High-strength, toughness, wear-resistant and corrosion-resistant bainite steel rail for heavy-duty railway and manufacturing method thereof

A bainite, high-strength and toughness technology, used in other manufacturing equipment/tools, rails, manufacturing tools, etc., can solve the problems of lack of corrosion resistance, increased element segregation, and increased production costs, and it is easier to achieve stable composition control. , The effect of increasing the reduction of section and the impact energy of the rail head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

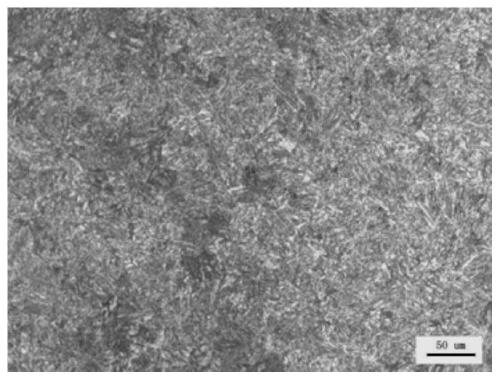

Image

Examples

Embodiment Construction

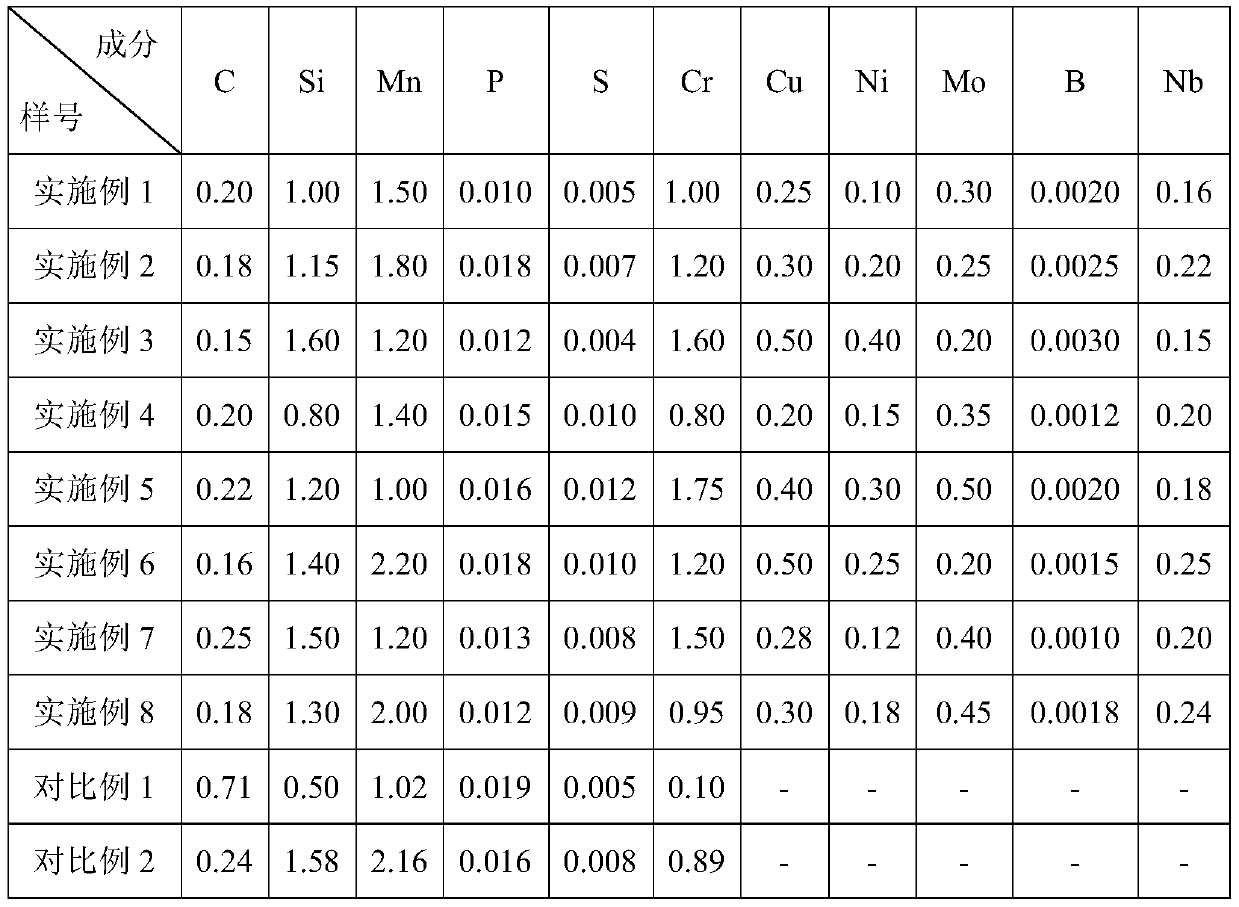

[0046] Below by embodiment the present invention will be further described.

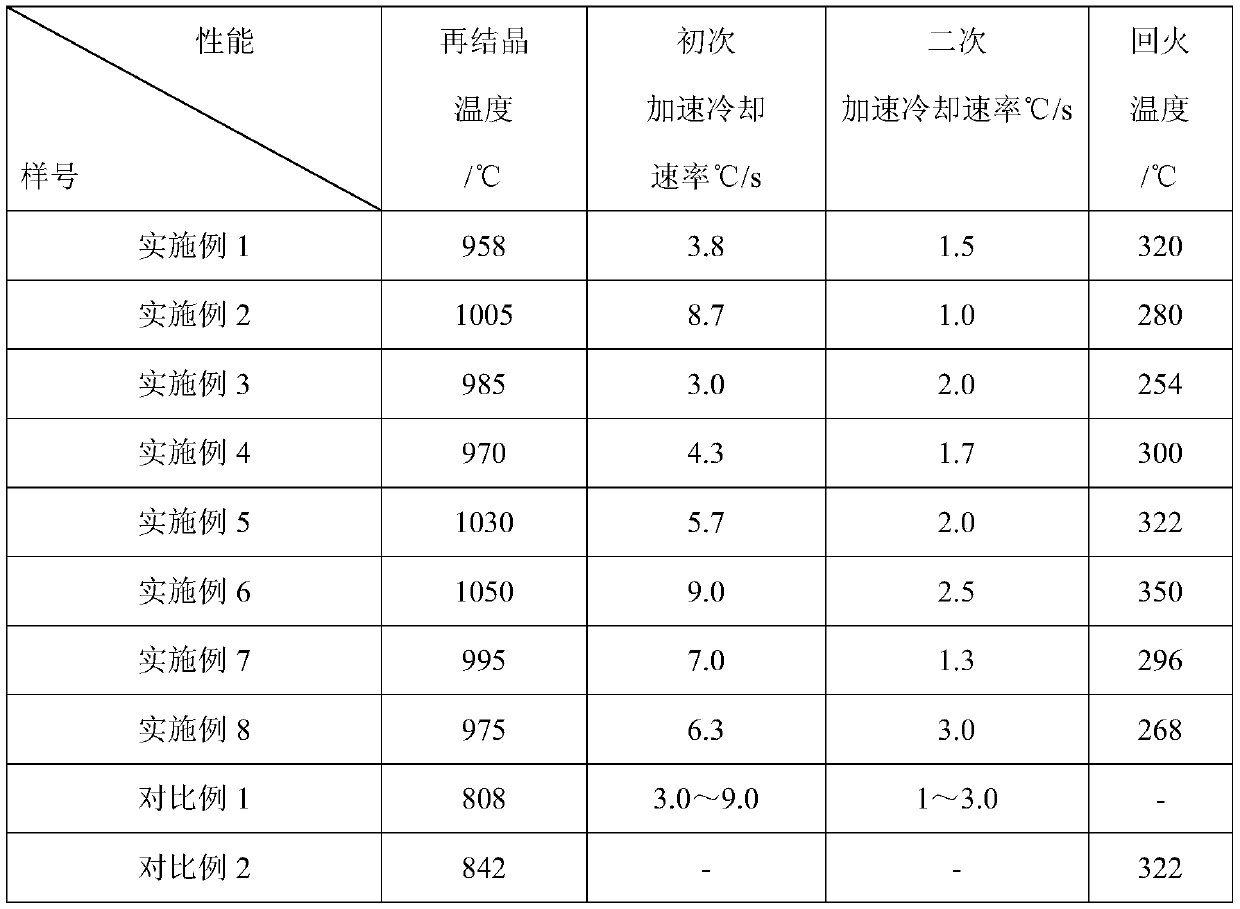

[0047] In the embodiment of the present invention, according to the component ratio of the technical solution, smelting→refining→bloom continuous casting→continuous casting slab heating→beginning→finish rolling→on-line heat treatment→off-line heat treatment;

[0048] The final rolling temperature is not lower than 950°C;

[0049] On-line heat treatment: the first accelerated cooling of the rail head is carried out in the range from the final rolling temperature to 550°C±50°C, the cooling rate is 3.0-9.0°C / s, and then the rail head is subjected to secondary accelerated cooling at a cooling rate of 1.0-3.0°C / s to 300℃±50℃;

[0050] Off-line heat treatment: Temper the above-mentioned rails, heat the rails at room temperature to 250-350°C and then cool with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com