Non-woven fabric spunlace machine

A technology of spunlace machine and non-woven fabric, applied in the field of machinery, can solve the problems affecting the durability and stability of the spunlace device, increase the burden on the water pump, etc., so as to reduce the burden on the water pump, improve the stability and improve the compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

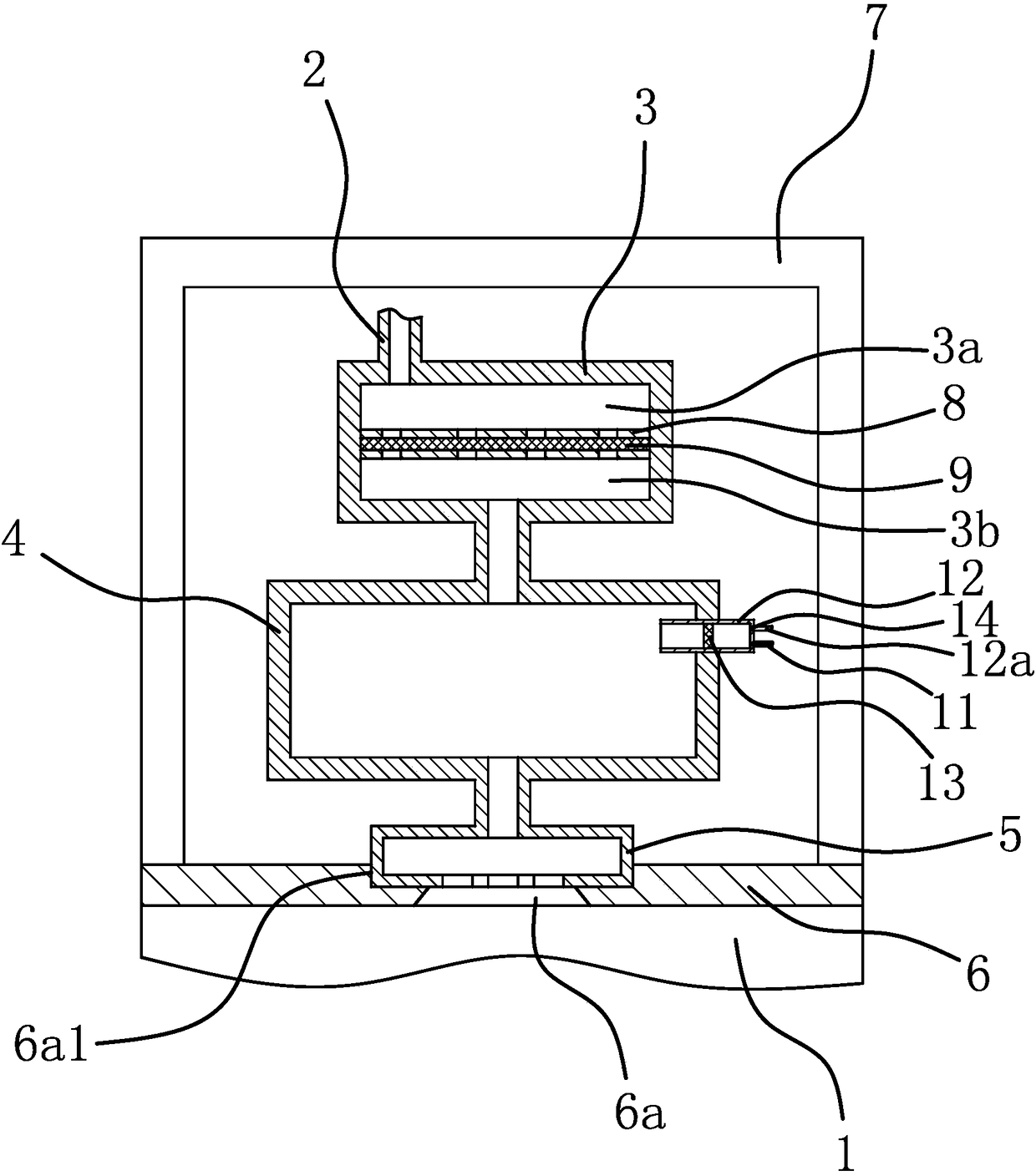

[0031] like figure 1 As shown, the non-woven spunlace machine includes a frame 1, and also includes a water inlet pipe 2, a filter box 3, a pressurized box 4 and a jet plate 5, the above-mentioned filter box 3, pressurized box 4 and jet plate 5 It is fixedly connected to the frame 1 from top to bottom and the three are connected. The inner end of the water inlet pipe 2 is connected with the filter box 3, and the outer end of the water inlet pipe 2 is used to connect with the water source. The filter box 3 has a filtering mechanism inside, and Pressure box 4 has a pressurizing mechanism that can increase its internal pressure.

[0032] It also includes a base plate 6 and a cover 7, the base plate 6 is fixedly connected to the middle of the frame 1, the cover 7 is connected to the base plate 6 and a cavity is formed inside the cover 7, the base plate 6 and the frame 1 cavity, the filter box 3, the pressurized box 4 and the jet plate 5 are all located at the connection cavity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com