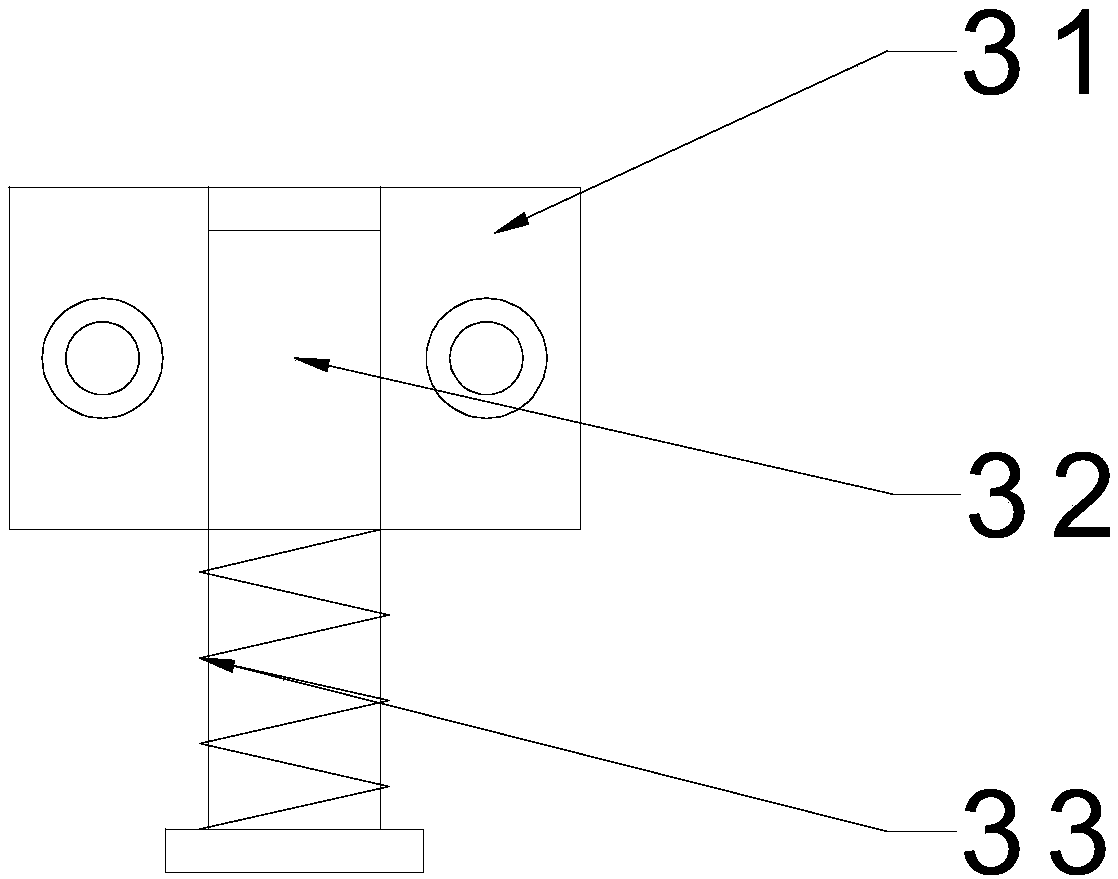

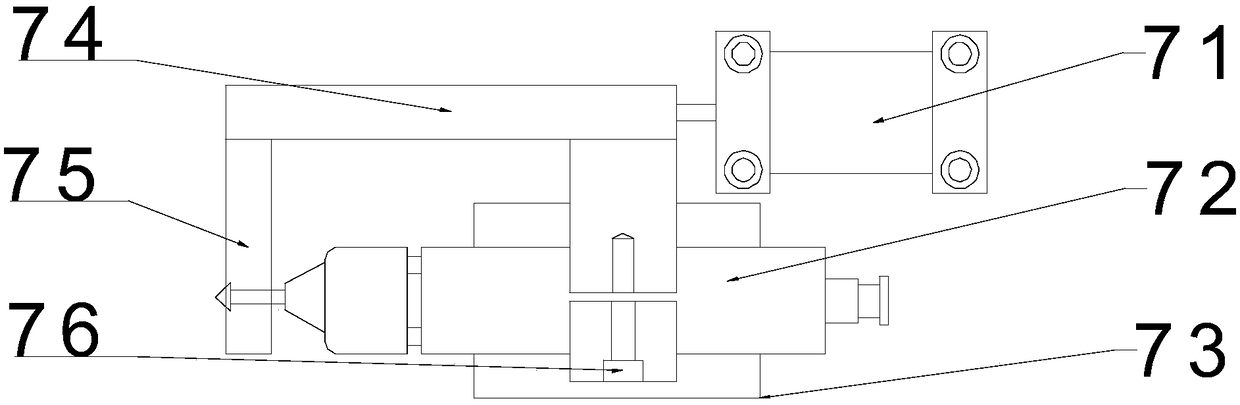

[0025] Such as Figure 1-5 As shown, in order to solve the above-mentioned technical problems, the technical solution adopted in the present invention is: a kind of chamfering equipment specially used for the beam of the sunroof sunshade curtain of an automobile, comprising a work surface 1, which is provided with a pair of sliding guide rails 4 arranged side by side on the work surface 1. The guide rail 4 is provided with a sliding bottom plate 8, and the sliding bottom plate 8 is provided with a pair of clamps 5 for clamping the workpiece. On the work surface 1, an air drill chamfering mechanism 7 is respectively provided outside the two clamps 5, and the air drill chamfering mechanism 7 Including the air drill propulsion cylinder 71 that is fixedly arranged on the work surface 1, the air drill propulsion cylinder 71 piston rod is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com